Scroll to:

Multilayer amorphous-crystalline high-entropy metal films

https://doi.org/10.17073/0368-0797-2023-2-191-196

Abstract

High-entropy alloys (HEA) are multi-element materials and contain at least five elements of similar concentration. HEA are, as a rule, single- phase thermodynamically stable substitutional solid solutions, mainly based on a body-centered cubic and face-centered cubic crystal lattice. Solid solution stabilization during the crystallization of a high-entropy alloy is provided by the interaction of a number of factors, namely, a high mixing entropy and low diffusion rate of components, and a low growth rate of crystallites from the melt. The purpose of this work was to obtain new knowledge about the structure and properties of high-entropy films synthesized on a metal substrate during deposition of a multi-element metal plasma in argon atmosphere. The plasma was formed as a result of independent plasma-assisted electric arc cathodes of the following metals: Ti, Al, Cu, Nb, Zr sputtering. As a result of the performed studies, the deposition mode was revealed, which allows the formation of films of various thicknesses of close to equiatomic composition. Transmission electron microscopy methods have established that the films are multilayer formations and have nanoscale amorphous-crystalline structure. Microhardness of the films significantly depends on the ratio of number of the forming elements and varies from 12 to 14 GPa, Young’s modulus – from 230 to 310 GPa. Crystallization of the films was carried out by irradiation with a pulsed electron beam. As a result of processing, a two-phase state is formed. The main phase is α-NbZrTiAl with a volume-centered cubic crystal lattice with a parameter of 0.32344 nm; the second phase of CuZr composition has a simple cubic lattice.

Keywords

For citations:

Ivanov Yu.F., Prokopenko N.A., Petrikova E.A., Shugurov V.V., Teresov A.D. Multilayer amorphous-crystalline high-entropy metal films. Izvestiya. Ferrous Metallurgy. 2023;66(2):191-196. https://doi.org/10.17073/0368-0797-2023-2-191-196

Introduction

High-entropy alloys are composed of multiple main elements, typically five or more, with similar concentrations, as opposed to conventional alloys consisting of one or, at most, two main elements and several dopants. The development of these alloys indicates a new paradigm in the design of modern materials [1 – 3]. Generally, high-entropy alloys (HEAs) exhibit a unique combination of mechanical, tribological, physical, chemical, and other properties. In most cases, HEAs are single phase, thermodynamically stable, substitutional solid solutions, mainly based on a body-centered cubic (BCC) or face-centered cubic (FCC) crystalline lattice [4].

It is assumed that the stabilization of solid solution during the crystallization of high entropy alloys (HEAs) is achieved through the high mixing entropy of the alloy components in the liquid state, lattice distortion, atom diffusion retardation, and the so-called “cocktail effect” [5]. Numerous studies have shown that HEAs can have a nanosized structure or even exist in an amorphous state due to the low diffusion rate of the constituent elements and low crystallites growth rate [6; 7].

It was demonstrated in [8] that HEAs have the potential to replace nickel-based heat-resistant alloys and be used as high-temperature material for the next generation. The researchers also suggested that due to their unique properties, HEAs have promising potential as coating material for high-temperature applications. This was illustrated by investigating a HEA coating with the composition of NiCo0.6Fe0.2Cr1.5SiAlTi0.2 processed by spark plasma sintering (SPS) and atmospheric plasma spraying (APS) and comparing the results with those of a cast MCrAlY alloy. The researchers [8] concluded that the HEA coatings processed by SPS and APS can replace conventional MCrAlY alloys as facing material for high-temperature application due to their significant high temperature hardness, good resistance to oxidation, and low heat conductivity and low-temperature expansion.

The authors [5] argue that the primary focus of research on HEAs should shift from attempts to obtain single-phase equiatomic composition to developing alloys that possess a correct balance of strengthening mechanisms and mechanical properties. Supporting this perspective, several studies [9 – 12] have demonstrated that HEAs can consist of multicomponent alloys of non-equiatomic composition, which are not single phase solid solutions. However, as shown in previous research [13 – 15], HEAs composed of refractory elements may exhibit high density (high specific weight) and brittleness. Despite the increasing number of publications dedicated to HEAs each year, as observed through Scopus analysis [16; 17], there is no consensus on the nature of the remarkable properties exhibit by these materials.

The objective of this study is to gain new insights into structure and properties of HEAs synthesized in thin (up to 5 μm) films through an ion plasma method. The method involves the deposition of a multielement metallic plasma produced by electric arc plasma-assisted simultaneous independent spraying of cathodes of selected elements.

Материал и методы исследования

Titanium, aluminum, copper, zirconium, and niobium were used as the HEA forming elements in this study. The substrates upon which HEA films were sputtered, included polished samples of AISI 321 stainless steel, commercially pure Ti-Grade2 titanium, and WC – 8 % Co hard alloy. HEA films, up to 5 μm in thickness, were formed using the QUINTA ion plasma facility developed in the laboratory of Plasma Emission Electronics at the Institute of High Current Electronics, Siberian Branch, Russian Academy of Sciences. This facility is part of UNIKUUM complex and is listed among the unique electrophysical facilities of Russia (https://ckp-rf.ru/usu/434216/) [18]. A portion of the HEA films was irradiated by pulse electron beam from the SOLO facility [19], with the following parameters: electron beam duration of 50 μs; energy density of electron beam of 20 J/cm2; and three acting pulses at the pulse frequency of 0.3 s\(^{-}\)1. The impact of the pulsed electron beam enabled the formation of an ultrafine (up to amorphous state) structure due to the superhigh cooling rate of the material, up to 106 K/s, resulting from heat removal to the integral cold substrate [20].

The structure, phase and elemental compositions of the HEA films were analyzed using scanning and transmission diffraction electron microscopy. The state of the crystalline lattice was investigated by X-ray structure analysis. The mechanical properties of the films were determined using microhardness measurements.

Results and discussion

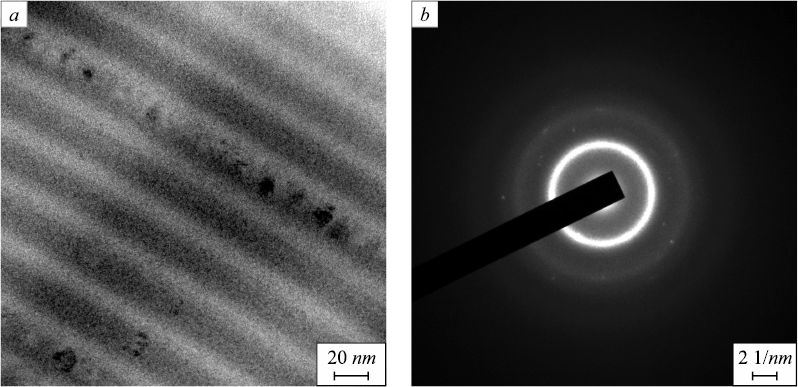

During this study, experiments were conducted on the deposition of multielement metal films. The modes of gas metallic plasma generation were also investigated, along with the radial distribution of ion current density for both the metallic and gas plasma sources. The deposition rates of films for individual components were measured, and the elemental composition of the films was determined using X-ray structure microanalysis methods. The optimum mode of deposition for HEA films was identified. The experiments involved the deposition of multielement metal films, studying the modes of generation of gas metallic plasma, and measuring the deposition rates of films of individual components. The elemental composition of the films was determined using X-ray structure microanalysis, and the optimum mode of deposition of HEA films was identified. The structure, phase and elemental compositions of both the HEA films and those irradiated by pulsed electron beam were analyzed using scanning and transmission electron microscopy, X-ray structure analysis, and other techniques. The HEA films were found to be a multilayer X-ray amorphous material (Fig. 1), with a thickness range of 12 to 23 nm and crystallite size of 2 – 3 nm. The hardness of HEA films ranged from 12 – 14 GPa, and the Young’s modulus ranged from 230 – 310 GPa.

Fig. 1. Electron microscopic image of HEA multilayer film formed as a result |

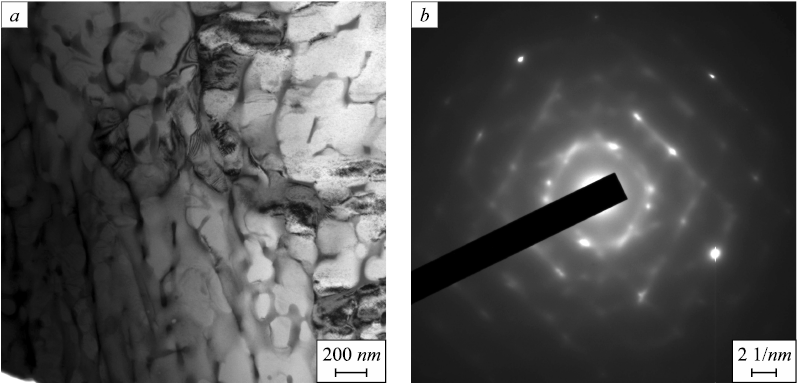

Irradiation of the HEA film by pulsed electron beam (20 J/cm2, 50 μs, 3 pulses) led to high-speed crystallization with formation of cellular structure (Fig. 2).

Fig. 2. Electron-microscopic image of HEA multilayer film formed as a result |

The cell size ranged from 300 to 600 nm. The cells were surrounded by interlayers of the second phase, with a thickness range of 20 – 110 nm. The cell volume was formed by the α-NbZrTiAl phase of BCC crystalline lattice with the constant of 0.32344 nm; while the interlayers of the second CuZr phase were located along the cell boundaries with a simple cubic lattice.

The hardness of films measured at the load on indenter of 30 mN ranged from 6.9 to 8.8 GPa and decreased with an increase in the energy density of the electron beam. The high hardness of the material was found to be due to substructural mechanisms (strengthening by subgrain boundaries, cells of high speed crystallization), dispersion mechanisms (strengthening by particles of the second phase located along the boundaries of crystallization cells), solid solution mechanisms (strengthening as a consequence of distortion of crystalline lattice by atoms of elements forming the alloy), and strengthening by internal stress fields formed as a consequence of the presence of phases with various coefficients of thermal expansion.

Conclusions

The present study determined the optimal deposition conditions for the formation of high-entropy alloy (HEA) films with an elemental composition close to equiatomic and characterized by high strength properties, while minimizing energy consumption. The resulting multilayer films were found to be amorphous crystalline and composed of 25.7Ti–17.0Al–21.9Nb–22.3Zr–13.6Cu. Additionally, the films were subjected to irradiation by pulsed electron beam under conditions of high-speed cooling, resulting in the formation of a cellular crystallization structure with submicron-sized cells. The α-NbZrTiAl phase of BCC crystalline lattice with a constant of 0.32344 nm formed the volume, and interlayers of the second CuZr phase located along the cell boundaries (simple cubic lattice).

The obtained results suggest that an environmentally-friendly fully-automated electron ion plasma method for formation of HEAs can be recommended to improve the service properties of various parts and items scientific and engineering applications.

References

1. Ye Y.F., Wang Q., Lu J., Liu C.T., Yang Y. High-entropy alloy: challenges and prospects. Materials Today. 2016;19(6): 349–362. https://doi.org/10.1016/j.mattod.2015.11.026

2. Cantor B., Chang I.T.H., Knight P., Vincent A.J.B. Microstructural development in equiatomic multicomponent alloys. Material Science and Engineering: A. 2004;375-377: 213–218. https://doi.org/10.1016/j.msea.2003.10.257

3. Yeh J.-W., Chen S.-K., Lin S.-J., Gan J.-Y., Chin T.-S., Shun T.-T., Tsau C.-H., Chang S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Advanced Engineering Materials. 2004;6(5):299–303. https://doi.org/10.1002/adem.200300567

4. Mao H., Chen HL., Chen Q. TCHEA1: A thermodynamic database not limited for “high entropy” alloys. Journal of Phase Equilibria and Diffusion. 2017;38:353–368. https://doi.org/10.1007/s11669-017-0570-7

5. Pickering E.J., Jones N.G. High-entropy alloys: A critical assessment of their founding principles and future prospects. International Materials Reviews. 2016;61(3):183–202. https://doi.org/10.1080/09506608.2016.1180020

6. Pogrebnyak A.D., Bagdasaryan A.A., Yakushchenko I.V., Beresnev V.M. The structure and properties of high-entropy alloys and nitride coatings based on them. Russian Chemical Reviews. 2014;83(11):1027–1061. (In Russ.). https://doi.org/10.1070/RCR4407

7. Miracle D.B., Senkov O.N. A critical review of high entropy alloys and related concepts. Acta Materialia. 2017;122: 448–511. https://doi.org/10.1016/j.actamat.2016.08.081

8. Praveen S., Kim H.S. High-entropy alloys: Potential candidates for high-temperature applications – An overview. Advanced Engineering Materials. 2018;20(1):1700645. https://doi.org/10.1002/adem.201700645

9. Nene S.S., Liu K., Frank M., Mishra R.S., Brennan R.E., Cho K.C., Li Z., Raabe D. Enhanced strength and ductility in a friction stir processing engineered dual phase high entropy alloy. Scientific Reports. 2017;7:16167. https://doi.org/10.1038/s41598-017-16509-9

10. Li Zh., Körmann F., Grabowski B., Neugebauer J., Raabe D. Ab initio assisted design of quinary dual-phase high-entropy alloys with transformation-induced plasticity. Acta Materialia. 2017;136:262–270. https://doi.org/10.1016/j.actamat.2017.07.023

11. Basu S., Li Zh., Pradeep K.G., Raabe D. Strain rate sensitivity of a TRIP-assisted dual-phase high-entropy alloy. Frontiers in Materials. 2018;5. https://doi.org/10.3389/fmats.2018.00030

12. Li Zh., Tasan C.C., Springer H., Gault B., Raabe D. Interstitial atoms enable joint twinning and transformation induced plasticity in strong and ductile high-entropy alloys. Scientific Reports. 2017;7:40704. https://doi.org/10.1038/srep40704

13. Trofimenko N.N., Efimochkin I.Yu., Bol’shakova A.N. Problems of creation and prospects of use of heat-resistant high-entropy alloys. Aviatsionnye materialy i tekhnologii. 2018; 2(51):3–8. (In Russ.). https://doi.org/10.18577/2071-9140-2018-0-2-3-8

14. Juan C.-C., Tsai M.-H., Tsai C.-W., Lin C.-M., Wang W.-R., Yang C.0C., Chen S.-K., Lin S.-J., Yeh J.-W. Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys. Intermetallics. 2015;62:76–83. https://doi.org/10.1016/j.intermet.2015.03.013

15. Schuh B., Mendez-Martin F., Völker B., George E.P., Clemens H., Pippan R., Hohenwarter A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Materialia. 2015;96:258–268. https://doi.org/10.1016/j.actamat.2015.06.025

16. Gu J., Zou J., Sun S.-K., Wang H., Yu S.-Y., Zhang J., Wang W., Fu Z. Dense and pure high-entropy metal diboride ceramics sintered from selfsynthesized powders via boro/carbothermal reduction approach. Science China Materials. 2019;62(12):1898–1909. https://doi.org/10.1007/s40843-019-9469-4

17. Gromov V.E., Konovalov S.V., Ivanov Yu.F., Osintsev K.A. Structure and Properties of High-Entropy Alloys. Springer Nature Switzerland AG, 2021:110. https://doi.org/10.1007/978-3-030-78364-8

18. Koval’ N.N., Ivanov Yu.F., Teresov A.D., Akhmadeev Yu. Kh., Krysina O.V., Petrikova E.A., Shugurov V.V., Lopatin I.V. Development of complex technology of electronic ion-plasma engineering of a surface of materials and products. Nanoinzheneriya. 2015;4(46):4–13. (In Russ.).

19. Devyatkov B.N., Koval’ N.N., Shchanin P.M. Obtaining high-current low-energy electron beams in systems with plasma emitter. Izvestiya vuzov. Fizika. 2001;44(9):36–43. (In Russ.).

20. Koval’ N.N., Ivanov Yu.F. Nanostructuring of surfaces of metalloceramic and ceramic materials by electron beams. Izvestiya vuzov. Fizika. 2008;51(5):60–70. (In Russ.).

About the Authors

Yu. F. IvanovRussian Federation

Yurii F. Ivanov, Dr. Sci. (Phys.-Math.), Prof., Chief Researcher of the Laboratory of Plasma Emission Electronics

2/3 Akademicheskii Ave., Tomsk 634055, Russian Federation

N. A. Prokopenko

Russian Federation

Nikita A. Prokopenko, Junior Researcher

2/3 Akademicheskii Ave., Tomsk 634055, Russian Federation

E. A. Petrikova

Russian Federation

Elizaveta A. Petrikova, Junior Researcher of the Laboratory of Plasma Emission Electronics

2/3 Akademicheskii Ave., Tomsk 634055, Russian Federation

V. V. Shugurov

Russian Federation

Vladimir V. Shugurov, Research Associate

2/3 Akademicheskii Ave., Tomsk 634055, Russian Federation

A. D. Teresov

Russian Federation

Anton D. Teresov, Research Associate

2/3 Akademicheskii Ave., Tomsk 634055, Russian Federation

Review

For citations:

Ivanov Yu.F., Prokopenko N.A., Petrikova E.A., Shugurov V.V., Teresov A.D. Multilayer amorphous-crystalline high-entropy metal films. Izvestiya. Ferrous Metallurgy. 2023;66(2):191-196. https://doi.org/10.17073/0368-0797-2023-2-191-196