Scroll to:

Limiting energy characteristics during laser pulse treatment of tungsten-cobalt hard alloys

https://doi.org/10.17073/0368-0797-2025-4-357-365

Abstract

The considered analytical method for determining the optimal mode of hardening pulsed laser treatment (LT) of tungsten-cobalt hard alloys is based on the study of the patterns of temperature field formation during hardening of hard alloys, determination of thermal stresses occurring in the laser exposure zone (LEZ) during laser pulse treatment, and their comparison with the stresses of fracture of the alloy individual structural elements. The optimal modes of hardening LT of the alloys of WC group are considered to be modes that meet two criteria. First, the temperature on the LEZ surface should be in the range of 1290 °C < T < 1400 °C, when the alloy does not contain weakening it phases of the η-Co3W3C, θ-Co3W2C, or χ-Co3W9C4 types, and increase in grain size of the carbide phase is insignificant. Secondly, cracks of an arbitrary scale are unacceptable in the LEZ, that is, the thermal stresses resulting from the fracture should not exceed the stresses of fracture of the alloy structural elements. The calculation of thermal stresses occurring in a hard alloy during LT within a single carbide grain was carried out in accordance with the Hooke’s law. Calculations performed for both single and multiple treatments allow us to establish that for all the studied modes, with variations in the laser energy density from 0.9 to 1.8 J/mm2 and treatment multiplicity from 1 to 10, when the surface temperature is in the range of 1290 – 1400 °C, the thermal stresses in the carbide phase are lower than minimum fracture stresses and do not exceed 80 MPa. The proposed analytical method for determining the limiting energy characteristics makes it possible to establish pulsed LT modes that provide dispersion hardening of hard alloys of the WC group in the absence of destructive changes in the material. The data obtained on defect-free LT modes are in good agreement with the earlier results of measurements of acoustic emission signals during treatment of hard alloys (VK8 alloy).

Keywords

For citations:

Yaresko S.I., Balakirov S.N., Oskolkova T.N. Limiting energy characteristics during laser pulse treatment of tungsten-cobalt hard alloys. Izvestiya. Ferrous Metallurgy. 2025;68(4):357-365. https://doi.org/10.17073/0368-0797-2025-4-357-365

Introduction

In mechanical engineering production, the primary tool materials are hard alloys, specifically WC–Co system alloys with a cobalt content of 6 – 8 wt. %. Modern industrial demands require enhanced wear resistance of hard-alloy cutting tools (CT), primarily due to the expanding range of workpiece materials – from heat-resistant and high-temperature alloys to composite materials. Various approaches have been proposed to address this issue by modifying the composition and structure of hard alloys, both in the bulk and at the surface. One such method is hardening laser treatment (LT) of the rake face of the cutting edge. This method has been shown to significantly increase the service life of hard-alloy tools – by several times [1 ‒ 3]. Nevertheless, in mechanical engineering practice, laser hardening of CTs is used much less frequently than other methods, such as the application of wear-resistant coatings [4; 5]. Wear-resistant coatings, like the modified structures formed in the surface layer of the laser treatment zone, act as effective barriers against diffusion interaction between the workpiece and tool materials under high cutting speeds. After LT, increased resistance to fracture of the cobalt binder phase – manifested as reduced embrittlement of the surface layer during tool operation – is attributed to the presence of excess tungsten dissolved in cobalt, which inhibits iron diffusion into cobalt and the formation of iron – tungsten carbides during cutting [6].

Despite the advantages of laser hardening of hard alloys, one of the key challenges in improving the performance of CTs lies in determining the optimal LT modes. This is due to the complex stress state formed in the laser treatment zone, which arises from the differing thermophysical properties of the alloy phases and the limited size of the heated area. The optimal LT mode must ensure hardening of the alloy while preserving the continuity of the surface layer. When selecting parameters for hardening LT of hard alloys, it is essential to develop a prompt, reliable, and well-substantiated methodology.

The aim of this study is to develop a method for determining the optimal pulsed laser treatment mode for hardening tungsten – cobalt hard alloys.

Problem statement

A major advantage of pulsed laser treatment of hard alloys – when wear-resistant structures form in the laser exposure zone (LEZ) – is that it can be performed without compromising the integrity of the surface layer. In such cases, no additional modification of the cutting edge geometry is required, which significantly expands the range of applications. In particular, this makes it possible to process replaceable polyhedral hard-alloy inserts alongside brazed inserts.

However, the process of laser thermal treatment of tungsten–cobalt hard alloys is highly specific due to the material’s inherent heterogeneity and the characteristics of its manufacturing process. As a result, treatment often leads to destructive changes in the LEZ, including carbide grain coarsening, porosity, crack formation, and the development of complex (double) carbides [2; 7 ‒ 13].

The requirements for laser irradiation (LI) parameters that ensure defect-free processing of hard alloys have only been established for a limited number of specific cases. For instance, reference [2] describes single-pass irradiation using a Gaussian intensity distribution. To obtain a compact, fine-grained remelted layer at the surface, the use of a CO2 laser operating in pulsed mode is recommended [11]. However, for the most effective approach – repeated laser irradiation [2] – the issue of selecting processing parameters that ensure defect-free laser exposure and achieve actual hardening of the alloy remains unresolved.

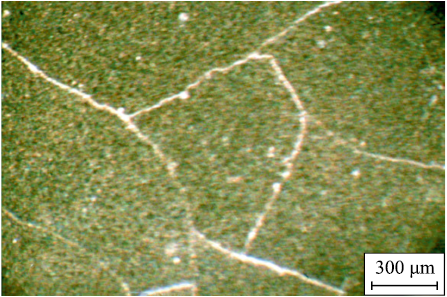

Determining the appropriate parameters for LT of hard alloys is challenging. At insufficient laser energy densities, alloy hardening does not occur, while excessively high energy densities result in crack formation within the laser treatment zone (Fig. 1).

Fig. 1. Cracks on the surface of laser treatment zone (VK8 alloy) |

Cracks – regardless of their origin, location, or depth – are the primary destructive factor during LT and play a critical role in determining the performance of hard alloys [7; 11 ‒ 14]. Several causes of crack formation in the LEZ can be identified. One major cause is the non-uniform energy distribution across the laser beam cross-section, which leads to cracks spanning the entire treated area. This issue can be addressed, for example, by using a focusing prismatic raster [2; 6; 15], which ensures that the intensity variation in the LEZ does not exceed 5 %. The limited heating depth also causes cracks, resulting in a fine-meshed pattern on the surface (Fig. 1) that penetrates to a depth comparable to the thickness of the modified layer. Another type of cracking affects the alloy microstructure itself, with cracks propagating through primary α-WC grains or along WC – WC grain boundaries. The main contributing factors are the mismatch between the thermal expansion coefficients of WC and the cobalt binder phase (αWC = 4.4·10–6 °C–1; αCo = 14.2·10–6 °C–1 [1]), strain hardening, and phase transformations during LT – particularly the formation of brittle complex carbides along grain boundaries, which deplete cobalt content in the alloy [2; 6; 15].

These mechanisms of crack formation result from the redistribution of micro- and macro-stresses within the LEZ. Under rapid heating during laser processing, the thermal stresses induced in the LEZ at certain irradiation doses may exceed the fracture stresses of individual structural elements of the alloy [1]. This phenomenon forms the basis for a method to determine the optimal LT parameters for WC–Co group alloys.

Given these considerations, it is appropriate to define the limiting energy characteristics of pulsed LT for tungsten – cobalt hard alloys based on the onset of microcrack formation on the LEZ surface. LT parameters should be selected to provide maximum surface temperature and depth of the hardened zone while reliably preventing the appearance of microcracks in the LEZ. This can be achieved by optimizing both the energy density and the number of laser pulses.

The laser treatment modes that lead to the onset of crack formation can be experimentally determined by gradually increasing the laser energy density and monitoring the integrity of the LEZ surface – either through visual inspection at (50 – 60)× magnification or by detecting acoustic emission (AE) signals [2]. However, this method is labor-intensive and suitable only under laboratory conditions.

Therefore, there is a growing need to develop a method for rapidly determining the limiting energy parameters of pulsed LT that ensure effective hardening of WC – Co group alloys without crack formation. In this study, an analytical method is proposed based on modeling the temperature field during LT, calculating the resulting thermal stresses in the LEZ, and comparing them with the fracture thresholds of the alloy’s structural components.

Materials and equipment

The study focused on a two-phase hard alloy VK6 (WC – 6 % Co), which, according to GOST 3882–74, is primarily intended for use in cutting and drilling tools. A methodology was developed and validated for calculating thermal stresses in the LEZ during pulsed laser treatment of this alloy. The same approach can also be applied to other alloys within the WC – Co group.

Irradiation was carried out using a laser system based on a pulsed solid-state glass laser doped with neodymium. The laser energy density (ε) ranged from 0.8 to 1.8 J/mm2, with a pulse duration of τ = (5 – 11)·10–3 s and a pulse repetition rate of 1 Hz. A focusing prismatic raster was used to create a uniform distribution of energy density in the LT zone at a area of 4×4 mm [2; 6; 15]. Several LT schemes and irradiation modes were tested in this study – both with and without the raster – and at different number of laser pulses (N).

The alloy microstructure after LT was examined on cross-sectional specimens using a Neophot-30 optical microscope and a Jeol JSM 6390A scanning electron microscope.

Temperature field distributions and temperature gradients in the LEZ were calculated using the Mathcad software package.

Calculation method

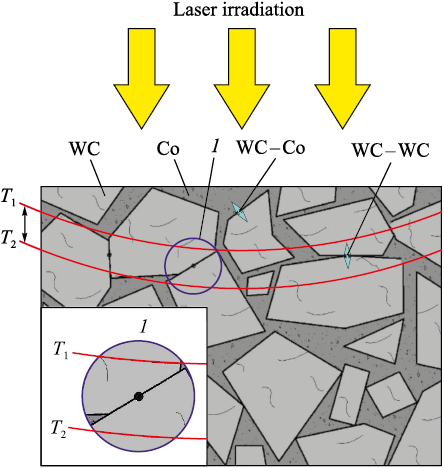

According to a structural model commonly used to describe the microstructure of tungsten–cobalt hard alloys [1; 16], the key structural elements in sintered hard alloys include WC grains, the cobalt binder, WC – WC grain boundaries, and WC – Co interfaces (Fig. 2). WC – Co group alloys are composite tool materials whose performance under contact loading – such as during cutting – is governed by the strength of each individual structural component [17]. The fracture stresses (σf ) of the structural elements in the VK8 alloy are as follows: cobalt binder layer (1.5 µm thick): σf = 5000 MPa, WC grain (2 µm): σf = 180 MPa, WC – WC boundary: σf = 80 MPa, WC – Co boundary: σf = 100 MPa [18]. These values indicate that fracture in the alloy most often initiates at the WC grain contacts, making the intergranular boundaries the weakest structural elements. In contrast, the cobalt binder phase is the most mechanically robust.

Fig. 2. Structural elements of a tungsten-cobalt alloy |

Finite element modeling of the stress state in VK8 alloy confirms [19] that the junctions of WC grains act as stress concentrators under both thermal stresses and mechanical loads, with local stress intensities several times higher than the applied stress. These findings are supported by [20], which showed that microcracks primarily initiate at WC/WC grain contacts and WC/Co phase boundaries. The sequence of weak links during the propagation of a main crack typically follows the path: WC/WC → WC → WC/Co → Co.

To model and calculate the thermal stresses induced during laser treatment, a representative structure containing all the alloy’s key elements was analyzed (Fig. 2). Within this structure, an individual tungsten carbide grain interacting with neighboring grains and the cobalt interlayer was isolated. It is assumed that the WC grain does not undergo plastic deformation, although slip along basal planes under external loading is possible [21]. The thermal stress that develops within a single WC grain, in accordance with Hooke’s law, can be calculated as:

| σ = ΔТαЕ, | (1) |

where ΔT is the temperature difference within the grain depth during LT; α = 4.9·10‒6 °С‒1 is the coefficient of linear thermal expansion [2]; E = 628 GPa is Young’s modulus [2].

The grain size of the carbide phase in hard alloys ranges from 0.5 to 6.0 µm [18]. For the purposes of validating the calculation methodology, an average carbide grain size of 4 µm was used in the modeling. This corresponds to the typical WC grain size in coarse-grained VK6-V and VK8-V hard alloys [2; 22].

The temperature field during pulsed laser treatment not only governs the structural and phase transformations in the LEZ [2; 6; 15] – which enhance interphase bonding – but also plays a critical role in determining the magnitude and distribution of residual stresses in the LEZ and, ultimately, the crack resistance of the alloy during processing. The selection of limiting energy parameters for pulsed LT of WC–Co group alloys must ensure dispersion hardening of the material without compromising the surface integrity of the LEZ.

Results and discussion

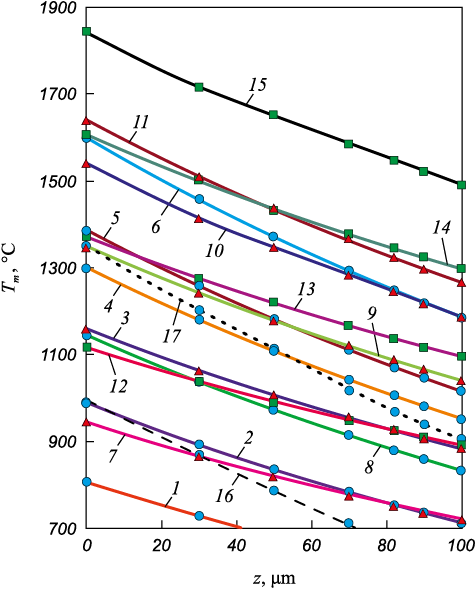

The temperature distribution in the LEZ during pulsed laser treatment was obtained using a one-dimensional linear heat conduction model for a semi-infinite homogeneous body exposed to a uniform planar surface heat source [2]. Fig. 3 presents the calculated temperature (Тm ) profiles of the carbide phase (WC) as a function of depth (z) within the LEZ, under various values of laser energy density (ε) and number of laser pulses (N).

Fig. 3. Temperature of VK6 alloy carbide phase as a function of LEZ |

Table 1 provides calculated surface temperature values in the LEZ, which were used to estimate the thermal stresses in those structural elements of the alloy most susceptible to fracture.

Table 1. Calculated values of LEZ surface temperature (z = 0)

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Microstructural and compositional analysis of the LEZ indicates that the most favorable conditions for pulsed LT of WC – Co hard alloys occur when the local temperature approaches the eutectic melting range of 1298 – 1357 °C or lies slightly outside it – specifically within the range of 1290 – 1400 °C – while the exposure time is maximized [2]. Under these conditions, grain coarsening in the carbide phase remains minimal, and the solubility of tungsten carbide in cobalt increases significantly compared to its solid-state solubility.

According to the simulation results, this optimal temperature range corresponds to LT modes 4 (ε = 1.4 J/mm2, N = 1), 5 (ε = 1.5 J/mm2, N = 1), 9 (ε = 1.2 J/mm2, N = 5), and 13 (ε = 1.0 J/mm2, N = 10) (Table 1), which align well with durability test data for laser-irradiated hard-alloy cutting tools [2; 6; 15]. Under these modes, the coarsening of carbide grains is negligible, and no formation of strength-degrading complex carbides such as η-Co3W3C, θ-Co3W2C, or χ-Co3W9C4 is observed. These phases reduce the content of metallic cobalt in the binder by chemically bonding with it, weakening the retention of the carbide framework, and ultimately leading to alloy fracture.

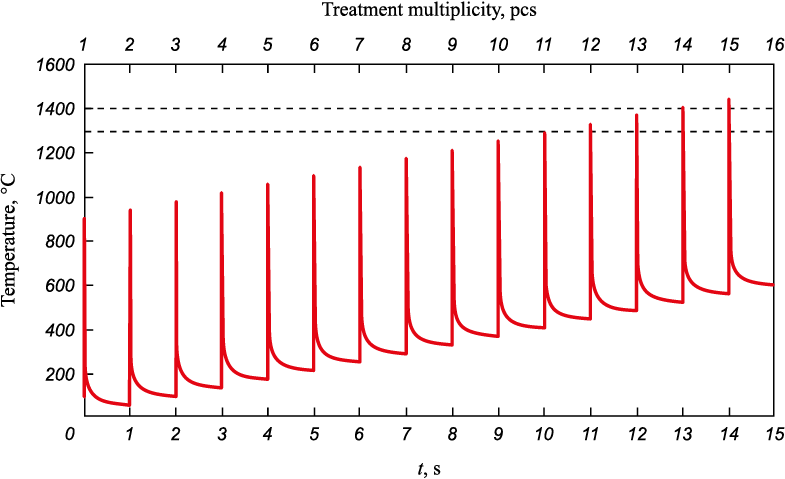

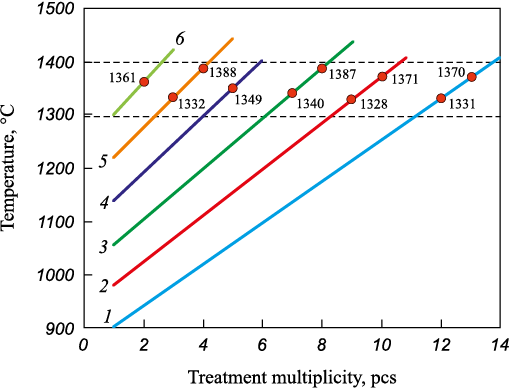

The temperature rise dynamics on the LEZ surface under repeated laser irradiation at ε = 0.9 J/mm2 are shown in Fig. 4 (the optimal temperature range of 1290 – 1400 °C is indicated by dashed lines). The LEZ surface temperature exceeds 1290 °C only after the twelfth pulse. Further increases in the number of laser pulses lead to destructive changes in the LEZ.

Fig. 4. Change in temperature of VK6 alloy surface under repeated irradiation (ε = 0.9 J/mm2) |

The LT modes and corresponding surface temperature ranges in the LEZ are summarized in Fig. 5. When the energy density exceeds 0.9 J/mm2, the target temperature range is reached with fewer pulses. For example, at ε = 1.1 J/mm2, it is achieved by the 7th or 8th pulse, and at ε = 1.4 J/mm2 – by the 1st or 2nd pulse.

Fig. 5. Temperature range of hardening of VK6 alloy |

The temperature distribution in the LEZ not only governs the structural and phase transformations during LT but also determines the thermal stress field, thereby directly influencing the mechanical strength of the material.

Assuming that the temperature gradient reaches its maximum at time t = 0,5τp (i.e., at the midpoint of the laser pulse duration), the temperature difference ΔТ required for calculating thermal stresses using equation (1) was obtained from the analytical temperature distribution T(z, t) described in [2]. Thermal stresses in the carbide phase – one of the structural elements most prone to fracture under load – were calculated for each LT mode by differentiating the T(z, t) function and adjusting the result to the typical WC grain size.

The optimal pulsed laser treatment modes for hardening WC – Co group alloys are those that meet two criteria. First, the surface temperature in the LEZ must lie within the range of 1290 °C < T < 1400 °C, where no strength-degrading phases are formed and grain coarsening of the carbide phase remains minimal. Second, no cracking of any scale should occur in the LEZ – that is, the thermal stresses induced by LT must not exceed the fracture strength of the alloy’s structural elements. It was established that for all investigated modes where the surface temperature remains within 1290 – 1400 °C (Fig. 5), the calculated thermal stresses in the carbide phase remain below the critical fracture stresses. The values of these stresses, calculated using equation (1), are presented in Table 2.

Table 2. Stresses in VK6 alloy carbide phase

|

Exceeding the upper limit of the specified temperature range does not necessarily cause grain fracture, but it typically promotes excessive grain growth and the formation of complex carbides along grain boundaries, which compromises the performance of the material as a cutting tool.

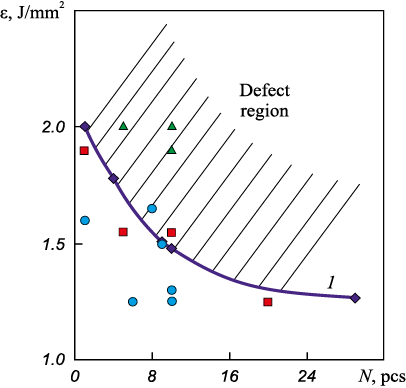

The results correlate well with acoustic emission (AE) signal measurements obtained during treatment of VK8 alloy (Fig. 6) [2]. As the total number of recorded AE pulses increases, crack resistance decreases. According to the experimental data, the defect-free processing region (NΣ = 0) lies below the curve in Fig. 6 and corresponds to the following LT conditions: N = 10 at ε = 1.25 and 1.30 J/mm2; N = 9 at ε = 1.5 J/mm2; N = 6 at ε = 1.25 J/mm2; N = 1 at ε = 1.6 J/mm2. Assuming that VK6 and VK8 alloys are comparable in terms of thermophysical properties [23], the data presented in Fig. 6 can be aligned with the calculated LT modes in Table 2. All LT modes listed in Table 2 fall within the defect-free processing region, where the stresses in the carbide phase remain below the fracture stresses.

Fig. 6. Limiting values of ε corresponding to appearance |

The proposed analytical method for determining limiting energy parameters allows for identifying pulsed LT modes that achieve dispersion hardening of the alloy without introducing destructive changes in the LEZ.

Conclusions

A methodology has been developed and validated for determining the limiting energy parameters of pulsed laser hardening of tungsten – cobalt hard alloys. It has been shown that the optimal LT modes must satisfy two conditions: first of all, the surface temperature in the LEZ should remain within 1290 – 1400 °C, where no strength-degrading phases are present and grain coarsening is minimal; secondly, the thermal stresses induced by LT must not exceed the fracture stress of the alloy’s structural components.

For all studied LT modes where the surface temperature lies within 1290 – 1400 °C, the calculated thermal stresses in the carbide phase remain below the fracture limit.

The identified defect-free laser treatment conditions correspond well with acoustic emission data obtained during processing of VK8 alloy.

References

1. Loshak M.G. Strength and Durability of Hard Alloys. Kiev: Naukova dumka; 1984:328. (In Russ.).

2. Yaresko S.I., Oskolkova T.N., Balakirov S.N. Modification of Structure and Properties of Tungsten-Cobalt Hard Alloys. Moscow; Vologda: Infra-Inzheneriya; 2023:400. (In Russ.).

3. Zimmermann M., Kirsch B., Kang Y., Herrmann T., Aurich J.C. Influence of the laser parameters on the cutting edge preparation and the performance of cemented carbide indexable inserts. Journal of Manufacturing Processes. 2000;58:845‒856. https://doi.org/10.1016/j.jmapro.2020.09.003

4. Tabakov V.P. Formation of Wear-Resistant Ion-Plasma Coatings for Cutting Tools. Moscow: Mashinostroenie; 2008:311. (In Russ.).

5. Grigor’ev S.N., Volosova M.A. Coating of Tools. Moscow: ITO; 2007:64. (In Russ.).

6. Yares’ko S.I. The effect of cobalt phase composition in hard alloys on tool wear after laser hardening. Powder Metallurgy аnd Functional Coatings. 2009;(2):54‒61. (In Russ.).

7. Karatas C., Yilbas B.S., Aleem A., Ahsan M. Laser treatment of cemented carbide cutting tool. Journal of Materials Processing Technology. 2007;183(2-3):234‒240. https://doi.org/10.1016/j.jmatprotec.2006.10.012

8. Oskolkova T.N., Glezer A.M. Current state of the scientific problem of WC–Co hard alloys surface hardening (Review). Izvestiya. Ferrous Metallurgy. 2017; 60(12):980‒991. (In Russ.). https://doi.org/10.17073/0368-0797-2017-12-980-991

9. Li T., Lou Q., Dong J., Wei Y., Liu J. Phase transformation during surface ablation of cobalt-cemented tungsten carbide with pulsed UV laser. Applied Physics A. 2001;73(3):391‒397. https://doi.org/10.1007/s003390100745

10. Kolodziejczak P., Wilkowski J., Barlak M. Modification of the surfaces of wood cutting tools using CO2 laser – SEM analysis. Annals of Warsaw University of Life Sciences – SGGW. Forestry and Wood Technology. 2017;98:48‒52.

11. Yilbas B.S., Shuja S.Z., Khan S.M.A. Laser repetitive pulse heating of tool surface. Optics & Laser Technology. 2011;43(4):754‒761. https://doi.org/10.1016/j.optlastec.2010.12.013

12. Hazzan K.E., Pacella M., See T.L. Understanding the surface integrity of laser surface engineered tungsten carbide. The International Journal of Advanced Manufacturing Technology. 2022;118:1141‒1163. https://doi.org/10.1007/s00170-021-07885-8

13. Schwanekamp T., Gussone J., Reuber M. Impact of laser irradiation on microstructure and phase development of tungsten carbide-cobalt. Procedia CIRP. 2020;94:239‒242. https://doi.org/10.1016/j.procir.2020.09.045

14. Yilbas B.S., Arif A.F.M., Karatas C., Ahsan M. Cemented carbide cutting tool: Laser processing and thermal stress analysis. Applied Surface Science. 2007;253(12):5544–5552. https://doi.org/10.1016/j.apsusc.2006.12.123

15. Yares’ko S.I. Wear and wear resistance analysis of hard alloy tools after laser treatment. Izvestiya SamNTs RAN. 2001;3(1):27‒37. (In Russ.).

16. Kresse T., Meinhard D., Bernthaler T., Schneider G. Hardness of WC‒Co hard metals: Preparation, quantitative microstructure analysis, structure-property relationship and modelling. International Journal of Refractory Metals and Hard Materials. 2018;75:287‒293. https://doi.org/10.1016/j.ijrmhm.2018.05.003

17. Kabaldin Yu.G., Seryi S.V., Kretinin O.V., Laptev I.L. Self-Organization and Nanostructural Processes in Metal Cutting. Nizhny Novgorod: Alekseev NSTU; 2014:173. (In Russ.).

18. Kabaldin Yu.G., Kretinin O.V., Seryi S.V., Shatagin D.A. Nanostructuring contact surface carbide tools in cutting. Trudy NGTU im. R.E. Alekseeva. 2012;(4(97)):123‒132. (In Russ.).

19. Dvornik M.I., Mikhailenko E.A. Research of WC-8%Co hard alloy strength by finite elements method. Chemical Physics and Mesoscopics. 2009;11(4):433‒440. (In Russ.).

20. Brackmann L., Röttger A., Weber S., Theisen W. Subcritical crack growth in hard alloys under cyclic loading. Fatigue & Fracture of Engineering Materials and Structures. 2021;44(2):349‒365. https://doi.org/10.1111/ffe.13363

21. Lantsev E.A., Nokhrin A.V., Chuvil’deev V.N., Boldin M.S., Blagoveshchenskiy Yu.V., Andreev P.V., Murashov A.A., Smetanina K.E., Isaeva N.V., Terentev A.V. Study of high-temperature deformation features of ceramics of binderless tungsten carbide with various particle sizes. Inorgamic Materials: Applied Research. 2022;13:1324–1332. https://doi.org/10.1134/S2075113322050240

22. Montik S.V. Influence of the mechanothermal formation technology of on wear resistance of a hard alloy. Vestnik Brestskogo gosudarstvennogo tekhnicheskogo universiteta. 2000;(4):32‒35. (In Russ.).

23. Tumanov V.I. Properties of Alloys of the Tungsten Carbide-Cobalt System. Moscow: Metallurgiya; 1971:95. (In Russ.).

About the Authors

S. I. YareskoRussian Federation

Sergei I. Yaresko, Dr. Sci. (Eng.), Head of the Laboratory of Laser-Induced Processes

221 Novo-Sadovaya Str., Samara 443011, Russian Federation

S. N. Balakirov

Russian Federation

Sergei N. Balakirov, Engineer of the Laboratory of Laser-Induced Processes

221 Novo-Sadovaya Str., Samara 443011, Russian Federation

T. N. Oskolkova

Russian Federation

Tat’yana N. Oskolkova, Dr. Sci. (Eng.), Prof. of the Chair of Ferrous Metallurgy and Chemical Technology

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Yaresko S.I., Balakirov S.N., Oskolkova T.N. Limiting energy characteristics during laser pulse treatment of tungsten-cobalt hard alloys. Izvestiya. Ferrous Metallurgy. 2025;68(4):357-365. https://doi.org/10.17073/0368-0797-2025-4-357-365