Scroll to:

Information modeling system for assessing instability of blast furnace functioning

https://doi.org/10.17073/0368-0797-2025-4-402-410

Abstract

The article discusses the development of an information modeling system for assessing the instability of a blast furnace. The presented approach is based on the application of mathematical models and methods for analyzing the parameters of the blast furnace process, which makes it possible to assess the impact of technological and organizational factors on the furnace stability. The developed system is designed for automated collection, processing and analysis of data in real time, as well as forecasting technological deviations. The methodology is based on the use of integral stability indicators, including the technical and economic characteristics of smelting, the properties of raw materials, the parameters of blast, gas dynamic, thermal and slag modes. To determine the integral indicators, a set of controlled and calculated features is used, ranked according to the degree of significance. The main modules of the system include functional blocks for data collection, calculations, analysis and visualization. The system architecture is implemented on the basis of a client-server approach, which provides the possibility of integration with existing metallurgical production management systems. The practical implementation of the system makes it possible to improve the performance of blast furnace smelting, reduce fluctuations in the parameters of the technological process and improve the quality of the resulting cast iron. The above calculation examples confirm effectiveness of the developed tool. The presented results may be useful for the specialists in the field of blast furnace production automation, as well as for the researchers involved in analysis and forecasting of instability of technological processes.

For citations:

Spirin N.A., Gurin I.A., Lavrov V.V. Information modeling system for assessing instability of blast furnace functioning. Izvestiya. Ferrous Metallurgy. 2025;68(4):402-410. https://doi.org/10.17073/0368-0797-2025-4-402-410

Introduction

The development of information and control systems for blast furnaces aims to create an efficient management framework that ensures stable production while minimizing costs. These systems must account for technological requirements and the specific features of the equipment. To support the advancement of an automated system for analyzing the operating parameters of individual furnaces and the blast furnace shop as a whole, an information modeling system is being developed to assess process instability in blast furnace operations [1].

Fluctuations in charge composition [2 – 4] and smelting parameters [5 – 7] can significantly impact furnace performance. These variations affect the composition and temperature of the hot metal and lead to pressure losses in the burden’s gas column. As a result, key parameters may exceed the limits defined by hot metal quality requirements and the need to maintain steady furnace operation under varying counterflow conditions [8; 9]. Several factors directly influence the furnace’s thermal state and the resulting temperature and composition of the hot metal. These include the iron content in the charge, moisture and ash content of the coke, blast air temperature and humidity, natural gas consumption, the ratio of iron-bearing materials to coke, and their distribution at the furnace top [10 – 12]. Variations in these parameters lead to fluctuations in the furnace’s thermal balance, causing deviations in the average silicon content and temperature of the hot metal. Instability in the smelting process, especially when using iron ore feedstock with variable chemical composition, can significantly degrade the quality of the molten blast furnace products. For example, reference data [5] show that reducing fluctuations in sinter basicity (CaO/SiO2 ) by ±(0.075 – 0.100) units can increase blast furnace productivity by 1.5 % and lower specific coke consumption by 0.8 %.

The total potential benefit of reducing variability in blast furnace parameters is estimated at a 5 – 6 % reduction in coke consumption and a 9 – 10 % increase in productivity. Moreover, a 0.1 % reduction in the standard deviation of iron content in the burden results in a 0.28 % decrease in coke consumption and a 0.29 % increase in productivity [2]. Organizational factors that affect the process include furnace downtime, idle running, regularities in burden charging, and tapping schedules. The impact of some of these factors remains poorly studied and is proposed to be evaluated using empirical data [13 – 15]. These include the mechanical and physicochemical properties of raw materials and coke, as well as gas distribution within the furnace. Assessing their influence requires further research and development of mathematical process models.

Existing systems often lack the precision or flexibility to fully account for all factors affecting operational stability. This highlights the need for advanced information-based modeling systems capable of handling multiple variables and providing real-time analysis of blast furnace instability.

Algorithmic support of the information modeling system

To assess the smelting process stability, the following key integral indicators (B1 ) have been developed:

1. Technical, economic, and technological performance indicators of smelting (В1 ).

2. Indicators of raw material properties (iron ore materials, coke, fluxes) (В2 ).

3. Indicators of blast and gas dynamic modes (В3 ).

4. Indicators of the thermal mode (В4 ).

5. Indicators of the slag mode (В5 ).

6. An integral indicator of blast furnace operating stability based on В3 , В4 , В5 , characterizing the blast, gas-dynamic, thermal, and slag modes (ВBF ).

7. Final stability indicator of raw material properties and overall blast furnace operation (Вfinal ).

The types and number of features used in the assessment depend on the specific integral indicator being calculated.

In addition to controlled (measured) parameters, the stability assessment incorporates a set of calculated parameters that describe the blast conditions, gas dynamics, thermal and slag modes, and the technological parameters of blast furnace smelting, as detailed in [16 – 18].

The approximate number of features used for evaluating each integral indicator is provided in the Table.

Number of features used to calculate the stability indicators

| |||||||||||||||||||||||||||||||||||||||||||

For a given time interval of blast furnace operation, the root mean square (RMS) deviations ΔXi of both controlled and calculated features are used as input data for computing each integral indicator (B1 ).

Under stable operating conditions, the RMS deviation ΔXi of the i-th feature – used to characterize furnace stability during the specified period – must not exceed a predefined threshold value \(\Delta X_i^{{\rm{pre}}}\), which is a model setting:

| \[\Delta {X_i} \le \Delta X_i^{{\rm{pre}}}.\] | (1) |

If condition (1) is satisfied (“True”), the i-th feature identifier Рi is assigned a value of 1; otherwise (“False”), it is assigned a value of 0. All features are then ranked. Each feature is assigned a normalized rank value Ri , ranging from 0 to 1, determined using an expert evaluation method.

The stability of blast furnace operation for each of the integral indicators Bj is calculated using the following relationship:

| \[{B_j} = \left( {\sum\limits_{i = 1}^n {{P_i}\frac{{{R_i}}}{{\sum\limits_{i = 1}^n {{R_i}} }}} } \right) \cdot 100{\rm{ }}\% ,\] | (2) |

where n is the number of features associated with the given integral indicator Bj .

If the resulting value of Bj exceeds 80 % (according to normative and reference data), the furnace operation is considered stable with respect to that indicator.

If Bj falls within the range of 60 – 80 %, the furnace operation is assessed as unstable with respect to that indicator.

If Bj is below 60 %, the blast furnace is considered to have operated in an unstable mode for the corresponding integral indicator.

To determine the overall stability criteria for furnace operation and process conditions, the following integral indicators are calculated:

– the integral indicator of blast furnace operating stability ВBF , based on В3 , В4 , В5 , characterizing the blast, gas-dynamic, thermal, and slag modes:

| \[{B_{{\rm{BF}}}} = \left( {\sum\limits_{i = 3}^5 {{B_i}\frac{{{R_i}}}{{\sum\limits_{i = 3}^5 {{R_i}} }}} } \right) \cdot 100{\rm{ }}\% ,\] | (3) |

– the final stability indicator of furnace operation:

Key system requirements

Key system requirements are as follows:

– automated data collection: the system must automatically collect real-time data on blast furnace operating parameters;

– real-time visualization: the system must present analysis results in the form of graphs, tables, and charts that are easy for operating personnel to interpret;

– seamless integration: the system should integrate smoothly with the plant’s existing process control systems.

Functional modeling of the information

modeling system

The design of the information modeling system is based on functional modeling methodology and the IDEF0 graphical notation for structured analysis and design. The IDEF0 method is founded on the SADT (Structural Analysis and Design Technique) [19 – 21]. The model, developed using the Ramus Educational software package [21], consists of more than 50 blocks across four levels of decomposition. These blocks define the system’s key functions, the relationships among functional units, the control inputs, and the execution mechanisms for each function.

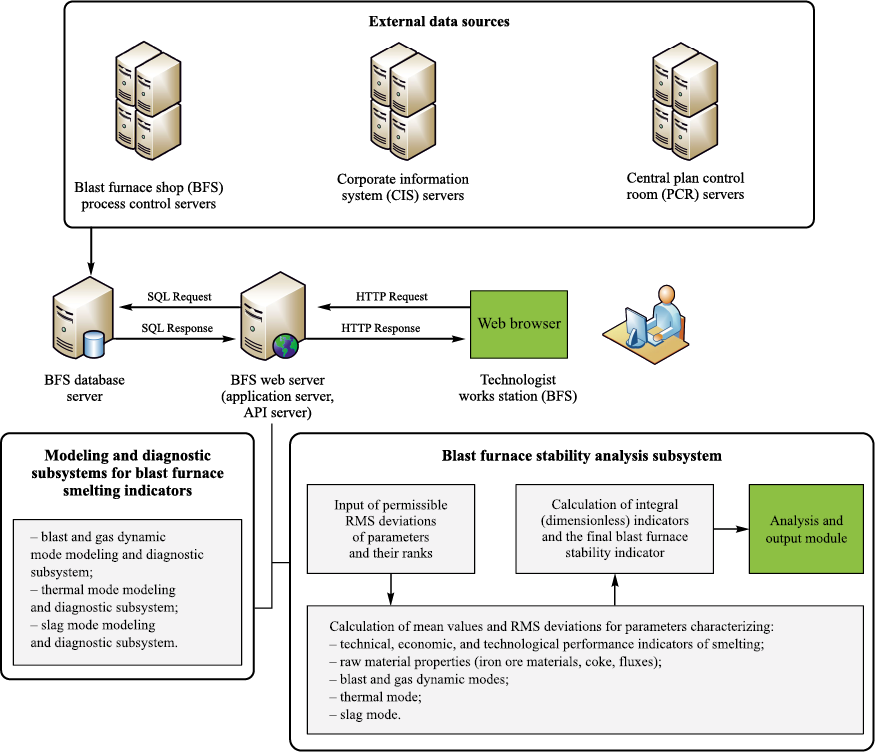

Architecture of the information modeling system

The architecture of the developed information modeling system for assessing blast furnace operation instability is shown in Fig. 1. The system is divided into small, independent blocks – modules – each implementing a functionally complete segment of the program. This modular approach allows the functionality of individual components to be updated without requiring changes to the entire system, enhancing its reliability and scalability. The modules are implemented using mathematical libraries and classes [22].

Fig. 1. Architecture of the information modeling system for assessing the instability of a blast furnace |

The information modeling system includes the following modules:

– input module for entering the permissible values of the RMS deviations and the feature ranks (\(\Delta X_i^{{\rm{доп}}}\), Ri );

– computation module for calculating the arithmetic means and RMS deviations of parameters characterizing the technical, economic, and technological indicators of smelting; the properties of raw materials (iron ore materials, coke, and fluxes); as well as the blast, gas-dynamic, thermal, and slag modes;

– module for calculating stability scores of blast furnace operation for each integral indicator Bj , the overall stability indicator ВBF , and the final stability indicator Вfinal ;

– analysis and output module for processing and presenting the results.

The output from the calculation modules is analyzed and presented in both numerical and graphical formats. The system also provides the option to generate and export reports in Microsoft Excel format.

Software implementation

of the Information modeling system

The software implementation of the information modeling system is based on a client–server architecture, designed to to enable seamless integration with existing enterprise software and facilitate data exchange via an API (Application Programming Interface) [23]. The client–server model follows a classic three-tier architecture consisting of the presentation layer, application layer, and data layer.

The presentation layer is implemented using high-level web technologies: JavaScript, HTML5, and CSS (Cascading Style Sheets). The visual design is built using the Bootstrap framework, and the user interface is developed with the UmiJS and React libraries. Graph plotting is handled by Ant Design Charts. This layer is supported by the users’ computing resources – specifically, their web browsers.

The application layer is developed in C# using the ASP.NET Core MVC framework and the .NET 8 platform [24]. ASP.NET Core handles user requests through a middleware pipeline, which includes the following components.

Error handling middleware, which enables the system to signal software-related issues when exceptions occur, and to continue functioning properly, including correctly displaying web pages in cases such as database connection failures, calculation algorithm errors, and other similar situations.

Authentication middleware, which integrates the standard ASP.NET Identity mechanism for authentication and authorization into the information system and manages user accounts.

Session middleware, which processes temporary user data during system usage.

Web API middleware, which incorporates the routing system, dependency injection, model binding, and data validation.

The data layer consists of a database and software components for managing read/write access. The system uses PostgreSQL as the database management system. Communication between the application and the database is handled via Entity Framework Core, which uses ORM (Object-Relational Mapping) technology. ORM allows developers to work with data as objects or classes in object-oriented programming languages and to build virtual database schemas. Input of initial blast furnace operation data for a given time period can be carried out either through the API and integration with the blast furnace process control systems (PCS) or manually.

Description of the information modeling

system software functions

The developed software module provides the following capabilities:

1. Selection of operating periods via a calendar interface, with the option to set the data averaging interval (hour, shift, day, week, or hot metal tapping period).

2. Selection of one or more blast furnaces to be included in the analysis.

3. Calculation of average values and RMS deviations for a set of operational indicators.

4. Presentation of analysis results in an intuitive format, including tables and histograms; individual blast furnaces can be assigned distinct colors for baseline and comparison periods.

5. Notification of out-of-range values, with customizable alerts configured for all or selected blast furnaces.

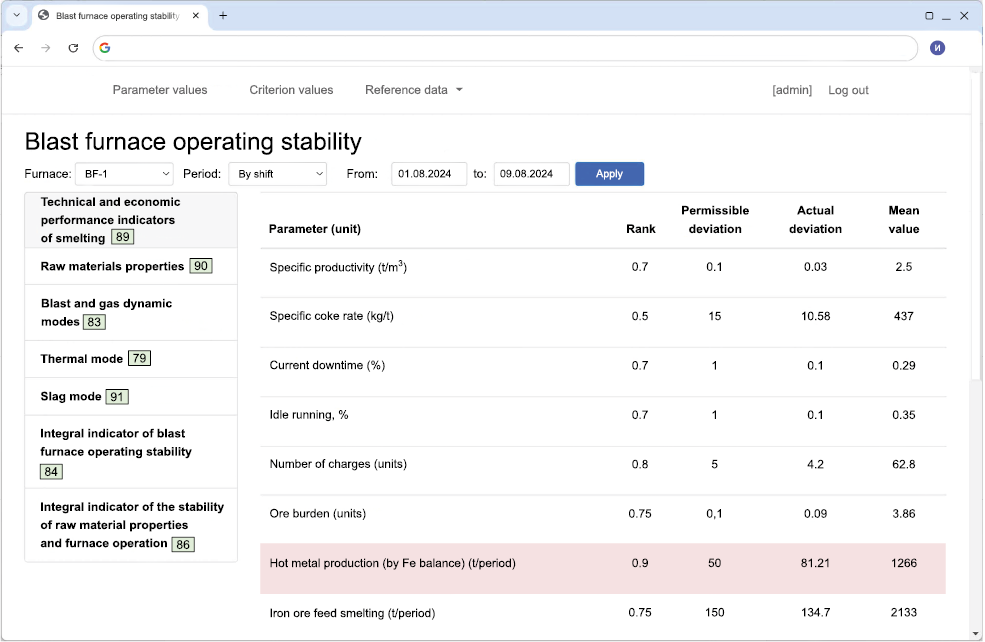

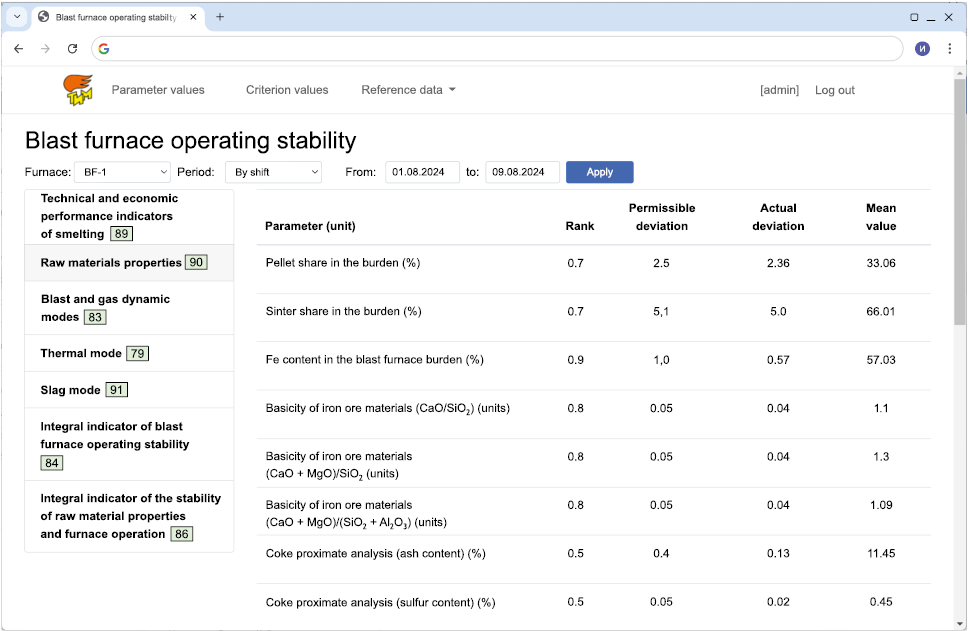

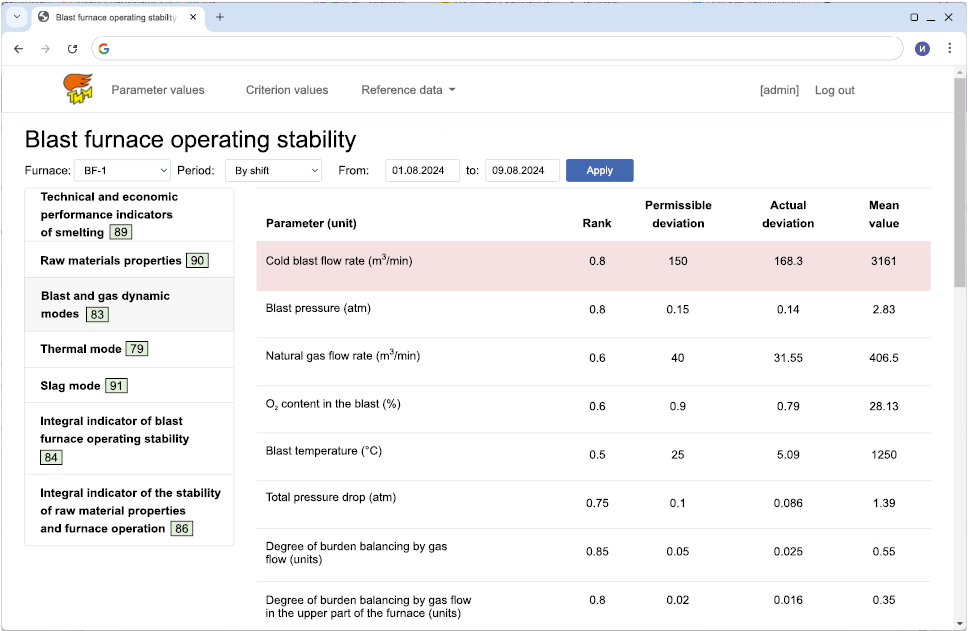

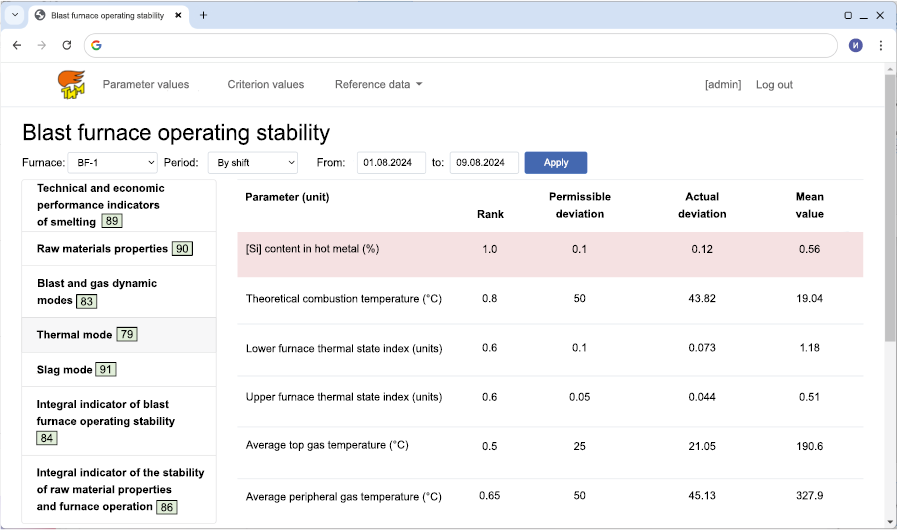

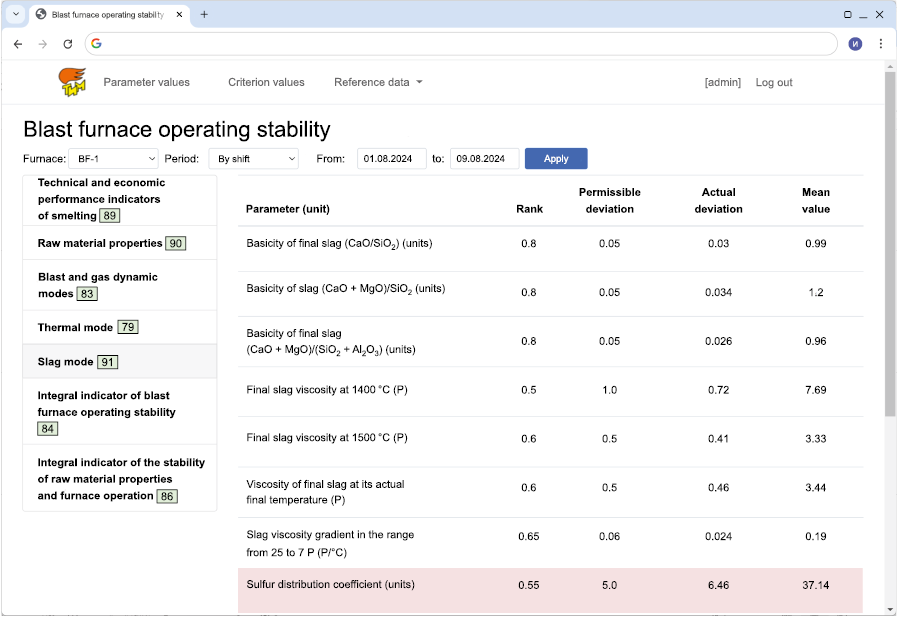

Figs. 2 – 6 show fragments of the system’s web interface illustrating the modeling results of blast furnace instability assessment.

For the analyzed period, the modeling results indicated stable operation with respect to technical, economic, and technological indicators, raw material properties, blast and gas dynamic modes, and the slag mode. However, instability was observed in the thermal mode. The values of the integral indicators exceeded 80 %, indicating overall stable operation of the blast furnace.

Fig. 2. Fragment of a web page for assessing the instability of technical,

Fig. 3. Fragment of a web page for assessing the instability of raw material properties

Fig. 4. Fragment of a web page for assessing the instability of indicators

Fig. 5. Fragment of a web page for assessing the instability of thermal mode indicators

Fig. 6. Fragment of a web page for assessing the instability of slag mode indicators |

Conclusions

Using modern information technologies, an information modeling system has been developed for evaluating the instability of blast furnace operation. The system supports automated data collection and processing, and calculates a set of parameters that characterize the technical, economic, and technological performance of the smelting process, raw material properties, and the thermal, blast, and gas dynamic modes, as well as the processing of molten blast furnace products.

References

1. Spirin N.A., Lavrov V.V., Gurin I.A., Zubakov S.V. Evaluation of blast furnace instability. In: Automation Systems (in Education, Science and Production) AS’2024. Proceedings of the All-Rus. Sci. and Pract. Conf. (with Int. Participation). Novokuznetsk: SibSIU; 2024:167–171. (In Russ.).

2. Tovarovskii I.G. Blast-Furnace Smelting. Dnepropetrovsk: Porogi; 2009:768. (In Russ.).

3. Tovarovsky I.G., Merkulov A.E. Analytical study of blast-furnace smelting processes and modes at various iron contents in the charge. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2010;(4(1324)): 19–27. (In Russ.).

4. Gerdes M., Chenault R., Kurunov I., Lingardi O., Ricketts D. Modern Blast Furnace Process. Moscow: Metallurgizdat; 2016:280. (In Russ.).

5. Ostroukhov M.Ya., Shparber L.Ya. Guide of Blast Furnace Master. Moscow: Metallurgiya; 1977:304. (In Russ.).

6. Bolshakov V.I., Semenov Y.S., Ivancha N.G., Vishnyakov V.I., Shumelchik E.I., Podkorytov A.L., Semion I.Y., Kuznetsov A.M., Zubenko A.V. Study of the flow of burden materials and their distribution on the furnace top of a modern blast furnace. Metallurgical and Mining Industry. 2012;4(3):158–165.

7. Bol’shakov V.I. The Technology of High-Efficiency Energy-Saving Blast Furnace Smelting. Kyiv: Naukova dumka; 2007:411. (In Russ.).

8. Bol’shakov V.I., Murav’eva I.G., Semenov Yu.S. Forecasting the thermal condition of blast furnace hearth. Stal’. 2009;(5):7–9. (In Russ.).

9. Babarykin N.N. Theory and Technology of Blast Furnace Process. Magnitogorsk: MSTU; 2009:257. (In Russ.).

10. Fojtik D., Tuma J., Faruzel P. Computer modelling of burden distribution in the blast furnace equipped by a bell-less top charging system. Ironmaking & Steelmaking. 2021;48(10):1226–1238. https://doi.org/10.1080/03019233.2021.1952829

11. Cameron I., Sukhram M., Lefebvre K., Davenport W. Blast Furnace Ironmaking: Analysis, Control and Optimization. 1st ed. Elsevier Science; 2019:828. https://doi.org/10.1016/C2017-0-00007-1

12. Gordon Y., Izumskiy N., Matveienko G., Chaika O., Lebid V., Vyshinskya O. Diagnostics, optimization and mathematical models of coke-sinter-hot metal production process. In: AISTech 2019 – Proceedings of the Iron & Steel Technology Conference. 2019;2019:479–484. https://doi.org/10.33313/377/050

13. Agrawal A., Agarwal M.K., Kothari A.K., Mallick S. A mathematical model to control thermal stability of blast furnace using proactive thermal indicator. Ironmaking & Steelmaking. 2019;46(2):133–140. https://doi.org/10.1080/03019233.2017.1353765

14. Ueda S., Natsui S., Nogami H., Yagi J., Ariyama T. Recent progress and future perspective on mathematical modeling of blast furnace. ISIJ International. 2010;50(7):914–923. https://doi.org/10.2355/isijinternational.50.914

15. Taylor A.G. The application of principal component analysis for predicting blast furnace stability. IFAC Proceedings Volumes. 1998;31(23):223–226. https://doi.org/10.1016/S1474-6670(17)35884-6

16. Pavlov A.V., Onorin O.P., Spirin N.A., Lavrov V.V., Gurin I.A. Some Issues of Technology, Management and Diagnostics of Blast Furnace Smelting. Yekaterinburg: AMK “Den’ RA”; 2023:282. (In Russ.).

17. Spirin N.A., Lavrov V.V., Rybolovlev V.Yu., Krasnobaev A.V., Onorin O.P., Kosachenko I.E. Model Decision Support Systems in the Automated Process Control System of Blast Furnace. Yekaterinburg: UrFU; 2011:462. (In Russ.).

18. Spirin N.A., Lavrov V.V., Rybolovlev V.Yu., Gileva L.Yu., Krasnobaev A.V., Shvydkii V.S., Onorin O.P., Shchipanov K.A., Burykin A.A. Mathematical Modeling of Metallurgical Processes in Automated Process Control. Yekaterinburg: UrFU; 2014:558. (In Russ.).

19. Methodology of functional modeling IDEF0. State standard of Russia. Moscow: IPK “Izdatel’stvo standartov”; 2000:75.

20. Waissi G.R., Demir M., Humble J.E., Lev B. Automation of strategy using IDEF0 – A proof of concept. Operations Research Perspectives. 2015;2:106–113. https://doi.org/10.1016/j.orp.2015.05.001

21. Popov A.I. Free Tools for Designing Information Systems. Moscow: IPK “Izdatel’stvo standartov”; 2014;78. (In Russ.).

22. Gurin I.A., Lavrov V.V., Spirin N.A., Nikitin A.G. Web-technologies for construction of automated information-modeling systems of technological processes in metallurgy. Izvestiya. Ferrous Metallurgy. 2017;60(7):573–579. (In Russ.). https://doi.org/10.17073/0368-0797-2017-7-573-579

23. Peralta J.H. Microservice APIs in Python: Using Python, Flask, Fastapi, Openapi and More. Manning Publications; 2023:425.

24. Price M.J. C# 10 and .NET 6 – Modern Cross-Platform Development. 6th Ed. Packt Publishing; 2021:826.

About the Authors

N. A. SpirinRussian Federation

Nikolai A. Spirin, Dr. Sci. (Eng.), Prof., Head of the Chair “Thermal Physics and Informatics in Metallurgy”

28 Mira Str., Yekaterinburg 620002, Russian Federation

I. A. Gurin

Russian Federation

Ivan A. Gurin, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Thermal Physics and Informatics in Metallurgy”

28 Mira Str., Yekaterinburg 620002, Russian Federation

V. V. Lavrov

Russian Federation

Vladislav V. Lavrov, Dr. Sci. (Eng.), Prof. of the Chair “Thermal Physics and Informatics in Metallurgy”

28 Mira Str., Yekaterinburg 620002, Russian Federation

Review

For citations:

Spirin N.A., Gurin I.A., Lavrov V.V. Information modeling system for assessing instability of blast furnace functioning. Izvestiya. Ferrous Metallurgy. 2025;68(4):402-410. https://doi.org/10.17073/0368-0797-2025-4-402-410