Scroll to:

Mathematical modelling system for metallurgical enterprise: Operation and usability enhancement

https://doi.org/10.17073/0368-0797-2023-1-119-126

Abstract

Metallurgical plants (smelters) adjust their production plans to match changing global demand. EVRAZ West Siberian Metallurgical Combine JSC (EVRAZ ZSMK) employs furnace charges and pellets containing 110 components, with a product range exceeding 2000 items that vary from month to month. The production plan is optimized individually for each manufacturing process, with the goal of minimizing costs and maximizing output. This paper discusses the development and deployment of the smelter simulation system currently in use at EVRAZ ZSMK. Unlike other solutions, this system performs concurrent, end-to-end optimization of all smelter processes, with the ultimate goal of maximizing the company's profit. During the system's operation from 2019 to 2020, users encountered tedious and time-consuming tasks, such as creating 60 production plans per year, conducting 10,000 test iterations, and analyzing 30 scenarios. To gather statistical data, a feedback form was used, which identified several issues. Firstly, the mathematical model fails with incorrect input data. Secondly, repeated analyses are required to identify and interpret the plan/actual cost discrepancies. Thirdly, data validation errors, such as incorrect chemical composition or model settings unsuitable for the specific timeframe, were observed. To address these shortcomings, several measures were developed: an input data validator (before and after analysis) was introduced; sensitivity and factor analysis modules were developed to aid in identifying and interpreting cost discrepancies; a chemical composition uploading tool was developed to ensure data validation. Finally, the system was retrained on historical datasets to improve its accuracy.

For citations:

Leont’ev А.S., Rybenko I.А. Mathematical modelling system for metallurgical enterprise: Operation and usability enhancement. Izvestiya. Ferrous Metallurgy. 2023;66(1):119-126. https://doi.org/10.17073/0368-0797-2023-1-119-126

Introduction

Nowadays, steelmakers mostly use the sintering and blast furnace process [1]. Usually, iron is reduced from ore in blast furnaces as pig iron and then the impurities are oxidized in steelmaking converters or electric furnaces with subsequent ladle refining [2].

The metallurgical industry consumes a lot of resources and energy. Smelters introduce both investment-based and zero-cost initiatives to reduce costs through optimal production planning. Planning is essentially an optimal allocation of expensive (purchased) or insufficient (in-house) resources to maximize profit. It is a pressing problem for smelters buying raw materials from third-party suppliers. The key challenge is that the charge for each furnace may consist of hundreds of components in various combinations. For example, EVRAZ ZSMK makes the charge for cast iron production from more than 110 components [3]. Planning cannot be done manually because it is so complicated and includes the following concurrent processes:

– optimizing the charge composition for cost;

– optimizing the recycling content [4];

– analyzing the production processes [5].

Process simulation models became commercially available worldwide in 2010. Such models should be highly flexible [6] which is exactly what the Russian smelter needs in the current situation.

This paper covers the deployment of a production planning system at EVRAZ ZSMK, and new tools improving the system’s efficiency.

Currently, the sintering and blast furnace process is the predominant method used by steelmakers [1]. This process involves reducing iron from ore in blast furnaces to produce pig iron, which is then further processed in steelmaking converters or electric furnaces, followed by ladle refining to remove impurities [2]. However, the metallurgical industry is known for its high consumption of resources and energy. In order to reduce costs and achieve optimal production planning, smelters are introducing investment-based and zero-cost initiatives. Production planning involves the optimal allocation of expensive (purchased) or insufficient (in-house) resources to maximize profit. This is particularly challenging for smelters that purchase raw materials from third-party suppliers, as the charge for each furnace may consist of hundreds of components in various combinations.

For example, EVRAZ ZSMK uses more than 110 components in the charge for cast iron production [3]. Manual planning is not feasible due to the complexity of concurrent processes, which include optimizing the charge composition for cost, optimizing the recycling content [4], and analyzing production processes [5]. Since 2010, commercially available process simulation models have been used worldwide to address this challenge. To be effective, these models should be highly flexible, which is precisely what is needed by the Russian smelter in the current situation [6]. This paper discusses the implementation of a production planning system at EVRAZ ZSMK, as well as new tools that improve the system’s efficiency.

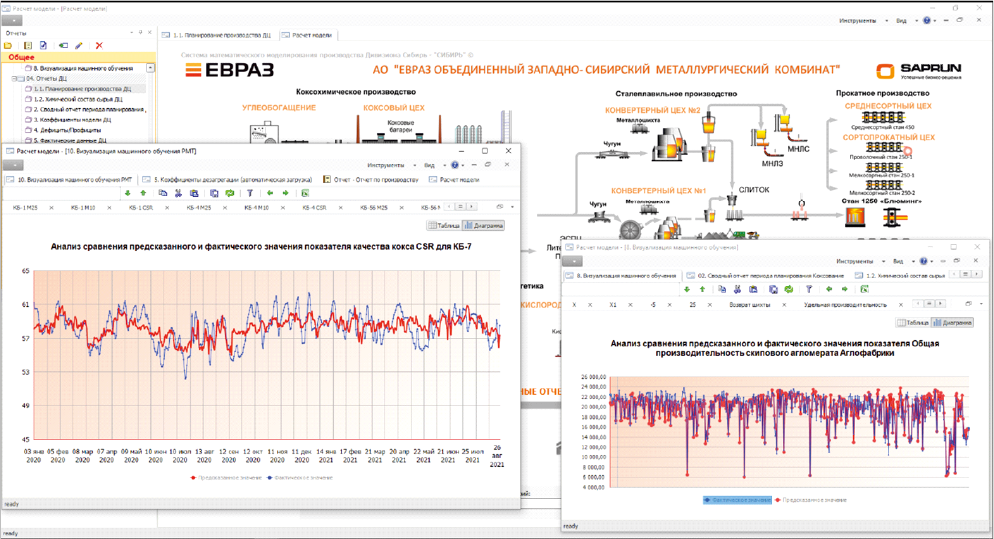

Mathematical Model Summary

In 2019, EVRAZ ZSMK successfully deployed a mathematical model that covers every production stage from ore mining to steel rolling. The system offers easy integration with third-party analysis modules. Fig. 1 shows the main window of the Forecast process simulation system (PSS). Initially, the system was developed to optimize the production plan in financial terms at each site and at the corporate level.

Fig. 1. Main window of the “Forecast” process simulation system |

However, the optimization results were challenging to interpret. For example, in cases where the system suggests 100 % of composition 1 pellets instead of composition 2 and 3 pellets, it is not clear why such a switch would lead to cost savings or if it would even be advantageous. Therefore a new option was added to the system to enable users to select either planning or scenario analysis mode. In the planning mode, the system suggests an optimal production plan that meets constraints, while in the scenario mode, the system estimates costs for various possible scenarios. This enhanced the system’s efficiency but increased user effort.

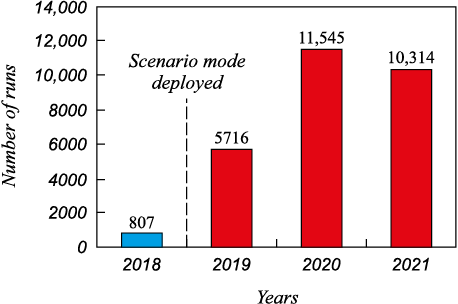

A detailed analysis of system usage statistics was conducted to identify bottlenecks, which revealed that only 30 out of 3000 scenarios analyzed in 2020 were implemented. Moreover, the new scenario mode considerably increased user efforts and the number of simulation runs. The total number of analysis cases run was more than 11,545, indicating that each scenario had to undergo 3 – 4 runs to ensure error-free results. The study results are illustrated in Fig. 2.

Fig. 2. System use statistics |

After analyzing the results, we developed special productivity-boosting tools for the system users. In addition, we added a simulation experiment capability to the system. With the rise of resource-saving technologies, computational experiments have become necessary to analyze processes and system behavior. As such, the company required a simulation tool for such experiments.

A computational experiment typically involves several steps. First, the input data is entered and validated. Following this, physical experiments are conducted to fine-tune the mathematical model [7].

Input Data Validation

“Data Validation” tool

The input data is validated before running the solver to identify any incorrect values. For user convenience, the validation tool is programmed to start automatically before each simulation run, providing brief explanations and displaying the input data status.

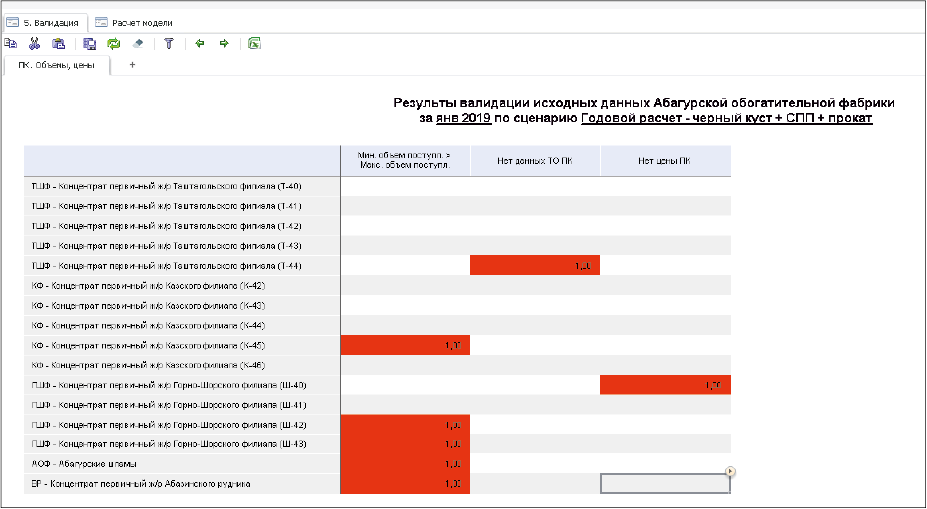

Consider the report from the Abagursk Concentration Facility (Fig. 3).

Fig. 3. Report on validation results for Abagur concentrating plant |

The report is checked against the following rules applied to concentration facility reports:

– the minimum reconcentrate intake should be less than or equal to the maximum intake;

– if the maximum intake value is non-zero, the ore preparability tables should report non-zero values;

– if the maximum intake value is non-zero, the preconcentrate price should be non-zero.

“Checklist” tool

The “Checklist” tool is launched after successfully simulating a model. It displays the solution to the optimization problem and checks it for compliance with process constraints. The solution is then checked against the checklist as a post-processing stage. If a rule is not satisfied and the solution fails to meet process requirements, it is highlighted in red. Some of the rules checked by the tool are:

– whether the raw o re stock is underutilized. This rule checks for unused ore resources since in-house ore stock should be used first;

– the sinter cake output is less than the production capacity. This rule checks if the sinter production plan underutilizes the available equipment capacity;

– whether the pig iron output is less than the production capacity. This rule checks if the pig iron production plan underutilizes the available equipment capacity.

“Chemical Composition Uploading” Tool

Entering the raw chemical composition into the system was a time-consuming process. The mathematical model requires an extended chemical composition for each charge component (e.g., TiO2 , ZnO, etc.). However, extended analysis incurs higher costs and is often outsourced. Therefore, the in-house lab can only provide incomplete analysis and updates the record once a quarter or upon request.

The chemical composition data is sourced from both lab test reports and raw material data sheets. Lab reports are given priority, and if they are unavailable, data sheets are used instead. Consequently, the chemical compositions for all materials over the planning period (scenario) are uploaded into the system. If a chemical composition is updated, the new data overwrites the old values.

These tools have significantly reduced potential data entry errors as more than 10,000 values are entered every month.

Result Analysis Tools

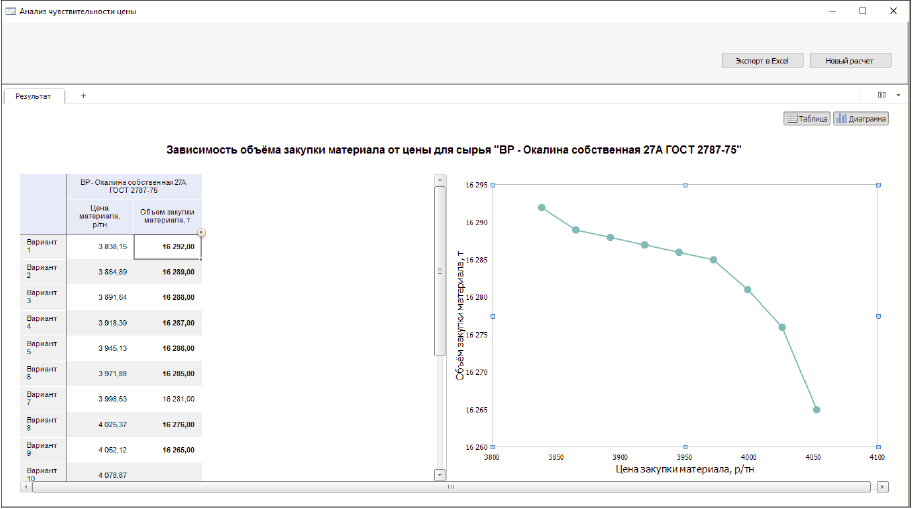

“Price Sensitivity Analysis” Tool

Price sensitivity analysis aims to identify the relationship between raw material prices and purchase volume. To conduct this analysis, the user specifies the material of interest, along with lower and upper price limits. The user also specifies the number of increments in the price sensitivity analysis window.

Once the price sensitivity analysis is completed, the results are presented in the form of a table and diagram, as shown in Fig. 4. The user can export the results to Excel by clicking on the “Export to Excel” button.

Fig. 4. Results of price sensitivity analysis |

“Pipeline Processing” Tool

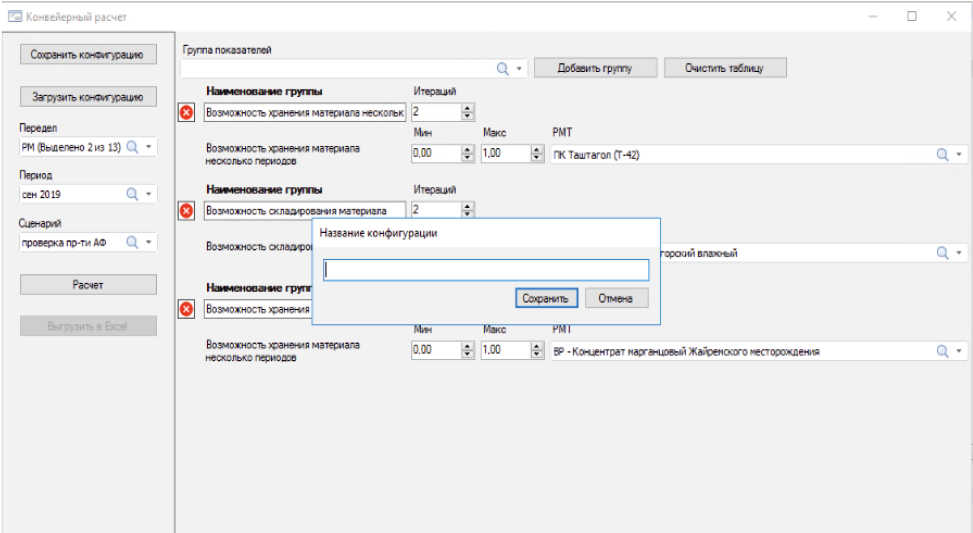

The batch scenario simulation tool allows for multiple simulations to be run with varying input data within specified ranges and increments. The tool window is displayed in Fig. 5.

The results of the simulations are presented in the form of a standard Production Report and can be exported to Excel by clicking on the “Export to Excel” button and specifying the path and file name. The user also has the option to save the configuration for later use.

Fig. 5. Pipeline processing tool |

“Model Factor Calculation” Tool

This tool is designed to recalculate the factors utilized in several plant models, including the sinter plant, byproduct coke-making plant, melt shop, and LD plant models. These factors are estimated based on historical data. In this discussion, we will specifically focus on the factor estimation process for the sinter plant model.

The blast furnace process is responsible for the production of pig iron from sinter, pellets, and briquettes. In order to ensure high-performance blast furnace operation, fine ore and concentrate are converted into larger fragments, which provide better gas permeability [8]. This is typically accomplished through one of three processes: briquetting, agglomeration sintering, or pelletizing. Agglomeration sintering is the most commonly used process due to its significant advantages over the other options. For instance, agglomeration sintering makes it possible to utilize by-products and in-house waste, such as sludge and furnace dust, resulting in water savings and reduced air pollution [9].

One challenge of sinter plants is the inconsistent composition of the ore concentrate, furnace fuel, and flux, as well as varying base-to-silica ratios. Estimating sinter machine capacity based solely on ore concentrate and factor recalculation is insufficient to achieve the required simulation accuracy. Instead, only machine learning on historical datasets can effectively estimate every factor that affects the sinter machine’s capacity and sinter cake quality. Market price analysis over the last five years has shown that the price of sinter cake made from purchased ore concentrate is lower than that of purchased pellets. To increase sinter cake output, several options exist, including:

– increasing plant capacity;

– intensifying the sintering process;

– increasing yield through better sinter quality or reducing fines;

– and using substandard sinter in the blast furnace as a compromise [10, 11].

Charge optimization [12 – 15] is the key factor for the sinter quality and sinter machine capacity [16 – 19]. It is a zero-cost profit booster [12].

A regression model for the sinter plant output is as follows:

y = b0 + b1 x1 + b2 x2 + ... + bn xn ,

where y is the expected sinter output, tons; b0 is the intercept term; b1 , b2 , ... bn are the regression coefficients; x1 , x2 , ... xn are the factors affecting the sinter output.

To estimate sinter quality, the Random Forest method was utilized due to its higher prediction accuracy when compared to regression. The Random Forest method is an ensemble learning method that was proposed by Leo Breiman and Adele Cutler. It utilizes multiple decision trees to generate predictions. The algorithm combines two key concepts: Breiman’s bagging and the random subspace method by Tin Kam Ho. This method can be applied to classification, regression, and clustering problems. The core idea behind this method is to use a large ensemble of decision trees, where each individual tree may produce a poor classification quality but the collective output of many trees produces more accurate and reliable results1.

Conclusions

In modern times, user experience has become the most critical aspect of simulation and optimization tools. Even the most accurate and flexible solution can be rejected by users due to its confusing user interface. To overcome this issue, we applied system analysis and software adoption rate assessment to identify and rectify any bottlenecks in the software’s usability.

References

1. Lisienko V.G., Solov’eva N.V., Trofimova O.G. Alternative Metallurgy: Problem of Alloying, Model Efficiency Estimates. Moscow: Izd. Teplotekhnik; 2007: 440. (In Russ.).

2. Protopopov E.V., Kalinogorskii A.N., Ganzer A.A. Steelmaking production: Current state and directions of development. In: Metallurgy: Technologies, Innovations, Quality. Proceedings of the XX Int. Sci. and Pract. Conf. Part 1. Novokuznetsk: ITs SibSIU; 2019: 9–14. (In Russ.).

3. Leont’ev A.S., Rybenko I.A., Borisov A.S., Volkova I.V. Experience in development and application of a mathematical modeling system at JSC “EVRAZ ZSMK”. In: Modeling and High-Tech Information Technologies in Technical and Socio-Economic Systems. Proceedings of the V All-Russ. Sci. and Pract. Conf. with Int. Participation. Novokuznetsk: ITs SibSIU; 2021: 250–255. (In Russ.).

4. Golodova M.A., Dmitrienko V.I., Rozhikhina I.D., Nokhrina O.I., Rybenko I.A. Study of process conditions for vanadium and iron reduction from vanadium converter slag. Izvestiya. Ferrous Metallurgy. 2011; 54(4): 3–5. (In Russ.).

5. Rybenko I.A., Mochalov S.P. Modeling and Optimization of Stationary Modes of Metallurgical Processes. Novokuznetsk: ITs SibSIU; 2015: 168. (In Russ.).

6. Cech M., Lenort R., Tolstykh T., Shkarupeta E. Modeling metallurgical supply chain resilience using Markov process. In: Proceedings of 28th Int. Conf. on Metallurgy and Materials. 2019: 1798–1803. https://doi.org/10.37904/metal.2019.782

7. Rybenko I.A. Solving problems of optimization of metallurgical processes using the instrumental system “Engineering-Metallurgy”. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2018; 1(3): 42–47. (In Russ.).

8. Spirin N.A., Ovchinnikov Yu.N., Shvydkii V.S., Yaroshenko Yu.G. Heat Exchange and Efficiency Improvement of Blast Furnace Smelting. Yekaterinburg: USTU; 1995: 243. (In Russ.).

9. Frolov Yu.A. Agglomeration. Technology, Heat Engineering. Moscow: Metallurgiya; 2006: 600. (In Russ.).

10. Bizhanov A., Chizhikova V. Agglomeration in Metallurgy. Springer; 2020: 453. https://doi.org/10.1007/978-3-030-26025-5

11. Majumder A., Biswas C., Saugata Dhar, Rajib Dey, Das G.C. Use of artificial neural network to predict the yield of sinter plant as a function of production parameters. In: International Conference on Innovative Computing and Cutting-edge Technologies. 2020: 13–26. https://doi.org/10.1007/978-3-030-65407-8_2

12. Kumar V., Sairam S.D.S.S., Kumar S., Singh A., Nayak D., Sah R., Mahapatra P.C. Prediction of iron ore sinter properties using statistical technique. Transactions of the Indian Institute of Metals. 2017; 70: 1661–1670. https://doi.org/10.1007/s12666-016-0964-y

13. Mochón J., Ruiz-Bustinza I., Cores A., Verdeja L., etc. Iron ore sintering. Part 2. Quality indices and productivity. In: Network of Non-Commercial Academy-Owned Open Access Scientific Journals. 2014: 168–177. http://doi.org/10.15446/dyna.v81n183.41568

14. Shao H., Yi Z., Chen Z., Zhou Z., Deng Z. Application of artificial neural networks for prediction of sinter quality based on process parameters control. Transactions of the Institute of Measurement and Control. 2019; 42(3): 422–429. http://doi.org/10.1177/0142331219883501

15. Mallick A., Dhara S., Rath S. Application of machine learning algorithms for prediction of sinter machine productivity. Machine Learning with Applications. 2021; 6: 100186. http://doi.org/10.1016/j.mlwa.2021.100186

16. Song L., Qing L., Xiaojie L., Yanqin S. Synthetically predicting the quality index of sinter using machine learning model. Ironmaking & Steelmaking. 2020; 47(7): 828–836. http://doi.org/10.1080/03019233.2019.1617573

17. Mitterlehner J., Loeffler G., Winter F., Hofbauer H., Schmid H., Zwittag E., Buergler T.H., Pammer O., Stiasny H. Modeling and simulation of heat front propagation in the iron ore sintering process. ISIJ International. 2004; 44(1): 11–20. http://doi.org/10.2355/isijinternational.44.11

18. Yang W., Rui C., Choi S., Choi E., Lee D., Huh W. Modeling of combustion and heat transfer in an iron ore sintering bed with considerations of multiple solid phases. ISIJ International. 2004; 44(3): 492–499. http://doi.org/10.2355/isijinternational.44.492

19. Calhoun P., Su X., Spoon K.M., Levine R.A., Fan J. Random forest. Wiley StatsRef: Statistics Reference Online. 2021: 1–20. http://doi.org/10.1002/9781118445112.stat08287

About the Authors

А. S. Leont’evRussian Federation

Aleksei S. Leont’ev, Postgraduate of the Chair of Applied Information Technologies and Programming

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

I. А. Rybenko

Russian Federation

Inna A. Rybenko, Dr. Sci. (Eng.), Prof., Head of the Chair of Applied Information Technologies and Programming

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Leont’ev А.S., Rybenko I.А. Mathematical modelling system for metallurgical enterprise: Operation and usability enhancement. Izvestiya. Ferrous Metallurgy. 2023;66(1):119-126. https://doi.org/10.17073/0368-0797-2023-1-119-126