Scroll to:

Actual progress of production waste disposal problems

https://doi.org/10.17073/0368-0797-2025-2-131-138

Abstract

For many countries the problem of industrial and household waste disposal is particularly acute, since the annual accumulation of all types of waste is quite large (about 7 billion tons), and their reuse does not exceed 30 %. At the same time, industrial waste has a negative impact on living organisms and the environment. Therefore, ways of recycling household and production wastes are necessary. This article considers the problems of utilization, processing (recycling) of industrial and household waste and the prospects of their application in various industries. The influence of different formulations of initial components (microsilica, blast furnace slag, slaked lime), their fractions on physical and mechanical properties of the obtained new composite materials is considered. The obtained materials were investigated in order to determine the values of compressive strength and percentage of water absorption. Thus, all samples have low water absorption percentage (0 – 13.12 %), except for Sample 7 (41.34 %), consisting of 2 parts of microsilica, 1 part of slag and 1 part of lime. It was found that high values of compressive strength are observed in the samples which include microsilica. Samples 3 and 4, composed of microsilica and slag jointly, have the lowest compressive strength of 14.74 and 17.18 kgf/cm2, respectively. However, Sample 8, which is composed of 2 parts of microsilica, slag and lime simultaneously, is characterized by the highest compressive strength value of 51.16 kgf/cm2. Microsilica has a greater influence on the increase of strength properties. At the same time, the use of industrial waste in the creation of new secondary materials leads to a reduction in the cost of production, expansion of the raw material base of the country, as well as reducing the environmental load of the region.

Keywords

For citations:

Ulyeva G.A., Tuyskhan K., Matsugina E.M., Volokitina I.E., Akhmetova G.E. Actual progress of production waste disposal problems. Izvestiya. Ferrous Metallurgy. 2025;68(2):131-138. https://doi.org/10.17073/0368-0797-2025-2-131-138

Introduction

In recent years, the fields of metallurgy, engineering and materials science have been rapidly evolving [1 – 4]. However, the problem of solid and household waste remains unresolved in every country worldwide1, 2. For example, in the CIS countries, this issue is particularly severe, as the annual accumulation of all types of waste reaches approximately 7 billion tons, with the reuse rate of less than 30 %. A major concern is the direct impact of waste on human life as it is concentrated in residential and recreational areas. To address this issue, waste must be integrated into natural cycles, removed and utilized. The most viable solution is to develop efficient recycling methods and establish a new industry sector [5 – 8]. However, many challenges along must be overcome, some of which are complex but solvable [9].

Currently, industrial waste in Kazakhstan amounts to 31.6 billion tons, with an annual increase of approximately 1 million tons in recent years3.

However, according to the 2022 report On the state of the environment and use of natural resources of the Republic of Kazakhstan, the volume of industrial waste exceeds 895 million tons. Kostanai, Pavlodar, and Karaganda regions are the leaders in generating this waste. Approximately half of the waste from these regions is recycled. However, regions such as Turkestan (0.76 %), Almaty (9.32 %), and Zhambyl (7.38 %) have low recycling rates. In 2022, the percentage of recycled and disposed industrial waste reached 40.03 %, which is higher than the 38.2 % recorded in 20214.

Forced storage of huge amounts of waste and their disposal in dumps cause significant losses to the national economy due to unused opportunities for utilizing secondary raw materials, while industrial waste production results in damage amounting to tens of millions [10 – 12]. Another equally important aspect of the issue is the negative impact of industrial waste on the environment. The atmosphere is being severely polluted at an alarming rate by a variety of industrial emissions2 [12].

Scientists from both domestic and foreign institutions are engaged in addressing the problem of industrial and household waste disposal [13 – 15]. One known method involves processing dusty silicon waste by remelting it in a solid-liquid aluminum medium [13; 16]. This method allows the use of pulverized silicon waste in the smelting of aluminum alloys. However, it is not suitable for recycling other silicon-containing powdered materials.

It is known that crystalline silicon in the 20 – 50 mm fraction is used for the production of aluminum-silicon alloys, while dust-like and fine fractions resulting from crushing and screening are sent to dumps, leading to a decrease in silicon utilization in the production of the these alloys. Papers [17 – 19] proposed a method for processing waste silicon, which includes introducing silicon into the aluminum melt with stirring. This method is distinguished by the fact that silicon fractions of 0.1 – 20.0 mm are introduced onto the surface of the melt at 670 – 680 °C, followed by heating to 720 – 750 °C at a rate of 2.5 – 4.0 °С/mm to improve silicon assimilation and reduce metal losses from oxidation by shortening the melting duration.

Technologists and scientists in Kazakhstan are developing methods to recover captured dust in order to obtain high-quality technical silicon. This will not only reduce production cost but also lessed the environmental impact by decreasing emissions. Microsilica processing technologies are also being developed to produce briquette mono-blends.

The paper [20] presents a technology for obtaining silica filler intended for use in the production of rubber materials at the Karaganda Rubber Technical Plant, as well as other industries.

Existing technologies for the disposal of silicon-containing powdery waste, despite their diversity, have one common feature: the silicon remains present in silicon-containing waste even after recycling. In other words, its chemical state does not change [21; 22].

Thus, based on the given literature review, the authors of this article present a technology for the disposal of industrial and domestic waste, specifically microsilica, to obtain secondary composite materials [23].

Material and methods

The ratio of initial components was 1:1 (Samples 1, 3, 5), 2:1 (Samples 2, 4, 6), 1:1:1 (Sample 7), and 2:1:1 (Sample 8). Table 1 shows the composition of the obtained samples.

Table 1. Ratio of initial components

| |||||||||||||||||||||||||||||||||||||||||||||||

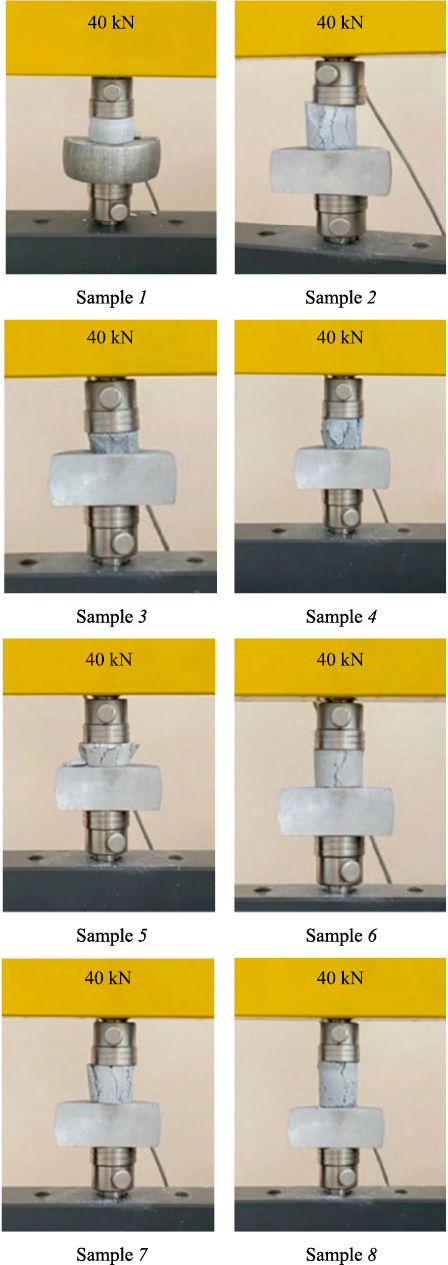

All materials were sieved through a sieve with a fraction of 1 – 2 mm, followed by weighing. The initial components were then combined in a dry state and mixed until evenly distributed. After thorough mixing, 5 – 7 g of water was gradually added and mixed to form a homogeneous mixture. The resulting composition was transferred into molds, shaken, and tamped down. The complete drying time of the molds was 14 days (see Fig. 1). After drying, the samples were removed, inspected for integrity, and weighed. At the same time, all dried samples produced a metallic sound when tapped.

Fig. 1. Samples obtained after drying |

The study of the physical and mechanical properties of the obtained secondary materials was carried out in three stages:

– Stage 1 – study of samples for water absorption without coating;

– Stage 2 – study of coated samples for water absorption;

– Stage 3 – compression testing of samples.

The samples were then tested for water absorption according to GOST 12730.3–2020. In this process, the samples were completely immersed in water. Bubbles were released during soaking, which may indicate the presence of internal pores. The samples remained in water until bubble release was complete. After soaking, the samples were weighed. Then, they were placed in a SNOL-type furnace heated to 150 – 200 ℃ and dried until their mass became constant, with re-weighing.

The calculation of water absorption Wm of the samples was performed according to the formula (GOST 12730.3–2020)

\[{W_{\rm{m}}} = \frac{{{m_w} - {m_d}}}{{{m_d}}} \cdot 100{\rm{ }}\% ,\]

where md is dried sample weight, g, and mw is water-saturated sample weight, g.

For optimal water absorption performance, the authors suggest applying a protective varnish to the samples and re-testing them for water absorption. After coating, the samples were dried at room conditions for 24 h. After drying, they were checked and weighed.

When the samples were kept in water, no bubbles were released, unlike in the first water absorption test, because all pores were completely blocked by the varnish. However, some samples floated to the surface, suggesting the presence of internal pores.

After soaking in water, the samples were weighed and left to dry for 24 h under room conditions. Re-weighing was performed every 24 h until the samples reached a constant mass, and the percentage of water absorption was re-determined (Table 2).

Table 2. Процент водопоглощения после двух этапов

| ||||||||||||||||||||||||||||||||

Then, the samples were subjected to compression testing on a 40KU testing machine according to GOST 10180–2012. The behavior of the samples during compression testing corresponded to GOST 10180–2012.

Prior to testing, each sample underwent side grinding to ensure parallelism of the sample sides (Fig. 2).

Fig. 2. Sample on the testing machine before and after fracture |

Results

The water absorption results are presented in Table 2, and the compression test results are summarized in Table 3.

Table 3. Compression test results

|

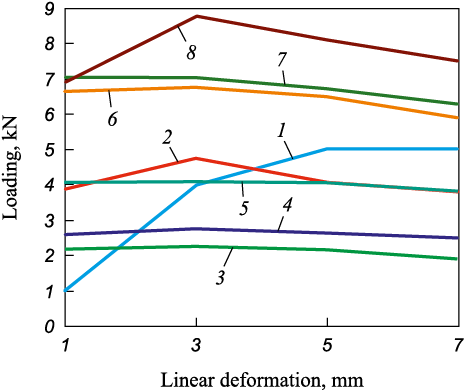

Table 3 shows that Samples 3 and 4 have the lowest compressive strength, at 14.74 and 17.18 kgf/cm2, respectively. The composition of these samples includes microsilica and slag, with slag having a greater weakening effect. It should be noted that in Sample 4 the microsilica content was doubled, which resulted in an increase in the strength index. However, when comparing Samples 5 and 6, which contain slag and lime, the combination and interaction of these components enhance compressive strength, especially as the slag content increases.

Samples 1 and 2, containing microsilica and lime, have moderate compressive strength values of 28.20 and 24.64 kgf/cm2, respectively.

It is also worth noting that samples with a three-component composition of microsilica, slag, and lime exhibit the highest compressive strength, particularly Sample 8 (51.16 kgf/cm2). In this sample, the microsilica content is doubled compared to Sample 7, which contributes to the material’s hardening.

Thus, the properties of the material vary depending on the composition. For example, microsilica has been shown to enhance strength, as seen in Sample 4. Similarly, slag contributes to increase strength, as observed in Sample 6, where lime is the second component.

The compression diagrams of the tested samples are shown in Fig. 3.

Fig. 3. Compression test diagrams |

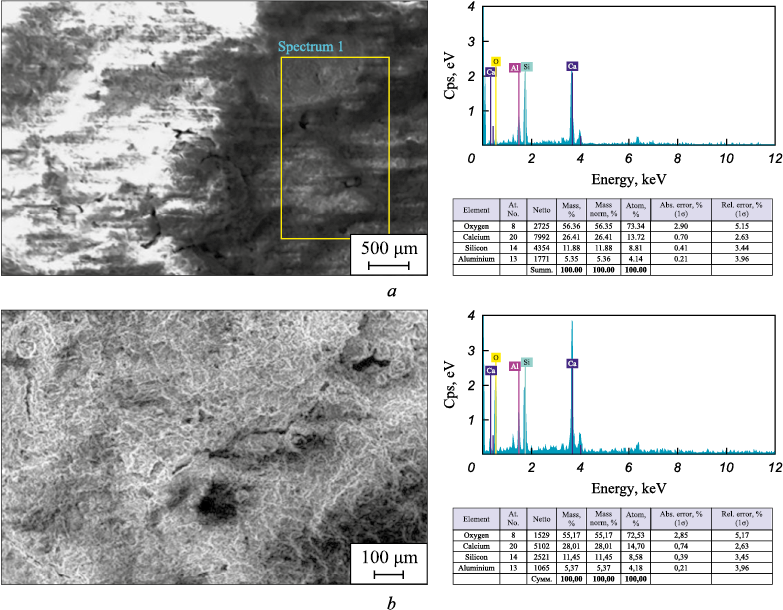

Fractures of Samples 3 and 8 (samples with the lowest and the highest compressive strength value) were studied using a scanning electron microscope EVO18 (Qarmet JSC) (Fig. 4).

Fig. 4. Material structure: |

Discussion

Stage 1. Samples 1 and 2 show unsatisfactory result according to Table 2. Their composition consists of microsilica and lime in a 1:1 and 2:1 ratio, with water absorption values of 44.7 and 53.3 %. The negative effect is probably due to the second component, hygroscopic lime.

Samples 3 and 4, composed of microsilica and slag in a 1:1 and 2:1 ratio, demonstrate good water absorption values of 16.6 and 15.7 %, respectively. This suggests that these initial components reduce hydrophilicity.

Similarly, Samples 5 and 6, with slag-to-lime ratios of 1:1 and 2:1, also showed favorable results: water absorption decreased from 27.6 to 24.32 % as the slag content increased from 25 to 50 g.

Samples 7 and 8, composed of microsilica, slag, and lime in a 1:1:1 and 2:1:1 ratio, exhibited unsatisfactory results, with water absorption values of 58.3 and 62.2 %, respectively. Notably, higher microsilica content correlates with higher water absorption.

Stage 2. It is evident that water absorption results improved significantly in samples coated with protective varnish. Specifically, Samples 1, 2, 3, and 8 demonstrated the lowest water absorption values of 1.93, 2.64, 2.33, and 4.66 % respectively. Sample 5 achieved an excellent water absorption rate of 0 %.

Samples 4 and 7 exhibited moderate water absorption values of 13.12 and 12.5 %, respectively.

However, Sample 7 has the worst water absorption performance (41.34 %). This may be due to the presence of macropores and the unpredictable behavior of the original components in a 1:1:1 ratio with the protective varnish.

Thus, different compositions and ratios lead to varying final properties. Each component interacts differently, allowing for the selection of optimal properties through proper material composition. It is also worth noting that Sample 5, with a slag-lime composition in a 1:1 ratio, has the best water absorption performance, while Sample 7, with a microsilica-slag-lime composition in a 1:1:1 ratio, showed the worst results.

The structure of Sample 3, which exhibited the lowest value of compressive strength, is characterized by a loose structure and uneven distribution of microsilica and slag throughout its volume. The sample is friable.

The experimental data comply with GOST 12730.3–2020 “Water absorption”, GOST 10180–2012 “Compressive strength”.

Conclusion

This study demonstrates the feasibility of using industrial and household waste to produce secondary materials with a functional set of physical and mechanical properties. The developed samples with high water absorption values can be used as interior cladding material. However, when coated with a protective layer, these materials can also serve as exterior cladding . At the same time, materials based on microsilica and blast furnace slag exhibit satisfactory strength properties (17.18 – 51.16 kgf/cm2), expanding their potential applications.

The development of waste disposal and recycling methods remains a major economic challenge. Addressing this issue will change the perception of industrial waste as an end product, promoting more active use of recycling methods while shifting the focus toward generating economic benefits from this process.

References

1. Volokitin A.V., Volokitina I.E., Latypova M.A., Chigirinsky V.V., Kolesnikov A.S. Effect of controlled rolling on the structural and phase transformation. Progress in Physics of Metals. 2023;24(1):132–156. https://doi.org/10.15407/ufm.24.01.132

2. Volokitina I., Volokitin A., Denissova A., Fedorova T., Lawrinuk D., Kolesnikov A., Yerzhanov A., Kuatbay Y., Liseitsev Yu. Effect of thermomechanical processing of building stainless wire to increase its durability. Case Studies in Construction Materials. 2023;19:e02346. https://doi.org/10.1016/j.cscm.2023.e02346

3. Volokitina I., Bychkov A., Volokitin A., Kolesnikov A. Natural aging of aluminum alloy 2024 after severe plastic deformation. Metallography, Microstructure, and Analysis. 2023;12(3):564–566. https://doi.org/10.1007/s13632-023-00966-y

4. Volokitina I., Sapargaliyeva B., Agabekova A., Ulyeva G., Yerzhanov A., Kozlov P. Study of changes in microstructure and metal interface Cu/Al during bimetallic construction wire straining. Case Studies in Construction Materials. 2023;18:e02162. https://doi.org/10.1016/j.cscm.2023.e02162

5. Gelmanova Z.S., Bazarov B.A., Mezentseva A.V., Konakbaeva A.N., Toleshov A.K. Industrial safety management at mining enterprises in Kazakhstan. Mining Informational and Analytical Bulletin. 2021;(2-1):184–198. (In Russ.). https://doi.org/10.25018/0236-1493-2021-21-0-184-198

6. Zhangabay N., Baidilla I., Tagybayev A., Suleimenov U., Kurganbekov Zh., Kambarov M., Kolesnikov A., Ibraimbayeva G., Abshenov Kh., Volokitina I., Nsanbayev B., Anarbayev Y., Kozlov P. Thermophysical indicators of elaborated sandwich cladding constructions with heat-reflective coverings and air gaps. Case Studies in Construction Materials. 2023; 18:e02161. https://doi.org/10.1016/j.cscm.2023.e02161

7. Volokitinа I.E., Volokitin A.V. Changes in microstructure and mechanical properties of steel-copper wire during deformation. Metallurgist. 2023;67:232–239. https://doi.org/10.1007/s11015-023-01510-7

8. Nurumgaliyev A., Zhuniskaliyev T., Shevko V., Mukhambetgaliyev Y., Yerekeyeva G., Kelamanov B., Kuatbay Y., Badikova A. Modeling and development of technology for smelting a complex alloy (ligature) Fe-Si-Mn-Al from manganese-containing briquettes and high-ash coals. Scientific Reports. 2024;14(1):7456. https://doi.org/10.1038/s41598-024-57529-6

9. Ruberti M. The chip manufacturing industry: Environmental impacts and eco-efficiency analysis. Science of the Total Environment. 2023;858(2):159873. https://doi.org/10.1016/j.scitotenv.2022.159873

10. Ma M., Wang T., Ke X., Liu Y., Song Y., Shang X., Li J., Han Q. A novel slag composite for the adsorption of heavy metals: Preparation, characterization and mechanisms. Environmental Research. 2023;216(2):114442. https://doi.org/10.1016/j.envres.2022.114442

11. Ulyeva G.A., Akhmetova G.Е., Tuyskhan K., Tulegenov A.V. State-of-the-Art and analysis of characteristics, properties, significance and application prospects of metallurgical slags. Progress in Physics of Metals. 2022;23:108–130. https://doi.org/10.15407/ufm.23.01.108

12. Chang Z., Long G., Zhou J., Cong M. Valorization of sewage sludge in the fabrication of construction and building materials: А review. Resources Conservation and Recycling. 2020;154:104606. https://doi.org/10.1016/j.resconrec.2019.104606

13. Raheem A., Sikarwar V., He J., Dastyar W., Dionysiou D.D., Wang W., Zhao M. Opportunities and challenges in sustainable treatment and resource reuse of sewage sludge: A review. Chemical Engineering Journal. 2018;337:616–641. http://dx.doi.org/10.1016/j.cej.2017.12.149

14. Ulyeva G.A., Akhmetova G.Е., Tuyskhan K., Reshotrina E.N. Development of new composite materials based on “Metal-Non-metal” with improved functional properties. Metallophysics and Advanced Technologies. 2022;44:1137–1146. http://dx.doi.org/10.15407/mfint.44.09.1137

15. Nowaka O., Enderle P., Varbanov P. Ways to optimize the energy balance of municipal wastewater systems: Lessons learned from Austrian applications. Journal of Cleaner Production. 2015;88:125–131. https://doi.org/10.1016/j.jclepro.2014.08.068

16. Gavrilin I.V., Kechin V.A., Koltyshev V.I. Method of remelting of dusty silicon waste in the medium of solid liquid aluminum. Patent RU 2180013 C1. Publ. 27.02.2002.

17. Lisai V.E., Malen’kikh A.N., Zverev Yu.A., Teplyakov F.K., Gorbunov V.A., Danilov S.N. Method of silicon waste processing. Patent RU 2016110 C1. Publ. 15.07.1994.

18. Wang S., Zhou P., Liu X., Zhang S., Jia Q. Effect of modified coal tar pitch addition on the microstructure and properties of Al2O3–SiC–C castables for solid waste incinerators. Ceramics International. 2022;48(14):20778–20790. https://doi.org/10.1016/j.ceramint.2022.04.060

19. Chen G., Li Y., Huang L., Zhang C., Luo X. Preparation of Al-Si alloy from silicon cutting waste: Enabling oxide surface removing and silicon utilization improving via vacuum sintering. Science of the Total Environment. 2023;863:161038. https://doi.org/10.1016/j.scitotenv.2022.161038

20. Sal’keeva L.K., Sevost’yanova K.A., Kakolina G.M., Tazhbaev E.M., Sugralina L.M., Omasheva A.V. Method of obtaining precipitated silica filler. Patent C01B 33/18. Bulleten’ izobretenii. 2016;15.

21. Liang S., Zhou X., Ruan S., Kastiukas G., Sun Y. Milled waste glass powder in magnesium-silicate-hydrate cement: Technical and environmental assessment. Journal of Materials in Civil Engineering. 2023;35(1):04022379. https://doi.org/10.1061/(ASCE)MT.1943-5533.000455

22. Beskopylny A.N., Stel’makh S.A., Shcherban’ E.M., Beskopylny N., El’shaeva D. A study on the cement gel formation process during the creation of nanomodified high-performance concrete based on nanosilica. Gels. 2022;8(6):346. https://doi.org/10.3390/gels8060346

23. Abdurakhmanov B.M., Kurbanov M.S., Nuraliev U.M., Andriyko L.S. Application of methane and micro silica for silicon carbide synthesis. Powder Metallurgy and Metal Ceramics. 2022;61(5–6):298–307. https://doi.org/10.1007/s11106-022-00317-6

About the Authors

G. A. UlyevaKazakhstan

Gulnara A. Ulyeva, Leading Specialist of the Laboratory of Metallography and Defectoscopy of the Analytical Control Center, JSC “Qarmet”; Cand. Sci. (Eng.), Assist. Prof. of the Chair of Metallurgy and Materials Science, Karaganda State Industrial University

1 Respubliki Ave., Timertau, Karaganda Region 101400, Republic of Kazakhstan

30 Respubliki Ave., Timertau, Karaganda Region 101400, Republic of Kazakhstan

K. Tuyskhan

Kazakhstan

Kurmetbek Tuyskhan, Master Student, Doctoral

30 Respubliki Ave., Timertau, Karaganda Region 101400, Republic of Kazakhstan

E. M. Matsugina

Kazakhstan

Ekaterina M. Matsugina, MA Student

30 Respubliki Ave., Timertau, Karaganda Region 101400, Republic of Kazakhstan

I. E. Volokitina

Kazakhstan

Irina E. Volokitina, PhD, Prof. of the Chair of Metallurgy and Materials Science

30 Respubliki Ave., Timertau, Karaganda Region 101400, Republic of Kazakhstan

G. E. Akhmetova

Kazakhstan

Gulzhainat E. Akhmetova, PhD, Assist. Prof. of the Chair of Metallurgy and Materials Science

30 Respubliki Ave., Timertau, Karaganda Region 101400, Republic of Kazakhstan

Review

For citations:

Ulyeva G.A., Tuyskhan K., Matsugina E.M., Volokitina I.E., Akhmetova G.E. Actual progress of production waste disposal problems. Izvestiya. Ferrous Metallurgy. 2025;68(2):131-138. https://doi.org/10.17073/0368-0797-2025-2-131-138