Scroll to:

Physics of hardening of the rolling surface of rail head from hypereutectoid steel after operation

https://doi.org/10.17073/0368-0797-2024-4-424-432

Abstract

In Russia, with its extensive railway system, for more than 5 years, special-purpose rails of increased wear resistance and contact endurance of the DH400RK category were produced from steel with a carbon content >0.8 %. On the head rolling surface of differentially hardened long rails made of hypereutectoid steel after long-term operation, transmission electron microscopy methods revealed the morphological components of the structure: lamellar pearlite, fragmented pearlite, destroyed lamellar pearlite, globular pearlite, completely destroyed pearlite, subgrain structure. The contribution of hardening due to: lattice friction, solid solution hardening, pearlite hardening, incoherent cementite particles, grain boundaries and subboundaries, dislocation substructure and internal stress fields were quantified. A hierarchy of these mechanisms was made and it was noted that for the fillet surface of the rail head, the main hardening mechanism is hardening by incoherent particles, as well as mechanisms caused by internal long-range (local) stresses, internal shear stresses (“forests” of dislocations) and substructural hardening. For the rolling surface along the central axis of the rail head, the main role in hardening belongs to long-range stress fields (especially its elastic component), hardening by incoherent particles and substructural hardening. Taking into account the volume fractions of the morphological components and their yield strength, the additive yield strength on the head rolling surface in the center and on the fillet was determined: 7950 and 2218 MPa, respectively. The paper presents a physical interpretation of the difference in values of the additive yield strength on the rolling surface of the rail head in the center and on the fillet.

Keywords

For citations:

Popova N.A., Gromov V.E., Yur’ev A.B., Martusevich E.A., Porfir’ev M.A. Physics of hardening of the rolling surface of rail head from hypereutectoid steel after operation. Izvestiya. Ferrous Metallurgy. 2024;67(4):424-432. https://doi.org/10.17073/0368-0797-2024-4-424-432

Introduction

Rails are predominantly removed from service due to contact fatigue damage and surface wear [1; 2]. In recent years, with increasing railway traffic speeds and axle loads, the operational durability requirements for rails have become more demanding [3 – 5]. From both practical and fundamental perspectives, the development of special-purpose rails with enhanced performance characteristics is of significant importance [6 – 8]. In Russia, home to one of the world’s longest railway networks, this challenge has been addressed since 2018 through the production of long, differentially hardened rails with improved wear resistance and contact fatigue strength, classified as DT400IK [9]. These rails are manufactured from steel containing more than 0.8 wt. % carbon, which ensures the formation of a subgrain structure with a high density of low-angle boundaries in the surface layer. Modern physical materials science techniques, particularly transmission electron microscopy [10 – 12], are employed to monitor changes in structure, phase composition, and defect substructure that lead to the degradation of mechanical properties [13 – 15]. Improving the technology for special-purpose rail production and ensuring high-performance properties requires a deep understanding of the physical nature and evolution trends of the structural-phase states and fine substructure in the surface layers of rails [16 – 18]. Such data are crucial for reliably achieving the target of transporting up to 2 billion tons [19 – 21]. Analysis conducted on rails made of hypoeutectoid steel with carbon content below 0.8 wt. % – as presented in [22 – 25] – has enabled the quantification of physical hardening mechanisms, the establishment of their hierarchy, and the determination of overall yield strength. However, there is a notable lack of studies focused on rails made of hypereutectoid steel.

The objective of this study is to compare the deformation hardening mechanisms of the rolling surface and fillet of special-purpose DH400RK rails after they have been in operation on the Russian Railways (RZD) test circuit at Scherbinka, following a tonnage of 187 million tons (gross).

Materials and methods

The internal structure and phase composition were studied on samples of differentially hardened DH400RK category rails, made from E0.9C–Cr–N–V–Fe grade steel produced by EVRAZ ZSMK, after they had undergone a tonnage of 187 million tons (gross) at the Russian Railways (RZD) test circuit. The chemical composition of E90HAF rail steel, according to GOST 5185 – 2013 and TS 24.10.75111-298-057576.2017, included the following main elements, wt. %: 0.92 С, 0.4 Si, 1.0 Mn, 0.3 Cr, 0.14 V, with iron as the base. The mechanical properties are as follows: yield strength – over 900 MPa, tensile strength – 1350 MPa. relative elongation – 9.0 %, relative reduction – 18 %, impact toughness – 15 J/cm2, and hardness on the rolling surface of the rail head – 400 – 450 HB.

The rolling surface and fillet of the rail head were investigated (Fig. 1) using transmission electron microscopy (TEM) on thin foils with a JEM-2100 electron microscope (Jeol, Japan) [26 – 28].

Fig. 1. Schematic representation of a rail sample after passing a tonnage of 187 million tons, |

To evaluate the hardening mechanisms that contribute to the yield strength in the studied steel, each sample was analyzed for structural morphological features, phase composition, and fine structure parameters, including the volume fractions of morphological constituents Pv . The localization of the carbide phase (cementite) was identified, and for each specific location, the shape, size (d), particle spacing (r), and volume fraction (δ) of the particles were determined. In each morphological component, as well as in the material as a whole, the scalar ρ and excessive ρ± dislocation densities were calculated, along with the amplitudes of internal stresses generated by them – namely, shear stresses (σf , or “forests” of dislocations) and long-range stresses (σl ), which arise in regions with an excess dislocation density. All quantitative parameters of the fine structure were measured within each morphological component and statistically processed, with the mean values presented in Table 1 (where D1 represents the fragment or subgrain size; χ, χpl and χel represent the curvature-torsion amplitude of the crystal lattice and its plastic and elastic components, respectively; \(\sigma _{\rm{l}}^{{\rm{pl}}}\) and \(\sigma _{\rm{l}}^{{\rm{el}}}\) are the amplitudes of internal long-range stresses and their plastic and elastic components.

Table 1. Quantitative parameters of the structure of hypereutectoid rail steel

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The technique for determining these quantitative parameters is detailed in [9; 29].

Results and discussion

The studies have shown that regardless of the location on the rail head surface (Fig. 1) the following morphological components are observed in the structure: lamellar (ideal) pearlite with parallel alternating lamellae of ferrite and cementite; fragmented lamellar pearlite, in which dislocation walls across the di-rection of α-phase plates are formed; destroyed lamellar perlite with bent, cut and crushed Fe3C lamellae; globular pearlite in the form of grains with globular Fe3C particles, subgrain structure – small equiaxed fragments with cementite particles along the boundaries and in the junctions. The images of these morphological components are consistent with those observed for rails made of hypoeutectoid steel, as shown in [1].

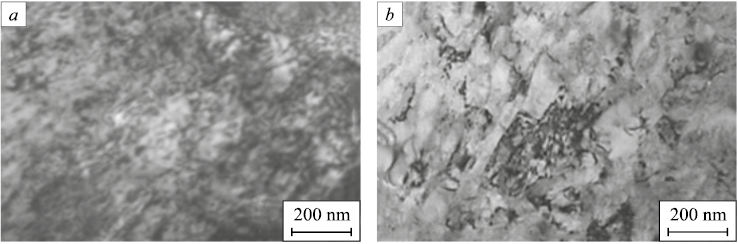

A different type of structure was identified on the fillet surface – a completely destroyed structure. This structure, characterized by completely destroyed pearlite colonies, contains small, chaotically arranged carbide particles (Fe3C) with an acicular shape and a high scalar dislocation density (Fig. 2, а).

Fig. 2. TEM images of a completely destroyed (a) and subgrain structure (b) |

The material on the rolling surface in the head center predominantly consists of a subgrain structure (90 %) (Fig. 2, b), while this structure accounts for only 2 % of the fillet surface. The research demonstrated that, in all morphological components, the dislocation structure type remains consistent: the dislocation substructure is represented by dense dislocation arrays. In all morphological components, there are bend extinction contours, originating from interfaces of pearlite grains and colonies, cementite plates in pearlite grains, fragment and subgrain boundaries, carbide particles (cementite) of lamellar and rounded shapes located on the boundaries and within the dislocation fragments and subgrains, junctions of subgrains, and the dislocation substructure.

Calculations presented in [9] indicate that, in the fillet surface layer, within the ideal, destroyed, and globular pearlite, the scalar density of dislocations ρ is higher than the excess density of dislocations ρ± , as determined from the width of the bend extinction contours (Table 1), meaning that ρ > ρ± and, accordingly, σl < σf . This indicates that the curvature-twist of the crystal lattice in these morphological components is purely plastic in nature. In fragmented pearlite, as well as in completely destroyed and subgrain structures, the value ρ is smaller than the calculated value of ρ± , meaning ρ < ρ± and, σf < σl , which implies that the curvature-twist of the crystal lattice in these components is elastic-plastic in nature. However, in fragmented pearlite and completely destroyed structures χpl \( \gg \) χel , whereas in the subgrain structure χpl ≈ χel (Table 1).

In the surface layer of the rail head center, the value ρ in all morphological components was found to be smaller than the value of ρ± calculated based on the width of extinction contours [9] (Table 2). This indicates that the curvature-twist of the crystal lattice in all morphological components is elastic-plastic, with χ = χpl + χel . In the subgrain structure, which occupies the majority of the material, χel is nearly three times greater than χpl .

Table 2. Parameters of the fine structure of pearlite in the rolling surface center

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In the surface layer of the rail head, elastic-plastic curvature-twist of the crystal lattice is observed across all morphological components. Notably, in the subgrain structure, which makes up 90 % of the material, the values of χ and σl are the highest, while the value of σpl is more than an order of magnitude smaller than that of σel (Table 2). This explains the presence of microcracks in these areas.

The quantitative results presented in Tables 1 and 2 served as the basis for calculating the additive (total) yield strength in each morphological component and for the material as a whole. It is important to note that individual mechanisms contribute differently to overall strengthening, as these are influenced by various factors in each case [30 – 32]. Therefore, when estimating the additive yield strength σad , it is crucial to consider the volume fractions Pv of each morphological component σi

\[\sigma = \sum {{P_i}{\sigma _i}} ,\]

where Рi and σi are volume fractions and yield strength of each morphological component of the structure.

Previously, it was assumed that the additive yield strength could be determined by simply summing the contributions of individual hardening mechanisms [30]. However, it has now been demonstrated that, in some cases, these values should be summed using a quadratic approximation [31; 32]. This approach is particularly relevant for the mechanisms Δσf and Δσg , which act locally and inhomogeneously within the grains. Thus,

\[{\sigma _{{\rm{ad}}}} = \Delta {\sigma _{\rm{p}}} + \Delta {\sigma _{{\rm{s}}}} + \Delta {\sigma _{\rm{g}}} + \Delta {\sigma _{{\rm{or}}}} + \Delta {\sigma _{{\rm{perl}}}} + \Delta {\sigma _{{\rm{ss}}}} + \sqrt {\Delta \sigma _{\rm{f}}^2 + \Delta \sigma _{\rm{l}}^2} ,\]

where Δσn = 35 MPa [9] represents the friction stress of dislocations in the crystal lattice of α-iron; Δσs refers to solid solution hardening (the hardening of ferrite solid solution by dissolved alloying elements); Δσg denotes grain boundary hardening (due to grain boundaries); Δσor is the hardening of material by incoherent particles as dislocations bypass them via the Orowan mechanism; Δσperl represents hardening due to pearlitic component (barrier inhibition within pearlitic colonies); Δσss refers to substructural hardening (due to intraphase boundaries) the formula contains no such values); Δσf is the hardening by the “forest” of dislocations that cut glide dislocations (internal shear stress); and Δσl represents hardening by long-range stress fields (internal moment or local stresses), with Δσl = Δσel + Δσpl ; where Δσel is the elastic component and Δσpl is the plastic component of long-range stresses.

The contributions of these hardening mechanisms were qualitatively assessed using the formulas given in [29; 31; 32], and the results are presented in Tables 3 and 4.

Table 3. Contribution of various mechanisms to hardening of hypereutectoid rail steel

Table 4. Contribution of various mechanisms to hardening of rail steel

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The analysis of data from Tables 3 and 4 shows that the strength of the steel is multifactorial, with physical mechanisms that are cumulative in nature. For the fillet surface, the primary hardening mechanism is Orowan strengthening (Δσor ). This is primarily because the completely destroyed structure occupies the majority (60 %) of the fillet surface. The contributions from long-range stress fields (Δσg ) and the stresses from the “forest” of dislocations (Δσf )are also significant. The emerging subgrain structure forms numerous grain junctions, leading to an increase in the sources of extinction contours and, consequently, a growth in Δσg . However, since the volume fraction of the subgrain structure (Pv ) is low (2 %), its contribution to the strengthening of the fillet surface is minimal. The strengthening is primarily due to the fragmented substructure and the completely destroyed structure. The additive yield strength at the fillet surface is 2218 MPa.

For the central part of the rolling surface of the rail head, the additive yield strength is much higher, reaching 7950 MPa. The main hardening mechanisms (Table 4) include strengthening by internal elastic local stresses, substructural strengthening, and strengthening by incoherent particles.

The significant difference in the values of additive yield strength (\(\sigma _{{\rm{ad}}}^{{\rm{fillet}}} < \sigma _{{\rm{ad}}}^{{\rm{centr}}}\)) can be explained by the fact that, in the head center’s rolling surface, the volume fraction of the subgrain structure is 45 times higher than that in the fillet. The subgrains form in the nanometer size range, leading to a high density of sub-boundaries and junctions (primarily triple junctions) of subgrains, which are the sources of extinction contours (mainly elastic). These contours result in high values of internal long-range stresses, with the elastic component being more than an order of magnitude higher than the plastic one. This combination determines the final effect. On the fillet surface, the main morphological components are destroyed pearlite and a completely destroyed structure with low-density boundaries.

Conclusions

Transmission electron microscopy was used to reveal the morphological components of the rolling surface of the rail head made of hypereutectoid steel, both at the center and in the fillet. The identified components include lamellar pearlite, fragmented pearlite, destroyed lamellar pearlite, globular pearlite, completely destroyed pearlite, and subgrain structure. We conducted a quantitative analysis of hardening mechanisms and assessed the contributions from lattice friction, solid solution hardening, pearlite hardening, incoherent cementite particles, grain boundaries and sub-boundaries, dislocation substructure, and internal stress fields. For the fillet surface, we established that the main hardening mechanism is due to incoherent particles, along with mechanisms based on internal long-range (local) stresses, internal shear stresses (“forests” of dislocations), and substructural hardening.

For the central part of the rolling surface, the primary hardening mechanisms are long-range stress fields, incoherent particles, and substructural hardening. We determined the additive yield strength at the rolling surface and explained the difference in its values between the head center and the fillet.

References

1. Yur’ev A.A., Kuznetsov R.V., Gromov V.E., Ivanov Yu.F., Shlyarova Yu.A. Long Rails: Structure and Properties after Long-Term Operation. Novokuznetsk: Poligrafist; 2022:311. (In Russ.).

2. Shur E.A. Rails Damage. Moscow: Intekst; 2012:153. (In Russ.).

3. Steenbergen M. Rolling contact fatigue: Spalling versus transverse fracture of rails. Wear. 2017;380-381:96–105. http://doi.org/10.1016/j.wear.2017.03.003

4. Skrypnyk R., Ekh M., Nielsen J.C.O., Palsson B.A. Prediction of plastic deformation and wear in railway crossings – Comparing the performance of two rail steel grades. Wear. 2019;428-429:302–314. http://doi.org/10.1016/j.wear.2019.03.019

5. Miranda R.S., Rezende A.B., Fonseca S.T., Fernandes F.M., Sinatora A., Mei P.R. Fatigue and wear behavior of pearlitic and bainitic microstructures with the same chemical composition and hardness using twin-disc tests. Wear. 2022;494-495: 204253. http://doi.org/10.1016/j.wear.2022.204253

6. Pereira H.B., Alves L.H.D., Rezende A.B., Mei P.R., Goldenstein H. Influence of the microstructure on the rolling contact fatigue of rail steel: Spheroidized pearlite and fully pearlitic microstructure analysis. Wear. 2022;498-499:204299. http://doi.org/10.1016/j.wear.2022.204299

7. Ivanov Yu.F., Porfir’ev M.A., Gromov V.E., Kryukov R.E., Shlyarova Yu.A. Structural and phase states in the head of special-purpose rails after prolonged operation. Metally. 2023;(6):53–58. (In Russ.). https://doi.org/10.31857/S086957332306006X

8. Ivanisenko Yu., Fecht H.J. Microstructure modification in the surface layers of railway rails and wheels: Effect of high strain rate deformation. Steel Tech. 2008;3(1):19–23.

9. Porfir’ev M.A. Gromov V.E., Ivanov Yu.F., Popova N.A., Shlyarov V.V. Thin structure of long-length rails made of hypereutectoid steel after long-term operation. Novokuznetsk: Poligrafist; 2023:285. (In Russ.).

10. Nikas D., Zhang X., Ahlstrom J. Evaluation of local strength via microstructural quantification in a pearlitic rail steel deformed by simultaneous compression and torsion. Materials Science and Engineering: A. 2018;737:341–347. https://doi.org/10.1016/j.msea.2018.09.067

11. Masoumi M., Sinatora A., Sietsma H.G. Role of microstructure and crystallographic orientation in fatigue crack failure analysis of a heavy haul railway rail. Engineering Failure Analysis. 2019;96:320–329. http://doi.org/10.1016/j.engfailanal.2018.10.022

12. Turan M.E., Aydin F., Sun Y., Cetin M. Residual stress measurement by strain gauge and X-ray diffraction method in different shaped rails. Engineering Failure Analysis. 2019;96:525–529. https://doi.org/10.1016/j.engfailanal.2018.10.016

13. Li X.C., Ding H.H., Wang W.J., Guo J., Liu Q.Y., Zhou Z.R. Investigation on the relationship between microstructure and wear characteristic of rail materials. Tribology International. 2021;163:107152. http://doi.org/10.1016/j.triboint.2021.107152

14. Kanematsu Y., Uehigashi N., Matsui M., Noguchi S. Influence of a decarburized layer on the formation of microcracks in railway rails: On-site investigation and twindisc study. Wear. 2022;504–505:204427. https://doi.org/10.1016/j.wear.2022.204427

15. Rong K.-J., Xiao Y.-L., Shen M.-X., Zhao H.-P., Wang W.-J., Xiong G.-Y. Influence of ambient humidity on the adhesion and damage behavior of wheel-rail interface under hot weather condition. Wear. 2021;486-487:204091.

16. https://doi.org/10.1016/j.wear.2021.204091

17. Improvement of rail steels. Zheleznye dorogi mira. 2016;(1):74–76. (In Russ.).

18. Dobuzhskaya A.B., Galitsyn G.A., Yunin G.N., Polevoi E.V., Yunusov A.M. Effect of chemical composition, microstructure and mechanical properties on the wear resistance of rail steel. Steel in Translation. 2020;50(12):906–910. https://doi.org/10.3103/S0967091220120037

19. Wen J., Marteau J., Bouvier S., Risbet M., Cristofari F., Secorde P. Comparison of microstructure changes induced in two pearlitic rail steels subjected to a full-scale wheel/rail contact rig test. Wear. 2020;456-457:203354. http://doi.org/10.1016/j.wear.2020.203354

20. Hu Y., Guo L.C., Maiorino M., Liu J.P., Ding H.H., Lewis R., Meli E., Rindi A., Liu Q.Y., Wang W.J. Comparison of wear and rolling contact fatigue behaviours of bainitic and pearlitic rails under various rolling-sliding conditions. Wear. 2020;460-461:203455. http://doi.org/10.1016/j.wear.2020.203455

21. Hu Y., Zhou L., Ding H.H., Lewis R., Liu Q.Y., Guo J., Wang W.J. Microstructure evolution of railway pearlitic wheel steels under rolling-sliding contact loading. Tribology International. 2021;154:106685. http://doi.org/10.1016/j.triboint.2020.106685

22. Zhou L., Bai W., Han Z., Wang W., Hu Yu., Ding H., Lewis R., Meli E., Liu Q., Guo J. Comparison of the damage and microstructure evolution of eutectoid and hypereutectoid rail steels under a rolling-sliding contact. Wear. 2022;492-493: 204233. http://doi.org/10.1016/j.wear.2021.204233

23. Bai W., Zhou L., Wang P., Hu Y., Wang W., Ding H., Han Z., Xu X., Zhu M. Damage behavior of heavy-haul rail steels used from the mild conditions to harsh conditions. Wear. 2022;496-497:204290. http://doi.org/10.1016/j.wear.2022.204290

24. Alwahdi F.A.M., Kapoor A., Franklin F.J. Subsurface microstructural analysis and mechanical properties of pearlitic rail steels in service. Wear. 2013;302(1-2):1453–1460. http://doi.org/10.1016/j.wear.2012.12.058

25. Wang W.J., Lewis R., Yang B., Guo L.C., Liu Q.Y., Zhu M.H. Wear and damage transitions of wheel and rail materials under various contact conditions. Wear. 2016;362-363: 146–152. http://doi.org/10.1016/j.wear.2016.05.021

26. Pan R., Ren R., Zhao X., Chen C. Influence of microstructure evolution during the sliding wear of CL65 steel. Wear. 2018;400-401:169–176. http://doi.org/10.1016/j.wear.2018.01.005

27. Egerton F.R. Physical Principles of Electron Microscopy. Basel: Springer International Publishing; 2016:196. https://doi.org/10.1007/978-3-319-39877-8

28. Kumar C.S.S.R. Transmission Electron Microscopy. Characterization of Nanomaterials. New York: Springer; 2014:717.

29. Carter C.B., Williams D.B. Transmission Electron Microscopy: Diffraction, Imaging, and Spectrometry. Berlin: Springer International Publishing; 2016:518. https://doi.org/10.1017/S1431927618000296

30. Popova N.A., Gromov V.E., Ivanov Yu.F., Porfir’ev M.A., Nikonenko E.L., Shlyarova Yu.A. Effect of long-term operation on the structural-phase state of hypereutectoid rail steel. Materialovedenie. 2023;(10):17–28. (In Russ.). https://doi.org/10.31044/1684-579Х-2023-0-10-17-28

31. Gol’dshtein M.I., Farber V.M. Dispersion Hardening of Steel. Moscow: Metallurgiya; 1979:208. (In Russ.).

32. Kozlov E.V., Koneva N.A. The nature of metal materials hardening. Izvestiya vuzov. Fizika. 2002;45(3):52–71. (In Russ.).

33. Kozlov E.V., Malinovskaya V.A., Popova N.A. Quantitative assessment of hardening of nitrocemented steel 20Kh2N4A after low tempering. Izvestiya. Ferrous Metallurgy. 2006; 49(6):37–39. (In Russ.).

About the Authors

N. A. PopovaRussian Federation

Natal’ya A. Popova, Cand. Sci. (Eng.), Research Associate of the Scientific and Educational Laboratory “Nanomaterials and Nanotechnologies”

2 Solyanaya Sqr., Tomsk 634003, Russian Federation

V. E. Gromov

Russian Federation

Viktor E. Gromov, Dr. Sci. (Phys.-Math.), Prof., Head of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. B. Yur’ev

Russian Federation

Aleksei B. Yur’ev, Dr. Sci. (Eng.), Prof., Rector

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

E. A. Martusevich

Russian Federation

Efim A. Martusevich, Cand. Sci. (Eng.), Research Associate of the Laboratory of Electron Microscopy and Image Processing

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

M. A. Porfir’ev

Russian Federation

Mikhail A. Porfir’ev, Research Associate of Department of Scientific Researches

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Popova N.A., Gromov V.E., Yur’ev A.B., Martusevich E.A., Porfir’ev M.A. Physics of hardening of the rolling surface of rail head from hypereutectoid steel after operation. Izvestiya. Ferrous Metallurgy. 2024;67(4):424-432. https://doi.org/10.17073/0368-0797-2024-4-424-432

JATS XML