Scroll to:

Patterns of localized deformation at pre-fracture stage in carbon steel – stainless steel bimetal

https://doi.org/10.17073/0368-0797-2023-3-320-326

Abstract

The work is devoted to the study of strain localization at macroscale level during parabolic mechanical hardening and pre-fracture under quasi-static loading of a carbon steel – stainless steel bimetal. The problem of estimating the scale of the phenomena that determine plasticity is decisive in the development of any theories of plastic deformation, in particular, dislocation theories. The main difficulty in constructing such theories is the reconciling the dislocation scales, characteristic for most deformation and mechanical hardening mechanisms, with macroscopic parameters of deformation processes. In the framework of the autowave model of localized plastic deformation, this problem can be reduced to the possibility of obtaining parameters from the results of macroscale observations of localized plastic flow development. During the experiments, it was confirmed that in a bimetal at any forming stage, a specific pattern of localization centers distribution is spontaneously generated - a pattern of localized plastic flow. The shape of such patterns is determined by the law of mechanical hardening acting in the material. It is shown that the observed localization patterns can be used as an informative feature in predicting the plasticity margin. In the process of uniaxial tension at the stage of parabolic mechanical hardening of the bimetal, the deformation mode is realized with the formation of several potential fracture centers. It was established that at the pre-fracture stage, during the time evolution of the wave pattern of deformation localization, the zone of active plastic deformation narrows, but the number of centers in it either remains the same with a decrease in the distance between them, or even increases. The result of this process is the formation of a macroscopic neck, and then fracture. At the pre-fracture stage, the collapse point indicates the place of future fracture and signals the need to stop the deformation process in order to avoid the fracture of the bimetallic material. Thus, the well-known manifestation of deformation macroscopic localization – formation of a neck – is preceded by complex phenomena of mutually coordinated motion of localized plasticity centers at the pre-fracture stage.

For citations:

Barannikova S.A., Li Yu.V. Patterns of localized deformation at pre-fracture stage in carbon steel – stainless steel bimetal. Izvestiya. Ferrous Metallurgy. 2023;66(3):320-326. https://doi.org/10.17073/0368-0797-2023-3-320-326

Introduction

In physical description of plastic flow still poses an unsolved issue concerning the reasons and essence of changes in the pattern of macroscopic localization and deformational hardening during the transition from one stage of the process to another. While the mechanisms of deformational hardening at specific stages of deformation have been extensively studied at the microscopic level [1], the main problem remains unresolved: understanding exhaustion of one mechanism and the initiation of another. Consequently, there are gaps in the macroscopic description of the plasticity phenomenon. On the one hand, this hinders a complete comprehension of material hardening, and on the other hand, it impedes the development of technological procedures for material processing such as rolling, forging, stamping, and drawing, which involve significant plastic deformations [2]. Therefore, there is a need to expand and clarify the model and mechanism of metals’ response to external mechanical impacts. This will facilitate the development of a modern variant of plasticity theory, which takes into account the physical, mechanical, and materials science aspects of the bimetal materials problem [3]. Bimetal materials find wide applications in various technological fields due to their ability to provide not only qualitatively new product properties but also significant savings in expensive materials. During the combined rolling of workpieces composed of dissimilar metal components, the complex development patterns of their plastic flow along the length of the deformation center determine the intricate formation of the junction zone [4].

Extensive research has been conducted over several decades to investigate the structure and mechanical properties of bimetal materials [5 – 7]. As a result, issues related to their production technology have been resolved, methods to enhance the mechanical properties of finished products have been identified, and a significant amount of experimental data has been collected, shedding light on various aspects of their structure and property control [8 – 11]. However, the existing theoretical concepts fail to provide adequate predictions for the failure of bimetals in the form of lamination during plastic forming processes. Although the application of layered composite materials mechanics approaches [12; 13] has allowed for the prediction of lamination in bimetal materials under small elastic-plastic deformations [14; 15], which are typical for operational loads, forecasting such processes under high plastic deformations remains challenging.

Studies conducted in [16; 17] have demonstrated that the patterns of plastic deformation localization in tensioned bimetal samples exhibit autowave characteristics [18 – 21]. During the elastic-plastic transition, localized plastic deformation zones originate in the regions of the bimetal junction and propagate as Lueders fronts. Initially, they occur in the main layer of low carbon steel and subsequently in the cladding layers of stainless steel [16; 17]. This research provides data on the distribution of local deformations in the main and cladding layers of bimetal materials at advanced stages of plastic flow and fracture. Furthermore, it enables a comparison of the localized deformation patterns observed in different bimetal components deformed under identical conditions.

Experimental

A corrosion resistant bimetal consisting of low carbon steel St3sp and stainless steel 12Kh18N9T was chosen for the study.

The bimetal was obtained by pouring and subsequently rolling into a sheet 8 mm thick sheet.

The method involved preparing two or multilayer ingots by pouring one or more layers onto a solid layer of a different composition [3]. The main layer, with a thickness of approximately 6.7 mm, consisted of low carbon steel St3sp. The upper and lower cladding layers, with a thickness of approximately 0.75 mm, were made of stainless steel 12Kh18N9T. Flat samples, measuring 42×8×2 mm, were cut from sheets of three-layer metal in such a way that the working surface (observation surface) was perpendicular to the sheet rolling direction.

The microstructure and elemental composition of the bimetal junction zone have been extensively discussed in [16; 17]. The structure of the base metal St3sp is typical of low carbon steels, with a ferrite matrix containing a small amount of pearlite. The structure of the cladding metal 12Kh18N9T is characteristic of stainless steels, consisting of elongated austenite grains aligned along the rolling axis. The formation of α′ martensite deformation in the cladding layer of stainless steel 12Kh18N9T, resulting from the tension of the 12Kh18N9T + St3sp bimetal, was determined through X-ray diffraction analysis. X-ray diffraction patterns were obtained using monochromatized CuKα radiation with a DRON3 facility. Analysis of the X-ray diffraction patterns of the bimetal’s surface layer revealed that the initial state consisted solely of austenite (γ phase) with a lattice parameter of a = 3.5999 Å. Upon tensile deformation of the bimetal samples, a deformation-induced γ – α′ phase transformation occurred in the surface layers of stainless steel 12Kh18H9T [9], resulting in a two-phase structure with varying ratios of α and γ phases. With a total deformation εtot = 15 %, the content of α′ martensite (a = 2.8873 Å) was approximately 52 ± 4 %, while the remaining phase was austenite (γ phase) with a lattice parameter of a = 3.5999 Å.

The samples were subjected to stretching using a Walter + Bai LFM125 testing machine at an ambient temperature, with a deformation rate of 6.67·10\(^{-}\)5 s\(^{-}\)1. To analyze the stages of deformation hardening described by the Ludwik–Hollomon empirical equation σ = Kε\(^{n}\) (where K and n are material constants), the values of K and n were determine by plotting the “stress – true deformation” relationship on double logarithmic coordinates ln(s – s0 ) = f (lne).

According to the concept of material failure, considering damage accumulation [13], the damage parameter D can be calculated as follows [22]:

\[D = - \frac{1}{2}\ln \left( {\frac{{{{\tilde E}_i}}}{{{E_0}}}} \right),\]

where E0 is the elasticity modulus (Young’s modulus); \({\tilde E_i}\) is the secant modulus.

In this study, the secant modulus was determined from the slope of the linear section of the tension diagrams obtained in the cyclic load-unload mode, with an interval of 2.5 % of the total deformation.

To observe the macroscopic localization of plastic deformation, a technique combining mechanical tests for uniaxial tension with the correlation of digital speckle images was employed. This technique enables the reconstruction of displacement vector fields on the surface of flat samples at different stages of the process and the calculation of the components of the plastic deformation tensor. Further details and the capabilities of this technique are described in [18 – 21] and will not be discussed further in this context.

Results and discussion

Previous research [16] has demonstrated that during the tensioning process of a bimetal specimen composed of low carbon steel St3sp and austenitic stainless steel 12H18N9T, which have different mechanical properties, the initial plastic flow occurs in the softer main layer, while the more resilient cladding stainless steel layer deforms elastically. Both the base layer and the cladding layer undergo plastic deformation in the flow region. Analysis of the distribution patterns of local deformations revealed that, during the early stages of plastic flow in the three-layer bimetal, a single front in the form of the Chernov–Lueders band (CLB) first appears at the interface of the composite in the main layer of low carbon St3sp steel, subsequently initiating the formation of the CLB front in the 12H18N9T steel cladding layer. A single localization front propagates throughout the entire flow region, encompassing both the main and cladding layer.

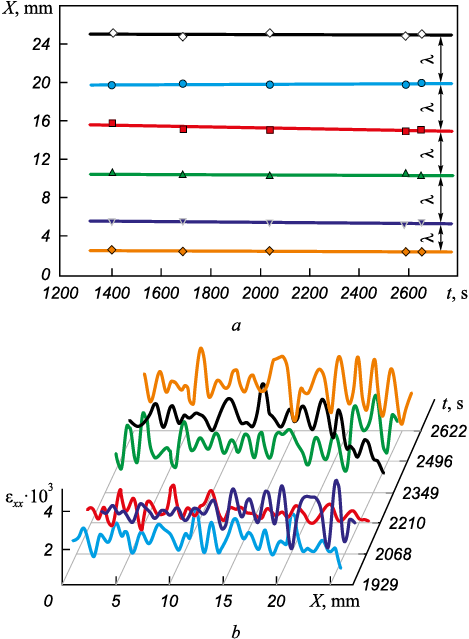

During the stage of parabolic deformation hardening, a system of stationary areas of plastic deformation localization εxx with a spatial period of λ = 4 ± 1 mm is observed in the main layer of low carbon steel St3sp bimetal (Fig. 1, a). It is worth noting that a change in the increments of local strains εxx(x, t) in the main St3sp layer was observed during the transition from the stage of parabolic strain hardening to the stage of pre-fracture of the bimetal (Fig. 1, b).

Fig. 1. Kinetic diagrams X(t) of the positions of localized strain |

Subsequently, during the pre-fracture stage of the bimetal, the previously immobile centers of plastic deformation localization εxx in the main St3sp layer begin to move coordinately, converging towards a high-amplitude maximum of local deformations. Similar to a monolithic sample of St3sp low carbon steel, the presence of a high-amplitude maximum in the form of localized elongation distributions indicates the formation of a macroscopic neck and future ductile fracture within the main layer of the St3sp bimetal.

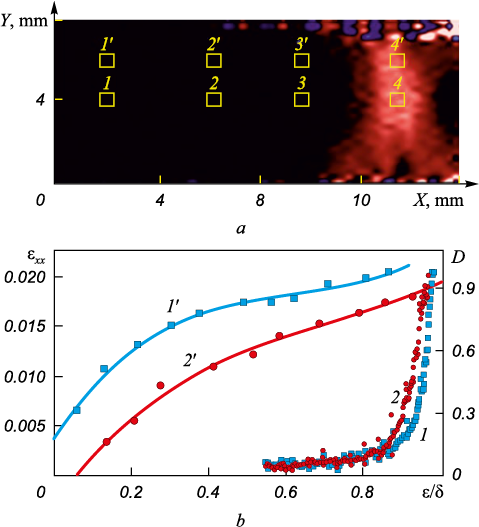

To conduct a comprehensive analysis of the evolution of localized elongation distributions εxx during the transition from the parabolic stage of strain hardening to the pre-fracture stage of the bimetal, we examined the changes in the overall values of the εxx component at various points along the tension axis. Specifically, we focused on the main layer of the St3sp steel bimetal (Fig. 2, a, points 1 – 4) and the vicinity of the material junction zone (Fig. 2, a, points 1′ – 4′) within the time interval of t = 1400 ÷ 3850 s, corresponding to a total deformation of εtot = 0.12 ÷ 0.33.

Fig. 2. Areas for analysis of local elongations total values |

The investigation has revealed that the average total value of localized elongations, εxx remains relatively constant during the parabolic deformation hardening stage. However, it begins to deviate from this constant level at a total strain of εtot = 0.19 ÷ 0.25, marking the transition from the parabolic strain hardening stage to the pre-fracture stage (Fig. 2, b, curves 1 and 2). In the region of plastic deformation localization (Fig. 2, a, points 4 and 4′) both in the main layer of low carbon steel St3sp (Fig. 2, b, curve 2) and near the cladding layer of stainless steel 12Kh18N9T (Fig. 2, b, curve 1) a significant increase in the total values of localized elongations, εxx is observed. This increase corresponds to the transition from the parabolic strain hardening stage to the pre-fracture stage of the bimetal.

By taking the logarithm of the εxx (ε/δ) dependencies (Fig. 2, b, curves 1 and 2), it was possible to identify linear segments with different slopes. The first point of intersection of these straight lines represents the start of the parabolic deformation hardening stage, while the second point indicates its end and the transition to the pre-fracture stage.

Mathematical analysis of the εxx (ε/δ) dependences (Fig. 2, b, curves 1 and 2), which correspond increase in localized elongations in the localization zone of the main and cladding layers of the bimetal during the pre-fracture stage, was performed using the double t-criterion method [23]. Statistical analysis revealed that the difference in the slope of curves 1 and 2 (Fig. 2, b) for the base and cladding metals is significant, as the double t-criterion | t | = 17.5 > 2.3, indicating | t | > tα, f , where the reference value of the Student’s coefficient tα, f = 2.3 [23].

The results indicate that during the transition from the parabolic stage to the pre-fracture stage of the bimetal, the increment of localized elongations εxx in the localization center (Fig. 2, a, points 4 and 4′) is greater in the cladding layer of stainless steel 12Kh18N9T (Fig. 2, b, curve 1) compared to the main layer of low carbon steel St3sp (Fig. 2, b, curve 2). This difference is likely associated with the nature of damage accumulation in the different layers of the bimetal during stretching.

The damage parameter D was calculated using Equation (1) during the uniaxial tension mechanical tests in the load-unload mode. Analysis of the data revealed an exponential relationship between the damage parameter and the total tensile strain in both individual components and the bimetal specimens. Considering the significant differences in the mechanical properties of the materials in different layers of the bimetal, it is more reasonable to examine the dependence of the damage parameter D on the normalized total tensile strain ε, relative to the elongation at fracture δ for each material. From the combined dependencies of total localized elongations εxx and the damage parameter D on the normalized plasticity ε/δ (Fig. 2, b), it can be observed that the accumulation of damage and the increase in localized elongations at the same level of total deformation occur more rapidly in the cladding layer of austenitic stainless steel 12Kh18N9T (curves 1 – 1′) compared to the main layer of low carbon steel St3sp (curves 2 – 2′) in the bimetal.

It has been determined that the fracture of the bimetal initiates at a total deformation of εtot = 0.33, where a crack forms in the cladding layer of stainless steel. Subsequently, the crack propagates into the main layer of low carbon steel and divides into several microcracks during its propagation. The primary crack in the main layer follows a stepwise zigzag trajectory. Once the crack traverses the entire cross-section of the samples at a total deformation of εtot = 33.5, the bimetal experiences complete fracture. The fracture behavior of low carbon steel St3sp and austenitic stainless steel 12Kh18N9T differs significantly. The main component of the bimetal, St3sp steel, exhibits a viscous fracture mechanism, while the cladding layer composed of 12Kh18N9T steel undergoes brittle fracture [24]. These findings substantiate the distinct nature of the damage parameter dependencies in different layers of the bimetal during loading (Fig. 2, b).

During uniaxial tension of the bimetal beyond the yield point, the occurrence of microcracks at the interface between the two layers is observed, particularly on the cladding side. This phenomenon can be attributed to the presence of a stress gradient in the junction zone, which arises due to chemical and structural heterogeneities [16; 17]. Although stainless steel 12Kh18N9T possesses high strength and ductility in its monolithic state, the joint deformation of the bimetal, rolled to a thickness of 8 mm, leads to more intense plastic deformation localization and the accumulation of microcracks in the cladding layer compared to the low-strength main layer of low carbon steel.

Conclusions

During the analysis of localized deformation patterns in the 12Kh18N9T + St3sp bimetal at advanced stages of plastic flow using speckle image correlation, the following regularities were observed.

In the main layer of low carbon steel (St3sp) bimetal, during the parabolic deformation hardening stage, a stationary system of equidistant areas of deformation localization is formed with a spatial period of approximately 4 ± 1 mm. At the prefracture stage, the fixed centers of plastic deformation localization within the main layer initiate coordinated movement towards the center characterized by high amplitudes of the εxx component of local elongation. This movement eventually leads to the formation of a neck region and subsequent ductile fracture of the specimen.

A significant exponential growth in the cumulative value of localized elongations εxx was observed during the transition from the parabolic deformation hardening stage to the prefracture stage in the region where the neck of the bimetal forms. This growth in elongations was observed in both the main layer of low carbon steel and the cladding layer of stainless steel.

References

1. Rao S.I., Dimiduk D.M., Tang M., Uchic M.D., Parthasarathy T.A., Woodward C. Estimating the strength of single-ended dislocation sources in micron-sized single crystals. Philosophical Magazine. 2007;87(30):4777–4794. http://dx.doi.org/10.1080/14786430701591513

2. Gronostajski Z., Pater Z., Madej L., Gontarz A., Lisiecki L., Łukaszek-Sołek A., Łuksza J., Mróz S., Muskalski Z., Muzykiewicz W., Pietrzyk M., Śliwa R.E., Tomczak J., Wiewiórowska S., Winiarski G., Zasadziński J., Ziółkiewicz S. Recent development trends in metal forming. Archives of Civil and Mechanical Engineering. 2019;19(3):898–941. http://dx.doi.org/10.1016/j.acme.2019.04.005

3. Zasukha P.F., Korshchikov V.D., Bukhvalov O.B., Ershov A.A. Bimetallic Rolled Products. Moscow: Metallurgiya; 1971:264. (In Russ.).

4. Li L., Nagai K., Yin F. Progress in cold roll bonding of metals. Science and Technology of Advanced Materials. 2008;9(2):023001. http://dx.doi.org/10.1088/1468-6996/9/2/023001

5. Deb-Roy T., Wie H.L., Zuback J.S., Mukherjee T., Elmer J.W., Milewski J.O., Beese A.M., Wilson-Heid A., De A., Zhang W. Additive manufacturing of metallic components – Process, structure and properties. Progress in Materials Science. 2018;92:112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

6. Hinojos A., Mireles J., Reichardt A., Frigola P., Hosemann P., Murr L.E., Wicker R.B. Joining of Inconel 718 and 316 Stainless Steel using electron beam melting additive manufacturing technology. Materials and Design. 2016;94:17–27. http://dx.doi.org/10.1016/j.matdes.2016.01.041

7. Hofmann D.C., Roberts S., Otis R., Kolodziejska J., Dillon R.P., Suh J., Shapiro A.A., Li Z.-K., Borgonia J.-P. Developing gradient metal alloys through radial deposition additive manufacturing. Scientific Reports. 2014;4:5357. http://dx.doi.org/10.1038/srep05357

8. Li Z., Lin Y.C., Zhang L., Jia F., Jiang Z., Jiao S. Investigation of compact tensile and fracture mechanical properties of a duplex stainless steel bimetal composite with the interfacial zone. Journal of Materials Research and Technology. 2022;19:809–820. https://dx.doi.org/10.1016/j.jmrt.2022.05.085

9. Li Z., Zhaо J., Jia F., Liang X., Zhang Q., Yuan X., Jiao S., Jiang Z. Interfacial characteristics and mechanical properties of duplex stainless steel bimetal composite by heat treatment. Materials Science and Engineering: A. 2020;787:139513. http://dx.doi.org/10.1016/j.msea.2020.139513

10. Chen N., Ali Khan H., Wan Z., Lippert J., Sun H., Shang S.-L., Liu Z.-K., Li J. Microstructural characteristics and crack formation in additively manufactured bimetal material of 316L stainless steel and Inconel 625. Additive Manufacturing. 2020;32:101037. https://doi.org/10.1016/j.addma.2020.101037

11. Li Z., Zhao J., Jia F., Lu Y., Liang X., Yuan X., Jiao S., Zhou C., Jiang Z. Hot deformation behaviour and interfacial characteristics of bimetal composite at elevated temperatures. Intermetallics. 2020;125:106893. http://dx.doi.org/10.1016/j.intermet.2020.106893

12. Fudzii T., Dzako M. Mechanics of Composite Materials Fracture. Moscow: Mir; 1982:232. (In Russ.).

13. Murakami S. Continuum Damage Mechanics. Springer: Netherlands; 2012:402.

14. Gladkovskii S.V., Trunina T.A., Kokovikhin E.A., Vichuzhanin D.I., Golubkova I.A. Formation of structure and properties of lamellar metal compounds. Zagotovitel’nye proizvodstva v mashinostroenii. 2010;(4):41–45. (In Russ.).

15. Smirnov S.V., Golubkova I.A. Simulation of cold rolling of thin strips by finite element method. Zagotovitel’nye proizvodstva v mashinostroenii. 2010;(5):27–30. (In Russ.).

16. Barannikova S.A., Bochkareva A.V., Li Yu.V., Lunev A.G., Shlyakhova G.V., Zuev L.B. Investigation of localization patterns of plastic deformation and fracture of a two-layer metal material. Fundamental’nye problemy sovremennogo materialovedeniya. 2016;13(4):511–516. (In Russ.).

17. Shlyakhova G.V., Barannikova S.A., Bochkareva A.V., Li Yu.V., Zuev L.B. Study of the structure of bimetal construction carbon steel – stainless steel. Izvestiya. Ferrous Metallurgy. 2018;61(4):300–305. (In Russ.). https://doi.org/10.17073/0368-0797-2018-4-300-305

18. Zuev L.B. Autowave Mechanics of plastic flow. Springer Tracts in Mechanical Engineering. 2021:245–274. https://doi.org/10.1007/978-3-030-60124-9_12

19. Zuev L.B., Khon Yu.A. Plastic flow as a process of the formation of spatio-temporal structures. Part I. Qualitative and quantitative patterns. Fizicheskaya Mezomechanika. 2021;24(6):5–14. (In Russ.). https://doi.org/10.24412/1683-805X-2021-6-5-14

20. Barannikova S.A., Kosinov D.A., Zuev L.B., Gromov V.E., Konovalov S.V. Hydrogen effect on macrolocalization of plastic deformation of low carbon steel. Izvestiya. Ferrous Metallurgy. 2016;59(12):891–895. (In Russ.). https://doi.org/10.17073/0368-0797-2016-12-891-895

21. Danilov V.I., Barannikova S.A., Zuev L.B. Localized strain autowaves at the initial stage of plastic flow in single crystals. Technical Physics. 2003;48(11):1429–1435. https://doi.org/10.1134/1.1626775

22. Chow C.L., Wang J. An anisotropic theory of continuum damage mechanics for ductile fracture. Engineering Fracture Mechanics. 1987;27(5):547–558. https://doi.org/10.1016/0013-7944(87)90108-1

23. Mendenhall W.M., Sincich T.L. Statistics for Engineering and the Sciences. New York: Chapman and Hall/CRC; 2016:1182. https://doi.org/10.1201/b19628

24. Gorkunov E.S., Zadvorkin S.M., Putilova E.A. Magnetic estimation of stresses applied to a two-layer steel ct3-steel 08x18h10t composite material during elastoplastic deformation by uniaxial tension. Russian Journal of Nondestructive Testing. 2012;48(8):495–504. https://doi.org/10.1134/S1061830912080050

About the Authors

S. A. BarannikovaRussian Federation

Svetlana A. Barannikova, Dr. Sci. (Phys.-Math.), Leading Researcher of the Laboratory of Strength Physics

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

Yu. V. Li

Russian Federation

Yuliya V. Li, Junior Researcher of the Laboratory of Strength Physics

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

Review

For citations:

Barannikova S.A., Li Yu.V. Patterns of localized deformation at pre-fracture stage in carbon steel – stainless steel bimetal. Izvestiya. Ferrous Metallurgy. 2023;66(3):320-326. https://doi.org/10.17073/0368-0797-2023-3-320-326