Scroll to:

Modeling the distribution of components emitted from oiled scale between water, gas, and dust media in blast furnace dedusting plant

https://doi.org/10.17073/0368-0797-2025-4-332-338

Abstract

Distribution of oil from oiled scale between various types of waste from blast furnace dedusting plant: dust, sludge, and slime water was estimated by physical modeling using a vertical tubular electric furnace. According to the mathematical modeling of thermal state of a metal container with oiled scale, intensive evaporation of oil in a blast furnace begins after it is loaded and lowered along the shaft to a depth approximately corresponding to three feeds. The oil was passed through a layer of sinter and pellets of the Mikhailovsky GOK heated to 500 °C with a mass of 0.6 kg and a particle size of 10 – 12 mm. Together with oil vapors, finely ground material was injected into the layer of iron ore raw materials (IORM), which imitated in component and fractional composition a mixture of blast furnace dust and sludge from a vacuum filtration plant (VFC) of blast furnace shop, taken in a ratio of 36:64. The physical modeling ensured compliance with the actual gas-dynamic mode in the area of blast furnace ore ridge, based on equality of the Reynolds criterion. The value of this criterion, equal to 215, was achieved in the laboratory model when argon was supplied with a flow rate of 70 L/min. According to the experimental results, distribution of oil was, % of the initial amount: 74.8 % decomposed on the IORM layer corresponding to three feeds; 9.1 % turned into blast furnace dust; 15.9 % turned into VFC sludge; there was no oil in the wet gas purification water; 0.2 % (30 mg) of the oil underwent wet dedusting in the form of an aerosol; a small amount of soot was observed on the pipeline walls. Gas phase of oil decomposition contained: 70 – 90 % H2 ; 1.5 % CO; 0.5 – 7.0 % CO2 ; 3.2 – 22.2 % CH4 ; 0.1 – 2.5 % Σ(C2H4 , C2H6 , C3H6 , C3H8 ). The content of benzo(a)pyrene controlled in Russia in oil vapor did not exceed 0.00058 %.

For citations:

Kharchenko A.S., Sysoev V.I., Sibagatullin S.K., Dzyuba A.V., Savinov A.S., Kharchenko E.O. Modeling the distribution of components emitted from oiled scale between water, gas, and dust media in blast furnace dedusting plant. Izvestiya. Ferrous Metallurgy. 2025;68(4):332-338. https://doi.org/10.17073/0368-0797-2025-4-332-338

Introduction

Improving the environmental performance of ferrous metals production and processing increasingly rely on recycling technogenic waste back into production [1; 2]. Among the most valuable iron bearing waste products generated at ferrous metallurgy plants is oiled scale from rolling mills [3 – 5]. This material consists almost entirely of iron oxides (with an iron content of 69 – 72 %) and contains virtually no gangue [6; 7]. Two main types of rolling scale are distinguished, differing in particle size and oil content. The coarse fraction (+2 mm), which accounts for up to 70 – 80 % of the total scale, contains less than 3 % oil and can be effectively used in the sinter burden. The fine fraction (particles smaller than 100 μm) contains a much higher oil content (up to 20 – 30 %), which makes its use in sintering more problematic. During sintering of a burden with elevated oil content, unburned oil residues evaporate, forming explosive mixtures in the oxidizing zones of the sinter machine gas tract. After condensation, the oil contaminates the exhauster blades, reducing their service life [8].

Alternative utilization methods for oiled rolling scale include preliminary chemical treatment (washing with alkali and surfactant solutions) [9; 10] or preliminary thermal treatment (rotary kilns, thermostats, mixers) [11; 12]. The de oiled product is then processed through sintering [14; 15] or briquetting [16]. However, these approaches have not been implemented on an industrial scale due to techno economic constraints, and the problem remains unresolved.

A more recent alternative to the multistage and costly preparation of oiled scale for blast furnace smelting – via sintering or briquetting with prior de oiling – is the direct charging of oiled scale into the blast furnace [17; 18]. According to a patented method [17], instead of using low strength briquettes, oiled scale can be placed in a metallic container designed to melt at temperatures of at least 1500 °C. This approach requires minimal additional equipment, shortens preparation time, eliminates the need for separate storage and disposal of extracted organic compounds, and avoids the purification of contaminated circulating water. However, when granulated oiled scale is charged into the blast furnace, incomplete decomposition of oil vapors passing through the burden may complicate the operation of the furnace dedusting system [19]. Therefore, it is important to evaluate how the oil contained in oiled scale affects the composition of blast furnace dust, VFC sludge, slime water, and the formation of the gas phase in blast furnace off takes.

Materials and methods

In this study, the distribution of oil among various types of blast furnace dedusting wastes (dust, sludge, and slime water) was investigated by physical modeling in a vertical tubular electric furnace. A heated layer of sinter and pellets from the Mikhailovsky GOK, with a particle size of 10 – 12 mm and a mass of 0.6 kg, was successively charged together with a mixture that reproduced, in component and fractional composition, blast furnace dust and sludge from the vacuum filtration plant (VFC) in a ratio of 36:64.

The iron ore raw materials (IORM) were placed in the isothermal zone of the furnace. Their mass was determined from calculations of the amount of material located above the horizon of intensive oil evaporation in the furnace. According to mathematical modeling of the thermal state of a metal container with oiled scale, intensive oil evaporation in the blast furnace begins after the container is charged and lowered along the shaft to a depth corresponding to approximately three feeds. Consequently, the oil vapors pass through a layer of IORM roughly equal in height to three feeds [20 – 22].

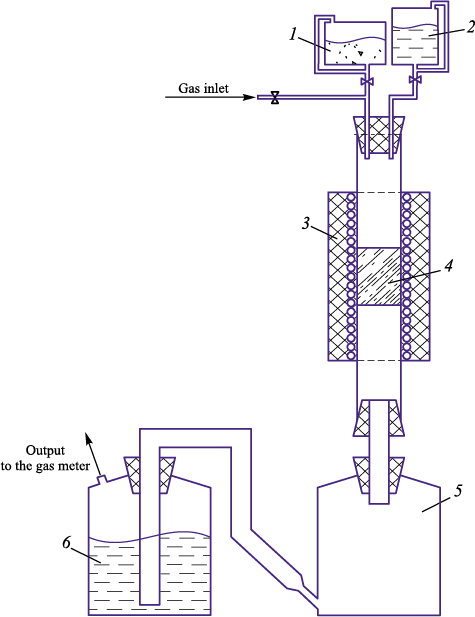

To generate a gas flow in which mixing of dust and oil occurred, high grade argon (99.987 %) in accordance with GOST 10157–2016 was supplied at a rate of 70 L/min. This provided a Reynolds criterion value corresponding to the actual gas dynamic mode in the burden ridge zone of the blast furnace. At the furnace outlet, a bottle for “dry” dust collection was installed to simulate the cyclone dedusting unit, followed by a bottle with water for “wet” sludge collection, representing wet gas purification in scrubbers (see Figure).

Scheme of experimental installation for physical modeling |

The parameters of gas and material movement in the laboratory installation were modeled to reflect the following blast furnace operating conditions:

– average daily IORM consumption – 6278 t;

– pellet share in IORM – 36 %;

– average daily consumption of oiled scale (1 % of IORM mass) – 63 t;

– average daily pig iron production – 3798 t;

– average daily top gas generation – 7,139,563 nm3;

– oil content in oiled scale – 15 %;

– oil mass in oiled scale – 9.4 t;

– water content in oiled scale – 10 %;

– water mass in oiled scale – 6.3 t;

– IORM mass per feed – 39 t;

– blast furnace dust yield – 4.6 kg/t hot metal;

– VFC sludge yield – 8.1 kg/t hot metal.

The component composition of dust used in the laboratory experiments was as follows:

1. Blast furnace dust (36 % of total mass):

– fractional composition: 10 % of class 1 – 3 mm and 90 % of class 0 – 1 mm;

– component composition:

– 75 % IORM mixture (64 % sinter and 36 % pellets);

– 25 % coke dust.

2. Sludge fraction (64 % of total mass):

– fractional composition: 100 % of class 0 – 0.2 mm;

– component composition:

– 75 % IORM mixture (64 % sinter and 36 % pellets);

– 25 % coke dust.

During the study, gas samples were taken and analyzed for the content of monoatomic, diatomic, and triatomic gases, as well as light hydrocarbons, using a Chromatec Crystal 5000 gas chromatograph system. For analysis, a packed column HayeSep Q (3 m) and a packed column NaX (3 m) with a Carboxen precolumn (0.5 m) were employed.

Oil samples were also taken to determine the content of seven polynuclear aromatic hydrocarbons (PAHs) –fluorene, phenanthrene, anthracene, fluoranthene, pyrene, chrysene, and benzo[a]pyrene – included in the list of 16 PAHs classified by the US Environmental Protection Agency (US EPA) as priority pollutants. Chromatographic analysis of the oil was carried out using a capillary column CR-5ms (5 % diphenyl/95 % dimethyl (polysiloxane)), 30 m × 0.32 mm × 0.25 μm.

Results

Calculated parameters of the laboratory study:

| Oil mass for simulating vapor filtration through the IORM layer, corresponding to one feed, g | 0.3 |

| Gas volume required for one feed, based on the oil vapor fraction in blast furnace top gas, L | 228 |

| Duration of oil injection corresponding to one feed, min | 3 |

| Dust mass loaded into the laboratory installation corresponding to one feed, g | 1.5 |

| Reynolds number, Re | 215 |

| Number of feeds in the laboratory installation | 50 |

To determine the oil content, thermogravimetric analysis was performed on the collected dust and sludge samples by heating them in an argon atmosphere. Weight losses were 5.2 % for dust and 4.9 % for sludge. With a dust-to-sludge ratio of 36:64, the overall oil content in the samples after testing was 5.0 %.

Water evaporation from bottle 6 after the experiment showed no significant oil in the aqueous phase. The oil aerosol concentration after wet scrubbing was determined from a vapor–gas sample collected with an NP ZM sampling pump in accordance with GOST R 51945–2002, using indicator tubes for oil aerosols.

Based on the laboratory experiments, the oil distribution was as follows (percent of the initial oil content):

– 74.8 – decomposed in the IORM layer equivalent to three batches;

– 9.1 – transferred to blast furnace dust;

– 15.9 – incorporated into vacuum filtration sludge;

– 0.2 (30 mg) – passed through wet gas cleaning as aerosol.

A small amount of soot was observed on the inner walls of the pipeline during the experiments. No oil was detected in the wet gas purification water, indicating that nearly all of it was adsorbed by suspended fine coke dust particles, which were subsequently filtered, dried, and incorporated into the vacuum filtration sludge. Under industrial conditions, this process would simplify the treatment of recirculating water.

The chemical composition of the gas phase containing oil decomposition products was also analyzed. Across different gas samples, the concentrations of the main components were within the following ranges: 70 – 90 % H2 ; 1 – 5 % CO; 0.5 – 7.0 % CO2 ; 3.2 – 22.2 % СH4 ; 0.1 – 2.5 % Σ (C2H4 , C2H6 , C3H6 , C3H8 ). The formation of these gas components is associated with three main oil decomposition pathways:

1 – (catalytic) dehydrogenation of oil hydrocarbons with cleavage of C–H bonds, producing hydrogen gas and unsaturated compounds prone to polymerization and oxidation. This process is promoted by calcium, iron, and manganese oxides;

2 – (catalytic) cracking of oil hydrocarbons with cleavage of C–C bonds, producing lower molecular weight hydrocarbons, including gaseous hydrocarbons such as methane, ethane, propane, and butane. This process is strongly promoted by complex silicates and aluminosilicates in the agglomerate binder, such as pyroxenes and olivines.

3 – reduction of iron oxides with the formation of CO and CO2 , which is intensified at higher temperatures and when using iron ore raw materials with higher reducibility.

Analysis of oil samples for polynuclear aromatic hydrocarbons (PAHs) showed that the concentration of benzo[a]pyrene, which is regulated in Russia, did not exceed 0.00058 % in oil vapors.

Characteristics and content of polynuclear aromatic hydrocarbons

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conclusions

An experimental assessment was conducted to evaluate the distribution of oil from oiled scale among different types of blast furnace dedusting plant – dust, sludge, and slime water – through physical modeling in a vertical tubular electric furnace. A mixture of sinter and pellets of the Mikhailovsky GOK (particle size 10 – 12 mm, mass 0.6 kg) was used to simulate, in terms of component and particle-size composition, blast furnace dust and vacuum filter sludge in a 36:64 ratio. When passing through a layer of iron ore raw materials (IORM) heated to 500 °C, 74.8 % of the oil decomposed within the IORM layer corresponding to three feeds; 9.1 % was transferred to blast furnace dust; and 15.9 % entered the vacuum filter sludge. Only 0.2 % of the oil underwent wet dedusting in the form of an aerosol, while no oil was detected in the wet gas purification water.

The gas phase of oil decomposition contained 70 – 90 % H2 ; 1 – 5 % CO; 0.5 – 7.0 % CO2 ; 3.2 – 22.2 % СH4 ; 0.1 – 2.5 % Σ (C2H4 , C2H6 , C3H6 , C3H8 ). A small amount of soot was observed on the pipeline walls, suggesting the possibility of soot deposition in blast furnace off-gas ducts.

References

1. Rovin S.L., Rovin L.E. New concept of recycling of dispersed iron-containing waste. In: Proceedings of the X Int. Sci. and Pract. Conf. “Progressive Casting Technologies”, Moscow, November 9–13, 2020. Moscow: Maska; 2020;238–243. (In Russ.).

2. Bulatov K.V., Gazaleeva G.I. Prospects for development of the technologies for recycling of ferrous metallurgy waste. In: Fundamental Research and Applied Developments of Processes of Processing and Utilization of Technogenic Formations: Proceedings of the V Congress with Int. Participation and the Conf. of Young Scientists “TECHNOGEN-2021”. Yekaterinburg: UB RAS; 2021:21–33. (In Russ.). https://doi.org/10.34923/technogen-ural.2021.60.16.003

3. Leont’ev L., Ponomarev V., Sheshukov O. Recycling and disposal of industrial waste from metallurgical production. Ecology and Industry of Russia. 2016;20(3):24–27. (In Russ.). https://doi.org/10.18412/1816-0395-2016-3-24-27

4. Remus M., Monsonet M.A.A., Roudier S., Sancho L.D. Best Available Techniques (BAT) Reference Document for Iron and Steel Production. Luxemburg: Publications office of the European Union; 2013:627.

5. Yessengaliev D., Mukhametkhan M., Mukhametkhan Ye., Zhabalova G., Kelamanov B., Kolesnikova O., Shyngysbayev B., Aikozova L., Kaskataeva K., Kuatbay Y. Studies of the possibility of improving the quality of iron ores and processing of technogenic composite iron-containing waste of metallurgical production. Journal of Composites Science. 2023;7(12):501. https://doi.org/10.3390/jcs7120501

6. Furmanski L.M., Muller T.G., Nuernberg J.B., Martins M.A., Arnt Â.B.C., da Rocha M.R., Zaccaron A., Peterson M. Efficient production of ferrous sulfate from steel mill scale waste. Journal of Sustainable Metallurgy. 2024;10(3):1783–1794. https://doi.org/10.1007/s40831-024-00900-8

7. Hryhoriev S., Petryshchev A., Sinyaeva N., Yurchenko A., Sklyar O., Kvitka S., Borysov V., Vlasiuk V., Tsymbal B., Borysova S. Studying the physical chemical properties of alloyed metallurgical waste as secondary resource saving raw materials. Eastern-European Journal of Enterprise Technologies. 2018;4(12(94)):43–48. https://doi.org/10.15587/1729-4061.2018.140924

8. Shatokha V.I., Gogenko O.O., Kripak S.M. Utilising of the oiled rolling mills scale in iron ore sintering process. Resources, Conservation and Recycling. 2011;55(4):435–440. https://doi.org/10.1016/j.resconrec.2010.11.006

9. Tanutrov I., Sviridova M. Directions to improve the processing methods of anthropogenic waste of the Ural Region. Ecology and Industry of Russia. 2015;19(8):31–35. (In Russ.). https://doi.org/10.18412/1816-0395-2015-8-31-35

10. Tanutrov I.N., Sviridova M.N., Chesnokov Yu.A., Marshuk L.A. Technological modeling of joint leaching of oily rolling scale and red mud. Izvestiya. Ferrous Metallurgy. 2020;63(11-12):891–898. (In Russ.). https://doi.org/10.17073/0368-0797-2020-11-12-891-898

11. Nemenov A.M. Events in figures and facts. Metallurg. 2016;(9):108–112. (In Russ.).

12. Chesnokov Yu.A., Marshuk L.A., Tanutrov I.N., Sviridova M.N. Pyro-metallurgical scheme of joint recycling of red sludge and rolled scale. In: Fundamental Research and Applied Developments of Processes of Processing and Utilization of Technogenic Formations: Proceedings of the V Congress with Int. Participation and the Conf. of Young Scientists “TECHNOGEN-2021”. Yekaterinburg: UB RAS; 2021:415–419. (In Russ.).

13. Rostovskii V.I., Pliskanovskii S.T., Ivanov A.I., Ispolov V.B., Gladush V.D., Ruchkin I.I., Zhunev A.G., Golubov A.F., Korop N.A. Certificate of authorship USSR no. 1086024 A1, MPC C22B 1/16. Method of agglomeration of iron ore materials. Bulleten’ izobretenii. 1984;14. (In Russ.).

14. Gurkin M.A., Tabakov M.S., Loginov V.N., Kashkarov E.A., Nevraev V.P., Nesterov A.S., Kuchin V.Yu., Detkova T.V., Yakushev V.S. Patent RF no. 2418079 C2, IPC C22B 1/16. Method of sinter production for blast furnace smelting. Bulleten’ izobretenii. 2011;13. (In Russ.).

15. Gotovtsev A.A., Efimenko Yu.G., Kabanov A.V., Koval Yu.I., Salnikov I.M., Stolberg E.Ya., Khvatov Yu.A.; Certificate of authorship USSR no. 1407979 A1, MPC C22B 1.14. Charge for disposal of oiled scale during agglomeration. Bulleten’ izobretenii. 1988;25. (In Russ.).

16. Salekh A.I.Sh., Gritsishin A.M. Patent RF no. 2321647 C1, IPC C22B 1.242, C22B 1.245. Method of briquetting iron-containing waste in the form of scale for smelting. Bulleten’ izobretenii. 2006;10. (In Russ.).

17. Gubanov V.I., Seifulov R.V., Selivanov V.N., Chernousov P.I., Yusfin Yu.S. Patent RF no. 2131929 C1, IPC C21B 5/00. Method for producing pig iron using blast furnace production at a metallurgical enterprise. Bulleten’ izobretenii. 1999. (In Russ.).

18. Khusnutdinov I.Sh., Khusnutdinov S.I., Alekseeva A.A., Bazhin V.Yu., Dubovikov O.A., Johann L.Sh. Patent RF no. 2730304 C1, IPC F23G 7/05, F23G 5/027. Method of disposal of oil- and oil-containing waste, oiled scale, waste from coke production. Bulleten’ izobretenii. 2020;24. (In Russ.).

19. Somova Yu.V., Sviridova T.V., Alekseeva P.A., Nekerov E.A., Schwabecher D. Analysis of methods for processing oily mill scale and oily sludge for iron and steel production. IOP Conference Series: Earth and Environmental Science. 2021;839:042046. https://doi.org/10.1088/1755-1315/839/4/042046

20. Savinov A.S., Kharchenko A.S., Sibagatullin S.K., Dzyuba A.V., Sysoev V.I., Kharchenko E.O., Pavlov A.V. Forecasting the temperature of oiled scale packed in a metal container when moving in a blast furnace from the blast-furnace mouth to the iron receiver. Theory and technology of metallurgical production. 2024;(4(51)):24–29. (In Russ.).

21. Molgaard J., Smeltzer W.W. Thermal conductivity of magnetite and hematite. Journal of Applied Physics. 1971; 42(9):3644–3647. https://doi.org/10.1063/1.1660785

22. Dzyuba A.V., Savinov A.S., Kharchenko A.S., Sibagatullin S.K., Sysoev V.I., Kharchenko M.V. Strength characteristics of containers with oiled scale made approximately to the size of coke. In: Heat Engineering and Computer Science in Education, Science and Production: Proceedings of the XII All-Rus. Sci. and Pract. Conf. of Students, Postgraduates and Young Scientists (TIM’2024) with International Participation. Yekaterinburg, May 16–17, 2024. Yekaterinburg: UrFU; 2024:37–41. (In Russ.).

About the Authors

A. S. KharchenkoRussian Federation

Aleksandr S. Kharchenko, Dr. Sci. (Eng.), Assist. Prof., Head of the Chair of Metallurgy and Chemical Technologies

38 Lenina Ave., Magnitogorsk, Chelyabinsk Region 455000, Russian Federation

V. I. Sysoev

Russian Federation

Victor I. Sysoev, Cand. Sci. (Eng.), Head of the Laboratory of the Chair of Metallurgy and Chemical Technologies

38 Lenina Ave., Magnitogorsk, Chelyabinsk Region 455000, Russian Federation

S. K. Sibagatullin

Russian Federation

Salavat K. Sibagatullin, Dr. Sci. (Eng.), Prof. of the Chair of Metallurgy and Chemical Technologies

38 Lenina Ave., Magnitogorsk, Chelyabinsk Region 455000, Russian Federation

A. V. Dzyuba

Russian Federation

Andrei V. Dzyuba, Postgraduate of the Chair of Metallurgy and Chemical Technologies

38 Lenina Ave., Magnitogorsk, Chelyabinsk Region 455000, Russian Federation

A. S. Savinov

Russian Federation

Aleksandr S. Savinov, Dr. Sci. (Eng.), Assist. Prof., Head of the Chair of Mechanics

38 Lenina Ave., Magnitogorsk, Chelyabinsk Region 455000, Russian Federation

E. O. Kharchenko

Russian Federation

Elena O. Kharchenko, Cand. Sci. (Eng.), Senior Lecturer of the Chair of Metallurgy and Chemical Technologies

38 Lenina Ave., Magnitogorsk, Chelyabinsk Region 455000, Russian Federation

Review

For citations:

Kharchenko A.S., Sysoev V.I., Sibagatullin S.K., Dzyuba A.V., Savinov A.S., Kharchenko E.O. Modeling the distribution of components emitted from oiled scale between water, gas, and dust media in blast furnace dedusting plant. Izvestiya. Ferrous Metallurgy. 2025;68(4):332-338. https://doi.org/10.17073/0368-0797-2025-4-332-338