Scroll to:

Prospects for creation of high-speed high-entropy steels

https://doi.org/10.17073/0368-0797-2025-4-349-356

Abstract

A new class of materials created at the beginning of the 21st century – high–entropy alloys – attracts the attention of researchers in the field of physical materials science. Based on the analysis of recent literature data, the current state of the problem of creating and researching medium- and high-entropy high-speed steels is considered. Due to solid-solution hardening and nano-precipitation hardening based on medium- and high-entropy alloys of complex composition, it is possible to create high-speed steels with high hardness, thermal resistance and impact strength. The presented results of studies of tribological characteristics and microhardness of high-speed steels indicate the dependence of these characteristics on entropy. The lowest values of cutting forces and contact temperatures are typical for cutting tools made of high-speed steel with a high level of entropy. Thus, when developing new high-speed grades, preference should be given to the compositions with a high level of entropy, since they provide better tribological characteristics and higher wear resistance. The structural and phase state of surfacing of high-entropy high-speed molybdenum steel of non-equiatomic composition on medium-carbon steel in a nitrogen medium was studied by the methods of modern physical materials science. X-ray spectral analysis methods determined the elemental composition of surfacing outer layer, and X-ray phase analysis revealed that solid solutions based on α-iron (88 wt. %) and γ-iron (12 wt. %) are the main phases of the deposited layer material. The calculation of the configuration entropy of this high-speed high-entropy steel gives a value of 1.93R (where R is the universal gas constant). The conclusion is made about the relevance and prospects of the development and research of high-energy alloys.

Keywords

For citations:

Gromov V.E., Minenko S.S., Chapaikin A.S., Semin A.P., Shlyarova Yu.A. Prospects for creation of high-speed high-entropy steels. Izvestiya. Ferrous Metallurgy. 2025;68(4):349-356. https://doi.org/10.17073/0368-0797-2025-4-349-356

Introduction

The emergence of a new class of materials – high-entropy alloys (HEAs) and compounds – at the beginning of the 21st century marked a significant milestone in the development of metallic materials [1; 2]. The original findings from research into the structural–phase states and properties of a broad range of HEAs have been summarized in several studies [3; 4], as well as in analytical reviews and monographs [5 – 8]. Subsequent reports have described high-entropy carbides, borides, nitrides, silicides, and thin films and coatings produced via magnetron sputtering. The number of HEAs and related compounds synthesized to date is vast and continues to grow steadily. The composition and properties of HEAs can be predicted using thermodynamic calculations, particularly through the CALPHAD software package [9]. However, regardless of the design method used, it is ultimately the data on the structural–phase states and resulting material properties that determine potential areas of application. For example, several HEAs demonstrate high strength and ductility at low and even cryogenic temperatures, making them promising candidates for use in Arctic and Antarctic environments [9 – 11]. A review of recent publications in materials science, condensed matter physics, metallurgy, and heat treatment shows that all major types of HEAs with practical relevance are currently under development and investigation. These include structural, cryogenic-, and heat-resistant alloys, as well as corrosion-, radiation-, and wear-resistant materials, and those with specific magnetic or electrical properties. Particularly noteworthy are medium- and high-entropy high-speed steels [12; 13]. However, the number of publications dedicated to this topic remains limited.

High-speed steels are a subgroup of high-carbon martensitic steels that contain strong carbide-forming elements – primarily tungsten, molybdenum, vanadium, and others. Over the past century, since the development of the R18 high-speed steel grade, a range of tungsten–molybdenum steel grades – including R6M5, R7M4K5, and others – have been developed to meet the specific needs of the metalworking, mechanical engineering, and metallurgical industries. A major direction in the further development of high-speed steels involves replacing tungsten, which is both scarce and expensive, with molybdenum. This substitution is well justified, as molybdenum and tungsten are located in the same group and in adjacent periods of the Periodic Table of Elements developed by D.I. Mendeleev, and thus have comparable effects on the structure and properties of high-speed steels.

In recent years, researchers and practitioners alike have shown increasing interest in the development of HSSs based on high-entropy (HEAs) and medium-entropy alloys (MEAs) with complex compositions. These materials exhibit high hardness, thermal stability, and impact toughness as a result of solid-solution strengthening and nano-precipitation hardening [4; 14; 15]. An innovative HEA design strategy was proposed in [15], which involves introducing ductile, multicomponent intermetallic nanoparticles with high density. This approach has been shown to yield strength levels up to 1.5 GPa and ductility of up to 50 %. The addition of alloying elements such as aluminum, copper, cobalt, and nickel in equiatomic ratios increases the alloy’s configuration entropy, thereby improving its performance characteristics [16]. A comparative analysis was conducted on the properties of a newly developed MEA-based high-speed steel with the composition Fex(Al, Co, Cr, Cu, Ni)88.05Mo5N6C0.95 . The results demonstrated that this alloy shows superior hardness after quenching and tempering compared to the conventional R6M5 high-speed steel. This improvement is attributed to the alloy’s high degree of alloying, which enhances both solid-solution hardening within the martensitic matrix and dispersion strengthening. Additionally, the transformation of Me2C-type carbides contributes to compensating for the loss of hardness typically associated with a reduced total volume of carbides.

Ongoing research into the use of HEAs and MEAs for high-speed steel developing also offers economic advantages, particularly due to the use of low-cost base elements such as iron. When an alloy contains three or more elements in equiatomic proportions, its configuration entropy increases. For MEAs, the configuration entropy is typically around 1.0R to 1.5R (where R is the universal gas constant) [17 – 24]. In [25], laser surfacing was employed to produce a coating of medium-entropy high-speed steels with the composition Fe68(Al, Co, Cr, Cu, Mo, Ni, V, W)32 . The resulting coating exhibited a hard martensitic matrix with secondary hardening and a network of coherent nanoscale Me2C carbides. The high concentration of alloying elements provided excellent wear and oxidation resistance, with no formation of undesirable precipitates or coarse carbides. The addition of aluminum and cobalt was shown to improve strength and enhance secondary hardening [26; 27], while copper contributed to the formation of nanoscale carbide particles, helping to achieve an optimal balance of strength and impact strength [28]. Notably, the incorporation of chromium, cobalt, aluminum, and other antioxidant elements led to significantly lower thermal wear compared to laser-deposited coatings based on conventional high-speed steel grade R6M5. At the same time, the microstructure of the MEA-based coating remained similar to that of traditional high-speed steel and consists of a martensitic matrix with a finely dispersed carbide phase [25].

The optimized carbide distribution achieved through alloying and heat treatment, along with high hardness, makes MEA- and HEA-based high-speed steels promising for industrial applications. First, in conventional high-speed steel, increasing hardness typically requires raising the carbon content, which leads to the formation of a continuous network of primary carbides, thereby reducing impact toughness. Second, the high hardness and brittleness of conventional high-speed steels after quenching often impair machinability. In contrast, MEA- and HEA-based high-speed steels experience significant strengthening during tempering, allowing for lower hardness in the as-quenched state – an advantage that enhances their suitability for machining.

The CALPHAD (Calculation Phase Diagram) thermodynamic modeling approach enables the prediction of phase compositions in HEAs, as shown in studies [29 – 32]. However, this task remains challenging, largely due to incomplete thermodynamic descriptions – particularly for ternary systems [29].

A quantitative relationship between the entropy of high-speed steels and their tribological properties under dry sliding against structural and stainless steels was established in studies [12; 13; 33]. Focusing on the practical outcomes of these investigations, the authors interpret entropy primarily in terms of “thermal entropy,” which likely reflects the vibrational contribution – in addition to configurational and electronic components – to the total mixing entropy [34]. As shown in [34], mixing entropy is a key thermodynamic parameter for predicting the phase stability of HEAs. Using density functional theory (DFT) calculations, the authors quantified the individual contributions of vibrational, configurational, and electronic entropy. Accounting for all entropy components is crucial for developing a robust theoretical framework for the computational design of stable high-entropy alloys.

The ability to predict certain performance characteristics of experimental cutting tool materials in advance is supported by the study of thermodynamic aspects of wear processes under friction and cutting conditions. Wear resistance, a key factor determining tool life, is largely governed by the material’s tribological properties. Significant reductions in wear rate during friction and cutting can be achieved by creating a thermodynamic state characterized by a low density of accumulated thermal entropy. This effect can be achieved by using materials with inherently high entropy. High-entropy high-speed steels used in cutting applications are characterized by low absolute and relative thermoelectromotive force (thermo-EMF), which improves their resistance to gas corrosion. Both thermal entropy and thermo-EMF depend on the chemical composition of the material and can serve as integrated indicators of its structure. Thermal entropy (S), like other thermodynamic potentials, can be calculated using the additivity rule, provided the chemical composition is known (see Table 1). In [12], a correlation between the entropy of high-speed steel and its tribological properties as well as its elastic–strength characteristics in surface layers was confirmed experimentally.

Table 1. Composition and thermal entropy of high-speed steels [12; 13]

|

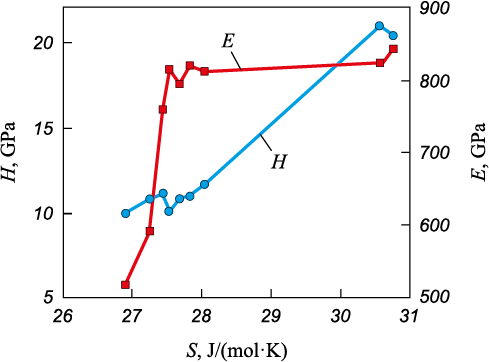

Studies on structural steel 30KhGSA have shown that increasing the entropy of high-speed steel leads to a rise in the microhardness and microelastic modulus of surface layers, while the coefficient of friction decreases at a sliding speed of 1 m/s.

Analysis of the steady-state friction force indicates a reduction in the adhesive component of friction in high-entropy high-speed steels. This effect is attributed to the lower tendency to form adhesive junctions and the reduced shear strength of those junctions, resulting in a lower friction coefficient.

The tendency of materials to form adhesive bonds (weld bridges) is influenced by the surface properties of low-entropy high-speed steels, such as R6M3 and R6M5 grades (Fig. 1). In these materials, lower hardness and higher ductility promote faster degradation of the protective surface film and more rapid formation of adhesive junctions.

Fig. 1. Dependence of microhardness (H) and microelastic modulus (E) |

The most favorable friction characteristics have been observed in steels with high entropy, which appears to be linked to the formation behavior and composition of the third body (transfer layer). In high-entropy high-speed steel, the growth rate of the third body exceeds its rate of breakdown, and the resulting third-body layer thickness promotes separation of the contacting surfaces, thereby reducing both the strength of adhesive bonds and the coefficient of friction. These effects manifest under conditions of sufficiently high thermomechanical activation in the friction zone. It has been established that deposited layers on samples of high-entropy high-speed steel exhibit greater stability due to the high hardness and low ductility of their surface layers. In [12], the authors examined third-body formation during friction in high-speed steels with different entropy levels. In the first approximation, this process is characterized by two parameters: the maximum attainable thickness of the transfer layer under given conditions and its relative growth rate. The study demonstrates that entropy, as a structure-sensitive parameter, can be used to predict the tribological behavior of both existing and newly developed high-speed steel grades.

Tribological tests of standard high-speed steel grades under dry sliding against 12Kh18N9T stainless steel have shown that frictional interaction in high-entropy high-speed steels is accompanied by a gradual thickening of the layer composed of dissipative structures over time [13]. This intermediate layer serves a shielding function, protecting the surfaces of the contacting bodies from damage. However, it also exhibits high shear resistance, resulting in elevated coefficients of friction. In contrast, the friction process in high-speed steels with low thermal entropy is characterized by a gradual convergence of the contacting bodies over time. This group of steels demonstrated lower friction coefficients, along with significant changes in surface microrelief compared to the initial condition.

Study [33] addresses the pressing issue of how cutting temperature and cutting forces relate to the entropy of high-speed steels. While tool wear resistance is known to be closely linked to the entropy of the material, the specific relationship between entropy – particularly as a structure-sensitive property – and cutting forces or temperatures during machining remains poorly understood. In machining, heat dissipation is the dominant energy loss mechanism in the cutting zone, and its intensity can be evaluated by monitoring temperature. Cutting temperature is primarily influenced by process parameters such as cutting speed, depth of cut, and feed rate – with cutting speed being the most critical. Elevated temperatures, driven by increased cutting forces, accelerate tool wear and limit the maximum usable cutting speed due to the heat resistance of the tool material.

Experimental studies of the same high-entropy high-speed steels (Table 1) demonstrated that, across all cutting speeds within the tested range, tools made from high-speed steel with higher thermal entropy consistently exhibited lower cutting forces and contact temperatures. These findings suggest that in the development of advanced high-speed steels, preference should be given to compositions with high thermal entropy, as they offer better tribological performance, greater wear resistance, and support higher cutting speeds and productivity compared to low-entropy alternatives.

In recent years, there has been growing interest in developing resource-efficient and energy-saving technologies for plasma and electric arc surfacing using high-hardness high-speed steels [35; 36]. The incorporation of nitrogen as an alloying element in these processes significantly improves wear resistance, strength, corrosion resistance, and impact strength. These enhancements are primarily attributed to increased microhardness of the coating’s structural components, resulting from the formation of carbonitrides. Electric arc surfacing in a nitrogen-rich shielding and alloying atmosphere using a current-carrying flux-cored wire offers significant advantages over alternative surfacing methods [35; 36].

However, there remains a notable lack of studies – particularly those employing modern physical materials science techniques – focused on elucidating the mechanisms responsible for the enhanced functional properties of M10-type high-speed steel surfacing. This knowledge gap limits their broader industrial application.

The objective of the present study is to investigate the structure, elemental composition, and phase composition of a non-equiatomic high-entropy M10-type high-speed steel surfacing using methods of modern physical materials science.

Materials and methods

The samples for investigation were fabricated by plasma surfacing using a current-carrying flux-cored wire in a nitrogen atmosphere on 30KhGSA structural steel. The chemical composition of 30KhGSA steel (wt. %): C 0.3; Cr 0.9; Mn 0.8; Si 0.9; balance – Fe. The chemical composition of the M10 surcacing alloy (wt. %): Mo 11.87; Cr 4.24; Co 3.48; V 1.77; Si 0.94; Mn 0.50. Technical-grade nitrogen (GOST 9293–74) was used as the shielding gas at a flow rate of 20–22 L/min. The surfacing was performed on a UD-417 unit under the following parameters: welding current 140 – 160 A, arc voltage 50 – 55 V, surfacing speed 15 – 18 m/h, and arc length 20 mm. The coating was deposited in four layers, with a total thickness of 9 mm.

The microstructure and elemental composition of the deposited layer were examined using a KYKY-EM6900 scanning electron microscope equipped with a thermionic tungsten cathode and an energy-dispersive X-ray spectrometer (EDS) for elemental microanalysis. Phase composition and structural parameters were analyzed using an XRD-6000 diffractometer with CuKα radiation. Phase identification was carried out using the PDF-4+ database in combination with full-pattern refinement via POWDER CELL 2.4 software.

Results and discussion

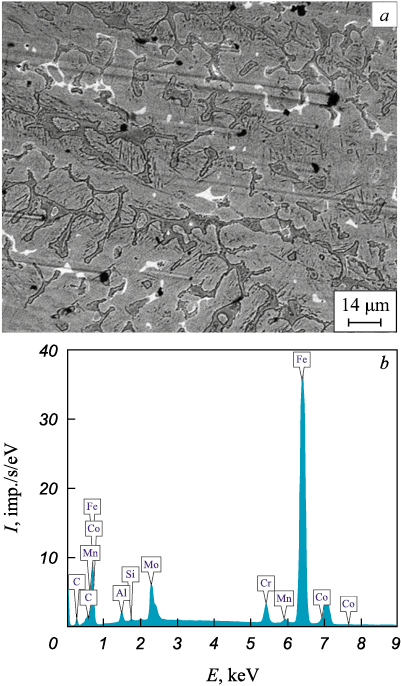

The etched cross-section of the layer formed by surfacing 30KhGSA steel with M9Yu flux-cored wire in a nitrogen atmosphere revealed a polycrystalline dendritic structure, as shown in Fig. 2.

Fig. 2. Electron microscopic image of structure of the deposited layer |

Energy-dispersive X-ray spectroscopy (EDS) analysis of the deposited surface (Fig. 2, Table 2) confirmed the presence of chemical elements matching the nominal composition of the alloy.

Table 2. Results of micro-X-ray spectral analysis of elemental composition

| ||||||||||||||||||||||||||||||||

Elemental mapping revealed localized enrichment of several alloying elements – namely molybdenum, chromium, and aluminum – within the surface layer of the deposited material, indicating a non-uniform distribution of elements.

X-ray phase analysis identified the dominant phases in the surfaced layer as solid solutions based on α-iron (88 wt. %) and γ-iron (12 wt. %). The formation of these solid solutions is corroborated by notable deviations of the measured lattice parameters – 0.28803 nm for α-Fe and 0.36050 nm for γ-Fe – from their standard reference values [37]. In addition, the XRD patterns exhibited low-intensity diffraction peaks attributed to carbide phases present in the surfaced layer.

The configuration entropy of the high-entropy high-speed steel investigated in this study, calculated following the methodology outlined in [38], was found to be 1.93R.

This analysis of recent advances in the development and characterization of medium- and high-entropy high-speed steels, combined with the authors’ experimental findings on the structural and phase composition of arc-surfaced layers produced in a nitrogen atmosphere using a non-equiatomic molybdenum-based high-entropy alloy, underscores the scientific and practical relevance of this research direction.

Conclusion

The article provides an overview of recent domestic and international studies on medium- and high-entropy high-speed steels. These steels exhibit superior hardness after quenching and tempering compared to conventional high-speed steel grade R6M5. The underlying strengthening mechanisms are examined, and correlations between configuration entropy and tribological performance under dry sliding conditions are discussed. The study presents experimental data on the structure, chemical composition, and phase constituents of a surfaced layer deposited onto medium-carbon steel using a high-entropy molybdenum-based high-speed steel. The findings support the conclusion that the development of next-generation high-entropy high-speed steels represents a promising direction in advanced tool material design.

References

1. Yeh J.-W., Chen Y.-L., Lin S.-J., Chen S.-K. High-entropy alloys – A new era of exploration. Materials Science Forum. 2007;560:1–9. https://doi.org/10.4028/www.scientific.net/MSF.560.1

2. Chapaikin A.S., Gromov V.E., Zhang P., Ivanov Yu.F., Kryukov R.E., Shlyarov V.V., Semin A.P. Structural-phase states and properties of plasma surfacing with high-speed steel in a nitrogen enviroment. Bulletin of the Siberian State Industrial University. 2024;(1(47)):35–46. (In Russ.). https://doi.org/10.57070/2304-4497-2024-1(47)-35-47

3. Pochetukha V.V., Bashchenko L.P., Gostevskaya A.N., Budovskikh E.A., Gromov V.E., Chapaikin A.S. Structure and properties of plasma coatings from high-speed steel after high-temperature tempering. Bulletin of the Siberian State Industrial University. 2023;(3(45)):30–38. (In Russ.). https://doi.org/10.57070/2304-4497-2023-3(45)-30-38

4. Liu H., Gu C., Zhai K., Wang C. Strengthening and toughening the FeNiCrMn medium entropy alloy by novel ultrafine precipitate networks. Vacuum. 2020;184:109995. https://doi.org/10.1016/j.vacuum.2020.109995

5. Miracle D.B., Senkov O.N. A critical review of high entropy alloys and related concepts. Acta Materialia. 2017;122: 448–511. https://doi.org/10.1016/j.actamat.2016.08.081

6. Zhang W., Liaw P.K., Zhang Y. Science and technology in high-entropy alloys. Science China Materials. 2018;61(1): 2–22. https://doi.org/10.1007/s40843-017-9195-8

7. Gromov V.Е., Konovalov S.V., Ivanov Yu.F., Osintsev K.A. Structure and Properties of High-Entropy Alloys. Springer, Advanced Structured Materials: 2021;107:110. https://doi.org/10.1007/978-3-030-78364-8

8. Gromov V.Е., Ivanov Yu.F., Osintsev K.A., Shlyarova Yu.A., Panchenko I.A. High Entropy Alloys: Structure and Properties. Moscow: Ru Science; 2022:204.

9. Rogachev A.S. Structure, stability, and properties of high-entropy alloys. Physics of Metals and Metallography. 2020;121: 733–864. https://doi.org/10.1134/S0031918X20080098

10. Murty B.S., Yeh J.-W., Ranganathan S., Bhattacharjee P.P. High-Entropy Alloys. 2nd ed. Amsterdam: Elsevier; 2019:374.

11. Zhang Y. High-Entropy Materials: A Brief Introduction. Singapore: Springer Nature; 2019:159. https://doi.org/10.1007/978-981-13-8526-1

12. Ryzhkin A.A., Fominoff E.V., Shuchev C.G. Study on tribological characteristics of high entropy high-speed steels in conditions of dry friction on structural steel. In: Proceedings of the 4th Int. Conf. on Industrial Engineering. 2018:1819–1827. https://doi.org/10.1007/978-3-319-95630-5_195

13. Fominov E., Shuchev C., Cherednichenko O., Metelkova N., Filonenko L. Tribological properties of high-entropy high-speed steels under conditions of friction on stainless steel 12H18N9T. In: XI Int. Sci. and Pract. Conf. Innovative Technologies in Environmental Science and Education (ITSE-2023). 2023;431:06013. https://doi.org/10.1051/e3sconf/202343106013

14. He J.Y., Wang H., Huang H.L, Xu X.D., Chen M.W., Wu Y., Liu X.J., Nieh T.G., An K., Lu Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Materialia. 2016;102:187–196. https://doi.org/10.1016/j.actamat.2015.08.076

15. Yang T., Zhao Y.L., Tong Y., Jiao Z.B., Wei J., Cai J.X., Han X.D., Chen D., Hu A., Kai J.J., Lu K., Liu Y., Liu C.T. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science. 2018;362(6427): 933–937. https://doi.org/10.1126/science.aas8815

16. Dou B., Zhang H., Tao Y., Ma Q., Guo S. Effect of Fe on type and distribution of carbides in medium-entropy high-speed steels. Tungsten. 2023;5(1):189–197. https://doi.org/10.1007/s42864-022-00138-5

17. Gludovatz B., Hohenwarter A., Thurston K.V.S., Bei H., Wu Z., George E.P., Ritchie R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nature Communications. 2016;7:10602. https://doi.org/10.1038/ncomms10602

18. Huang H., Wang J., Yang H., Ji S., Liu Z. Strengthening CoCrNi medium-entropy alloy by tuning lattice defects. Scripta Materialia. 2020;188:216–221. https://doi.org/10.1016/j.scriptamat.2020.07.027

19. Zhang H., Pan Y., He Y.Z., Jiao H.S. Microstructure and properties of 6FeNiCoSiCrAlTi high-entropy alloy coating prepared by laser cladding. Applied Surface Science. 2011;257(6):2259–2263. https://doi.org/10.1016/j.apsusc.2010.09.084

20. Yao M.J., Pradeep K.G., Tasan C.C., Raabe D. A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility. Scripta Materialia. 2014;72-73:5–8. https://doi.org/10.1016/j.scriptamat.2013.09.030

21. Zhuang Y.X., Liu W.J., Chen Z.Y., Xue H.D., He J.C. Efect of elemental interaction on microstructure and mechanical properties of FeCoNiCuAl alloys. Materials Science and Engineering: A. 2012;556:395–399. https://doi.org/10.1016/j.msea.2012.07.003

22. Aguilar-Hurtado J.Y., Vargas-Uscategui A., Zambrano-Mera D., Palma-Hillerns R. The effect of boron content on the microstructure and mechanical properties of Fe50–XMn30Co10Cr10BX (X = 0, 0.3, 0.6 and 17 wt.%) multi-component alloys prepared by arc-melting. Material Science and Engineering: A. 2019;748:244–252. https://doi.org/10.1016/j.msea.2019.01.088

23. Choi M., Ondicho I., Park N., Tsuji N. Strength–ductility balance in an ultrafne-grained non-equiatomic Fe50(CoCrMnNi)50 mediumentropy alloy with a fully recrystallized microstructure. Journal of Alloys Compounds. 2019;780:959–966. https://doi.org/10.1016/j.jallcom.2018.11.265

24. Li R., Wang Z., Guo Z., Liaw P., Tao Z., Li L., Zhang Y. Graded microstructures of Al-Li-Mg-Zn-Cu entropic alloys under supergravity. Science China Materials. 2019;62(5): 736–744. https://doi.org/10.1007/s40843-018-9365-8

25. Zhang H., Dou B., Tang H., He Y., Guo S. Secondary hardening in laser rapidly solidified Fe68(MoWCrVCoNiAlCu)32 medium-entropy high-speed steel coatings. Materials and Design. 2018;159:224–231. https://doi.org/10.1016/j.matdes.2018.08.050

26. Ma S., Pan W., Xing J., Guo S., Fu H., Lyu P. Microstructure and hardening behavior of Al-modified Fe–1.5 wt%B–0.4 wt%C highspeed steel during heat treatment. Materials Characterization. 2017;132:1–9. https://doi.org/10.1016/j.matchar.2017.08.001

27. Moon H.K., Lee K.B., Kwon H. Influences of Co addition and austenitizing temperature on secondary hardening and impact fracture behavior in P/M high speed steels of W–Mo–Cr–V(–Co) system. Material Science and Engineering: A. 2008;474(1-2):328–334. https://doi.org/10.1016/j.msea.2007.04.014

28. Long B.Z., Zhang Y., Guo C.H., Cui Y., Sun L.X., Chen D., Jiang F.C., Zhao T., Zhao G., Zhang Z.W. Enhanced dynamic mechanical properties and resistance to the formation of adiabatic shear band by Cu-rich nano-precipitates in high-strength steels. International Journal of Plasticity. 2020;138:102924. https://doi.org/10.1016/j.ijplas.2020.102924

29. Do H.-S., Choi W.-M., Lee B.-J. A thermodynamic description for the Co-Cr-Fe-Mn-Ni system. Journal of Materials Science. 2022;57:1373–1389. https://doi.org/10.1007/s10853-021-06604-8

30. Otto F., Dlouhý A., Pradeep K.G., Kuběnová M., Raabe D., Eggeler G., George E.P. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Materialia. 2016;112:40–52. https://doi.org/10.1016/j.actamat.2016.04.005

31. Stepanov N.D., Shaysultanov D.G., Ozerov M.S., Zherebtsov S.V., Salishchev G.A. Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing. Materials Letters. 2016;185:1–4. https://doi.org/10.1016/j.matlet.2016.08.088

32. Shafiei A. Design of eutectic high entropy alloys. Metallurgical and Materials Transactions A. 2022;53:4329–4361. https://doi.org/10.1007/s11661-022-06831-x

33. Beskopylny A.N., Fominov E.V., Shuchev C.G., Egorov M.S. The influence of thermodynamical characteristics of high speed steels on temperature and forces values when turning construction steel. IOP Conference Series: Materials Science and Engineering. 2020;996:012003. https://doi.org/10.1088/1757-899X/996/1/012003

34. Mauzoor A., Pandey S., Chokraborty D., Phillpot S.R., Aidhy D.S. Entropy contributions to phase stability in binary random solid solutions. Computational Materials. 2018;4(1):47. https://doi.org/10.1038/s41524-018-0102-y

35. Gromov V.E., Chapaikin A.S., Nevskii S.A. Structure, Properties and Models of High-Speed Steel after Tempering and Electron Beam Treatment. Novokuznetsk: Polygraphist; 2024:171. (In Russ.).

36. Ivanov Yu.F., Gromov V.E., Potekaev A.I., Guseva T.P., Chapaikin A.S., Vashchuk E.S., Romanov D.A. Structure and properties of R18U surfacing of high-speed steel after its high tempering. Russian Physics Journal. 2023:66(7): 731–739. https://doi.org/10.1007/s11182-023-02999-w

37. Kurdyumov V.G., Utevskii L.M., Entin R.I. Transformations in Iron and Steel. Moscow: Nauka; 1977:238. (In Russ.).

38. Osintsev K.A., Panchenko I.A., Konovalov S.V. Prediction of the phase composition of Co-Cr-Zr-Mn-Ni high-entropy alloy by calculating phenomenological criteria. Fundamental’nye problemy sovremennogo materialovedeniya. 2021;18(4):441–449. (In Russ.). https://doi.org/10.25712/ASTU.1811-1416.2021.04.006

About the Authors

V. E. GromovRussian Federation

Viktor E. Gromov, Dr. Sci. (Phys.-Math.), Prof., Head of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

S. S. Minenko

Russian Federation

Sergei S. Minenko, Candidates for a degree of Cand. Sci. (Eng.) of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. S. Chapaikin

Russian Federation

Aleksandr S. Chapaikin, Postgraduate of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. P. Semin

Russian Federation

Aleksandr P. Semin, Cand. Sci. (Eng.), Senior Researcher of the Department of Scientific Research, Assist. Prof. of the Chair of Engineering Structures, Building Technologies and Materials

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Yu. A. Shlyarova

Russian Federation

Yuliya A. Shlyarova, Research Associate of Department of Scientific Researches

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Gromov V.E., Minenko S.S., Chapaikin A.S., Semin A.P., Shlyarova Yu.A. Prospects for creation of high-speed high-entropy steels. Izvestiya. Ferrous Metallurgy. 2025;68(4):349-356. https://doi.org/10.17073/0368-0797-2025-4-349-356