Scroll to:

Using digital simulation models to optimize the operation of complex production facilities

https://doi.org/10.17073/0368-0797-2025-2-188-194

Abstract

Using the example of formalized description of the converter production at JSC EVRAZ United West Siberian Metallurgical Plant consisting of two converter shops with two and three units, it is shown that the issues of planning production volumes and repairs of metallurgical units, building end-to-end schedules of units are complex and multifactorial tasks characterized by the discreteness and non-linearity of the functions describing them. The formalization of the tasks of optimizing production processes with specified constraints and criteria showed that features of the studied process of converter production make it almost impossible to build and use analytical solutions. The approach chosen by the authors to the solution (taking into account these circumstances) is based on the use of a digital discrete event simulation model. Such a model is a digital copy of the investigated process of converter production, reflects its structure, performance, technical condition and parameters: duration of converter campaign, duration of repair periods, etc. The model uses various control mechanisms to solve the problems of distributing the input flow of cast iron between converter shops, forming schedules for the operation of individual converters and their repairs, accumulates information as it functions for the purpose of optimizing and predicting the results of the operation process. It allows one to collect data on the operation of converter production and use predictive analytics tools to plan repairs, provides data that cannot be obtained directly on a physical object and which can be used to optimize system parameters, and generates datasets for visualizing individual results of the operation process.

Keywords

For citations:

Zimin A.V., Kornet M.Е., Burkova I.V., Zimin V.V. Using digital simulation models to optimize the operation of complex production facilities. Izvestiya. Ferrous Metallurgy. 2025;68(2):188-194. https://doi.org/10.17073/0368-0797-2025-2-188-194

Introduction

The tasks of planning repairs and calendar schedules for converter operation in the steelmaking production of a metallurgical plant have significant specific features, which are due to the discreteness, non-linearity, and strong interdependence of these tasks. It is advisable to approach such tasks as a comprehensive solution to a single general task, without decomposition, since under conditions of strong interrelations, decomposition does not allow for stable and effective solutions to individual subtasks due to the limitations imposed by the decomposition procedure [1; 2]. However, obtaining a comprehensive solution using analytical methods for the planning object under consideration is extremely difficult – if not entirely impossible. Therefore, the authors of the study decided to construct a discrete event digital simulation model of the functioning process of converter production at a metallurgical plant with two steelmaking shops, comprising two and three converters, respectively [3 – 5]. The presence of such a model makes it possible to find a comprehensive solution to the tasks under investigation.

Evolution of simulation model concepts

and modern functional requirements

The original concept of a simulation model was developed for industrial products, where a clear link existed between the simulation model and the product at every stage of its life cycle – from creation to disposal. As the approach evolved, it was extended to cover production processes as well [6 – 8]. According to the framework presented in [3], the evolution of simulation models progresses through four stages:

1 – physical objects (products) are created without any simulation model (i.e., no digital prototype);

2 – a simulation model (digital prototype) is used only at the design stage of the product;

3 – there is information exchange between the physical object and the digital model;

4 – physical object and digital model interact in real time, enabling continuous improvement of both the physical system and its digital counterpart.

This concept – involving real-time interaction between a physical object (or process) in the real world and its digital model in the virtual space, as well as the exchange of information between the two – reflects the idea of a digital twin [9 – 11].

Based on this classification, the goal of the present study is to develop a digital model of the functioning process of converter production at a metallurgical plant that corresponds to the third stage of this evolution. At the current stage, generally accepted functional requirements for such a digital model of converter production include the following:

– accurately representing the structure of production, the performance and technical condition of units, the duration of converter campaigns, the length of repair periods, and other key parameters;

– employing various control mechanisms to distribute the input flow of cast iron between converter shops and to generate calendar schedules for the operation and repair of individual converters;

– accumulating operational data over time for the purpose of optimizing and forecasting the performance of the production process;

– collecting data on the functioning of converter production and applying predictive analytics tools for repair planning;

– providing information that cannot be obtained directly from the physical object but is valuable for optimizing the performance parameters of converter production;

– generating datasets that support the visualization of individual aspects of the model’s functioning process [12 – 14].

The virtual component of the digital twin consists of two main parts: the digital master and the digital shadow. The digital master contains the core information required to construct the simulated process. The digital shadow represents the set of data that the functioning physical object (process) “casts” into the virtual space, along with models that allow for forecasting the properties of the process within certain limits [15 – 17].

Elements of formalized description of converter production functioning process

Basic concepts and notation. Let us denote the steelmaking production as O = {OI , OII }, which includes two shops. Here, OI = {o1 , o2 , o3 } and OII = {o4 , o5 }, meaning that the first shop includes three converters of the same type, and the second shop consists of two identical units. As the time interval for the planning tasks under investigation, we consider a sequence (T1 , T2 , …, Tj , …, Tp ) of p months, \({T_j} = (\Delta {t_l}|l = {\overline {1,L} _j})\) (where Lj denotes the number of days in the j-th month). Each converter is treated as a discrete unit operating in cyclical mode. When describing a converter, we introduce the tuple oi = o( fi , ρi , gi , Ki , \(k_{ij}^b\), ri ), (where fi – amount of steel produced by the unit per cycle (tons); ρi – consumption coefficient characterizing the need for cast iron gi to produce one ton of steel (gi = fiρi , ρ < 1); Ki – normative duration of the campaign of the converter (i.e. the number of heats the unit must perform on one lining from one cold repair to the next); \(k_{ij}^b\) – number of heats completed by the i-th converter at the beginning of the j-th planning period; riν , \(\nu = \overline {1,2,...} \) – durations (in days) of shutdowns (due to repair or waiting) for the i-th converter. Due to the uniformity of converters in each shop, the following equalities can be assumed:

| \[\begin{array}{c}{f_i} = {f_I},{\rm{ }}i = \overline {1,3} {\rm{; }}{\rho _i} = {\rho _I}, i = \overline {1,3} {\rm{; }}\\{g_i} = {g_I}; {K_i} = {K_I},{\rm{ }}i = \overline {1,3} ;\end{array}\] | (1) |

| \[\begin{array}{c}{f_i} = {f_{II}}, i = \overline {4,5} {\rm{; }}{\rho _i} = {\rho _{II}}, i = \overline {4,5} {\rm{; }}\\{g_i} = {g_{II}};{K_i} = {K_{II}},{\rm{ }}i = \overline {4,5} .\end{array}\] | (2) |

Let us denote by mij (Δtl ), mIj (Δtl ), mIIj (Δtl ) the number of heats produced by converter i, and by shops OI and OII , respectively, during the l-th day of the j-th period. Accordingly, we have

| \[\begin{array}{c}\sum\limits_{i = 1}^3 {{m_{ij}}(\Delta {t_l})} = {m_{Ij}}(\Delta {t_l});\\\sum\limits_{i = 4}^5 {{m_{ij}}(\Delta {t_l})} = {m_{IIj}}(\Delta {t_l}).\end{array}\] | (3) |

The calendar schedule of operation of the i-th converter in the j-th month is defined as the sequence

| \[({m_{ij}}(\Delta {t_l})|l = {\overrightarrow {1,L} _j}).\] | (4) |

If l is a day on which the converter undergoes repair or is placed in reserve, then mij(Δtl ) = 0.

We introduce the function kij(l), which represents the number of heats performed by the i-th converter from the beginning of the campaign up to and including the l-th day of the j-th period. The values of this function are limited by the normative duration of the converter campaign

| \[{k_{ij}}(l) \le \left\{ {\begin{array}{*{20}{c}}{{K_I},{\rm{ }}i = \overline {1,3,} }\\{{K_{II}},{\rm{ }}i = \overline {4,5.} }\end{array}} \right.\] | (5) |

Let us denote by \(k_{ij}^b\) the number of heats completed by the i-th converter at the beginning of the j-th planning period. Then, taking into account condition (4), the number of heats \(k_{ij}^e\), produced by the i-th converter by the end of the j-th planning period can be represented as

| \[k_{ij}^e = k_{ij}^b + \sum\limits_{l = 1}^{{S_j}} {{m_i}\left( {\Delta {t_{{s_j}}}} \right)} ,\] | (6) |

where \(k_{ij}^e = k_{ij + 1}^n.\)

Structural constraints on the functioning of converters in the shops. When a converter executes the calendar schedule of operation as defined in expression (4), the value of the function increases by mij(Δtl ) on each subsequent day, according to the rule: [kij(l) = kij (l – 1) + mij(Δtl )], until it reaches the normative duration of the converter campaign. The function kij(l) has a “sawtooth” form, where the width of each “tooth” base depends on the calendar schedule of the converter’s operation and may span several planning periods. Once the maximum value is reached, the function retains this value until the end of the converter’s repair. Upon completion of the repair (or when the converter is placed in reserve), the function resets to zero. The fluctuations of the function kij(l) are regular in nature, but they do not follow a fixed period.

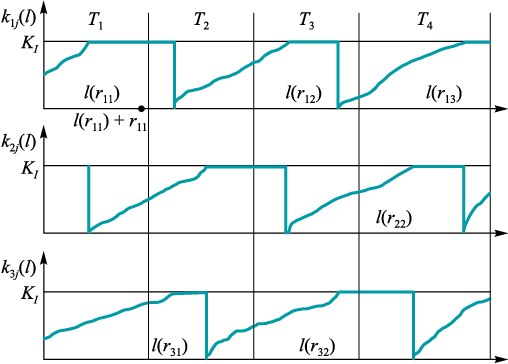

Fig. 1. Design operation scheme of converters of Shop 1 |

The design scheme of converter operation for Shop 1 is presented in Fig. 1. According to this scheme, simultaneous operation of all three converters is not allowed. Instead, the configuration assumes the continuous operation of two units, while the third is either undergoing repair or is held in reserve. This structure ensures that at any given time, exactly two converters are active, thereby maintaining a balanced operational load and enabling scheduled repairs without full production stoppage. Let us define the state sij (l) of the i-th converter of the first shop on the l-th day of the j-th planning period as follows:

| \[{s_{ij}}(l) = \left\{ {\begin{array}{*{20}{c}}{wr,{\rm{ }}0 \le {k_{ij}}(l) \le K;}\\{rm,{\rm{ }}{k_{ij}}(l) = K;}\\{rz,{\rm{ }}{k_{ij}}(l) = 0.}\end{array}} \right.\] | (7) |

A description of the state transitions of the converters during the time interval from l(r11 ) to l(r31 ) (see Fig. 1) is presented in the corresponding Table.

Operating procedure of converters of Shop 1

| |||||||||||||||||

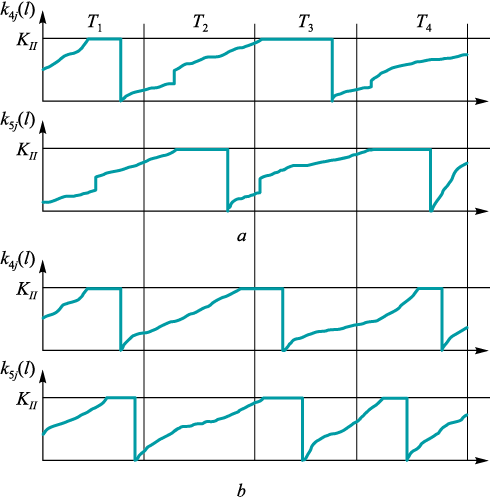

The design solutions and the repair management system for the second shop do not allow more than one cold repair to be carried out within a single planning period. Fig. 2 presents examples of permissible and unacceptable operational schemes for the converters in the second shop.

Fig. 2. Permissible (a) and unacceptable (b) operating schemes |

It should be noted that, in order to achieve maximum separation between the repairs of converters 4 and 5 – expressed in terms of the number of heats performed – the absolute difference between the values of the functions k4 (l) and k5 (l) must be as large as possible. The maximum value of this absolute difference equals K/2 (Fig. 3). This maximum separation condition also applies to the first shop, since, according to the design scheme of converter operation, two out of the three units are in operation on each day.

Fig. 3. Dependence of the absolute difference |k4(l) – k5(l)| |

Quantitative constraints on converter operation. The simultaneous operation of units within the shops is subject to a set of technological constraints that define the allowable range for the number of heats per day in each shop, depending on whether one or two converters are operating at the same time:

| \[\underline {m_I^1} \le {m_{ij}}(\Delta {t_l}) \le \overrightarrow {m_I^1} ,{\rm{ }}i = {\rm{ }}\overline {1,3} ,{\rm{ }}j = \overrightarrow { 1,P} ;\] | (8) |

| \[\underline {m_{II}^1} \le {m_{ij}}(\Delta {t_l}) \le \overrightarrow {m_{II}^1} ,{\rm{ }}i = \overline {4,5} ,{\rm{ }}j = \overrightarrow {1,P} ;\] | (9) |

| \[\begin{array}{c}2\underline {m_I^1} \le \left[ {{m_{ij}}(\Delta {t_l}) + {m_{i'j}}(\Delta {t_l})} \right] \le \overline {2m_I^1} ;{\rm{ }}\\i \ne i',{\rm{ }}i,{\rm{ }}i' = \overline {1,3} ,{\rm{ }}j = \overrightarrow {1,P} ;\end{array}\] | (10) |

| \[2\underline {m_{II}^1} \le \left[ {{m_{4j}}(\Delta {t_l}) + {m_{5j}}(\Delta {t_l})} \right] \le \overline {2m_{II}^1} ,{\rm{ }}j = \overrightarrow {1,P} ,\] | (11) |

where \(\underline {m_I^1} \), \(\overrightarrow {m_I^1} \), \(\underline {m_{II}^1} \), \(\overrightarrow {m_{II}^1} \), 2\(\underline {m_I^1} \), 2\(\overrightarrow {m_I^1} \), 2\(\underline {m_{II}^1} \), 2\(\overrightarrow {m_{II}^1} \) represent the minimum and maximum number of heats produced in the first and second shops, respectively, under two operating modes: with a single converter in operation, and with two converters in operation. Note that 2\(\underline {m_I^1} \) < \(\overrightarrow {m_I^1} \) and 2\(\underline {m_{II}^1} \) < \(\overrightarrow {m_{II}^1} \), since otherwise, the shop would be unable to produce the number of heats within the ranges from \(\overrightarrow {m_I^1} \) to 2\(\underline {m_I^1} \) and from \(\overrightarrow {m_{II}^1} \) to 2\(\underline {m_{II}^1} \), which does not correspond to actual operating conditions. Operation involving three converters simultaneously in the first shop is technologically infeasible.

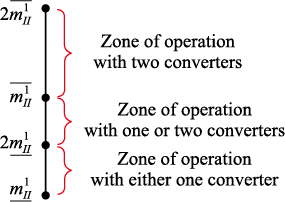

Thus, the first shop, which according to the design solutions must operate continuously with two converters, can produce between 2\(\underline {m_I^1} \) and 2\(\underline {m_{II}^1} \) heats per day. Each unit may perform between \(\underline {m_I^1} \) and \(\overrightarrow {m_I^1} \) heats. The second shop, in the range from \(\underline {m_{II}^1} \) to 2\(\underline {m_{II}^1} \) heats, can operate only with one converter (operating mode 1), in the range from 2\(\underline {m_{II}^1} \) to \(\overrightarrow {m_{II}^1} \) it can operate with either one or two converters (operating mode 2), and in the range from \(\overrightarrow {m_{II}^1} \) to 2\(\overrightarrow {m_{II}^1} \) it can operate only with two converters (operating mode 3) (Fig. 4).

Fig. 4. Ranges of operating modes of converters of Shop 2 |

Determining the required daily cast iron production volumes in the blast furnace shop. Cast iron, which serves as the main component of the converter charge, is produced by three blast furnaces (continuous-operation units). Each blast furnace is described by the following parameters: the average daily cast iron production volume gq(Δt) at full capacity, which depends on the furnace volume; the production volume at reduced capacity gq(Δt)/2, which may apply during periods of scheduled preventive maintenance, the overhaul schedule \(\left[ {{r_q}{\rm{ = }}\Delta {t_l}{\rm{| }}l {\rm{ = }}\left( {\overline {l_{qj}^b,l_{qj'}^e} } \right)} \right]\) typically carried out once every 4 – 5 years; the schedule \(r_{qj}^{{\rm{ppr}}} = (l_{qj}^1,{\rm{ }}..,{\rm{ }}l_{qj}^\nu ),\) of planned preventive repairs during the j-th planning period, whose duration usually does not exceed 12 h (here \(q = \overline {1,3} \) is the number of the blast furnace; \(l_{qj}^b,{\rm{ }}l_{qj'}^e\) are the start and end dates of the overhaul, respectively; ν is the number of planned preventive repairs in the j-th planning period.

Let gqj (Δtl ) denote the planned cast iron production volume for the q-th blast furnace on the l-th day of the j-th planning period

| \[{g_{qj}}(\Delta {t_l}) = \left\{ {\begin{array}{*{20}{c}}{{g_q}(\Delta t),{\rm{ }}l \notin (\overline {l_{qj}^b,{\rm{ }}l_{q{j^/}}^e} );}\\{0,{\rm{ }}l \in (\overline {l_{qj}^b,{\rm{ }}l_{q{j^/}}^e} );}\\{\frac{{{g_q}(\Delta t)}}{2},{\rm{ }}l \in (l_{qj}^1,{\rm{ }}..,{\rm{ }}l_{qj}^\nu ).}\end{array}} \right.\] | (12) |

It is clear that the total cast iron production volume on l-th day is equal to

| \[{g_j}(\Delta {t_l}) = \sum\limits_{q = 1}^3 {{g_{qj}}(\Delta {t_l})} ,{\rm{ }}l = \overline {1,{L_j}} .\] | (13) |

The sequence \(\left( {{g_j}(\Delta {t_l})|l = \overline {1,{L_j}} } \right)\) describes the planned daily cast iron production of the blast furnace shop during the j-th planning period. Given the calendar schedule of converter operation defined by expression (4), the following equalities must hold

| \[{g_I}\sum\limits_{i = 1}^3 {{m_{ij}}(\Delta {t_l}) + {\rm{ }}} {g_{II}}\sum\limits_{i = 4}^5 {{m_{ij}}(\Delta {t_l}) = {g_j}(\Delta {t_l}),{\rm{ }}l = \overline {1,{L_j}} } .\] | (14) |

Specific features of the tasks under investigation

and the approach to their solution

The main applied tasks that require solutions based on the above-described model representations of the object of study include:

1. Forming the schedules \(\left( {{m_{Ij}}(\Delta {t_l})|l = \overline {1,{L_j}} } \right),{\rm{ }}\left( {{m_{IIj}}(\Delta {t_l})|l = \overline {1,{L_j}} } \right)\) of converter heats based on the cast iron production schedule \(\left( {{g_j}(\Delta {t_l})|l = \overline {1,{L_j}} } \right)\) for each j-th period, in order to determine monthly planned targets for the converter shops;

2. Forming the repair schedules for the converters

| \[\begin{array}{c}{\left( {l_{ij}^n,{\rm{ }}l_{ij'}^e} \right)_\nu } \subset \bigcup\limits_{j = 1}^P {{T_j}} ,{\rm{ }}i = {\rm{ }}\overrightarrow {1,5} ,{\rm{ }}\nu = \overline {1,2,...} ,{\rm{ }}\\{r_\nu } = \left\{ {\begin{array}{*{20}{c}}{l_{ij'}^e - l_{ij}^n,{\rm{ }}j = j';{\rm{ }}}\\{{L_j} - l_{ij}^n + l_{ij'}^e,{\rm{ }}j \ne j'}\end{array}} \right.\end{array}\] | (15) |

in the converter production shops, with the aim of planning the work of the maintenance services of the metallurgical plant;

3. Forming the operation \(\left[ {({m_{ij}}(\Delta {t_l})|l = {{\overrightarrow {1,L} }_j})|i = \overline {1,3} } \right]\) and \(\left[ {({m_{ij}}(\Delta {t_l})|l = {{\overrightarrow {1,L} }_j})|i = \overline {4,5} } \right]\) schedules of the converter shops, to ensure processing of incoming liquid cast iron from the blast furnace shop.

Thus, the main features of the investigated tasks include the discreteness and non-linearity of the functions, functionals, operators, parameters, and criteria that define these tasks. In particular, according to Fig. 3, one of the preferred criteria in calendar scheduling may be defined as follows

| \[\begin{array}{c}Q = \sum\limits_{j = 1}^P {\left[ {\left( {\left| {k_{ij}^e - k_{i'j}^e} \right| - 0,5{K_1}} \right)} \right. + } \\\left. { + \left( {\left| {k_{4j}^e - k_{5j}^e} \right| - 0,5{K_{II}}} \right)} \right] \to \min ,\end{array}\] | (16) |

this criterion is aimed at ensuring the maximum separation of repairs of the two operating converters (expressed in terms of the number of heats performed). The corresponding functional Q belongs to the class of discrete and nonlinear functionals. The discreteness and non-linearity of the tasks hinder or make it impossible to build analytical models capable of identifying and ranking the set of admissible solutions.

Thus, the formalization of the studied tasks shows that the specific features of the process of functioning of converter production make it difficult – or practically impossible – to develop and apply analytical solutions. Considering these circumstances, the authors selected an approach based on the development and use of a digital discrete event simulation model, which:

– serves as a digital copy of the process of functioning of the converter production under study, reflects its structure, performance, technical condition, and parameters such as duration of converter campaigns, repair periods, and others;

– applies various control mechanisms to solve the tasks of distributing the input flow of cast iron between converter shops and forming calendar schedules for the operation and repair of individual converter;

– accumulates information over the course of its functioning for the purpose of optimization and forecasting of the process results;

– allows collecting data on the process of functioning of converter production and using predictive analytics tools to plan repairs;

–provides data that cannot be obtained directly on the physical object, but can be used to optimize the parameters of the system;

– generates datasets for the visualization of individual results of the functioning process [18 – 20].

Conclusions

A significant interdependence, discreteness, and non-linearity of the tasks related to planning production volumes, repairs, and converter operation schedules have been demonstrated. The necessity of developing a digital discrete-event simulation model of the process of functioning of converter production at a metallurgical plant has been substantiated, in order to obtain numerical solutions to the tasks under study through computer modeling.

References

1. Lesdon L. Optimization of Large Systems. Moscow: Nauka; 1975:432. (In Russ.).

2. Hamann-Lohmer J., Lasch R. Production planning and scheduling in multi-factory production networks: A systematic literature review. International Journal of Production Research. 2021;59(7):2028–2054. https://doi.org/10.1080/00207543.2020.1797207

3. Prokhorov A., Lysachev M. The Digital Doppelganger. Analysis, Trends, and World Experience. Borovkov A.I. ed. Moscow: All’ansPrint; 2020:401. (In Russ.).

4. Glaessgen E.H., Stargel D.S. The digital twin paradigm for future NASA and U.S. air force vehicles. In: 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conf. 20th AI. 23–26 April 2012, Honolulu, Hawaii. https://doi.org/10.2514/6.2012-1818

5. The new age of manufacturing: Digital twin technology & IoT [Electronic resource]. URL: http://www.innovation4.cn/library/r46394/. (Accessed: 20.01.2025).

6. Modern manufacturing’s triple play: Digital twins, analytics and the internet of things [Electronic resource]. URL: https://www.nextspace.com/recommended-reading/modern-manufacturings-triple-play-digital-twins-analytics-and-iot. (Accessed: 20.01.2025).

7. Digital doppelgangers in retail – who are they and why do you urgently need to get to know them? [Electronic resource]. Available at URL: https://new-retail.ru/tehnologii/tsifrovye_dvoyniki_v_riteyle_kto_eto_takie_i_pochemu_s_nimi_srochno_nuzhno_znakomitsya5533/?ysclid=m8ajyzvqlj502045804. (Accessed: 20.01.2025). (In Russ.).

8. “15 key components of modern production” (Nano news net website) [Electronic resource]. Available at URL: https://www.nanonewsnet.ru/articles/2017/15-klyuchevykh-komponentov-sovremennogo-proizvodstva. (Accessed: 20.01.2025). (In Russ.).

9. Digital twins and digital shadows in high-tech industry. Available at URL: https://4science.ru/articles/Cifrovie-dvoiniki-i-cifrovie-teni-v-visokotehnologichnoi-promishlennosti. (Accessed: 20.01.2025). (In Russ.).

10. Key tools and formats for the development of the digital economy: “smart” digital twins and the NTI SPbPU Center [Electronic resource]. Available at URL: https://nticenter.spbstu.ru/news/6722. (Accessed: 20.01.2025). (In Russ.).

11. UK team to develop rapid virtual testing technique for manufactured components [Electronic resource]. URL: https://www.theengineer.co.uk/content/news/uk-team-to-develop-rapid-virtual-testing-technique-for-manufactured-components/. (Accessed: 20.01.2025).

12. Borovkov A.I., Ryabov Yu.A. Definition, development and application of digital twins: Approach of the NTI SPbPU Competence Center “New Production Technologies”. Digital substation. 2019;(12):20–25. (In Russ.).

13. Design with Confidence (Commentary). CIMdata [Electronic resource]. URL: https://www.cimdata.com/de/resources/complimentary-reports-research/commentaries/item/3345-design-with-confidence-commentary/3345-design-with-confidence-commentary. (Accessed: 20.01.2025).

14. Rodič B. Industry 4.0 and the new simulation modelling paradigm. Organizacija. 2017;50(3):193–207. https://doi.org/10.1515/orga-2017-0017

15. Mukherjee T., DebRoy T. A digital twin for rapid qualification of 3D printed metallic components. Applied Materials Today. 2019;14:59–65. https://doi.org/10.1016/j.apmt.2018.11.003

16. Lind M. Digital thread. Aras [Electronic resource]. URL: https://community.aras.com/b/english/posts/promise-of-the-digital-thread. (Accessed: 28.05.2020)

17. A new paradigm of digital design and modeling of globally competitive products of a new generation [Electronic resource]. Available at URL: http://fea.ru/news/6721. (Accessed: 20.01.2025). (In Russ.).

18. Prokhorov I.M., Zimin A.V., Burkova I.V., Zimin V.V. Formulation and decomposition of the task of scheduling repairs and operation of steelmaking converters. Management systems and information technologies. 2024;(2(96)):38–40. (In Russ.).

19. Kornet M.E., Zimin A.V., Burkova I.V., Zimin V.V. Planning BOF repair system in conditions of quasi-periodic operation of units. Izvestiya. Ferrous Metallurgy. 2024;67(6):738–743. https://doi.org/10.17073/0368-0797-2024-6-738-743

20. Prokhorov I.M., Zimin A.V., Burkova I.V., Zimin V.V. The procedure for solving the problem of scheduling repairs of converters in a steelmaking plant with two units. Management systems and information technologies. 2024;(2(96)):64–67. (In Russ.).

About the Authors

A. V. ZiminRussian Federation

Aleksei V. Zimin, Dr. Sci. (Eng.), Assist. Prof., Head of the Chair of Automation and Information Systems

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

M. Е. Kornet

Russian Federation

Maria E. Kornet, Senior Lecturer of the Chair of Engineering Cybernetics

4 Leninskyii Ave., Moscow 119049, Russian Federation

I. V. Burkova

Russian Federation

Irina V. Burkova, Dr. Sci. (Eng.), Assist. Prof., Leading Researcher

65 Profsoyuznaya Str., Moscow 117997, Russian Federation

V. V. Zimin

Russian Federation

Valerii V. Zimin, Dr. Sci. (Eng.), Prof. of the Chair of Automation and Information Systems

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Zimin A.V., Kornet M.Е., Burkova I.V., Zimin V.V. Using digital simulation models to optimize the operation of complex production facilities. Izvestiya. Ferrous Metallurgy. 2025;68(2):188-194. https://doi.org/10.17073/0368-0797-2025-2-188-194

JATS XML