Scroll to:

Comparative analysis of the structure and properties of hypereutectoid railway rails

https://doi.org/10.17073/0368-0797-2025-6-556-562

Abstract

Due to the constant increase in axial loads and the weight of rolling stock intended for passenger and freight heavy traffic, more stringent requirements are being put forward by consumers of rail products. The pearlite-grade carbon steels currently used for the industrial production of rails have high consumer properties, namely, resistance to wear and the formation of contact and fatigue defects, which makes it possible to ensure operability in a wide range of operational and climatic conditions along the entire length of the railway network. An important technical task is to establish the patterns of formation of the microstructure of rails depending on the chemical composition of steel and influence of the structure on properties of the finished products. One of the main parameters determining the structure and consumer properties of pearlite steel railway rails is the size of the interlamellar spacing. Improving the operational stability of rails is one of the main tasks of the specialists of JSC EVRAZ ZSMK, the Kuzbass Metallurgical Plant, one of the five largest manufacturers of railway rails in the world. The results of a comparative analysis of chemical composition, size of the interlamellar spacing, as well as the strength and plastic properties of the metal of pearlite-class railway rails are presented. In accordance with GOST R 51685-2022, 90KhAF steel is hypereutectoid in terms of carbon content. As a result of the conducted research, the relationships between parameters of the structure and the physico-mechanical properties of rails, as well as between content of the main chemical elements in steel and the interlamellar spacing of perlite, were established.

Keywords

For citations:

Bessonova O.V., Polevoi E.V., Oskolkova T.N., Komarova T.A. Comparative analysis of the structure and properties of hypereutectoid railway rails. Izvestiya. Ferrous Metallurgy. 2025;68(6):556-562. https://doi.org/10.17073/0368-0797-2025-6-556-562

Introduction

Consumers of rail products are increasingly demanding longer intervals between maintenance operations and improved durability and reliability of rails, which remain the primary and most heavily loaded component of the railway superstructure. The operational durability of rails is governed to a large extent by the steel’s structural and phase state. For this reason, a key technical objective is to clarify how the rail microstructure forms as a function of steel chemical composition and how the resulting structure affects the properties of the finished products.

Numerous studies [1 – 3] have identified the principal trends linking microstructure to rail operational durability. Worldwide, rails are most commonly manufactured from high-carbon pearlite-grade steels. Under accelerated cooling, these steels develop a fine lamellar ferrite – carbide mixture (pearlite), which provides a favorable combination of hardness, strength and ductility, impact toughness, fracture toughness, contact fatigue strength, and wear resistance [4 – 6]. Among the parameters that control both the microstructure and the consumer properties of pearlitic railway rails, a central role is played by the interlamellar spacing (ILS). In this work, ILS is understood as the sum of the thicknesses of the ferrite and cementite lamellae that form in rails after rolling and differential heat treatment [7 – 9]. Despite its importance, this aspect remains insufficiently explored [10 – 12]. Therefore, quantifying this structural parameter is essential when designing steel compositions, selecting heat-strengthening modes, and setting temperature – deformation rolling schedules aimed at achieving the required quality indicators of metal products.

This study presents the results of a comparative analysis of the chemical composition, interlamellar spacing, and strength and ductility properties of R65 railway rails manufactured by JSC EVRAZ United West Siberian Metallurgical Plant (JSC EVRAZ ZSMK) [13].

Materials and methods

d using the residual heat from pre-rolling heating, were selected as the object of investigation. According to GOST R 51685 – 2022, 90KhAF steel is classified as hypereutectoid with respect to carbon content.

To evaluate the metal quality of the rails, tensile tests were performed in accordance with GOST 1497 – 2023 using a Z-250 universal testing machine. Impact bending tests were carried out in accordance with GOST 9454 – 78 on an RKP-450 pendulum impact tester. Hardness measurements were conducted on the running surface of the rail head in accordance with GOST 9012 – 59 using a NEMESIS 9503 universal hardness tester.

Microstructural studies and measurements were performed using a Tescan MIRA3 scanning electron microscope (SEM). The interlamellar spacing and grain diameter were evaluated on transverse metallographic sections prepared from the fillet region after electropolishing and etching in a 4 % alcoholic solution of nitric acid.

The region selected for interlamellar spacing measurements was located at a distance of 2 – 4 mm from the running surface of the rail head. This location was chosen because it corresponds to the zone experiencing the maximum contact stresses arising from wheel – rail interaction during service. In accordance with the procedure described in [14], interlamellar spacing measurements were carried out within pearlite colonies exhibiting a clearly pronounced parallel arrangement of lamellae, regardless of their apparent spacing (visible interlamellar spacing). The obtained data were subsequently processed taking into account the asymmetry coefficient, followed by calculation of the average value of the true interlamellar spacing. Lamellar spacings showing evident signs of deformation (fractured, broken, or strongly curved lamellae) were excluded from the analysis.

Grain diameter in the rail steel of the investigated compositions was determined near the fillet surface using the ferrite/cementite network method in accordance with GOST 5639 – 82 “Steels and alloys. Methods for revealing and determining grain size”.

Results

The chemical composition of the investigated rail steels, conventionally designated as compositions 1 – 5, is presented in Table 1. Heating, rolling, and heat treatment of the rails were carried out under identical temperature – time processing conditions. For each nominal composition, several heats were selected and grouped, differing primarily in carbon, chromium, vanadium, and molybdenum contents. The contents of the remaining elements do not differ significantly between the heats, meet the requirements of GOST R 51685 – 2022, and are therefore not reported here.

Table 1. Chemical composition of the studied rails metal

| ||||||||||||||||||||||||||||||||||||||||||||||

The data show that all compositions meet the requirements of GOST R 51685 – 2022 with respect to carbon, chromium, and vanadium. Additional microalloying with molybdenum is permitted and is not regulated by the standard. A comparison of the chemical compositions indicates that composition 1 has the lowest carbon content, whereas composition 2 has the highest; compositions 3 – 5 fall in between. Vanadium contents are generally comparable, except for composition 5, where vanadium is lower by 0.04 – 0.06 % than in the other steels. The rail steels of compositions 4 and 5 contain more molybdenum, by approximately 0.012 and 0.004 %, respectively. Chromium is lowest in compositions 1 and 2; compositions 3 – 5 show slightly higher chromium levels, exceeding those of compositions 1 and 2 by 0.04 – 0.07 % on average.

It is well known [15; 16], that carbide-forming elements strongly affect the kinetics of austenite decomposition and, consequently, the shape of the isothermal transformation diagram. Specifically, the pearlitic and bainitic transformations become clearly separated, and an intermediate region with increased austenite stability appears. Studies [17 – 19] have shown that chromium alloying of pearlitic steels results in solid-solution strengthening of ferrite, chromium enrichment of cementite with formation of (Fe, Cr)3C, and possibly the formation of chromium carbides. In [20], the conditions for forming a pearlitic structure during rail heat strengthening were analyzed, and relationships were established between the total carbon and chromium content ((C + Cr), %), the pearlitic transformation temperature, and the interlamellar spacing of pearlite in the steels under consideration (Table 1). In addition, dependencies of strength and ductility on carbon and chromium contents were identified; the combined (C + Cr) content should exceed 1.2 %, which promotes a finer pearlitic structure and provides an optimal balance between strength and ductility. In the present steels, the combined carbon and chromium content is broadly similar and exceeds 1.2 %, except for composition 1 (1.17 %). This is consistent with the relatively high strength values obtained while retaining high ductility (Table 2).

Table 2. Mechanical properties and hardness

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mechanical testing showed that, in terms of tensile properties, impact toughness, and hardness measured on the running surface of the rail head, all investigated steels substantially exceed the standard requirements for hypereutectoid rails intended for DT370IK and DT400IK categories. Composition 3, in which carbon, chromium, and vanadium are increased simultaneously, exhibits the most favorable combination of strength, ductility, and impact toughness. At the same time, the running-surface hardness of the rail head in composition 3 is only slightly higher than that of composition 1, which contains the lowest levels of carbon and the above alloying elements. A threefold increase in molybdenum content in composition 4 is accompanied by a marked increase in impact toughness and by higher strength and ductility compared with the other steels. A reduction in the vanadium and molybdenum contents in experimental alloy 5 results in a pronounced decrease in impact toughness and ductility, while strength characteristics and hardness at the running surface of the finished rail head remain unchanged.

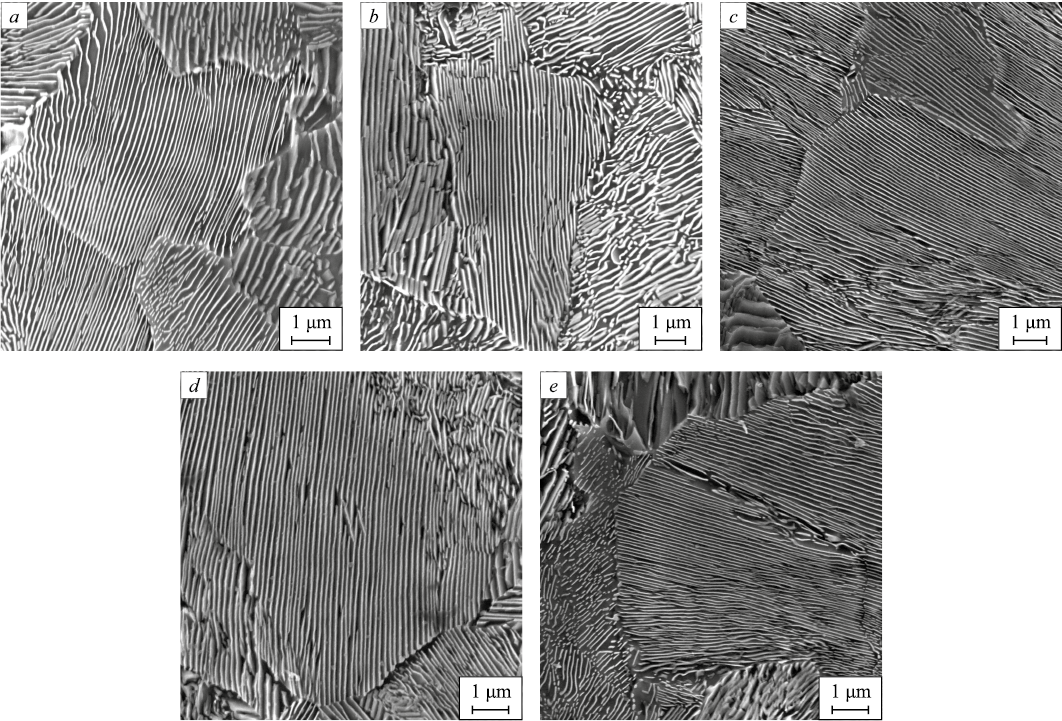

After rolling and differential heat treatment, the investigated rail steel exhibits a pearlitic microstructure, predominantly composed of pearlite lamellae with a regular morphology (Fig. 1).

Fig. 1. Microstructure of the studied rails metal of compositions 1 – 5 (а – д) |

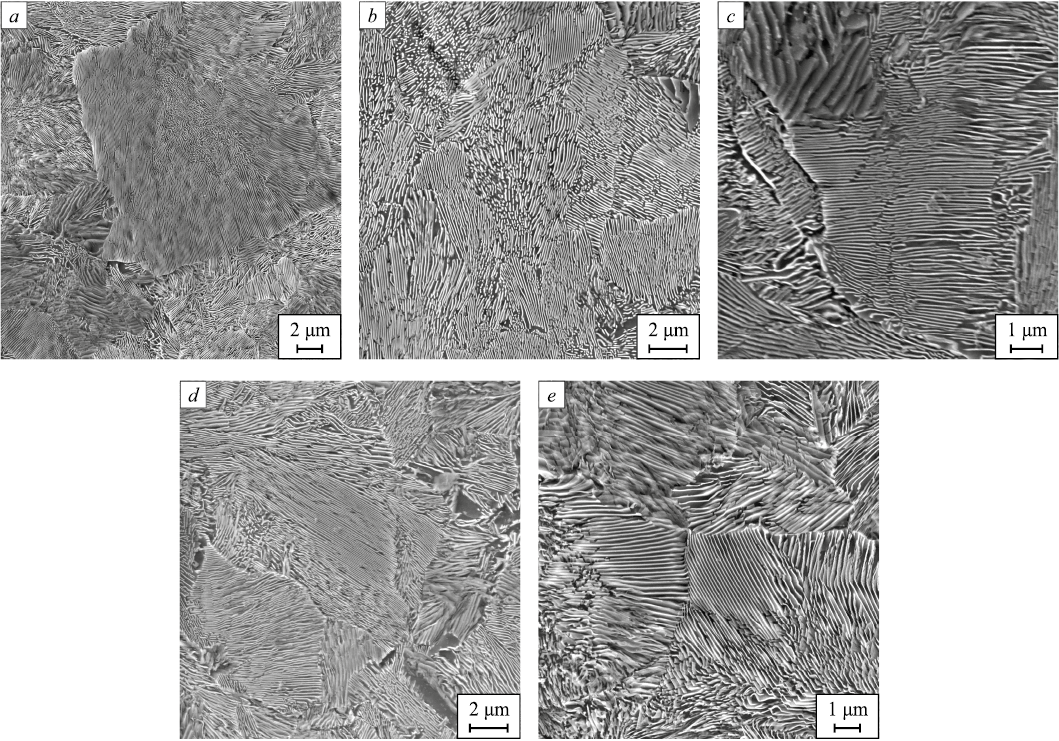

At the same time, a considerable number of deformed pearlite colonies with broken and “wavy” lamellae are observed, as well as regions characterized by interwoven pearlite colonies (Fig. 2).

Fig. 2. Microstructure of the studied rails metal of compositions 1 – 5 with deformable plates (а – д) |

As part of the quantitative analysis, key microstructural parameters – namely, the interlamellar spacing (pearlite dispersion) and grain diameter – were evaluated.

The results of the microstructural measurements, presented in Table 3, are given as arithmetic mean values with the corresponding standard deviations.

Table 3. Microstructure parameters

|

The data indicate that the average interlamellar spacing of pearlite and grain size measured in the rail steels of the investigated compositions are generally comparable. An exception is observed for compositions 1 and 2, in which the interlamellar spacing amounts to 0.116 and 0.112 µm, respectively, indicating comparatively lower strength levels. In contrast, the rail steel of composition 4 exhibits a significantly smaller average grain size – by approximately 3 – 5 µm – than the steels of the other investigated compositions (Table 3). The increased vanadium and molybdenum contents in composition 4 likely contributed to the enhancement of impact toughness as well as strength and ductility characteristics, which can generally be attributed to the grain growth – retarding effect of these elements during rail heat treatment [21].

Conclusions

A comparative analysis was carried out covering the chemical composition, strength and ductility characteristics, and quantitative microstructural parameters of railway rails produced from hypereutectoid 90KhAF steel for the five investigated compositions.

The most favorable combination of strength and ductility characteristics – based on tensile testing, impact bending tests, and hardness measured on the running surface of the rail head – was obtained for rails produced from experimental composition 4, which is characterized by slightly increased contents of the microalloying elements vanadium and molybdenum, by approximately 0.01 – 0.06 and 0.008 – 0.012 wt. %, respectively.

Quantitative evaluation of the microstructural parameters showed that the average interlamellar spacing of pearlite in the investigated samples remains at a comparable level. At the same time, the rail steel of composition 4 exhibits a finer-grained structure, with the grain diameter reduced by 3 – 5 µm. This finer grain structure, in combination with a dispersed pearlitic microstructure, contributed to achieving an optimal balance between strength and ductility in the investigated rails.

In service, a rail’s resistance to contact fatigue defects and other damage mechanisms is influenced by many factors. Understanding how the microstructure forms and how it should be matched to the required mechanical properties enables the design of rails tailored to specific track sections, improving in-service performance and extending service life.

References

1. Dobuzhskaya A.B., Galitsyn G.A., Mukhranov N.V., Fomichev M.S., Belokurova E.V., Belikov S.V. Structural and phase transformations in the cooling of rail steel. Steel in Translation. 2015;45(11):894-899. https://doi.org/10.3103/S0967091215110066

2. Polevoy E.V., Dobuzhskaya A.B., Temlyantsev M.V. Influence of speed of cooling on formation of structure of a rail steel microalloyed by vanadium and niobium. Bulletin of PNRPU. 2016;18(4):7–20. (In Russ.).

3. Singh A., Kesharwani Er.G.S., Mandal V., Ruhela A. Improvement of the mechanical properties of rail Thermit welds by heat treatment. International Railway Journal of Engineering and Technology. 2020;7(7):419–432.

4. Ivano G., Katsuya I. Technological and operational characteristics of rails with high carbon content. In: Improving the Quality and Conditions of Operation of Rails and Rail Fasteners: Proceedings. Yekaterinburg: UIM; 2012:72–81. (In Russ.).

5. Gray G.T., Thompson A.W., Williams J.C. Influence of microstructure on fatigue crack initiation in fully pearlitic steels. Metallurgical Transactions A. 1985;16(3):753–760. https://doi.org/10.1007/BF02814826

6. Masaharu U., Kenji M. Effects of carbon content and hardness on rolling contact fatigue resistance in heavily loaded pearlitic rail steels. Wear. 2020;444-445:203120. https://doi.org/10.1016/j.wear.2019.203120

7. Shur E.A. The influence of structure on the operational stability of rails. In: The Influence of the Properties of a Metal Matrix on the Operational Stability of Rails: Proceedings. Yekaterinburg: UIM; 2006:37–63. (In Russ.).

8. Pavlov V.V., Godik L.A., Korneva L.V., Kozyrev N.A., Gizatulin R.A. Production of wear-resistant rails. Izvestiya. Ferrous Metallurgy. 2007;50(10):35–37. (In Russ.).

9. Godefroid L.B., Souza A.T., Pinto M.A. Fracture toughness, fatigue crack resistance and wear resistance of two railroad steels. Journal of Materials Research and Technology. 2020;9(5):9588–9597. https://doi.org/10.1016/j.jmrt.2020.06.092

10. Ray A. Microalloying with niobium in rail steels. Materials Science and Technology. 2017;33(14):1584–1600. https://doi.org/10.1080/02670836.2017.1309111

11. Babachenko O.I., Kononenko H.A., Podolskyi R.V., Safronova O.A. Steel for railroad rails with improved operating properties. Materials Science. 2021;56(6):814–819. https://doi.org/10.1007/s11003-021-00499-1

12. Guo N., Liu Q., Xin Yu., Luan B., Zhou Z. The application of back-scattered electron imaging for characterization of pearlitic steels. Science China. Technological Sciences. 2011;54(9):2368–2372. https://doi.org/10.1007/s11431-011-4500-3

13. Polevoy E.V., Yunin Gh.N., Golovatenko A.V., Temliantsev M.V. Recent developments of rail steel products at the “West Siberian Iron & Steel Works”. Stal’. 2019;(7):55–58. (In Russ.).

14. Bessonova O.V., Polevoi E.V., Oskolkova T.N. Comparative analysis of the microstructure and properties of rails with various chemical compositions. Bulletin of the Siberian State Industrial University. 2023;(4(46)):46‒56. (In Russ.). http://doi.org/10.57070/2304-4497-2023-4(46)-46-56

15. Yur’ev A.A., Ivanov Yu.F., Gromov E.V., Musorina E.V., Rubannikova Yu.A. Redistribution of carbon in the structure of rail steel after long-term operation. Bulletin of the Siberian State Industrial University. 2017;(4):4–8.

16. Egorova L.Yu. Influence of perlite structural state on physico-mechanical and corrosion properties of high-carbon steels: Extended Abstract of Cand. Sci. Diss. Yekaterinburg: IFM UB RAS; 2014:23. (In Russ.).

17. Shur Ev.A., Bychkova N.Ya., Trushevsy S.M. Physical aspects of rolling contact fatigue of rail steels. Wear. 2005;258(7-8):1165–1171. http://dx.doi.org/10.1016/j.wear.2004.03.027

18. Ivanisenko Yu., Fecht H.J. Microstructure modification in the surface layers of rail-way rails and wheels: Effect of high strain rate deformation. Steel Tech. 2008;3(1):19–23.

19. Novozhilov I.S., Cherednikov V.A., Polevoj E.V., Rubtsov V.Yu., Ulegin K.A. Micro-alloying effect and hot deformation on austenite decay kinetics of rail steel. Roll Pass Design Bureau. 2022;(20):11–22. (In Russ.).

20. Dobuzhskaya A.B., Galitsyn G.A., Polevoy E.V., Bessonova O.V. Development of a methodology for estimating the interplate distance of perlite in rail steel. In: Improving the Quality and Operating Conditions of Rails and Rail Fasteners: Proceedings. Yekaterinburg: UIM; 2022:137–151. (In Russ.).

21. Gol’dstein M.I., Farber V.M. Dispersion Hardening of Steel. Moscow: Metallurgiya; 1979:208. (In Russ.).

About the Authors

O. V. BessonovaRussian Federation

Olga V. Bessonova, Chief Specialist in Electron Microscopy and Research

16 Kosmicheskoe Route, Novokuznetsk, Kemerovo Region – Kuzbass 654043, Russian Federation

E. V. Polevoi

Russian Federation

Egor V. Polevoi, Cand. Sci. (Eng.), Head of the Research Department

16 Kosmicheskoe Route, Novokuznetsk, Kemerovo Region – Kuzbass 654043, Russian Federation

T. N. Oskolkova

Russian Federation

Tat’yana N. Oskolkova, Dr. Sci. (Eng.), Prof. of the Chair of Ferrous Metallurgy and Chemical Technology

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

T. A. Komarova

Russian Federation

Tat’yana A. Komarova, Chief Specialist

16 Kosmicheskoe Route, Novokuznetsk, Kemerovo Region – Kuzbass 654043, Russian Federation

Review

For citations:

Bessonova O.V., Polevoi E.V., Oskolkova T.N., Komarova T.A. Comparative analysis of the structure and properties of hypereutectoid railway rails. Izvestiya. Ferrous Metallurgy. 2025;68(6):556-562. https://doi.org/10.17073/0368-0797-2025-6-556-562