Scroll to:

Comparative analysis of kinetic and diffusion modes of natural gas combustion in EAF burners

https://doi.org/10.17073/0368-0797-2025-5-454-460

Abstract

In modern electric arc furnaces (EAF), charge heating by natural gas (NG) combustion products with process oxygen is widely used to reduce the power consumption and intensify the thermal performance. In existing EAF burners, gas and oxygen are supplied separately through oxygen gas and refining burners, which ensures the diffusion combustion mode. The diffusion mode in conditions of EAF working space has a number of disadvantages, such as non-optimal distribution of temperature and concentration fields of combustion products, increased burn-off of iron-containing components of the charge. This paper presents the results of a computational study of the physico-chemical properties of combustion products along the torch length for the burners of VAI FUCHS, SMS DEMAG and NTPF Etalon Ltd. companies at oxygen concentration in the oxidizer of 95 wt. %. The results of computer modeling of temperature fields in the torches were analyzed in order to assess the risk of flame “slip” into the burner internal volume. The authors carried out a comparative study of the characteristics of torches in the burner devices with diffusion and kinetic combustion modes. Based on the data obtained, a transition from the diffusion mode of natural gas combustion to the kinetic mode is proposed, which can increase the energy efficiency of using burners, uniformity of temperature and concentration fields of combustion products, and reduce carbon monoxide of the iron-containing charge. The study was performed using computer modeling in ANSYS software package in CFX module. The obtained results can be useful for optimizing thermal processes in EAF working space, reducing power consumption and preventing emergency operation of burners.

Keywords

For citations:

Glukhov I.V., Voronov G.V., Sheshukov O.Yu., Kalganov M.V. Comparative analysis of kinetic and diffusion modes of natural gas combustion in EAF burners. Izvestiya. Ferrous Metallurgy. 2025;68(5):454-460. https://doi.org/10.17073/0368-0797-2025-5-454-460

Introduction

Diffusion combustion of natural gas with process oxygen examined under conditions where the gas mixture forms in the free volume of the furnace, outside the burner [1 – 3]. In the diffusion combustion mode, gas and oxidizer are supplied separately until they meet at the interface between the gas and oxidizer streams. Due to molecular diffusion, a mixture is formed that is characteristic of a laminar diffusion flame at low flow velocities, or a molar diffusion process promoting large-scale turbulence typical of a turbulent diffusion flame. The gas–oxidizer mixture is partially formed both before ignition and during combustion, which complicates analysis of this process. The temperature, composition of combustion products, and their physical and thermophysical properties in the combustion zone – separated by the flame front from the initial mixture – affect both the primary stage of mixing and the rate of chemical reactions.

Temperature in the diffusion flame zone corresponds to the combustion temperature of a stoichiometric premixed mixture, provided that the thermal diffusivity coefficient equals the mutual diffusion coefficient of the gas and oxidizer and that heat losses to the surroundings are negligible. The fundamental principles of diffusion combustion theory were developed and published in [4 – 6]. In operating fuel-fired furnaces, taking into account their design features, technological processes, and thermal conditions, it is advisable to implement the kinetic combustion mode of natural gas with oxygen, which involves preparing a well-mixed premixed gas–oxygen mixture [7 – 10]. In this case, the mixture-formation stage is effectively excluded from the sequence of physicochemical processes. Heating and melting of the initial materials occur primarily through heat and mass transfer from the combustion products, with no unburned hydrocarbons remaining in the gas phase [11 – 14].

Thus, the aim of this study is to carry out a comparative analysis of kinetic and diffusion combustion modes of natural gas with an oxygen–air mixture (OAM) in EAF burners, based on computer modeling of temperature fields and CO/H2 concentrations.

Objectives:

To compare the torch characteristics of the VG burner (kinetic mode) and its analogues (VAI FUCHS, SMS DEMAG, and NTPF Etalon) during combustion of natural gas with oxygen and to evaluate the influence of combustion modes on.

– distribution of the temperature fields;

– the maximum concentrations of CO and H2 .

Materials and methods

A comparative study was carried out to analyze the torch characteristics during natural gas combustion with an oxygen–air mixture (OAM) in burners of various designs. The investigation included:

– diffusion burners used in modern electric arc furnaces (EAFs) manufactured by NTPF Etalon, SMS DEMAG, and VAI FUCHS;

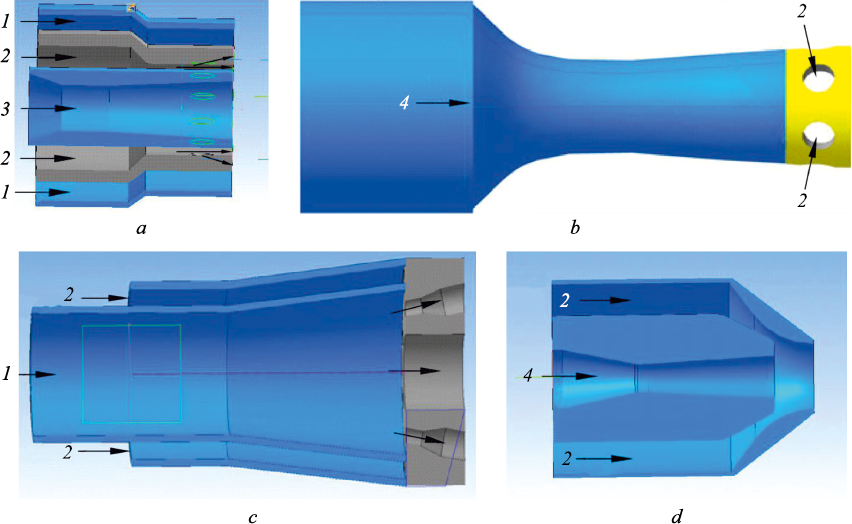

– the VG burner, a promising design operating in the kinetic combustion mode, which ensures preliminary mixing of the components in the diffuser (Fig. 1).

Fig. 1. Schemes of gas-oxygen burners designs: |

Experimental studies of combustion require significant time and financial resources for developing test procedures and using specialized measuring equipment. In contrast, computer modeling makes it possible to optimize burner design without manufacturing intermediate prototypes and to quickly analyze how design parameters and operating modes affect torch formation and its characteristics. Computer modeling greatly shortens development time and provides a reliable basis for evaluating the efficiency of various design modifications and technical solutions [15 – 17].

Combustion modeling was performed in the ANSYS software package (CFX module) using the following models and settings:

– extended Coherent Flamelet Model (ECFM);

– Total Energy heat transfer model;

– k–ε turbulence model.

Boundary conditions for the burners were as follows:

– oxygen flow rate: 0.553 kg/s (95 wt. %);

– natural gas flow rate: 0.092 kg/s (the natural gas composition was normalized to an equivalent methane concentration of 100 wt. %).

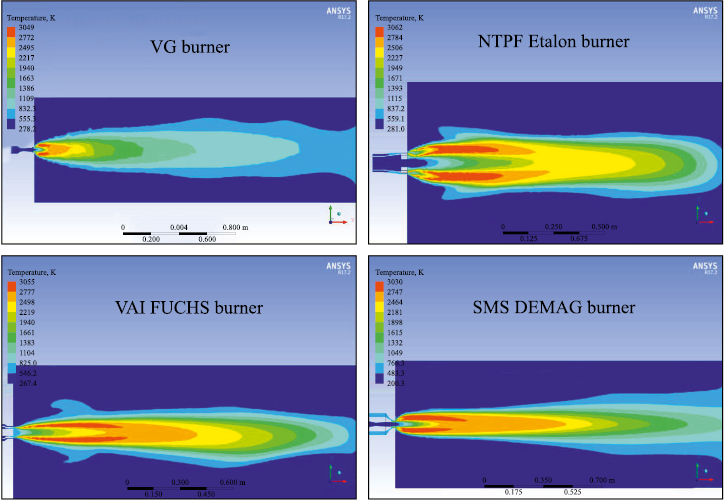

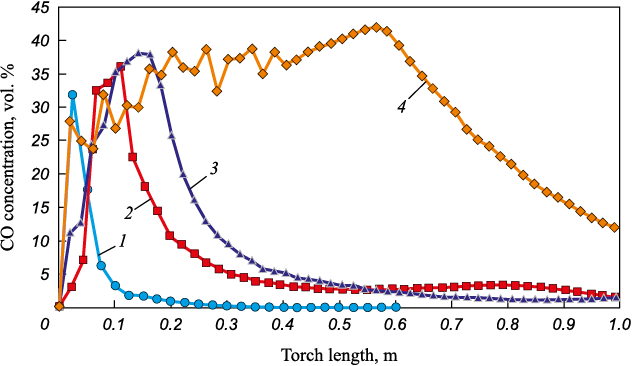

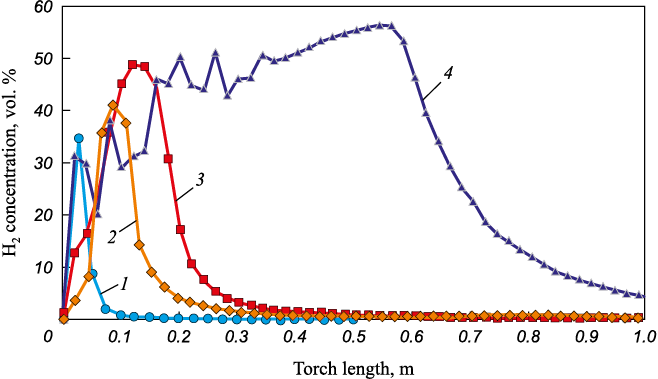

The variation of temperature (Т, K) and the maximum CO and H2 concentrations in the cross-section of combustion products along the torch length were determined (Figs. 2 – 4).

Fig. 2. Temperature fields of combustion products of the burner when burning natural gas

Fig. 3. Change in the maximum concentration of CO in cross-section of combustion products

Fig. 4. Change in the maximum concentration of hydrogen in cross-section of combustion |

As a result, comparative performance characteristics were obtained for burners with kinetic and diffusion combustion modes: the VG burner (kinetic mode) and the diffusion burners of NTPF Etalon, VAI FUCHS, and SMS DEMAG, operating at equal natural gas and oxygen flow rates.

Based on the analysis of the results, zones of intensive combustion were identified, corresponding to regions of minimal CH4 concentration and maximum temperature:

– for the NTPF Etalon burner – at a torch length of about 500 mm;

– for the VG burner – at a torch length of 100 – 200 mm;

– for the SMS DEMAG burner – at a torch length of about 500 mm;

– for the VAI FUCHS burner – at a torch length of over 1000 mm.

Afterburning regions can be diagnosed by elevated CO and H2 . The VG burner showed the lowest maxima – 32 vol. % CO and 35 vol. % H2 – whereas diffusion burners exhibited 36 – 42 vol. % CO and 41 – 56 vol. % H2 . These reductions (by 4 – 12 vol. % for CO and 6 – 14 vol. % for H2 ) indicate more complete and uniform natural-gas combustion in the kinetic combustion mode than in diffusion systems.

The criterion for the absence of flame-slip risk was taken to be the absence of regions with temperatures above 800 °C inside the burner’s internal cavity. No such high-temperature zones were detected for any of the burners examined. The maximum temperature of the combustion products in the torch ranged from 2757 to 2792 °C, while, at the same time, the gas-dynamic velocity in local flow regions varied widely – from 250 to 750 m/s (see Table). It should be noted that the temperature of the combustion products in the VG burner torch (2776 °C) corresponds to a gas-dynamic flow velocity 1.15 – 3.75 times higher than that of burners operating in the diffusion combustion mode [18; 19].

Performance indicators of the burners

|

The optimal efficiency of the VG burner under EAF operating conditions can also be achieved by maintaining the proper vertical distance from the molten bath surface (bath level), the angle of inclination in the vertical plane, and the tangential direction of combustion product flow in the horizontal plane [15; 20]. This configuration enables the most efficient utilization of the thermal energy of the combustion products for rapid and uniform heating of the charge, which enhances the steelmaking intensity, reduces power consumption, and increases overall productivity.

Conclusions

This study shows that the VG burner, operating in the kinetic combustion mode, outperforms diffusion burners. It provides complete, rapid combustion of hydrocarbons in the premixed stream and prevents flame slip into the burner internal volume.

The results support the adoption of kinetic-type burners in modern steelmaking operations.

References

1. Belkovskii A.G., Kats Ya.L., Krasnyanskii M.V. Current state and development trends of steel production technology in EAF and their designs. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2013;(3): 72–78. (In Russ.).

2. Ryabov A.B., Chumanov I.V., Shishimirov M.V. Modern Methods of Steel Smelting in Electric Arc Furnaces: Tutorial. Moscow: Teplotekhnik; 2007:192. (In Russ.).

3. Voronov G.V., Glukhov I.V. Thermal and physical properties of methane family hydrocarbon and oxygen combustion products in state-of-the-art arc steel furnace. IOP Conference Series: Materials Science and Engineering. 2020;969(1):012043. https://doi.org/10.1088/1757-899X/969/1/012043

4. Zel’dovich Ya.B. Theory of Combustion and Detonation of Gases. Moscow; Leningrad: USSR Academy of Sciences; 1944:71. (In Russ.).

5. Shchetinkov E.S. Physics of Gas Combustion. Moscow: Nauka; 1965:739. (In Russ.).

6. Zel’dovich Ya.B., Barenblatt G.I., Librovich V.B., Makhviladze G.M. Mathematical Theory of Combustion and Explosion. Moscow: Nauka; 1980:479. (In Russ.).

7. Abel M., Hein M. The SIMETAL ultimate at Colakoglu, Turkey. Iron and Steel Technology. 2009;6(2):56–64.

8. Rathaba P.L., Craig I.K., Pistorius P.C. Influence of oxyfuel burner subsystem on the EAF process. IFAC Proceedings Volumes. 2004;37(15):215–220. https://doi.org/10.1016/S1474-6670(17)31026-1

9. Abel M., Knapp H., Moxon P., Cooke R. Oxygen-injection technology using Fuchs RCB burner in an EAF. Millennium Steel. 2004;(28):28–30.

10. Gottardi R., Miani S., Partyka A. Decarburization efficiency in EAF with hot metal charge. Iron & Steel Technology. 2012;(1):61–69.

11. Voronov G.V., Glukhov I.V. Natural gas burning with process oxygen in up-to-date arc steel furnace operating space. In: Proceedings of the 7th Int. Conf. on Industrial Engineering (ICIE 2021). 2022;358–365. https://doi.org/10.1007/978-3-030-85233-7_43

12. Gottardi R., Engin B., Miani S. Single EAF and single billet caster for 320 t/h productivity. SEAISI Quarterly Journal. 2009;2:13–22.

13. Kopfle J. EAF metallics. In: 5th Steel Scrap Conf., November 9–10, Chicago, 2011. 2011:271–282.

14. Kirschen M., Risonarta V., Pfeifer H. Energy efficiency and the influence of gas burners to the energy related carbon dioxide emissions of electric arc furnaces in steel industry. Energy. 2009;34(9):1065–1072. https://doi.org/10.1016/j.energy.2009.04.015

15. Sung Y., Lee S., Han K., Koo J., Lee S., Jang D., Oh C., Jang B. Improvement of energy efficiency and productivity in an electric arc furnace through the modification of side-wall injector systems. Processes. 2020;8(10):1202. https://doi.org/10.3390/pr8101202

16. Kovačič M., Stopar K., Vertnik R., Šarler B. Comprehensive electric arc furnace electric energy consumption modeling: A pilot study. Energies. 2019;12(11):2142. https://doi.org/10.3390/en12112142

17. Brhel J., Farmer C., Shver V. The JetBOxTM burner injector system for EAF steelmaking. Millennium Steel. 2006;87–97.

18. Voronov G.V., Glukhov I.V. Physicochemical properties of natural gas and oxygen combustion products at diffusion and kinetic burning. In: Proceedings of the 7th Int. Conf. on Industrial Engineering (ICIE 2021). 2022;318–324. https://doi.org/10.1007/978-3-030-85233-7_38

19. Voronov G.V., Antropov M.V., Glukhov I.V. Gas dynamics in the working space of a modern electric-arc steelmaking furnace. Refractories and Industrial Ceramics. 2015;55(6): 498–500. https://doi.org/10.1007/s11148-015-9752-1

20. Vintovkin A.A., Ladygichev M.G., Gusovskii V.L., Kapinova T.V. Burner Devices of Industrial Furnaces and Combustion Chambers (Designs and Technical Characteristics): Reference Book. Moscow: Teplotekhnik; 2008:553. (In Russ.).

About the Authors

I. V. GlukhovRussian Federation

Il’ya V. Glukhov, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Thermal Physics and Informatics in Metallurgy”, Ural Federal University named after the first President of Russia B.N. Yeltsin; Chief Specialist of the Technology Bureau, OJSC “Scientific Research Institute of Metallurgical Heat Engineering”

19 Mira Str., Yekaterinburg 620002, Russian Federation

16 Studencheskaya Str., Yekaterinburg 620137, Russian Federation

G. V. Voronov

Russian Federation

German V. Voronov, Dr. Sci. (Eng.), Prof. of the Chair “Thermal Physics and Informatics in Metallurgy”

19 Mira Str., Yekaterinburg 620002, Russian Federation

O. Yu. Sheshukov

Russian Federation

Oleg Yu. Sheshukov, Dr. Sci. (Eng.), Prof., Director of the Institute of New Materials and Technologies, Ural Federal University named after the first President of Russia B.N. Yeltsin; Chief Researcher of the Laboratory of Powder, Composite and Nano-Materials, Vatolin Institute of Metallurgy of the Ural Branch of the Russian Academy of Sciences

19 Mira Str., Yekaterinburg 620002, Russian Federation

101 Amundsena Str., Yekaterinburg 620016, Russian Federation

M. V. Kalganov

Russian Federation

Mikhail V. Kalganov, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Thermophysics and Informatics in Metallurgy”, Ural Federal University named after the first President of Russia B.N. Yeltsin; Head of the TLC “Special Purpose Draft Devices”, OJSC “Scientific Research Institute of Metallurgical Heat Engineering”

19 Mira Str., Yekaterinburg 620002, Russian Federation

16 Studencheskaya Str., Yekaterinburg 620137, Russian Federation

Review

For citations:

Glukhov I.V., Voronov G.V., Sheshukov O.Yu., Kalganov M.V. Comparative analysis of kinetic and diffusion modes of natural gas combustion in EAF burners. Izvestiya. Ferrous Metallurgy. 2025;68(5):454-460. https://doi.org/10.17073/0368-0797-2025-5-454-460