Scroll to:

Impact strength and fracture features of 12 % chromium ferritic-martensitic steel EP-823 in temperature range from –196 to 100 °С

https://doi.org/10.17073/0368-0797-2024-6-716-724

Abstract

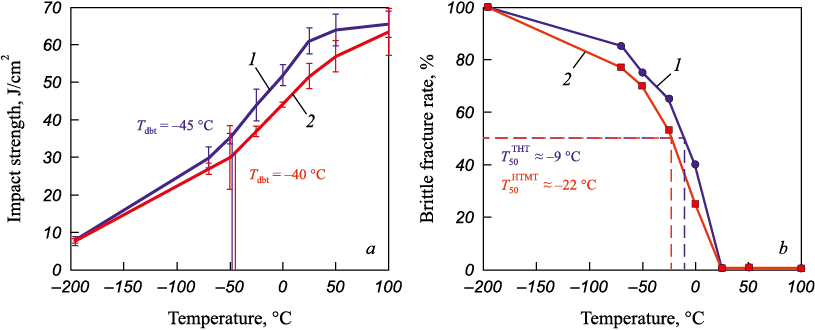

The authors investigated the patterns of fracture during impact bending tests and determined the values of impact strength and temperature of the ductile-brittle transition in temperature range from –196 to 100 °С of heat-resistant 12 % chromium ferritic-martensitic steel EP-823 in structural states after traditional heat (THT) and high-temperature thermomechanical (HTMT) treatments. After THT, temperature of the ductile-brittle transition Tdbt is approximately –45 °С, after HTMT – approximately –40 °С. At these temperatures, the impact energy (KCV) after THT is approximately 36 J/cm2, after HTMT – 32 J/cm2. Fractographic studies conducted by scanning electron microscopy of the fracture features of impact steel samples after two treatments (THT and HTMT) in the low-temperature test area (at cryogenic temperatures) showed a predominantly brittle nature of fracture, while fracture occurs by the mechanism of a transcrystalline quasi-cleavage. In the temperature range of the ductile-brittle transition, a mixed nature of fracture is observed, which passes through the mechanism of a transcrystalline quasi-cleavage with elements of ductile dimple fracture. In the temperature range from 50 to 100 °С, the extremely ductile nature of the fracture was detected, realized by the transcrystalline dimple fracture mechanism. After HTMT, there is a slight decrease (relative to THT) in the steel impact strength in almost the entire temperature range under consideration and, accordingly, an increase in the temperature of its ductile-brittle transition. This is due to the tests’ geometry, in which the direction of impact occurs in the plane of the layered structure, and it facilitates the formation of delamination cracks.

Keywords

For citations:

Spiridonova K.V., Litovchenko I.Yu., Polekhina N.A., Osipova V.V., Akkuzin S.A., Chernov V.M. Impact strength and fracture features of 12 % chromium ferritic-martensitic steel EP-823 in temperature range from –196 to 100 °С. Izvestiya. Ferrous Metallurgy. 2024;67(6):716-724. https://doi.org/10.17073/0368-0797-2024-6-716-724

Introduction

In recent decades, ferritic-martensitic steels containing 9 – 12 % chromium have been considered as structural materials for next-generation reactors [1 – 6]. Studies [7 – 10] on this class of steels have shown that they exhibit a combination of favorable mechanical properties, high creep resistance, corrosion resistance, thermal conductivity, resistance to radiation-induced swelling, and relatively low thermal expansion compared to previously used austenitic steels [11 – 15].

The key challenges in the development of ferritic-martensitic steels are improving their high-temperature strength above 600 °C and reducing their susceptibility to low-temperature embrittlement. Special attention is given to the phenomenon of cold brittleness in these steels, as body-centered cubic (BCC) metals transition from a high-energy ductile fracture mode to a low-energy brittle fracture mode via quasi-cleavage as the test temperature decreases [16; 17]. This transition is associated with the ductile-brittle transition temperature (Тdbt ). Moreover, under operating conditions, radiation exposure can lead to a reduction in fracture toughness and a shift of Тdbt to higher temperatures (300 – 400 °C) [17; 18], increasing the risk of premature structural failure. Therefore, developing methods to mitigate embrittlement and enhance the material’s resistance to low temperatures remains a critical research objective.

One of the Russian representatives of the ferritic-martensitic steel class with 12 % chromium is EP-823 steel (Fe–12Cr–Mo–Nb–W–V–B) [8]. This steel has been studied after different treatment methods, including traditional heat treatment (THT) and high-temperature thermomechanical treatment (HTMT) [8; 12; 19]. According to [8], HTMT enhances the strength and plastic properties of EP-823 steel over a wide temperature range (from –70 to 720 °C) compared to THT. The improvement in mechanical properties after HTMT is correlated with the following microstructural changes: a 1.5 – 2.0-fold reduction in the average size of martensitic blocks and ferritic grains; a threefold decrease in the average size of martensitic lamellae; an increase in dislocation density to (3 – 6)·1010 cm–2 in the ferrite phase and to (6 – 9)·1010 cm–2 in the martensite phase; and a 1.5-fold increase in the volume fraction of nanoscale MeX-type particles (Me = Nb, Mo; X = C, N) compared to THT [8]. It is important to note that, regardless of the treatment method, the primary hardening mechanisms of EP-823 steel include: dispersion hardening by nanoscale MeX carbonitrides via the Orowan mechanism; grain boundary hardening due to martensitic block boundaries and ferrite grain boundaries; and substructural hardening due to low-angle boundaries of martensitic lamellae and an increased dislocation density [19].

It is well known that the strength, plasticity, and impact properties of a material are interrelated. The mechanical properties of EP-823 steel under tensile testing conditions have been sufficiently studied [8]; however, the effect of processing regimes on its impact properties has not been previously investigated.

It is worth noting that when examining samples after hot rolling (specifically, those cut perpendicular to the rolling plane), a layered structure is observed (referred to in international literature as a “pancake structure”) [8; 15; 20 – 22]. This structure is characterized by a reduction in the effective grain size. It has been shown that this structural feature has a positive effect on impact toughness and the ductile-brittle transition temperature when the impact direction is perpendicular to the layers and, in particular cases, to the rolling plane, due to crack arrest within the layered structure [15; 20 – 22].

To investigate the effect of low-temperature embrittlement, Charpy impact tests were conducted in this study on 12 % chromium ferritic-martensitic EP-823 steel in structural states after THT and HTMT.

Materials and methods

EP-823 steel has the following chemical composition (wt. %): C 0.14; Cr 11.56; Mn 0.58; Mo 0.74; Nb 0.40; V 0.34; W 0.68; Ni 0.68; N 0.03; Si 1.09; Ce 0.10; Ti 0.01; B 0.006; Al 0.02; with iron as the balance [8; 10; 12; 19]. The processing schemes are as follows:

• THT consisted of heating to T = 1100 °C, holding for 1 h, air quenching, and tempering at T = 720 °C for 3 h;

• HTMT involved austenitization at T = 1100 °C for 1 h, followed by hot plastic deformation via rolling in the austenitic region to ε ≈ 50 % in a single pass, with subsequent water quenching. After deformation, the steel was tempered at T = 720 °C for 1 h [8; 12; 15; 19].

Impact toughness tests were carried out on an automated Instron 450MP pendulum impact tester using V-notched Charpy samples in structural states after THT and HTMT over a temperature range from –196 to 100 °C. According to GOST 9454–78, the sample dimensions were 55.0×2.0×8.0 mm, with a notch depth of 2.0 mm. Samples after HTMT were cut according to the designated scheme (Fig. 1), and the pendulum impact was applied in the transverse direction (TD). Cooling was performed in a KO-70 metal sample cooling chamber for 10 min immediately before testing. The testing time for cooled samples did not exceed 5 s. At test temperatures of 50–100 °C, the samples were additionally preheated. The impact toughness values were averaged based on the test results of at least three identical samples. The variation in the obtained impact toughness values did not exceed ±5 %.

Fig. 1. Scheme of cutting samples for impact tests: |

The temperature dependence of impact toughness KCV(Т) exhibits two plateaus: the upper plateau KCVmax and the lower plateau KCVmin . The ductile-brittle transition temperature (Тdbt ) is defined as the average value between KCVmax and KCVmin .

Fractographic analysis of the fracture surfaces of the tested steel samples was conducted using scanning electron microscopy with an Apreo 2S microscope. Additionally, in accordance with ASTM E23-05, the rates of brittle and ductile fracture components in EP-823 steel were calculated across the entire investigated temperature range, and the brittle transition temperature Т50 was determined, corresponding to the temperature at which the rate of brittle fracture reaches 50 %).

Results

The results of Charpy impact tests for EP-823 steel in structural states after THT and HTMT over a temperature range from –196 to 100 °C are presented in Fig. 2.

Fig. 2. Temperature dependences of EP-823 steel after THT (1) and HTMT (2) |

At elevated temperatures, the maximum impact toughness values are observed in EP-823 steel samples after both treatment methods. Specifically, the upper plateau energy (at T = 50 – 100 °C) is approximately 65 J/cm2 for THT-treated steel and 60 J/cm2 for HTMT-treated steel. As the test temperature decreases, the impact toughness declines, reaching approximately 7.7 J/cm2 at cryogenic temperatures (T = –196 °C) for both treatments. Across almost the entire investigated temperature range (except at T = –196 °C), the KCV values of steel after THT are higher than those obtained after HTMT.

The ductile-brittle transition temperature of EP-823 steel after THT and HTMT is –45 and –40 °C, respectively, with KCV values of approximately 36 and 32 J/cm2, respectively.

To establish a correlation between impact toughness values and fracture mechanisms, fractographic studies were conducted on EP-823 steel samples after impact tests in structural states following THT and HTMT, with fractures occurring within the temperature range of –196 to 100 °C. It is important to note that, after both treatments, the fractographic features and fracture mechanisms of EP-823 steel are qualitatively similar.

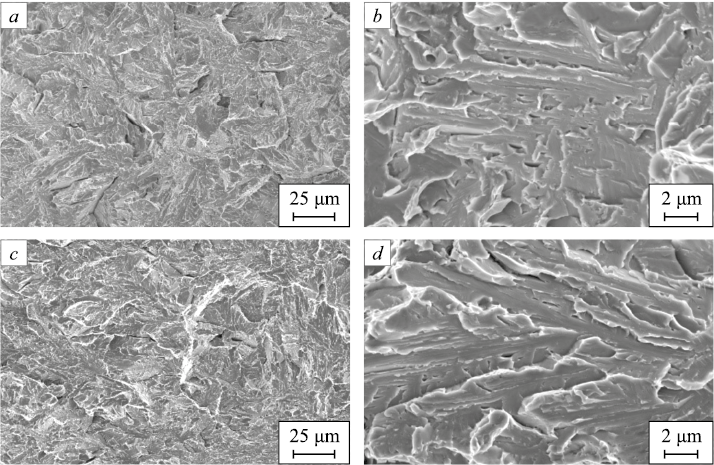

At a test temperature of –196 °C, after both treatment modes, the unstable crack propagation zone occupies the entire fracture surface. At this temperature, the fracture occurs by the transcrystalline (brittle) quasi-cleavage mechanism, with no ductile fracture regions observed (Fig. 3). The fracture surface exhibits quasi-cleavage facets, differing in size, shape, and orientation. A river-like pattern is frequently observed. The average facet width ranges from 3 to 7 μm, and additionally, narrow elongated facets approximately 10 μm in length are present on the fracture surface.

Fig. 3. SEM fractographic images of steel samples after impact tests at –196 °C |

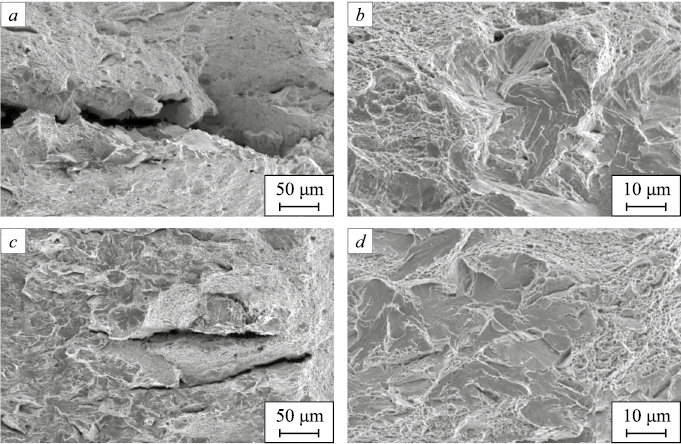

At test temperatures near Тdbt , the unstable crack propagation zone is significantly reduced compared to that at lower temperatures. In this zone, the fracture exhibits a mixed character, occurring through a combination of the transcrystalline quasi-cleavage mechanism and ductile dimple fracture elements (Fig. 4). Within the temperature range of –70 to 22 °C, multiple delamination microcracks are observed in HTMT-treated samples, propagating in the direction of the pendulum impact. These microcracks can reach lengths of up to 500 μm, with their widths not exceeding 0.2 μm. In contrast, THT-treated samples display only isolated cracks, oriented perpendicular to the fracture plane.

Fig. 4. SEM fractographic images of steel samples after impact tests at – 50 °C, |

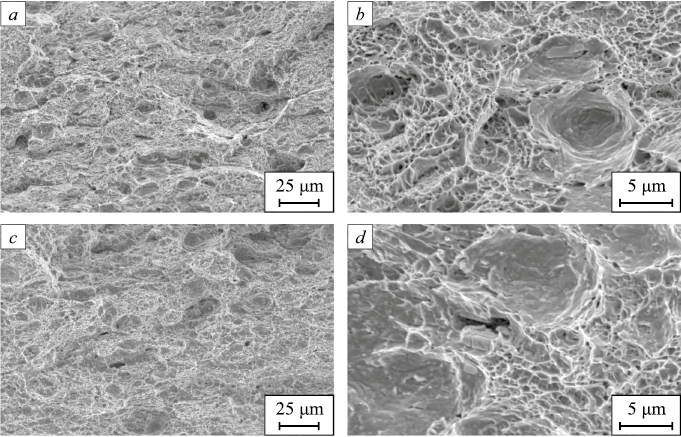

At the upper plateau of the impact toughness curve, the fracture occurs predominantly through the ductile transcrystalline dimple fracture mechanism, which involves the nucleation, growth, and coalescence of micropores. The average dimple size ranges from 1 to 5 μm, with some dimples reaching up to 10 μm in size (Fig. 5). Non-metallic inclusions are commonly found at the bottom of the dimples, while delamination cracks are absent at these elevated temperatures.

Fig. 5. SEM fractographic images of steel samples after impact tests at 100 °C, |

Fig. 2, b shows the brittle fracture fraction across the temperature range from –196 to 100 °C, based on fractographic analysis. The Т50 temperature, where the brittle fracture fraction reaches 50 %, is –9 °C for THT-treated EP-823 steel and –22 °C for HTMT-treated steel. These findings suggest that the transition in fracture mechanism occurs at higher temperatures in THT-treated steel compared to HTMT-treated steel.

Discussion of the results

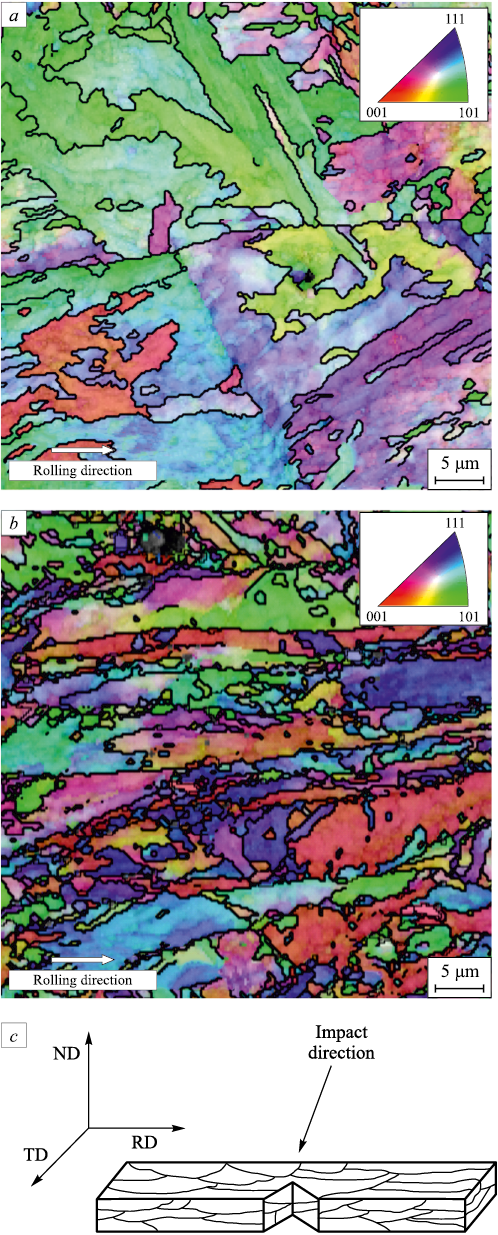

After HTMT, a slight decrease in impact toughness and an increase in Тdbt are observed compared to THT (Fig. 2, a). This behavior is clearly related to the microstructural features of the steel formed as a result of HTMT. It has been shown [8] hat in EP-823 steel after THT, the microstructure consists of equiaxed prior-austenite grains containing martensitic blocks and lamellae. After HTMT, the prior-austenite grains and martensitic blocks become elongated in the rolling plane, with a reduction in their average cross-sectional size. Fig. 6 presents EBSD images of the microstructure (the EBSD method using SEM is described in detail in [8]) of EP-823 steel in a section parallel to the rolling plane (Fig. 6, a) and in a section perpendicular to the rolling plane (Fig. 6, b), along with a schematic representation of the microstructure indicating the direction of the pendulum impact used in this study. Notably, after HTMT, the average grain size in the transverse section (Fig. 6, b) decreases by a factor of 2.2 (d ≈ 1.4 μm) compared to the corresponding value after THT (d ≈ 3.1 μm) [8].

Fig. 6. Microstructure of EP-823 steel after HTMT, obtained by the SEM EBSD method: |

Numerous studies [20 – 23] have reported that reducing grain size leads to an increase in impact toughness. The formation of a high density of grain boundaries helps to retard quasi-cleavage crack propagation, thereby enhancing the material’s toughness.

Another critical factor influencing impact toughness and Тdbt , is the test geometry relative to the layered structure formed during HTMT. When the impact direction is perpendicular to the layers (i.e., the rolling plane), the layered structure acts as a crack – arrester, inhibiting the propagation of the main crack and promoting the formation of secondary cracks along the layers (crack – arrester – type delamination) [20; 24 – 26]. This mechanism results in an increase in impact toughness and a decrease in Тdbt . Conversely, when the impact is applied along the layers, the crack propagates in a crack – divider, where the main crack splits mode (crack – divider – type delamination), leading to relatively low fracture toughness values [20 – 22; 24 – 26].

In the present case, the impact toughness of EP-823 steel after HTMT is determined by the interaction of two competing factors: the reduction in grain size compared to THT may contribute to an increase in impact toughness, while the formation of delamination cracks in the direction of the pendulum impact, parallel to the layered structure, tends to reduce it. The predominance of the second factor results in a slight reduction in impact toughness after HTMT and an increase in Тdbt compared to THT (Fig. 2, a).

Thus, despite the anisotropy of the microstructure formed after HTMT, the steel demonstrates satisfactory impact toughness under the selected unfavorable impact test geometry.

Conclusions

Based on Charpy impact tests conducted on EP-823 steel in structural states after THT and HTMT over the temperature range of –196 to 100 °C, the impact and the ductile-brittle transition temperature were determined. The results showed that after THT, Тdbt ≈ –45 °С with KCV ≈ 36 J/cm2, while after HTMT, Тdbt ≈ –40 °С, KCV ≈ 32 J/cm2.

Fractographic analysis using scanning electron microscopy revealed that in the low-temperature region (T = –196 °C), the steel exhibited a predominantly brittle fracture mode characterized by the transcrystalline quasi-cleavage mechanism. In the ductile-brittle transition region (T = –70 to 20 °C), a mixed fracture mode was observed, while at higher temperatures (50 – 100 °C), the fracture demonstrated a predominantly ductile character.

The slight reduction in impact toughness and the increase in Тdbt observed after HTMT, compared to THT, are attributed to the formation of multiple delamination cracks under the specific impact test geometry, where the impact direction is parallel to the planes of the layered structure.

Regardless of the treatment method (THT or HTMT), the investigated EP-823 steel demonstrates sufficiently low Тdbt values and satisfactory impact toughness, even under unfavorable impact test conditions.

References

1. Cabet C., Dalle F., Gaganidze E., Henry J., Tanigawa H. Ferritic-martensitic steels for fission and fusion applications. Journal of Nuclear Materials. 2019;523:510–537. https://doi.org/10.1016/j.jnucmat.2019.05.058

2. Yvon P. Structural Materials for Generation IV Nuclear Reactors. Amsterdam, Netherlands: Elsevier; 2017:664.

3. Odette R.G., Zinkle S.J. Structural Alloys for Nuclear Energy Applications. Amsterdam, Netherlands: Elsevier; 2019:655.

4. Zinkle S.J., Ghoniem N.M. Operating temperature windows for fusion reactor structural materials. Fusion Engineering and Design. 2000;51-52:55–71. https://doi.org/10.1016/S0920-3796(00)00320-3

5. Klueh R.L., Harries D.R. High-Chromium Ferritic and Martensitic Steels for Nuclear Applications. ASTM International; 2001:220. https://doi.org/10.1520/MONO3-EB

6. Yan W., Wang W., Shan Y., Yang K., Sha W. 9-12Cr Heat-Resistant Steels. Engineering Materials, Springer; 2015:223.

7. Ioltukhovsky A.G., Leontyeva-Smirnova M.V., Kazennov Y.I., Medvedeva E.A., Tselishchev A.V., Shamardin V.K., Povstyanko A.V., Ostrovsky S.E., Dvoryashin A.M., Porollo S.I., Vorobyev A.N., Khabarov V.S. Influence of operation conditions on structure and properties of 12 % Cr steels as candidate structural materials for fusion reactor. Journal of Nuclear Materials. 1998;258-263(2):1312–1318. https://doi.org/10.1016/S0022-3115(98)00396-1

8. Litovchenko I., Almaeva K., Polekhina N., Akkuzin S., Linnik V., Moskvichev E., Chernov V., Leontyeva-Smirnova M. The microstructure and mechanical properties of ferritic-martensitic steel EP-823 after high-temperature thermomechanical treatment. Metals. 2022;12(1):79. https://doi.org/10.3390/met12010079

9. Polekhina N.A., Litovchenko I.Y., Almaeva K.V., Tymentsev A.N., Chernov V.M., Leontieva-Smirnova M.V. Microstructure, structural-phase transformations, and mechanical properties of low-activation 12 % chromium ferritic-martensitic steel EK-181 depending on the treatment conditions. Inorganic Materials. 2022;13:1247–1260. https://doi.org/10.1134/S2075113322050355

10. Belomyttsev M.Yu., Molyarov V.G. Creep resistance of ferritic-martensitic steel 16Cr12MoWSiVNbB (EP-823). Izvestiya. Ferrous Metallurgy. 2019;62(4):290–302. (In Russ.). https://doi.org/10.17073/0368-0797-2019-4-290-302

11. Vivas J., San-Martin D., Caballero F.G., Capdevila C. High-chromium (9–12Cr) steels: Creep enhancement by conventional thermo-mechanical treatments. In: Metal Heat Treatments. Intechopen; 2020:1–23. https://doi.org/10.5772/intechopen.91931

12. Polekhina N.A., Litovchenko I.Yu., Almaeva K.V., Akkuzin S.A., Linnik V.V., Moskvichev E.N., Chernov V.M., Naumenko I.A., Saifutdinova M.S., Leontieva-Smirnova M.V. Special features of the surface layer structure of ferritic-martensitic EP-823-Sh steel after prolonged exposure to the flowing lead at 630 °C under low oxygen concentration. Journal of Nuclear Materials. 2022;572:154039. https://doi.org/10.1016/j.jnucmat.2022.154039

13. Saini N., Pandey Ch., Mahapatra M.M., Narang H.K., Mulik R.S., Kumar P. A comparative study of ductile-brittle transition behavior and fractography of P91 and P92 steel. Engineering Failure Analysis. 2017;81:245–253. http://dx.doi.org/10.1016/j.engfailanal.2017.06.044

14. Abe F., Kern T.-U., Viswanathan R. Creep-Resistant Steels. Cambridge, UK: Woodhead; 2008;700.

15. Polekhina N., Linnik V., Litovchenko I., Almaeva K., Akkuzin S., Moskvichev E., Chernov V., Leontyeva-Smirnova M., Degtyarev N., Moroz K. The microstructure, tensile and impact properties of low-activation ferritic-martensitic steel EK-181 after high-temperature thermomechanical treatment. Metals. 2022;12(11):1928. https://doi.org/10.3390/met12111928

16. Kurtz R.J., Odette G.R. Chapter 3 – Overview of reactor systems and operational environments for structural materials in fusion reactors. In: Structural Alloys for Nuclear Energy Applications. 2019:51–102. https://doi.org/10.1016/B978-0-12-397046-6.00003-4

17. Chatterjee A., Chakrabarti D., Moitra A., Mitra R., Bhaduri A.K. Effect of deformation temperature on the ductile-brittle transition behavior of a modified 9Cr-1Mo steel. Materials Science and Engineering: A. 2015;630:58–70. https://doi.org/10.1016/j.msea.2015.01.076

18. Chatterjee A., Chakrabarti D., Moitra A., Mitra R., Bhaduri A.K. Effect of normalization temperatures on ductile-brittle transition temperature of a modified 9Cr-1Mo steel. Materials Science and Engineering: A. 2014;618:219–231. https://doi.org/10.1016/j.msea.2014.09.021

19. Almaeva K.V., Litovchenko I.Yu., Polekhina N.A., Linnik V.V. Mechanisms of hardening of 12 % chromium ferritic-martensitic steel EP-823. Izvestiya. Ferrous Metallurgy. 2022;65(12):887–894. (In Russ.). https://doi.org/10.17073/0368-0797-2022-12-887-894

20. Yuzbekova D., Dudko V., Pydrin A., Gaidar S., Mironov S., Kaibyshev R. Effect of tempforming on strength and toughness of medium-carbon low-alloy steel. Materials. 2023;16(3):1202. https://doi.org/10.3390/ma16031202

21. Haskel H.L., Pauletti E., Martins J.P., de Carvalho A.L.M. Microstructure and microtexture assessment of delamination phenomena in Charpy impact tested specimens. Materials Research. 2014;17(5):1238. http://dx.doi.org/10.1590/1516-1439.268314

22. Kimura Y., Inoue T. Influence of warm tempforming on microstructure and mechanical properties in an ultrahigh-strength medium-carbon low-alloy steel. Metallurgical and Materials Transactions A. 2013;44:560–576. http://dx.doi.org/10.1007/s11661-012-1391-2

23. Pallaspuro S., Kaijalainen A., Mehtonen S., Kömi J., Zhang Zh., Porter D. Effect of microstructure on the impact toughness transition temperature of direct-quenched steels. Materials Science and Engineering: A. 2018;712:671–680. https://doi.org/10.1016/j.msea.2017.12.037

24. Inoue T., Yin F., Kimura Y., Tsuzaki K., Ochiai S. Delamination effect on impact properties of ultrafine-grained low-carbon steel processed by warm caliber rolling. Metallurgical and Materials Transactions: A. 2010;41:341–355. https://doi.org/10.1007/s11661-009-0093-x

25. Kimura Y., Inoue T. Mechanical property of ultrafine elongated grain structure steel processed by warm tempforming and its application to ultrahigh-strength bolt. ISIJ International. 2020;60(6):1108–1126. https://doi.org/10.2355/isijinternational.ISIJINT-2019-726

26. Dolzhenko A., Kaibyshev R., Belyakov A. Tempforming as an advanced processing method for carbon steels. Metals. 2020;10(12):1566. https://doi.org/10.3390/met10121566

About the Authors

K. V. SpiridonovaRussian Federation

Kseniya V. Spiridonova, Cand. Sci. (Phys.-Math.), Research Associate of the Laboratory of Materials Science of Shape Memory Alloys

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

I. Yu. Litovchenko

Russian Federation

Igor’ Yu. Litovchenko, Dr. Sci. (Phys.-Math.), Assist. Prof., Head of the Laboratory of Materials Science of Shape Memory Alloys

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

N. A. Polekhina

Russian Federation

Nadezhda A. Polekhina, Cand. Sci. (Phys.-Math.)., Senior Researcher of the Laboratory of Materials Science of Shape Memory Alloys

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

V. V. Osipova

Russian Federation

Valeriya V. Osipova, Postgraduate

36 Lenina Ave., Tomsk 634050, Russian Federation

S. A. Akkuzin

Russian Federation

Sergei A. Akkuzin, Junior Researcher of the Laboratory of Materials Science of Shape Memory Alloys

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

V. M. Chernov

Russian Federation

Vyacheslav M. Chernov, Dr. Sci. (Phys.-Math.), Prof., Chief Researcher

5a Rogova Str., Moscow 123098, Russian Federation

Review

For citations:

Spiridonova K.V., Litovchenko I.Yu., Polekhina N.A., Osipova V.V., Akkuzin S.A., Chernov V.M. Impact strength and fracture features of 12 % chromium ferritic-martensitic steel EP-823 in temperature range from –196 to 100 °С. Izvestiya. Ferrous Metallurgy. 2024;67(6):716-724. https://doi.org/10.17073/0368-0797-2024-6-716-724