Scroll to:

Investigation of changes in temperature of pressing tool during laser processing

https://doi.org/10.17073/0368-0797-2024-2-155-160

Abstract

The article is devoted to improving the wear resistance of forging tools, in particular punches for punching holes and cutting stamp dies. Low tool life leads to an increase in the cost of finished products, an increase in labor and material costs for replacing worn tools and adjusting them, a decrease in the productivity of pressing equipment and an increase in the number of defective products. A method is presented for theoretical research of solving the problem of calculating the temperature field of a stamp die tool during laser processing. A differential equation was compiled for a numerical solution of the problem. The authors proposed the modes of laser heat treatment of a punch for punching holes and a stamp die tool made of high-hardness steel. Field tests conducted in industrial conditions showed that the proposed laser heat treatment modes made it possible to increase resistance of the punch intended for punching holes by 2 – 3 times and the resistance of the stamp dies by 2.2 – 2.8 times.

For citations:

Chichenev N.A., Gorbatyuk S.M., Solomonov K.N., Snitko S.A., Chicheneva O.N. Investigation of changes in temperature of pressing tool during laser processing. Izvestiya. Ferrous Metallurgy. 2024;67(2):155-160. https://doi.org/10.17073/0368-0797-2024-2-155-160

Introduction

One of the most widely used methods of cold metal working (CMW) by pressure is cold stamping [1 – 3], which allows for the production of high-precision parts in a wide range. Cold forming dies are used as tools for this process [4 – 6]. In recent years, the development of new domestic technologies aimed at improving the quality of manufactured products and reducing their cost has become highly relevant. This task can be efficiently solved by improving equipment and tools, including CMW [9; 10].

Formulation of the problem

One of the main reasons of the failure of stamping tools is the wear of their working surfaces. To improve the durability of cold metal working (CMW) tools, thermal, thermochemical, and thermomechanical treatments are applied [11 – 13]. These methods significantly increase the hardness of the tool’s working surfaces and enhance the strength of the base metal from which the tool is made. Laser treatment is an effective method for improving the quality of CMW tools by processing their working surfaces. Laser treatment is characterized by a short exposure time to the treated surfaces and completely eliminates deformation. Only a thin surface layer of the processed part is heated when exposed to laser [14 – 16]. Numerous studies have shown that the thermal processes occurring during laser heating are similar to the results of heating metals by other methods. This allows for the application of classical equations of heat conduction theory to solve theoretical problems of laser processing, taking into account the specifics of laser heat treatment.

This work presents a solution to the problem of calculating the temperature field of a stamping tool when hardening its working surface using laser radiation.

Method of theoretical study of temperature field distribution during laser hardening

As it is known, the result of hardening tool steels [17; 18] significantly depends on distribution of the temperature field that forms during this process [19; 20]. To strengthen the surface layers, it is necessary to heat the working surface of the stamp above the austenitic transformation temperature Ta , after which it is rapidly cooled to a temperature below the pearlitic transformation temperature Tp . If a high-density laser beam is used for heat treatment, the surface layers of the tool will be heated to a temperature depending on the duration of the laser radiation and its power. After laser heating, the surface of the stamp quickly cools down due to the transfer of heat from the heated surface to the other distant areas of the tool. Moreover, temperature of the heated areas depends on their distance from the stamp surface. The depth of the hardened layer can be estimated by studying the characteristics of the resulting temperature field [21; 22].

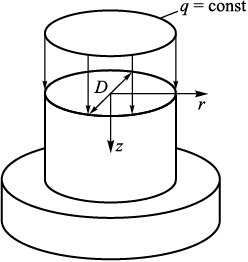

Let us provide a mathematical description of the temperature field for a cylindrical cutting punch (рис. 1).

Fig. 1. Calculation scheme for temperature field |

The change in temperature T over time t can be calculated by numerically solving a two-dimensional differential equation, which in a cylindrical coordinate system is given by [23 – 25]

\[\frac{{\partial T}}{{\partial t}} = a\left( {\frac{{{\partial ^2}T}}{{\partial {r^2}}} + \frac{1}{r}\frac{{\partial T}}{{\partial r}} + \frac{{{\partial ^2}T}}{{\partial {z^2}}}} \right).\]

Here, Т(r, z, t) is the temperature at an arbitrary point of the cutting punch at any given time t, characterized by cylindrical coordinates r and z; a is the thermal conductivity coefficient of the material of the cutting punch; q is the power density of the external heat source (laser radiation) [26 – 28].

Let us define initial and boundary conditions:

– at the initial moment of deformation of the workpiece, the temperature of the cutting punch is assumed to be uniform throughout the entire volume, i.e.

Т0 = Т(z, r, 0) = const;

– on the free surfaces of the punch, heat exchange of convective and radiant types occurs with the environment

\[\frac{{\partial T}}{{\partial t}} = \alpha \left( {{T_{{\rm{surf}}}} - {T_{{\rm{env}}}}} \right) + \varepsilon \sigma \left[ {{{\left( {{T_{{\rm{surf}}}} - 273} \right)}^4} - {{\left( {{T_{{\rm{env}}}} - 273} \right)}^4}} \right];\]

– radiant heat exchange occurs on the end (irradiated) surface of the punch

\[\frac{{\partial T}}{{\partial t}} = q + \varepsilon \sigma \left[ {{{\left( {{T_{{\rm{surf}}}} - 273} \right)}^4} - {{\left( {{T_{{\rm{env}}}} - 273} \right)}^4}} \right],\]

where α is the convective heat transfer coefficient; Тsurf and Тenv are the temperatures of punch surface and the environment, respectively; ε is the degree of emissivity of the punch surface; σ is the emissivity of an absolutely solid body.

Experimental results

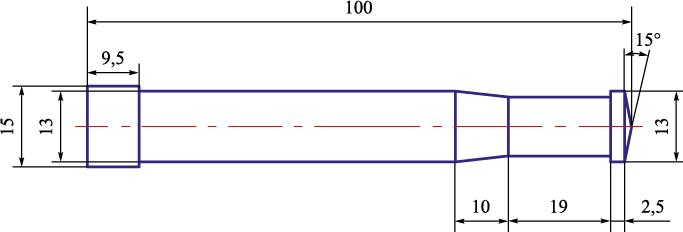

According to the methodology described above, theoretical and experimental studies were conducted on a punch (Fig. 2) made of high-hardness chromium tool steel Kh12M1 [29; 30] with a working surface diameter D = 13 mm.

Fig. 2. Hole punch |

Based on the analysis of the preliminary experiment results with samples made of Kh12M steel, which are consistent with known data from scientific and technical literature, the following thermal-physical parameters were used in further research:

– thermal conductivity coefficient λ = 0.028 W/(mm∙°C);

– temperature conductivity coefficient а = 7.78 mm2/s;

– quenching temperature Тq = 1000 °С;

– melting temperature Тm = 1280 °С.

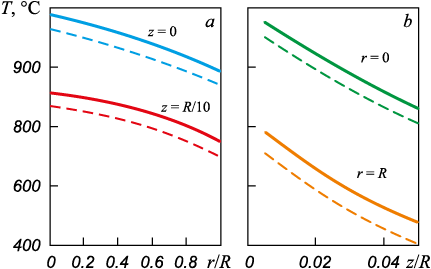

Fig. 3 shows the results of calculating the temperature field in axial and radial directions with λ = const (solid lines) and λ = f (T) (dashed lines) at a laser power of P = 0.97 kW, laser beam movement speed v = 12 mm/s, and laser spot diameter dsp = 4 mm. Analysis of the obtained graphs shows that the difference in the punch temperature obtained with constant and variable λ values is insignificant. Therefore, when conducting engineering calculations, the average value of the thermal conductivity coefficient can be used.

Fig. 3. Graphs of the punch temperature change in axial (a) and radial (b) directions |

Analysis of the results

The analysis of the obtained research results served as the basis for conducting a full-scale experiment. Two experimental batches of punches and dies made of Kh12M steel were manufactured for various stamping operations. The first batch underwent traditional bulk thermal treatment, while the second batch received additional strengthening treatment using a CO2 laser. Based on the data obtained, the following parameters of laser irradiation were recommended for efficient strengthening of the working surface of the stamping tool: with a laser spot diameter of dsp = 4 mm, laser power P = 0.95–0.99 kW, and laser beam movement speed v = 11–13 mm/s.

Pilot tests have shown that the durability of stamping tools significantly increases after laser heat treatment. For example, the working lifespan of punching punches after traditional thermal processing is 10 – 12 h, while after additional strengthening laser treatment, the durability increased to 20 – 36 h, that is, doubled or tripled. Pilot tests of a sample batch of blanking dies, consisting of 20 pieces, demonstrated that the application of additional strengthening treatment with a CO2 laser allows for a 2.2 – 2.8 times increase in their operational durability. The technical and economic efficiency of using laser strengthening is determined not only by saving on expensive tool steel but also by reducing labor costs due to aligning the replacement period of stamping tools with the schedule of preventive and repair works.

Conclusions

A methodology for theoretical analysis of the temperature field of a cylindrical punch formed during laser processing is proposed. The methodology is based on the numerical solution of a two-dimensional differential equation in cylindrical coordinates. As a result of the theoretical analysis, laser heat treatment modes have been proposed for stamping tools of various purposes made of Kh12M tool steel. Studies conducted in industrial conditions have shown that laser heat treatment carried out according to the proposed modes has allowed an increase in the operational durability of punches for hole punching by 2 – 3 times, and cutting dies by 2.2 – 2.8 times.

References

1. Rogov V.A., Poznyak G.G. Mechanical Engineering Technology. Stamping and Foundry production: Textbook. Moscow: Yurait Publ.; 2022:319.

2. Konstantinov I.L., Sidel’nikov S.B. Press Forging: Textbook. Moscow: Scientific Research Center INFRA-M; 2021:464.

3. Semenov E.I. Forging and Hot Stamping: Textbook. Moscow: MSIU; 2011:414.

4. Bocharov Yu.A. Press Forging Equipment: Textbook. Moscow: Akademiya; 2008:479.

5. Zhivov L.I., Ovchinnikov A.G., Skladchikov E.N. Press Forging Equipment: Textbook. Moscow: N.E. Bauman MSTU Publ.; 2006:560.

6. Efremov D.B., Stepanov V.M., Chicheneva O.N. Upgrading of the roll emergency lifting mechanism of the mill 2800 rolling stand of the JSC “Ural Steel”. Stal’. 2020;(8):44–47. (In Russ.).

7. Nefedov A.V., Svichkar V.V., Chicheneva O.N. Re-engineering of equipment to feed the melting furnace with aluminum charge. Lecture Notes in Mechanical Engineering. 2021: 1198–1204. https://doi.org/10.1007/978-3-030-54817-9_139

8. Nefedov A.V., Kitanov A.A. Chichenev N.A. Reengineering of the roller hardening machine of the sheet-rolling shop of JSC Ural Steel. Chernye metally. 2022;(3):22–26. (In Russ.).

9. Nefedov A.V., Tanchuk A.V., Chichenev N.A. Modernization of the tipper drive for ore trolleys at the Donskoy Mining and Processing Plant of TNK Kazchrome JSC. Gornyi zhurnal. 2022;(8):52–56. (In Russ.). https://doi.org/10.17580/gzh.2022.08.07

10. Samusev S.V., Fadeev V.A., Sidorova T.Yu. Development of effective calibrations for forming blank for production of longitudinal welded pipes of small and medium diameters. Metallurgist. 2020;64(7-8):658–664.

11. Gorbatyuk S.M., Morozova I.G., Naumova M.G. Development of the working model of production reindustrialization of die steel heat treatment. Izvestiya. Ferrous Metallurgy. 2017;60(5):410–415. (In Russ.). https://doi.org/10.17073/0368-0797-2017-5-410-415

12. Metallurgy and Heat Treatment of Steel and Cast Iron: Reference Book. In 3 vols. T. 3. Thermal and Thermomechanical Processing of Steel and Cast Iron / Rakhshtadt A.G., Kaputkina L.M., Prokoshkina S.D., Supova A.V. eds. Moscow: Intermet Engineering; 2007:919.

13. Steniko A., Tami V. Improvement of direct hardening process at the Nucor Tuscaloosa plant. Chernye metally. 2018;(12):41–43. (In Russ.).

14. Chichenev N.A., Gorbatyuk S.M., Naumova M.G., Morozova I.G. Using the similarity theory to describe laser hardening processes. CIS Iron and Steel Review. 2020;19:44–47

15. Grigor’yants A.G., Shiganov I.N., Misyurov A.I. Technological Processes of Laser Processing: Tutorial. Moscow: N.E. Bauman MSTU Publ.; 2006:663.

16. Laser Technologies for Materials Processing: Modern Problems of Fundamental Research and Applied Developments. Panchenko V.Ya. ed. Moscow: FIZMATLIT; 2009:664.

17. Milenin A., Petrov P., Petrov M., Krutina E. Numerical model of fracture in magnesium alloys during forming processes. Steel Research International. 2012;(SPL. ISSUE):847–850.

18. Maksimov E.A., Shatalov R.L., Krutina E.V. Procedures for calculation of deformation and energy-power parameters for combined rotary drawing and cross rolling of wheel disks. Proizvodstvo prokata. 2019;(10):9–14. (In Russ.).

19. Kiani-Rashid A.R., Rounaghi S.A. The new methods of graphite nodules detection in ductile cast iron. Materials and Manufacturing Processing. 2011;26(2):242–248. https://doi.org/10.1080/10426914.2010.520788

20. Di Cocco V., Iacoviello F., Cavallini M. Damaging micromechanisms characterization of a ferritic ductile cast iron. Engineering Fracture Mechanics. 2010;77(11):2016–2023. https://doi.org/10.1016/j.engfracmech.2010.03.037

21. Chaus A.S., Sojka J., Pokrovskii A.I. Effect of hot plastic deformation on microstructural changes in cast iron with globular graphite. The Physics of Metals and Metallography. 2013;114(1):84–95. https://doi.org/10.1134/S0031918X13010031

22. Zhao X., Jing T.F., Gao Y.W., Qiao G.Y., Zhou J.F., Wang W. Morphology of graphite in hot compressed nodular iron. Journal of Materials Science. 2004;39(19):6093–6096. https://doi.org/10.1023/B:JMSC.0000041709.60100.56

23. Carslaw H.S., Jaeger J.C. Conduction of Heat in Solids. London: Oxford University Press; 1947.

24. Tikhonov A.N., Samarskii A.A. Equations of Mathematical Physics: Textbook. Moscow: M.V. Lomonosov MSU; 2004:800.

25. Thambynayagam R. K. M. The Diffusion Handbook: Applied Solutions for Engineers. McGraw-Hill Professional; 2011:2048.

26. Tkachenko L.A., Repina A.V. Heat Transfer Theory: Tutorial. Kazan: Kazan University Publ.; 2017:151.

27. Ushakov I.V. Method of mechanical testing of laser treated metallic glass by indenters with different geometry. Proceedings of SPIE – The International Society for Optical Engineering. 2007;6597:659714. https://doi.org/10.1117/12.726773

28. Shinkaryov A.S., Ozherelkov D.Yu., Pelevin I.A., Eremin S.A., Anikin V.N., Burmistrov M.A., Chernyshikhin S.V., Gromov A.A., Nalivaiko A.Yu. Laser fusion of aluminum powder coated with diamond particles via selective laser melting: powder preparation and synthesis description. Coatings. 2021;11(10):1219. https://doi.org/10.3390/coatings11101219

29. Ganzulenko O.Y., Petkova A.P. Simulation and approbation of the marking laser process on metal materials. Journal of Physics: Conference Series. 2021;1753(1):012016. https://doi.org/10.1088/1742-6596/1753/1/012016

30. Pichuev A.V., Petrov V.L. Equivalent circuit for mine power distribution systems for the analysis of insulation leakage current. Mining Science and Technology (Russia). 2023;8(1):78–86. (In Russ.). https://doi.org/10.17073/2500-0632-2023-01-72

31. Zhang Y.Q., Jiang S.Y., Zhao Y.N., Shan D.B. Isothermal precision forging of complex-shape rotating disk of aluminum alloy based on processing map and digitized technology. Materials Science and Engineering: A. 2013;580:294–304. https://doi.org/10.1016/j.msea.2013.05.059

32. Zheng J.H., Lin J.G., Lee J., Pan R., Li C., Davies C.M. A novel constitutive model for multi-step stress relaxation ageing of a pre-strained 7xxx series alloy. International Journal of Plasticity. 2018;106:31–47. https://doi.org/10.1016/j.ijplas.2018.02.008

33.

34.

About the Authors

N. A. ChichenevRussian Federation

Nikolai A. Chichenev, Dr. Sci. (Eng.), Prof. of the Chair “Engineering of Technological Equipment”

4 Leninskii Ave., Moscow 119049, Russian Federation

S. M. Gorbatyuk

Russian Federation

Sergei M. Gorbatyuk, Dr. Sci. (Eng.), Prof. of the Chair “Engineering of Technological Equipment”

4 Leninskii Ave., Moscow 119049, Russian Federation

K. N. Solomonov

Russian Federation

Konstantin N. Solomonov, Dr. Sci. (Eng.), Prof. of the Chair of Social, Humanitarian, Natural Sciences and General Professional Discipline

75a Uritskogo Str., Voronezh 394026, Russian Federation

S. A. Snitko

Russian Federation

Sergei A. Snitko, Dr. Sci. (Eng.), Assist. Prof., Head of the Chair “Metal Forming”

58 Artema Str., Donetsk, Donetsk People’s Republic 283001, Russian Federation

O. N. Chicheneva

Russian Federation

Ol’ga N. Chicheneva, Cand. Sci. (Eng.), Assist. Prof.

4 Leninskii Ave., Moscow 119049, Russian Federation

Review

For citations:

Chichenev N.A., Gorbatyuk S.M., Solomonov K.N., Snitko S.A., Chicheneva O.N. Investigation of changes in temperature of pressing tool during laser processing. Izvestiya. Ferrous Metallurgy. 2024;67(2):155-160. https://doi.org/10.17073/0368-0797-2024-2-155-160