Scroll to:

Metallographic analysis of structural peculiarities of thin slab and rolled products manufactured thereof

https://doi.org/10.17073/0368-0797-2023-1-105-111

Abstract

The article describes the determination of level of zonal and dendritic segregations in slabs cast by thin slab technology. The calculated coefficients of variation of content of main and impurity chemical elements over slab cross-section do not exceed 10 %, while the zonal segregation are moderate. The content of manganese measured by the surface area occupied by dendritic axes and interdendritic spaces determines the level of dendritic segregation. The manganese concentration varies from 0.6 to 1.1 %, respectively. It was established that the dynamic soft reduction during solidification allows the primary dendritic structure to be refined, in order to form additional centers upon phase transformation of δ ferrite into austenite. The sizes of initial austenite grains formed accounting for the primary dendritic structure are 3 times lower in a thin slab than in a slab with the thickness of more than 200 mm. Transformations of dendritic structure during reductions demonstrate the high level of conditioning required for the formation of uniform austenite grains in semifinished rolled stock before finish rolling. The studies did not confirm the hypothesis that bainite of coarse morphology in the microstructure of hot rolled products is formed in segregation sites. The inherited influence of the primary dendritic structure on structure formation during rolling was detected. The manganese concentration varies between bainite and neighboring structure from 0.68% to 1.01% similarly to the level in initial dendritic segregation. The difference in the content of chemical elements influences on recrystallization of austenite grains during high temperature roughing. Bainite was formed in the frames of chemically depleted coarse austenite grains steady upon phase transformation.

For citations:

Vorozheva E.L., Smetanin K.S., Kislitsa V.V., Kudashov D.V. Metallographic analysis of structural peculiarities of thin slab and rolled products manufactured thereof. Izvestiya. Ferrous Metallurgy. 2023;66(1):105-111. https://doi.org/10.17073/0368-0797-2023-1-105-111

Introduction

The rolling production of various steel grades was implemented at the casting and rolling facility (CRF), JSC “Vyksa Metallurgical Plant”, including cold and corrosion resistant versions. The continuous improvement of product quality allows the properties of hot rolled product [1 – 5] to be enhanced. Thus the increase in the slab thickness from 90 to 105 mm resulted in increase in the facility efficiency [6]. In thin slab technology without recrystallization of austenite grains before rolling and restricted cumulative deformation, the initial cast structure exerts inherited influence on formation of final structure of rolled products [7]. The slab austenite structure before the start of rolling is determined by the cast metal structure previously formed during crystallization. The boundaries of initial cast grains are propagated along the interdendritic spaces. The grain shape and sizes depend on the solidifying conditions. The dispersity of cast structure changes from the surface to the middle of the slab thickness: consecutively the zones of fine crystals are formed, oriented columnar crystals and crystals of equiaxial shape. According to the results in [8 – 12], the distances between the dendritic axes of the second order increase from the surface to the center from 20 to 180 – 250 μm in thin slabs, respectively. This parameter in dendritic structure of classical thick slab is higher: 50 μm near surface, 350 μm in the middle of thickness.

It was experimentally established that under conditions of CRF in the course of blistering slab from micro-alloyed steel in tunnel furnace at 1150 – 1170 °C, about 60 % of dispersed particles are dissolved. The size of initial austenite grain in slab changes insignificantly [4]. Therefore, in order to achieve superior properties in rolled products, more disperse initial cast structure must be obtained before slab rolling by controlling metal solidifying [13]. In addition to the sizes of cast grains, the microstructure formation during rolling can be also influenced by chemical segregations stipulated by conditions of melt presence in liquid solid two phase region. During solidification there occurs subdivision of elements at macrolevel with formation zonal segregations. The dendritic character of solidification leads to microsegregations.

Generally, the main consequence of segregations can be the formation of structural heterogeneity in rolled metal negatively influencing on mechanical properties [14]. The aim of this work was to analyse the internal chemical and structural properties formed at the stages of solidification of thin slab and as a consequence of δ → γ transformation, and to determine their influence on the formation of microstructure during hot deformation.

Experimental

The research material was an array of ten industrial thin slabs of low carbon micro-alloyed steels, Grade K52, and respective rolled products.

The zonal chemical segregation was determined by slab thickness using atomic emission spectral analysis [15]. Five to seven measurements were made at each considered site: at least 30 burnings over the thickness of each slab. The dissipation of chemical elements over the slab cross section was estimated by the coefficient of variation calculated as the ratio of standard deviation in the data array to average value [11]. The distribution of chemical elements over the dendrite axes and interaxial spaces was estimated by manganese content [16; 17]. The cast structure was analyzed using a Carl Zeiss Axio Observer Dlm optical microscope on metallographic polished cross sections made from rapidly cooled slabs. The diameter of former austenite grains highlighted by ferrite was measured in the cross sections parallel to the slab wide faces. In these cross-sections, the grains are of equiaxial shape. Therefore, it was sufficient to measure the diameter without adjusting coefficients [18; 19]. The microstructure of rolled products was analyzed by reflected electron diffraction (RED) using Ultra 55 electron microscope equipped with HKL Channel 5 analytical system. The RED maps were plotted as 1/4 thickness of rolled products at 125× and 500× magnifications with scanning step of 0.5 and 0.1 μm, respectively. In the maps obtained, the low angle boundaries (LAB) were plotted at the grain boundary angle from 2 to 15°, and the high angle boundaries (HAB) at the angle boundaries of higher than 15°.

The grain sizes were estimated by the sizes of sites restricted by HAB [20].

Results and discussion

The calculated coefficients of array variation together with the data of spectral analysis (Table 1) demonstrate that the dissipation chemical elements over the cross section of thin slabs from low carbon micro-alloyed steel is insignificant. The variation coefficients of the main and impurity elements are lower than 10 %. In comparison with these results in a classical slab with the thickness of 250 mm of identical chemical composition, the coefficient of variation of carbon reaches 25.7 %. The dissipation of other elements is the same as in a thin slab. Therefore, the casting conditions of thin slabs allows metal close to chemically homogenous metal to be obtained.

Table 1. Variation coefficients

| |||||||||||||||||||||

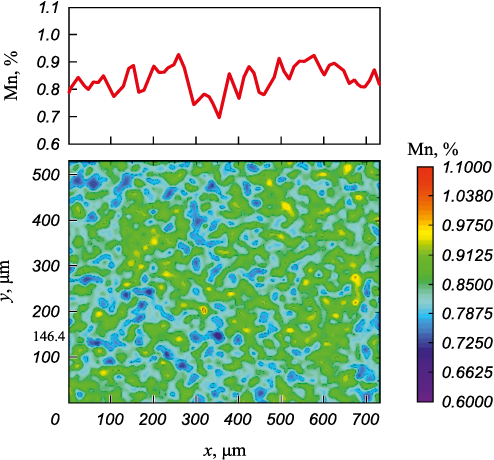

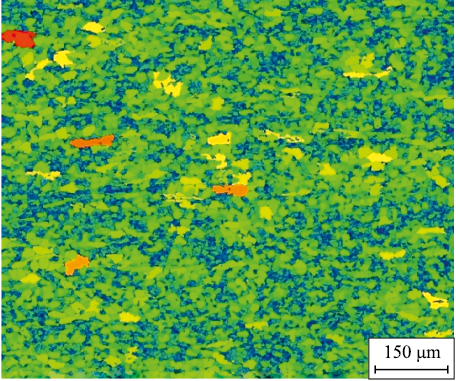

The zonal segregations are insignificant. Analysis of dendritic segregation demonstrated that the manganese content over the area occupied by dendritic axes and interdendritic spaces varies from 0.6 to 1.1 %. The manganese distribution map illustrates primary solidified state and dendritic segregation in a slab from low carbon steel (Fig. 1).

The classic tree structure in a thin slab of low carbon steel is violated. One of the reasons of destruction of the dendritic structure is the dynamic soft reduction during solidification, leading to breakage and refining of growing dendrites. Additional centers are formed for nucleation of austenite grains during phase transformation δ → γ [13], providing structure dispersity before hot rolling.

Fig. 1. Map of manganese distribution over the cross section |

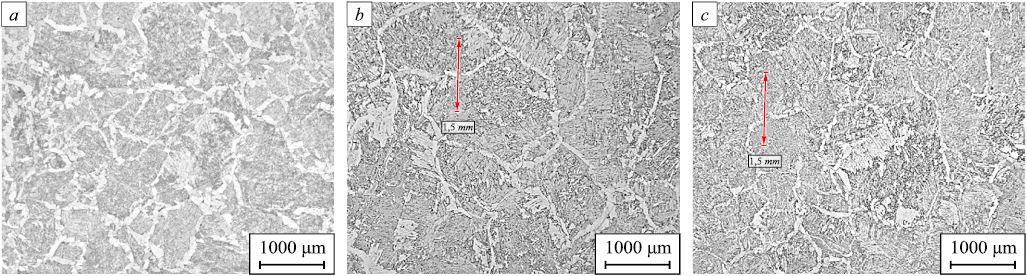

The size of initial austenite grains formed with accounting for primary dendritic structure is in the range from 0.5 to 1.5 mm. In the aims of comparison, in a classic slab with the thickness of higher than 200 mm before rolling preheating the grain size near the surface is 1.5 mm and increases to 4.5 mm in the middle of the thickness. The grains highlighted by ferrite in cross section parallel to wide faces of slabs with the thickness of 90 and 105 mm are illustrated in Fig. 2.

Fig. 2. View of grains in the planes parallel to the wide face of thin slabs: |

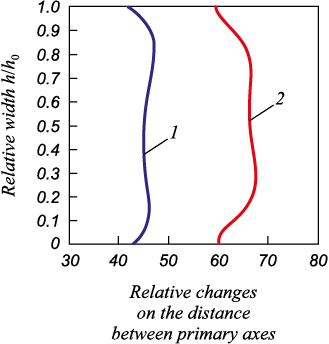

In the course of thermomechanical treatment, the structural heterogeneity is minimized due to correctly selected microalloying and significant reductions of slab in roughing train [1 – 5]. The deformation distribution curve plotted by relative changes of dendritic structure [21] in a slab during roughing demonstrated that actual reductions in the CRF roughing train provide uniform local deformations (Fig. 3), which are required for obtaining of homogeneous fine grain structure before roughing.

Fig. 3. Influence of deformation on dendrite transformation |

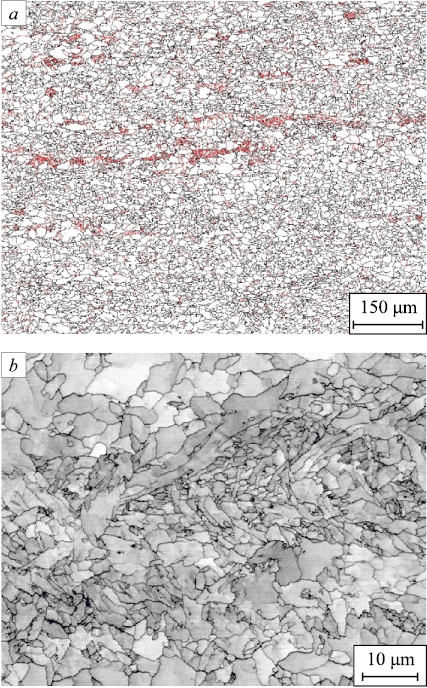

The maps of grain boundary and microstructure of final hot rolled products in the form of Kikuchi diffraction patterns are illustrated in Fig. 4. It can be seen that the structure is comprised mainly of polygonal ferrite (Fig. 4, a), the matrix of which contains bainite regions with predominant granular morphology (Fig. 4, b) and, to a lower extent, of rack morphology. The structure of granular bainite contains to a higher extent large angle boundaries [20], which can be observed in the grain boundary maps.

The maps are plotted to give a better demonstration of grain sizes in the structure of the considered samples (Fig. 5). Each site bounded by HAB is colored from blue to red. Blue corresponds to the finest grains, red corresponds to the coarsest sites. The structure is mainly homogenous in terms of grain sizes.

Fig. 4. Microstructure of hot rolled products:

Fig. 5. Grain size maps |

The grain measurements are summarized in Table 2. The fraction of large sizes of bainite of low temperature modification of rack morphology with LAB, formed in the frames of initial austenite grains, does not exceed 10 %.

Table 2. Grain size estimation based on the maps of reflected electron diffraction

|

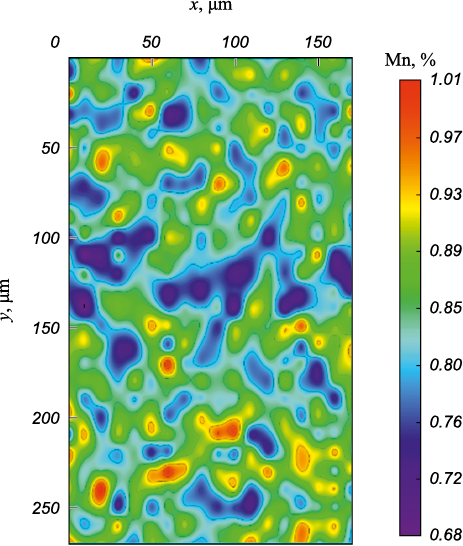

The map of manganese distribution over bainite surface area does not confirm the hypothesis that bainite of coarse morphology in the microstructure of hot rolled products is formed in segregation sites (Fig. 6). This figure demonstrates that it is identical with dendritic segregation. The manganese content in the surface area occupied by bainite and neighboring structure varies from 0.68 to 1.01 %, respectively. Bainite with LAB was formed in the frames of austenite grains steady upon phase transformation [22].

Fig. 6. Mn content at the site of bainite |

The difference in content of chemical elements between dendrite frames and in interdendritic spaces can influence on recrystallization of austenite grains during high temperature roughing. At a chemically pure site, the barrier action for prevention of growth of recrystallized austenite grains is weakened, in comparison with chemically enriched spaces. The determined regularity indicates that minimization of bainite fraction of coarse morphology in rolling is possible due to decrease in the initial dendritic segregation during solidification of liquid steel. The studies established that a decrease in the distance between dendritic axes of the second order by 30 μm in average results in a decrease in the dendritic segregation by 20 % [23]. The disperse primary dendritic structure is a prerequisite for formation of uniform recrystallized austenite structure during rolling in roughing train.

Conclusions

Estimation of zonal segregations demonstrated that dissipation of chemical elements over the cross section of thin slabs from low carbon micro-alloyed steel is insignificant. The coefficients of variation are less than 10 %. In comparison with these results in slab with the thickness of more than 200 mm the variation coefficient of carbon reaches 25.7 %.

The dendritic segregation illustrated by the map of manganese distribution demonstrated the primary solidified state of low carbon steel with violated structure of dendrite. The refining of growing dendrites in the course of solidification by dynamic reduction of slab provided additional centers for the nucleation of austenite grains upon phase transformation δ → γ. The sizes of initial austenite grains in the cast structure of thin slab are three times lower than in a slab with the thickness of higher than 200 mm.

The calculation of relative changes in the sizes of dendritic structure during roughing demonstrated uniform structural transformations required for obtaining of uniform austenite grain before entry into finishing train.

It was established that the nature of bainite with a higher density of low angle boundaries in final microstructure of rolled products is stipulated by the inherited influence of dendritic segregation during rolling. Decrease in the dendritic segregation is a prerequisite for formation of uniform recrystallized austenite structure during roughing.

References

1. Muntin A.V., Chastukhin A.V., Chervonnyi A.V., Naumenko V.V., Efron L.I., Ringinen D.A. Development of technology for production of rolled products of K60 strength class in conditions of casting and rolling complex. Problemy chernoi metallurgii i materialovedeniya. 2016; (3): 17–25. (In Russ.).

2. Muntin A.V. Advanced technologies of combined process of thin slabs continuous casting and hot strip rolling. Metallurgist. 2019; 62(9-10): 900–910. https://doi.org/10.1007/s11015-019-00747-5

3. Chervonnyi A.V., Ringinen D.A., Chastukhin A.V., Efron L.I., Muntin A.V., Naumenko V.V., Bagmet O.A. Structure and property formation for pipe coiled rolled product during manufacture under casting and rolling complex conditions. Metallurgist. 2019; 62(9-10): 1012–1021. https://doi.org/10.1007/s11015-019-00748-4

4. Chervonnyi A.V. Development of microalloyed steel compositions for electro-welded pipes of strength classes K56-K60 and their controlled rolling modes in the conditions of casting and rolling complex: Extended Abstract of Cand. Sci. Diss. Moscow; 2021: 16. (In Russ.).

5. Barykov A.M., Stepanov P.P. Development of Technologies for the Production of Steel, Rolled Products and Pipes at the Vyksa Production Site: Coll. of Papers. Barykov A.M. ed. Moscow: Metallurgizdat; 2016: 203. (In Russ.).

6. Kislitsa V.V., Maksaev E.N., Boiko A.S., Vorozheva E.L., Smetanin K.S. Evaluation of quality indices of slabs and rolled products with an increase in thickness of continuously cast billets. Steel in Translation. 2021; 51(8): 548–553. https://doi.org/10.3103/S0967091221080076

7. Efron L.I. Metal Science in “Big” Metallurgy. Pipe Steels. Moscow: Metallurgizdat; 2012: 696. (In Russ.).

8. Ruiz-Aparicio A. Evolution of Microstructure in Nb-Bearing Microalloyed Steels Produced by the Compact Strip Production Process: Master’s Thesis. University of Pittsburg; 2004: 162.

9. Garcia C.I., Ruiz-Aparicio A., Cho K., Ma Y.P, Graham C., Vazquez M., Ruiz-Aparicio L., DeArdo A.J. Microstructural characterization of the solidification and equilibrated microstructures of Nb-bearing microalloyed steels produced by the compact strip processing. Int. Symp. on Thin Slab Casting and Rolling (TSCR’2002), December 3–5,2002, Guangzhou, China. URL: https://www.researchgate.net/publication/304900786

10. Garcia C.I., Torkaz C., Graham C., DeArdo A.J. Physical metallurgy of high strength low alloy strip steel production using compact strip processing. Ironmaking and Steelmaking. 2005; 32(4): 314–318. https://doi.org/10.1179/174328105X48052

11. Vorozheva E.L., Kudashov D.V., Khlybov A.A., Smetanin K.S. Methods for studying the structural state of continuously cast slabs and the hot-rolled metal produced at the casting and rolling complex. Russian Metallurgy (Metally). 2022; (5): 496–494. http://doi.org/10.1134/S003602952205010X

12. Khlybov A., Vorozheva E. Studying on the internal quality of steel at various stages of production: Slab-rolled metall. Materials Science Forum. 2022; 1052: 377–383. https://doi.org/10.4028/p-0skw5n

13. Zhou T., O’Malley R.J., Zurob H.S., Subramanian M., Cho S.-H., Zhang P. Control of upstream austenite grain coarsening during the thin-slab cast direct-rolling (TSCDR) process. Metals. 2019; 9(158): 1–18. https://doi.org/10.3390/met9020158

14. Verhoven J.D. A review of microsegregation induced banding phenomena in steels. Journal of Materials Engineering and Performance. 2000; 9(3): 286–296. https://doi.org/10.1361/105994900770345935

15. GOST R 54153-2010. Steel. The method of atomic emission spectral analysis. Moscow: Standartinform; 2012: 28.

16. Presslinger H., Mayr M., Tragl E., Bernhard C. Assessment of the primary structure of slabs and the influence on hot- and cold-rolled strip structure. Steel Research International. 2006; 77(2): 107–115. https://doi.org/10.1002/srin.200606362

17. Yan C., Ju X., Meng Y., Shi X. Quantification of manganese dendritic segregation in 380CL steel billet by electron probe microanalysis. SN Applied Sciences. 2019; 1: 623. https://doi.org/10.1007/s42452-019-0612-3

18. Bernhard C., Reiter J., Presslinger H. A model for predicting the austenite grain size at the surface of continuously-cast slabs. Metallurgical and Materials Transactions B. 2008; 39(6): 885–895. https://doi.org/10.1007/s11663-008-9197-8

19. GOST 5639-82. Steels and alloys. Methods of detection and determination of grain size. Moscow: IPK Izdatel’stvo standartov; 2003: 16.

20. Efron L.I., Stepanov P.P., Vorkachev K.G., Kantor M.M., Bozhenov V.A., Smetanin K.S. Questioning the effect of bainite morphology on the impact viscosity of low-carbon steels. Steel in Translation. 2021; 51(9): 670–676. https://doi.org/10.3103/S0967091221090035

21. Levchenko G.V., Vorobei S.A., Demina E.G., Dement’eva Zh.A. Development of a method for assessing the workability of structural steel structure during hot deformation. In: VIII Int. Conf. “Deformation and Destruction of Materials and Nanomaterials”. Moscow. November 19–22, 2019: Coll. of Papers. Moscow: IMET RAS; 2019: 42–43.

22. Jayanti S. Austenitic grain size of steel. Engineering Notes. URL: https://www.engineeringenotes.com/metallurgy/steel/austenitic-grain-size-of-steel-metallurgy/25901

23. Vorozheva E.L., Kudashov D.V, Khlybov A.A., Smetanin K.S. Features of formation of the structure of thin slabs cast at different speeds, their influence on the structure and properties of hot-rolled steel. Chernye metally. 2022; (7): 27–34. https://doi.org/10.17580/chm.2022.07.05

About the Authors

E. L. VorozhevaRussian Federation

Evgeniya L. Vorozheva, Chief Specialist

45 Br. Batashevykh Str., Vyksa, Nizhny Novgorod Region 607060, Russian Federation

K. S. Smetanin

Russian Federation

Kirill S. Smetanin, Chief Specialist on Electron Microscopy and Radiography of the Laboratory of Metal Science

45 Br. Batashevykh Str., Vyksa, Nizhny Novgorod Region 607060, Russian Federation

V. V. Kislitsa

Russian Federation

Vyacheslav V. Kislitsa, Cand. Sci. (Eng.), Head of the Department of Metallurgical Processes

45 Br. Batashevykh Str., Vyksa, Nizhny Novgorod Region 607060, Russian Federation

D. V. Kudashov

Russian Federation

Dmitrii V. Kudashov, Cand. Sci. (Eng.), Chief Innovation Specialist, JSC “Vyksa Metallurgical Plant”; Director, Vyksa Branch of the National University of Science and Technology “MISIS”

45 Br. Batashevykh Str., Vyksa, Nizhny Novgorod Region 607060, Russian Federation

06 Kalinina Str., Shimorskoe, Vyksa District, Nizhny Novgorod Region 607060, Russian Federation

Review

For citations:

Vorozheva E.L., Smetanin K.S., Kislitsa V.V., Kudashov D.V. Metallographic analysis of structural peculiarities of thin slab and rolled products manufactured thereof. Izvestiya. Ferrous Metallurgy. 2023;66(1):105-111. https://doi.org/10.17073/0368-0797-2023-1-105-111