Scroll to:

Grain boundary migration and mechanical properties altering in Fe – 10Ni – 20Cr alloy under irradiation

https://doi.org/10.17073/0368-0797-2024-3-311-317

Abstract

Mechanisms of ∑5(210)[001] and ∑5(310)[001] symmetrical tilt grain boundaries migration in bicrystall Fe – 10Ni – 20Cr samples under irradiation were investigated by means of molecular dynamics method. The density of radiation defects grows quite quickly up to a dose of ~0.02 dpa and then reaches saturation. This is due to balancing of the radiation defects generation and annihilation rates. It is shown that at the early stage of irradiation, grain boundaries began to deviate stochastically from their initial positions due to interaction with cascades of atomic displacements and absorption of structural defects. During irradiation, the grain boundary region thickened and became rough. With an increase in the radiation dose, size of the clusters of point defects (tetrahedrons of stacking faults and dislocation loops) increased. Interaction with large clusters of point defects led to the formation of bends on initially flat surfaces of grain boundaries. At small distances between the boundaries, the high driving force between the curved surfaces of grain boundaries significantly increased the rates of their approach. The average migration rates of grain boundaries before their direct interaction with each other were approximately 0.8 m/s. As a result of their approach, the grain boundaries were annihilated, the potential energy of the sample decreased abruptly, and the grains merged. The annihilation of ∑5(310)[001] grain boundaries required twice the radiation dose compared to the ∑5(210)[001] grain boundaries . The direct interaction of grain boundaries with each other abruptly increased the velocity of their migration due to the emergence initiation of a driving force from the curved sections of the grain boundary surfaces. Influence of the radiation dose on deformation behavior features of the samples under uniaxial strains was studied. With an increase in the radiation dose, the elastic limit decreased rapidly and reached saturation at an irradiation dose of ~0.01 dpa.

Keywords

For citations:

Kryzhevich D.S., Korchuganov A.V., Zolnikov K.P. Grain boundary migration and mechanical properties altering in Fe – 10Ni – 20Cr alloy under irradiation. Izvestiya. Ferrous Metallurgy. 2024;67(3):311-317. https://doi.org/10.17073/0368-0797-2024-3-311-317

Введение

One of effective ways to enhance radiation resistance of materials is to form various kinds of interfaces [1 – 3]. The interfaces such as grain boundaries can accumulate a considerable part of defects generated during irradiation. Irradiation of nanocrystalline Ni and Cu samples showed that their grain boundaries are the main sink for radiation defects, which significantly reduces the density of structural defects compared to coarse-grained analogs [4]. The authors of [5] applied the molecular dynamic approach to show that grain boundaries actively absorb interstitials generated by atomic displacement cascades, and a significant number of vacancies remain in the bulk. Later, the excessive interstitials leave the grain boundaries, returning to the bulk where they enhance the recombination with vacancies. The experimental study of the ion-irradiated nanocrystalline gold revealed thermal instability of the generated defects caused by a high density of grain boundaries [6]. The works [7; 8] investigated the peculiarities of grain boundaries interaction with radiation defects at the microscopic level. It is noted that grain boundaries segregate in their region their own interstitials, which are characterized by higher mobility compared to vacancies and pores. However, the issues related to the grain boundaries absorbing defects with low mobility require additional research.

High-temperature heating of materials in the nuclear reactor zone significantly accelerates the recrystallization process based on the migration of boundaries [9; 10]. To contain this process, it is important to investigate the mechanisms of interaction of radiation-induced structural defects with moving grain boundaries. The grain boundary migration controls the evolution of the materials microstructure. The driving forces behind grain boundary migration can have different physical nature, which can be related to the anisotropy of elastic energy, inhomogeneous density of defects and impurities, temperature gradient, and curvature of the grain boundary surface [11]. These driving forces are often considered in experimental and numerical studies of grain boundary migration and recrystallization of polycrystalline materials [12 – 14].

Bicrystalline samples are a reasonable alternative for investigating the behavior features of individual grain boundaries under various types of external influences, both in experiments and in simulations [15 – 18]. In the absence of external influences and internal energy gradients, the migration of grain boundaries has the nature of random walk [18]. The effect of irradiation on the mobility of grain boundaries is a scientific challenge, which should be addressed to reveal the mechanisms of radiation-stimulated grain growth.

We investigated the mechanisms of grain boundary migration in bicrystal Fe – 10Ni – 20Cr samples with ∑5(210)[001] and ∑5(310)[001] symmetrical tilt grain boundaries during irradiation and also the effect of radiation dose on the nucleation and development of plasticity in these samples under uniaxial tension.

Research method

The simulated Fe – 10Ni – 20Cr alloy samples contained two ∑5(210)[001] or ∑5(310)[001] symmetrical tilt grain boundaries and were parallelepiped-shaped with ribs sized at 12×24×12 nm. The gamma-surface minimization algorithm [19] was used to determine the optimal configuration of the grain boundary. The initial temperature of the samples was 950 K. The interatomic interaction in the material was described by the many-body potential, which enables to correctly simulate atomic displacement cascades in the sample [20]. The atoms velocity distribution in the initial samples corresponded to the Maxwell distribution, and their initial direction was set using a random number generator. To speed up the calculation, the integration step was changed dynamically, the maximum atom displacement not exceeding 0.5 pm. The integration step for given loading conditions and temperature varied between 2·10\(^–\)18 and 3·10\(^–\)16 s. To simulate irradiation, a sequence of atomic displacement cascades was generated in the samples with the primary knocked-on atom energy of 10 keV. The primary knocked-on atom and the initial direction of its displacement were chosen using a random number generator. The primary knocked-on atom was always an iron atom. To estimate the accumulated radiation dose in the approximation of NRT theory, the threshold displacement energy was set equal to 40 eV, which is commonly used for iron and iron-based alloys [21]. After generation of the atomic displacement cascade, the system was relaxed for 10 ps and cooled by the thermostat to the initial temperature for 5 ps before generation of the next atomic displacement cascade. Mechanical loading was set by tension perpendicular to the grain boundary plane at a constant velocity of 5 m/s by scaling the atomic coordinates and the size of the simulated cell. As for the other directions, the system was deformed so that zero pressure could be maintained in each of these directions. Periodic boundary conditions were modeled in all directions. The simulation was performed using the LAMMPS computational package [22]. To identify local structural changes in the loaded sample, the Common Neighbor Analysis pattern for each atom was used [23]. The OVITo software was used to visualize the structure of simulated crystallites [24].

Calculation results

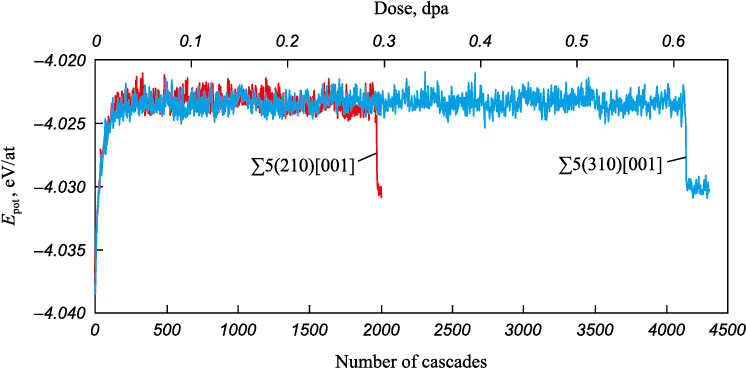

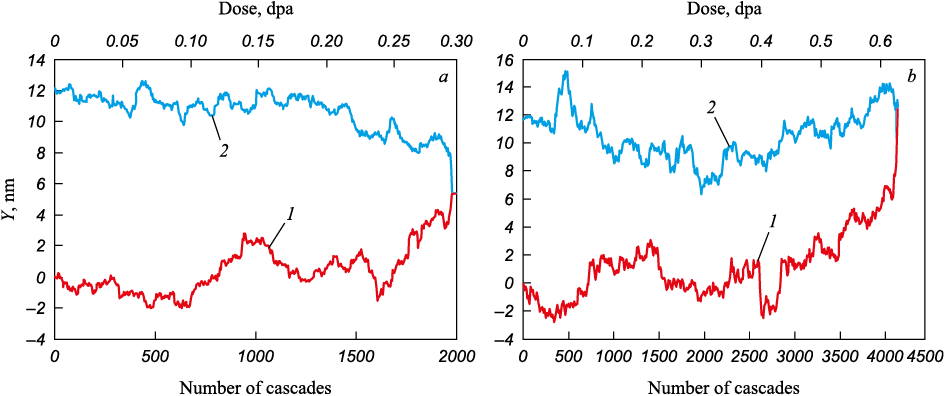

With the onset of irradiation, the simulated sample starts accumulating radiation-induced damage of the structure. The number of radiation defects grows quite rapidly up to a dose of ~0.02 dpa and at this value the radiation defect density reaches saturation. During irradiation, the growth of the potential energy of interatomic interaction gradually slows down (Fig. 1). At doses higher than 0.02 dpa, the rates of generation and annihilation of radiation defects equalize and the curves in Fig. 1 reach saturation. During irradiation, the grain boundaries grow thicker, and their initially flat surfaces develop roughness and curves. Fig. 2 presents the results of calculations of grain boundary positions in the simulated bicrystals. We can clearly see that the grain boundary movement is of a stick-slip nature. In addition, the curves presented in Fig. 2 feature irradiation intervals when grain boundaries moved both towards each other and in the opposite direction. At the same time, the trend towards their mutual approach is obvious. The impact of such processes as the generation and development of atomic displacement cascades, the cascades distance from grain boundaries, thermally activated defect diffusion, and the interaction of grain boundaries with various radiation defects in the structure, on the migration of grain boundaries accounts for these features [25].

Fig. 1. Potential energy vs radiation dose for the samples with different grain boundaries

Fig. 2. ∑5[210](001) (1) and ∑5[310](001) (2) grain boundary location vs radiation dose |

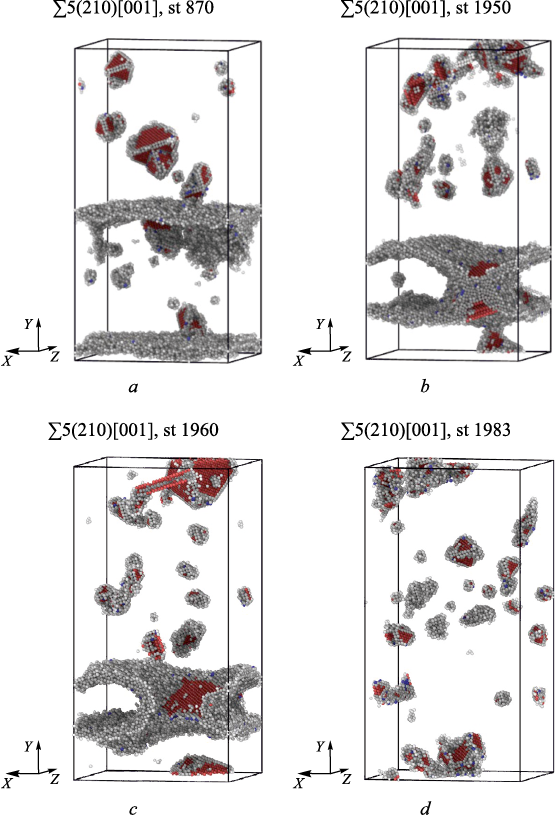

The evolution of the unirradiated sample for more than 200 ns at a temperature of 950 K shows that the grain boundaries do not shift. This indicates that the rate of thermally activated migration of grain boundaries in the sample is significantly lower than that of the radiation-stimulated one. Irradiation of the sample causes radiation-stimulated migration of grain boundaries, during which their structure changes, which can be clearly seen in Fig. 3. The structure of the grain boundaries alters due to the interaction and absorption of various radiation defects. Fig. 3 shows the structure of grain boundaries and large clusters at different radiation doses. The majority of large clusters represent tetrahedrons of stacking faults. At a radiation dose of 0.129 dpa (Fig. 3, a), grain boundaries slightly shifted from the initial position, but their initially flat surfaces locally curved due to the interaction with large clusters located nearby. Fig. 2, a shows that the distance between the boundaries could both increase and decrease during irradiation. The direction of grain boundary displacement was determined by attraction to large clusters formed randomly on one or the other side of the grain boundary surface. Note that elastic forces acting between the clusters of point defects and grain boundaries account for mutual attraction between them [26]. At a radiation dose of 0.290 dpa, the surfaces of the grain boundaries curved locally toward each other due to the joint attraction to a large cluster formed in the region between the grain boundaries (Fig. 3, b). The distance between the curved surfaces became sufficient for the grain boundaries to interact and rapidly approach each other (Fig. 3, c). The calculations showed that the average migration rates of grain boundaries before their direct interaction with each other were approximately 0.8 m/s. The interaction of the curved surface regions boosted the rate of the grain boundary migration by about an order of magnitude. After the grain boundaries approached and merged, they annihilated (Fig. 3, d), which caused a drastic fall in the potential energy of the simulated sample (Fig. 1).

Fig. 3. ∑5[210](001) grain boundary and radiation defects for different radiation doses |

The calculations showed that the mechanisms of grain boundary migration changed during irradiation. Thus, at an early stage, up to a radiation dose of about ~0.01 dpa, grain boundaries increased their mobility compared to unirradiated ones due to the interaction with atomic displacement cascades and absorption of radiation defects. At this stage, migration manifested by chaotic oscillations of grain boundary surfaces. As the radiation dose increased, larger and larger clusters began to form in the sample, interaction with which led to accelerated migration of grain boundaries. At the same time, the migration rate of grain boundaries accelerated and they shifted further relative to their initial positions. In this interval of radiation doses, the grain boundary migration transformed from chaotic oscillations of local surface areas into displacement of surfaces as a whole. As a result, the grain boundaries deviated significantly from their initial positions. When the distance between grain boundaries became less than 4 nm, the grains began to interact directly with each other. At the same time, the rate of their migration spiked due to the high driving force from the curved surfaces of grain boundaries. A bicrystal with ∑5(310)[001] grain boundaries behaves similarly under irradiation. However, in this case, twice the radiation dose was required for grain boundary annihilation (Fig. 2).

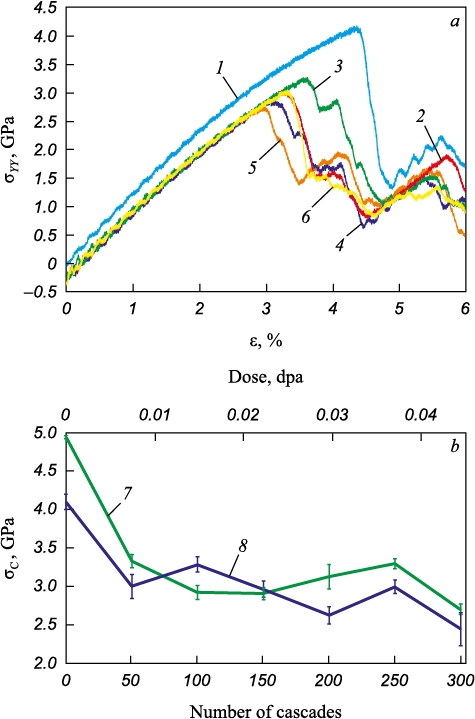

We investigated the behavior features of samples irradiated to different doses under uniaxial tension. The calculations showed that the mechanical properties of the sample, to a large extent, depend on the radiation dose, which determines the degree of the sample radiation-induced damage. The deformation behavior showed the following general trend: the growth of the radiation dose was accompanied by rather rapid decrease in the samples elastic limit (Fig. 4, a), the value of which reaches saturation at doses exceeding 0.01 dpa (Fig. 4, b). At the given radiation dose, the density and sizes of the formed radiation defects minimized the value of energy barriers for the emergence and propagation of stacking faults – the main carriers of plastic deformation in the simulated material. Note that the elastic limit reaches saturation at a lower radiation dose than that at which the processes of generation and annihilation of radiation defects reach balance. Deviations from the elastic limit average value at higher radiation doses were caused by peculiarities of the internal structural changes, primarily related to changes in the configuration and distribution of the large clusters and dislocation loops. These changes in the defect system were stochastic in nature (Fig. 4, b).

Fig. 4. Stress-strain dependence under uniaxial tension for different radiation doses |

Conclusions

The simulation results showed that the migration mechanisms of symmetrical tilt grain boundaries in Fe – 10Ni – 20Cr bicrystal change during irradiation. At low radiation doses, the migration of grain boundaries is manifested by stochastic deviations from the initial positions. This is attributed to the interaction of grain boundaries with atomic displacement cascades and absorption of mobile defects in the structure. Higher radiation doses cause formation of large clusters, interaction with which boosts the migration rate of grain boundaries and enhances local curvature of their surface. The driving force behind the migration of grain boundaries is their elastic interaction with large clusters. As the radiation dose increases further, grain boundaries tend to approach each other even more, which results in their annihilation. The migration rate spikes when the boundaries start interacting with each other. The driving force behind the migration is attributed to the strong mutual attraction between the nearby curved regions of the grain boundaries.

The calculations showed that the elastic limit of the simulated alloy drops rather rapidly, as the radiation dose grows up to 0.01 dpa, and then reaches saturation. With further irradiation, the elastic limit slightly deviates from the mean value. It is found that the elastic limit reaches saturation at a lower radiation dose than that at which the density of surviving radiation defects reaches saturation. This is because the lower radiation dose minimizes energy barriers required for the nucleation and development of plastic deformation in the material under study.

References

1. Zhang X., Hattar K., Chen Y., Shao L., Li J., Sun C., Yu K., Li N., Taheri M.L., Wang H., Wang J., Nastasi M. Radiation damage in nanostructured materials. Progress in Materials Science. 2018;96:217–321. https://doi.org/10.1016/j.pmatsci.2018.03.002

2. Grimes R.W., Konings R.J.M., Edwards L. Greater tolerance for nuclear materials. Nature Materials. 2008;7:683–685. https://doi.org/10.1038/nmat2266

3. Ackland G. Controlling radiation damage. Science. 2010; 327(5973):1587–1588. https://doi.org/10.1126/science.1188088

4. Nita N., Schaeublin R., Victoria M. Impact of irradiation on the microstructure of nanocrystalline materials. Journal of Nuclear Materials. 2004;329–333B:953–957. https://doi.org/10.1016/j.jnucmat.2004.04.058

5. Bai X.-M., Voter A.F., Hoagland R.G., Nastasi M., Uberuaga B.P. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science. 2010; 327(5973):1631–1634. https://doi.org/10.1126/science.1183723

6. Chimi Y., Iwase A., Ishikawa N., Kobiyama M., Inami T., Okuda S. Accumulation and recovery of defects in ion-irradiated nanocrystalline gold. Journal of Nuclear Materials. 2001;297(3):355–357. https://doi.org/10.1016/S0022-3115(01)00629-8

7. Bai X.-M., Uberuaga B.P. The influence of grain boundaries on radiation-induced point defect production in materials: A review of atomistic studies. JOM. 2013;65:360–373. https://doi.org/10.1007/s11837-012-0544-5

8. Beyerlein I.J., Demkowicz M.J., Misra A., Uberuaga B.P. Defect-interface interactions. Progress in Materials Science. 2015;74:125–210. https://doi.org/10.1016/j.pmatsci.2015.02.001

9. Li Y.H., Wang L., Li B., E J.C., Zhao F.P., Zhu J., Luo S.N. Thermally driven grain boundary migration and melting in Cu. The Journal of Chemical Physics. 2015;142(5):054706. https://doi.org/10.1063/1.4907272

10. Chen K., Han J., Srolovitz D.J. On the temperature dependence of grain boundary mobility. Acta Materialia. 2020; 194:412–421. https://doi.org/10.1016/j.actamat.2020.04.057

11. Gottstein G., Shvindlerman L.S. Grain Boundary Migration in Metals. CRC Press; 2009:711. https://doi.org/10.1201/9781420054361

12. Rupert T.J., Gianola D.S., Gan Y., Hemker K.J. Experimental observations of stress-driven grain boundary migration. Science. 2009;326(5960):1686–1690. https://doi.org/10.1126/science.1178226

13. Zhang H., Upmanyu M., Srolovitz D.J. Curvature driven grain boundary migration in aluminum: molecular dynamics simulations. Acta Materialia. 2005;53(1):79–86. https://doi.org/10.1016/j.actamat.2004.09.004

14. Tonks M., Millett P., Cai W., Wolf D. Analysis of the elastic strain energy driving force for grain boundary migration using phase field simulation. Scripta Materialia. 2010; 63(11):1049–1052. https://doi.org/10.1016/j.scriptamat.2010.07.034

15. Cahn J.W., Mishin Y., Suzuki A. Coupling grain boundary motion to shear deformation. Acta Materialia. 2006; 54(19):4953–4975. https://doi.org/10.1016/j.actamat.2006.08.004

16. Zhang H., Mendelev M.I., Srolovitz D.J. Computer simulation of the elastically driven migration of a flat grain boundary. Acta Materialia. 2004;52(9):2569–2576. https://doi.org/10.1016/j.actamat.2004.02.005

17. Yu W.S., Demkowicz M.J. Non-coherent Cu grain boundaries driven by continuous vacancy loading. Journal of Materials Science. 2015;50:4047–4065. https://doi.org/10.1007/s10853-015-8961-9

18. Olmsted D.L., Holm E.A., Foiles S.M. Survey of computed grain boundary properties in face-centered cubic metals – II: Grain boundary mobility. Acta Materialia. 2009; 57(13):3704–3713. https://doi.org/10.1016/j.actamat.2009.04.015

19. Mishin Y., Farkas D. Atomistic simulation of [001] symmetrical tilt grain boundaries in NiAl. Philosophical Magazine A. 1998;78(1):29–56. https://doi.org/10.1080/014186198253679

20. Béland L.K., Tamm A., Mu S., Samolyuk G.D., Osetsky Y.N., Aabloo A., Klintenberg M., Caro A., Stoller R.E. Accurate classical short-range forces for the study of collision cascades in Fe–Ni–Cr. Computer Physics Communication. 2017;219:11–19. https://doi.org/10.1016/j.cpc.2017.05.001

21. Stoller R.E., Toloczko M.B., Was G.S., Certain A.G., Dwaraknath S., Garner F.A. On the use of SRIM for computing radiation damage exposure. Nuclear Instruments and Methods in Physics Research. Section B. 2013;310:75–80. https://doi.org/10.1016/j.nimb.2013.05.008

22. Plimpton S. Fast parallel algorithms for short-range molecular dynamics. Journal of Computational Physics. 1995; 117(1):1–19. https://doi.org/10.1006/jcph.1995.1039

23. Honeycutt J.D., Andersen H.C. Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. Journal of Physical Chemistry. 1987;91(19):4950–4963. https://doi.org/10.1021/j100303a014

24. Stukowski A. Visualization and analysis of atomistic simulation data with OVITO – the Open Visualization Tool. Modelling and Simulation in Materials Science and Engineering. 2010;18:015012. https://doi.org/10.1088/0965-0393/18/1/015012

25. Jin M., Cao P., Short M.P. Mechanisms of grain boundary migration and growth in nanocrystalline metals under irradiation. Scripta Materialia. 2019;163:66–70. https://doi.org/10.1016/j.scriptamat.2018.12.038

26. Jin M., Cao P., Yip S., Short M.P. Radiation damage reduction by grain-boundary biased defect migration in nanocrystalline Cu. Acta Materialia. 2018;155:410–417. https://doi.org/10.1016/j.actamat.2018.05.071

About the Authors

D. S. KryzhevichRussian Federation

Dmitrii S. Kryzhevich, Cand. Sci. (Phys.-Math.), Research Associate of the Laboratory of Computer-Aided Design of Materials

2/4 Akademicheskii Ave., Tomsk 634021, Russian Federation

A. V. Korchuganov

Russian Federation

Aleksandr V. Korchuganov, Cand. Sci. (Phys.-Math.), Research Associate of the Laboratory of Computer-Aided Design of Materials

2/4 Akademicheskii Ave., Tomsk 634021, Russian Federation

K. P. Zolnikov

Russian Federation

Konstantin P. Zolnikov, Dr. Sci. (Phys.-Math.), Chief Researcher of the Laboratory of Computer-Aided Design of Materials

2/4 Akademicheskii Ave., Tomsk 634021, Russian Federation

Review

For citations:

Kryzhevich D.S., Korchuganov A.V., Zolnikov K.P. Grain boundary migration and mechanical properties altering in Fe – 10Ni – 20Cr alloy under irradiation. Izvestiya. Ferrous Metallurgy. 2024;67(3):311-317. https://doi.org/10.17073/0368-0797-2024-3-311-317