Scroll to:

Dependence of structure and properties of VT23 alloy on laser deposition parameters

https://doi.org/10.17073/0368-0797-2025-5-482-487

Abstract

The study analyzes the effect of laser power and velocity on the structural phase state and properties of complex-alloyed titanium alloy VT23 (Ti–Al–V–Mo–Cr–Fe) obtained by direct laser deposition. VT23 titanium alloy has a unique combination of strength, corrosion resistance, and biocompatibility, which makes it in demand in the aerospace and medical industries. However, traditional manufacturing methods (casting, stamping) often fail to provide the required accuracy and quality of complex parts. In this work, X-ray phase analysis and optical metallography revealed that the deposited samples consist of α- and β-phases (~20 % β-phase) with a typical “basket weave” structure. In macrostructure of the obtained samples, thermal bands and interlayer boundaries were recorded, the formation of which is associated with the peculiarities of crystallization process during direct laser deposition. The results of optical metallography showed that microstructure of the deposited material combines large columnar crystals in the overlap areas of two adjacent layers, as well as small equiaxed grains. Despite this distribution of structural components, the microhardness (~488 HV0.2 ) remains homogeneous throughout the deposited samples in both the laser scanning and sample deposition directions. The results confirm that direct laser deposition can be used to produce VT23 titanium alloy parts with a controlled microstructure. Optimization of the process parameters of direct laser deposition minimizes the probability of defect formation and provides stable mechanical properties, which opens prospects for application of the technology in the production of critical parts.

Keywords

For citations:

Safarova D.E., Bazaleeva K.O., Ponkratova Yu.Yu., Alekseev A.V. Dependence of structure and properties of VT23 alloy on laser deposition parameters. Izvestiya. Ferrous Metallurgy. 2025;68(5):482-487. https://doi.org/10.17073/0368-0797-2025-5-482-487

Introduction

Titanium alloys are widely known for their exceptional combination of high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, which makes them indispensable in aerospace, biomedical, and high-performance engineering applications [1 – 6]. Among these alloys, VT23 (Ti – Al – V – Mo – Cr – Fe) is particularly valued for its superior thermal stability, creep resistance, and weldability – properties that are critically important for aerospace components such as airframe structures, engine parts, and rocket housings [2 – 3]. Moreover, its biocompatibility and mechanical compatibility with human bone have promoted its use in medical implants, including orthopedic and dental prostheses [4 – 6]. However, traditional manufacturing methods such as casting and stamping often face challenges associated with the high reactivity, low thermal conductivity, and significant deformation resistance of titanium alloys, which complicate the production of complex geometries free of defects [4].

Additive manufacturing (AM) has emerged as a transformative approach to overcoming these limitations, with direct laser deposition (DLD) – one of the most promising directed energy deposition (DED) technologies – attracting particular attention. DLD offers unprecedented advantages such as near-net-shape fabrication, minimal material waste, and the ability to produce complex geometries that are difficult or even impossible to achieve by conventional means. Unlike powder bed fusion technologies such as selective laser melting (SLM), DLD enables the fabrication of large-scale parts, in-situ alloying, and hybrid manufacturing (e.g., repair or coating of existing components). However, the unique thermal cycles and rapid solidification inherent to DLD can lead to microstructural heterogeneity, residual stresses, and anisotropic mechanical properties that must be carefully managed to ensure optimal performance [4 – 10].

A critical issue in DLD of titanium alloys is the formation of large columnar grains and strong crystallographic textures along the build direction, which can adversely affect ductility and fatigue strength [4 – 15]. Furthermore, improper selection of process parameters may result in process-induced defects such as porosity, unmelted particles, and thermal cracking. Recent studies on similar titanium alloys (e.g., Ti–6Al–4V and TA15) produced by DLD have shown that laser power, scanning velocity, hatch spacing, and layer thickness have a pronounce [4 – 7; 9 – 10]. For instance, excessive energy input may cause porosity formation, while insufficient energy leads to lack of fusion. In addition, high cooling rates typical of DLD often promote the formation of acicular α′-martensite, which increases strength but reduces ductility compared with conventional α + β microstructures [4 – 7].

Considering these issues, the main objective of the present study is to systematically investigate the effect of direct laser deposition process parameters – including laser power, scanning velocity, and hatch spacing – on the microstructural evolution, phase composition, and mechanical properties of the VT23 alloy. By correlating the process–structure–property relationship, this study aims to establish optimized DLD parameters that minimize defects while achieving a balanced combination of strength and ductility.

Materials and methods

In this work, VT23 titanium alloy samples were fabricated by direct laser deposition (DLD). The chemical composition of the alloy is presented in the Table.

Chemical composition of VT23 powder

| |||||||||||||||||||||||||||||||||

Wall samples measuring 50×90×90 mm were fabricated by DLD method on a VT1-0 titanium alloy substrate. Deposition parameters were as follows: laser power of 1000 and 1100 W; scanning velocity of 1 m/min; and overlap between adjacent tracks equal to 0.7 of the track width.

Favorable process parameters were first screened on single tracks and then on monolayers.

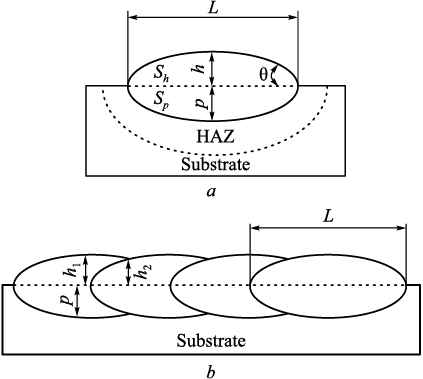

Fig. 1. Scheme of shapes: |

The quality of a single track was evaluated according to the following criteria:

– track shape factor f (f = h/L, where h is the bead height above the substrate; L is the single track width, Fig. 1, a)) should be within the range [0.20; 0.33];

– penetration coefficient d should be within the range [0.1; 0.4]

\[d = \frac{{{S_p}}}{{{S_p} + {S_h}}},\]

where Sp and Sh are the bead areas below and above the substrate surface, respectively;

– track width L should be within 1.7 – 3.0 mm for a laser spot diameter of 1.8 mm;

– base angle of the bead θ should be less than 90° [11 – 17].

Another important quality criterion was the absence of cracks.

The parameters of the monolayers had to satisfy the following conditions:

– height variation of the monolayer (h2 /h1 ) did not exceed 30 % of its maximum height;

– penetration depth was less than two-thirds of the layer height (Fig. 1, b) [12; 17].

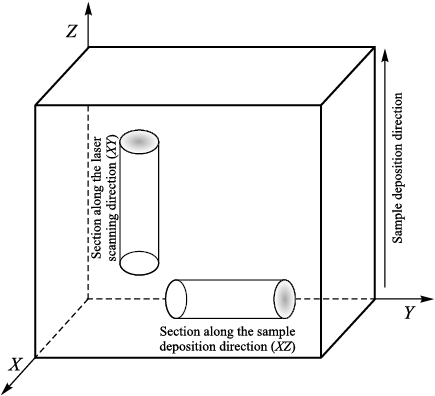

To study the structure, two sections were examined – along the deposition direction (XZ), and – along the laser scanning direction (XY) (Fig. 2).

Fig. 2. Sample cutting scheme |

Metallographic studies were performed on microsections prepared using standard procedures: grinding on abrasive paper and polishing with diamond suspensions (down to 1 µm). Etching to reveal structural features was carried out in a solution containing 3 mL HF, 15 mL HNO3 , and 82 mL H2O.

Structural examinations were conducted using an Olympus GX-51 inverted optical microscope at magnifications ranging from 50 to 500×.

For the analysis of the phase composition, samples were prepared for X-ray diffraction analysis. The preparation included grinding and electrolytic polishing using a Struers LectroPol-5 unit in A2 electrolyte (78 mL HClO4 , 90 mL distilled water, 730 mL C2H6O, 100 mL C6H14O2 ) for 15 min at 10 V.

X-ray diffraction patterns were obtained on a Bruker D8 Advance diffractometer with Bragg–Brentano focusing geometry, using CuKα radiation over a 2θ range of 30–100° with a step size Δ2θ = 0.07° and an exposure time of 2 s per point. The tube voltage and current were 40 kV and 35 mA, respectively. A semiconductor multichannel detector and the following slit system were used: a 2 mm divergence slit on the tube, and Soller slits (2.5 mm plate spacing) on both the tube and detector sides. During data acquisition, the samples were rotated at 60 rpm. The diffraction spectra were processed using Diffrac.Eva and Diffrac.Topas software packages.

Microhardness of the material was measured using a Pruftechnik KB50 SR microhardness tester by the recovered-imprint method under a 200 g (1.9 N) load.

Results and discussion

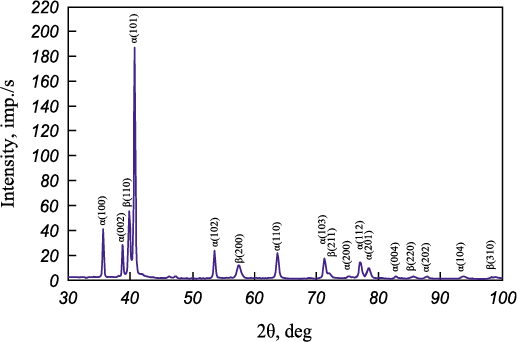

X-ray diffraction analysis revealed that the deposited material consists of the characteristic α- and β-phases, with HCP and BCC lattices, respectively (Fig. 3). Since the diffraction peaks of α′-martensite coincide with those of the α-phase, its presence in the structure cannot be unambiguously confirmed from the diffraction pattern. The amount of β-phase was found to be approximately 20 %.

Fig. 3. X-ray pattern of VT23 alloy obtained by direct laser deposition |

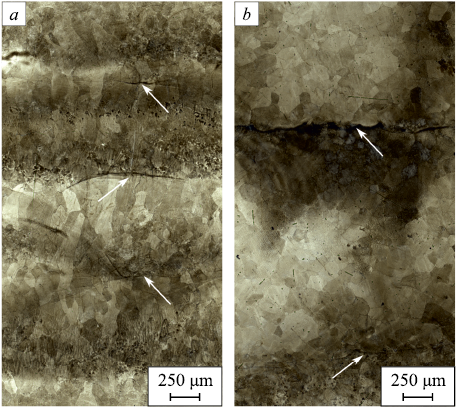

Optical metallography of the bulk samples revealed no macroscopic defects. After direct laser deposition, the α-phase appears as regions of basket-weave morphology and as a network along the boundaries of primary β-grains – features typical of this alloy both in the quenched state and after deposition [1 – 3; 8; 18 – 20]. In the scanning plane, large (~100 µm) equiaxed regions of primary β were observed.

Fig. 4 shows two types of bands distinguished by their etching contrast. According to the literature, the wide dark regions correspond to thermal-affected bands, while the narrow lines indicated by arrows are interlayer bands [18 – 20]. The thermally affected bands form in overlap zones of adjacent layers, where repeated thermal exposure during successive passes induces reheating and recrystallization, producing the observed etching contrast. The interlayer bands are regularly spaced and trace the boundaries of individual melt pools.

Fig. 4. Microstructure of VT23 alloy after direct laser deposition: |

As noted in [19], the formation of interlayer bands depends on the degree of alloying and the rate of diffusion processes in titanium alloys.

The grain morphology of the obtained material also deserves attention. During deposition, non-uniform nucleation occurs on partially melted powder particles within the melt pool, resulting in the formation of fine equiaxed grains. Subsequently, epitaxial growth develops: grains grow from the bottom of the melt pool, inheriting the structure of the underlying layer, which produces large columnar grains. The final grain morphology is therefore determined by the competition between these two mechanisms [20].

Structural examinations revealed heterogeneity in the size of structural constituents, as the material consists of a combination of large columnar and small equiaxed grains. This heterogeneity might suggest a non-uniform distribution of microhardness throughout the volume. However, the measurements showed that the microhardness of the deposited material is homogeneous throughout the deposited samples.

Additionally, the microhardness of the VT23 titanium alloy produced by direct laser deposition varied slightly with build direction and averaged 485 ± 5 HV0.2 along the laser scanning direction (XY) and 490 ± 20 HV0.2 along the sample deposition direction (XZ).

Conclusions

The direct laser deposition (DLD) technology enables the fabrication of defect-free VT23 titanium alloy samples.

X-ray diffraction analysis confirmed that the deposited alloy consists of α- and β-phases; however, differentiation between the α- and α′-phases is difficult due to the similarity of their crystal lattices.

The structure of the obtained alloy exhibits regions of different etching contrast, which most likely indicates recrystallization during deposition. The microstructure is represented by a basket-weave arrangement composed of randomly oriented α-phase plates.

The average microhardness of the material does not vary from the substrate to the top surface and remains at approximately 488 ± 10 HV0.2 both along the laser scanning direction and along the sample deposition direction.

References

1. Belov S.P., Brun M.Ya., Glazunov S.G., Kolachev B.A. Metallurgy of Titanium and Its Alloys. Moscow: Metallurgiya; 1992:352 p. (In Russ.).

2. Khorev A.I. Complex Alloying and Thermomechanical Processing of Titanium Alloys. Moscow: Mashinostroenie; 1979:228. (In Russ.).

3. Khorev A.I. Theory of alloying and heat treatment of high and ultra-high strength (α+β)-titanium alloys. Vestnik mashinostroeniya. 2010;(7):32–39. (In Russ.).

4. Jiang J., Liang C., Chen Y., Wang Y., Cui H., Xu J., Zhang D.Z. The influence of process parameters on the density, microstructure, and mechanical properties of TA15 titanium alloy fabricated by selective laser melting. Metals. 2025;15(3):233. https://doi.org/10.3390/met15030233

5. Fang Y., Dai G., Guo Y., Sun Z., Liu H., Yuan Q. Effect of laser oscillation on the microstructure and mechanical properties of laser melting deposition titanium alloys. Acta Metallurgica Sinica. 2022;59(1):136–146. https://doi.org/10.11900/0412.1961.2021.00600

6. Liu Z., He B., Lyu T., Zou Y. A review on additive manufacturing of titanium alloys for aerospace applications: Directed energy deposition and beyond Ti-6Al-4V. JOM. 2021;73:1804–1818. https://doi.org/10.1007/s11837-021-04670-6

7. Zhu Y., Tian X., Li J., Wang H. Microstructure evolution and layer bands of laser melting deposition Ti–6.5 Al–3.5 Mo–1.5 Zr–0.3 Si titanium alloy. Journal of Alloys and Compounds. 2014;616:468–474. https://doi.org/10.1016/j.jallcom.2014.07.161

8. Gladkovskii S.V., Veselova V.E., Patselov A.M., Khotinov V.A. The influence of deformation stability of β-phase in titanium alloy BT23 on the phase composition, microstructure, and mechanical properties after tension and impact test. Vestnik Permskogo natsional’nogo issledovatel’skogo politekhnicheskogo universiteta. Mashinostroenie, materialovedenie. 2019;21(4):26–33. (In Russ.). https://doi.org/10.15593/2224-9877/2019.4.03

9. Dang L., He X., Tang D., Wu B., Li Y. A fatigue life posterior analysis approach for laser-directed energy deposition Ti-6Al-4V alloy based on pore-induced failures by kernel ridge. Engineering Fracture Mechanics. 2023;289:109433. https://doi.org/10.1016/j.engfracmech.2023.109433

10. Ravi G.A., Qiu C., Attallah M.M. Microstructural control in a Ti-based alloy by changing laser processing mode and power during direct laser deposition. Materials Letters. 2016;179:104–108. https://doi.org/10.1016/j.matlet.2016.05.038

11. OST 1-90013–81. Industry Standard. Titanium Alloys. Grades. Moscow: VIAM; 1981:7. (In Russ.).

12. Grigor’yants A.G., Misyurov A.I., Tret’yakov R.S. Analysis of the influence of coaxial laser cladding parameters on bead formation. Tekhnologiya mashinostroeniya. 2011;(11): 19–21. (In Russ.).

13. Gibson I., Rosen D., Stucker B., Khorasani M. Additive Manufacturing Technologies. Cham, Switzerland: Springer; 2021;675. https://doi.org/10.1007/978-3-030-56127-7

14. Lewandowski J.J., Seifi M. Metal additive manufacturing: A review of mechanical properties. Annual Review of Materials Research. 2016;46:151–186. https://doi.org/10.1146/annurev-matsci-070115-032024

15. De Oliveira U., Ocelik V., De Hosson J.T.M. Analysis of coaxial laser cladding processing conditions. Surface and Coatings Technology. 2005;197(2–3):127–136. https://doi.org/10.1016/j.surfcoat.2004.06.029

16. Harooni A., Nasiri A.M., Gerlich A.P., Khajepour A., Khalifa A., King J.M. Processing window development for laser cladding of zirconium on zirconium alloy. Journal of Materials Processing Technology. 2016;230:263–271. https://doi.org/10.1016/j.jmatprotec.2015.11.028

17. Bazaleeva K.O., Tsvetkova E.V., Safarova D.E., Ponkratova Yu.Yu., Lugovoi M.E., Alekseev A.V., Baskov F.A. The influence of technological parameters of the laser engineered net shaping process on the quality of the formed object from titanium alloy VT23. Obrabotka metallov: tekhnologiya, oborudovanie, instrumenty. 2024;26(2):186–198. (In Russ.). https://doi.org/10.17212/1994-6309-2024-26.2-186-198

18. Shvetsov O.V., Kondrat’ev S.Yu. Effect of quenching and aging modes on the performance properties of the VT23 alloy. Global’naya energiya. 2018;24(2):119–133. (In Russ.). https://doi.org/10.18721/JEST.240210

19. He B., Li J., Cheng X., Wang H.M. Brittle fracture behavior of a laser additive manufactured near-β titanium alloy after low temperature aging. Materials Science and Engineering: A. 2017;699:229–238. https://doi.org/10.1016/j.msea.2017.05.050

20. Wang T., Zhu Y.Y., Zhang S.Q., Tang H.B., Wang H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. Journal of Alloys and Compounds. 2015;632:505–513. https://doi.org/10.1016/j.jallcom.2015.01.256

About the Authors

D. E. SafarovaRussian Federation

Daria E. Safarova, Junior Researcher, Postgraduate of the Chair of Engineering Technology

6 Miklukho-Maklaya Str., Moscow 117198, Russian Federation

K. O. Bazaleeva

Russian Federation

Kseniya O. Bazaleeva, Cand. Sci. (Phys.-Math.), Deputy Director of Additive and Edge Technologies Centre

6 Miklukho-Maklaya Str., Moscow 117198, Russian Federation

Yu. Yu. Ponkratova

Russian Federation

Yuliya Yu. Ponkratova, Research Associate

6 Miklukho-Maklaya Str., Moscow 117198, Russian Federation

A. V. Alekseev

Russian Federation

Andrei V. Alekseev, Engineer-Technologist of Additive and Edge Technologies Centre

6 Miklukho-Maklaya Str., Moscow 117198, Russian Federation

Review

For citations:

Safarova D.E., Bazaleeva K.O., Ponkratova Yu.Yu., Alekseev A.V. Dependence of structure and properties of VT23 alloy on laser deposition parameters. Izvestiya. Ferrous Metallurgy. 2025;68(5):482-487. https://doi.org/10.17073/0368-0797-2025-5-482-487