Scroll to:

Modeling the operation of ferroalloy furnace with increased power and electrode diameters

https://doi.org/10.17073/0368-0797-2025-4-339-341

Abstract

Using an electrolytic model, the authors investigated the operation of a ferroalloy furnace with increased electrode diameters and power. A traditional aqueous solution with a concentration of 0.2 % NaCl was used as the working fluid. Diameter of the electrodes was increased from 30 to 150 mm. The parameters of furnaces with a capacity from 7.5 – 10.5 to 81 MV·A during ferrosilicon smelting correspond to the results of simulation experiments, which were confirmed during the smelting of 45 % ferrosilicon in industrial furnaces with similar relative technological parameters. The type of dependence of the decrease in bath resistance on the increase in electrode diameter for industrial ferroalloy furnaces is similar to the dependence obtained as a result of modeling experiments. The factor of a significant decrease in the bath resistance due to an increase in electrode diameter for ferroalloy furnaces of different capacities during the smelting of a single alloy is very significant. With an increase in current strength of the electrode, electrical efficiency, the furnace power factor and the share of active power in the bath decrease. Analysis of the furnace parameters during smelting of 45 % ferrosilicon confirms the conclusions of electrolytic modeling of ferroalloy furnaces about the significant role of increasing the diameter of furnace electrodes in reducing the bath active resistance.

Keywords

For citations:

Shkirmontov A.P. Modeling the operation of ferroalloy furnace with increased power and electrode diameters. Izvestiya. Ferrous Metallurgy. 2025;68(4):339-341. https://doi.org/10.17073/0368-0797-2025-4-339-341

Introduction

Studies of ferroalloy electric furnace models have a long history and continue in a number of research works aimed at improving the arc model in three-phase furnaces [1] and achieving effective heat distribution in closed-arc baths [2]. In [3], comprehensive modeling of furnace operation during ferronickel smelting was carried out. Several domestic studies have investigated: charge melting models in six-electrode furnaces [4]; furnace control models with maintenance of slag bath resistance [5]; and favorable current distribution in multi-electrode furnaces [6]. A number of these models adequately reproduce real processes, making it possible to obtain reliable information on the parameters of furnace operation and their interaction. Various simulation models of furnaces are widely used, including electrolytic modeling of ferroalloy furnace baths.

Increasing the power of ferroalloy furnaces is accompanied by larger electrode diameters, which results in higher capital and operating costs, greater consumption of non-ferrous and ferrous metals, and technological challenges. For example, when furnace power increases from 7.5 – 10.5 to 105 MV·A, the diameter of self-baking electrodes grows significantly – from 900 to 1800 – 2000 mm (a 2.0 – 2.2-fold increase). The electrode current rises from 32 – 37 to 160 kA and above (a 4.3 – 5.0-fold increase). By contrast, the operating voltage increases far less significantly – from 130 to 230 – 300 V (a 1.8 – 2.3-fold increase) [7]. This only indirectly indicates a decrease in the active bath resistance of the furnace and the power factor, leading to higher power losses in the short network.

On an electrolytic furnace model, studies were carried out to determine and evaluate changes in active bath resistance (in the electrode–hearth section) as electrode diameters increased. For comparison, an analysis of the operating parameters of industrial ferroalloy furnaces with different capacities and electrode diameters was also performed.

Experimental procedure

A traditional aqueous solution with a concentration of 0.2 % NaCl was used as the working fluid in the model. The experiments followed a method similar to that described in [7]. The diameter of the graphitized electrodes was varied from 30 to 150 mm. The diameter of the conducting hearth of the model was calculated using the expression Dhearth = de + 2а, where de is the electrode diameter, mm and а is the distance from the electrode to the bath wall, mm. Typically, the electrode-to-wall distance in furnaces is (0.8 ÷ 1.0)de , with an average value of 0.9de . For all experiments, it was assumed that Dhearth = 2.8de . For ferroalloy smelting, the electrode–hearth distance corresponds to the range of (0.6 ÷ 0.8)de [8] (expressed in electrode diameters). The relative sub-electrode gap (h/de ) was set at 0.7 of the electrode diameter. The electrode immersion depth Δh in the electrolyte was taken as equal to the electrode diameter.

Installation description

Alternating current at 50 Hz was supplied through an autotransformer and an isolation transformer to a vertically positioned electrode and the conducting hearth of the furnace model. Bath resistance for each electrode diameter was determined from current and voltage measurements.

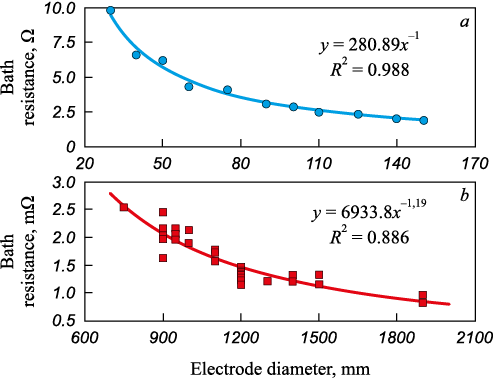

Conditions for modeling electrical parameters: ρ = const – specific electrical resistivity of the model bath, Ω·cm; h/de = const – sub-electrode gap, expressed in electrode diameters; Δh/de = const – electrode immersion depth, in electrode diameters; t = const = 23 °C – electrolyte temperature during the experiments. The variation in bath resistance of the model with increasing electrode diameter is shown in Fig. a.

Change in the bath active resistance with an increase in the electrode diameters |

For comparison, parameters of 43 furnaces used for ferrosilicon smelting (operating voltage, electrode current, and power factor) were analyzed. The active bath resistance of the furnace, Ract (mΩ), was determined according to the relation

\[{R_{{\rm{act}}}} = \frac{{{U_{{\rm{oper}}}}\cos \varphi }}{{1.73{I_{\rm{e}}}}},\]

where Uoper is the operating voltage at the transformer stage, V, cos φ is the furnace power factor, and Ie is the electrode current, kA.

The processed data for industrial ferrosilicon furnaces, showing the change in active bath resistance with increasing electrode diameter, are presented in Fig. b.

Discussion of the results

Increasing the electrode diameter in the ferroalloy furnace model results in a marked decrease in bath resistance. To validate this dependence, the parameters of 43 furnaces were analyzed. The power of the furnace transformers ranged from 7.5 – 10.5 to 81 MV·A, while the diameter of self-baking electrodes increased from 750 – 900 to 1900 – 2000 mm.

Notably, in industrial ferroalloy furnaces, the reduction in bath resistance with increasing electrode diameter follows the same trend as observed in the modeling experiments.

The findings can be applied as a methodological basis for laboratory training in ferroalloy production, particularly for studying the relationship between furnace power and self-baking electrode diameter.

The significant reduction in bath resistance with increasing electrode diameter across ferroalloy furnaces of different capacities, when smelting the same alloy, is of considerable importance. However, as electrode current rises substantially, energy performance indicators deteriorate: electrical efficiency, furnace power factor, and the proportion of active power in the bath all decrease.

Выводы

Analysis of furnace parameters during the smelting of 45 % ferrosilicon confirmed the results of electrolytic modeling of ferroalloy furnace operation, highlighting the significant role of increasing electrode diameter in lowering active bath resistance. In this case, the use of carbonaceous reducers with higher specific electrical resistivity, along with additional reactive power compensation, becomes necessary.

References

1. Saevarsdottir G., Larsen H.L., Bakken J.A. Modelling of AC arcs in three-phase submerged arc furnaces. In: Proceedings of the VII Int. Ferroalloys Congress: INFACON VII. Beijing, China. 7 – 10 June 1998. Beijing; 1998:317–322.

2. Li J. Discussion of ideal smelting model of submerged-arc furnace. In: Proceedings of the IX Int. Ferroalloys Congress: INFACON IX. Quebec City, Canada. 3 – 6 June 2001. Quebec City; 2001:121–130.

3. Oterdoom H., Degel R. Building a FeNi smelter simulator. In: Proceedings of the XII Int. Ferroalloys Congress: INFACON XII. Helsinki, Finland. 6 – 9 June 2010. Helsinki; 2010:215–227.

4. Lastochkina M.A. Model of charge melting in the bath of an ore-thermal furnace. Zapiski Gornogo instituta. 2002;150:119–123. (In Russ.).

5. Ryabov V.P., Khomyakov I.V., Chursin A.Yu. The model of an electric ore smelting furnace control system with maintaining the slag bath resistance. Bulletin of MPEI. 2020;(1): 82–88. (In Russ.). https://doi.org/10.24160/1993-6982-2020-1-82-88

6. Il’gachev A.N., Mikhadarov D.G. Study of the current in the multielectrode plant bath. Vestnik Chuvashskogo universiteta. 2023;(4):99–108. (In Russ.). https://doi.org/10.47026/1810-1909-2023-4-99-108

7. Shkirmontov A.P. Establishing the theoretical foundations and energy parameters for the production of ferroalloys with a larger-than-normal gap under the electrode. Metallurgist. 2009;53(5-6):300–308.

8. Shkirmontov A.P. Energy-Technological Parameters of Ferroalloy Smelting in Electric Furnaces. Moscow: NITU MISiS; 2018:216. (In Russ.).

About the Author

A. P. ShkirmontovRussian Federation

Aleksandr P. Shkirmontov, Dr. Sci. (Eng.), Director of the Editorial Center of Scientific Journals

49/2 Leningradskii Ave., Moscow 125167, Russian Federation

Review

For citations:

Shkirmontov A.P. Modeling the operation of ferroalloy furnace with increased power and electrode diameters. Izvestiya. Ferrous Metallurgy. 2025;68(4):339-341. https://doi.org/10.17073/0368-0797-2025-4-339-341