Scroll to:

Kuznetsk armor: The first frontiers of victory

https://doi.org/10.17073/0368-0797-2025-2-114-123

Abstract

The article discusses issues related to the accelerated transition of the Kuznetsk Metallurgical Plant (KMK) to production of armored steel in the conditions of the Great Patriotic War. The prerequisites and conditions for the transition from the production of exclusively peaceful products to the mass production of armored metal were determined. The authors clarified the stages of mastering new production technologies, the contribution of individual departments and production scientists, scientists from the Siberian Metallurgical Institute (SMI) to production of steel for victory. The emergence of Kuznetsk armor is viewed through the prism of contribution of the whole country and people to the common cause of the fight against fascism.

Keywords

For citations:

Tresvyatskii L.A., Protopopov E.V., Umanskii A.A., Khudoleev A.N. Kuznetsk armor: The first frontiers of victory. Izvestiya. Ferrous Metallurgy. 2025;68(2):114-123. https://doi.org/10.17073/0368-0797-2025-2-114-123

Introduction

From the very beginning of the Great Patriotic War, the country’s metallurgical industry was tasked with a strategic objective: to ensure the rapid launch of armored steel production. The development and transition to mass production of armored steel in 1941 at the Kuznetsk Metallurgical Plant (KMK) in the city of Stalinsk (now Novokuznetsk) was of great significance for strengthening the country’s defense capability during the difficult initial defensive stage of the war. played a crucial role in strengthening the nation’s defense capabilities during the initial and most challenging phase of the war. Due to the urgency and complexity of mastering new technologies and restructuring the plant’s infrastructure, many specific features and nuances of this transformation were not thoroughly documented and were subsequently lost to historical memory. Soviet-era scholarly literature addressed certain aspects of this transition but often reflected ideological, institutional, or other biases. In the post-Soviet period, this topic received limited attention; available accounts either reproduced established narratives or remained superficial.

As the 80th anniversary of Victory in the Great Patriotic War approaches, the need to reassess and recognize KMK’s contribution to the labor feat of the Soviet people becomes increasingly evident. The time has come to address several historical blind spots.

Legendary T-34 tank (active, taking part in the Victory Day celebrations) at the plant administration square |

Studying the issue

The 1930s in the USSR were marked by a major shift in national policy. The Soviet leadership identified fascist Germany and militarist Japan as the primary threats to peace and security. In response, a course was set to strengthen the country’s defense-industrial base. As part of the accelerated industrialization program, dozens of large industrial enterprises were established to provide the economic foundation for the anticipated confrontation with potential aggressors. Leadership of the newly emerging Soviet industry was centralized in the People’s Commissariat of Heavy Industry, headed by G.K. Ordzhonikidze. At the Kuznetsk Metallurgical Plant, among the metallurgists of Stalinsk, the People’s Commissar of Heavy Industry enjoyed exceptional respect. This was evidenced by the fact that, in 1933, the Siberian Metallurgical Institute (SMI) was named after Sergo Ordzhonikidze (then known as SICHM – Siberian Institute of Ferrous Metals), at the initiative of local workers.

Despite the significant achievements in the development of ferrous metallurgy during the prewar decade, they remained insufficient: the rapidly expanding domestic industry demanded ever-growing volumes of metal. While ferrous metals were mainly used for the production of civilian goods, defense manufacturing was concentrated at designated enterprises. The pace of industrial growth necessitated the creation of specialized commissariats. From 1939 onward, KMK fell under the jurisdiction of the People’s Commissariat of Ferrous Metallurgy of the USSR. This commissariat was responsible for producing civilian products but was also tasked with switching to defense production in the event of war.

Between April 1932 and January 1941, KMK experienced rapid development – from the launch of its first blast furnace to the commissioning of the fifteenth 300-ton open-hearth furnace. The rate of equipment commissioning was remarkable:

• 1932: Blast furnaces No. 1 and 2, open-hearth furnaces No. 1, 2, and 3, and the blooming mill were commissioned;

• 1933: Open-hearth furnaces No. 4, 5, 6, and 7;

• 1934: Blast furnaces No. 3 and 4, and open-hearth furnaces No. 6, 8, and 9;

• 1935: Open-hearth furnaces No. 11 and 12, and a sheet-rolling mill;

• 1936: Open-hearth furnace No. 13 and rolling mill “500”;

• 1937: Rolling mill “900”;

• 1940: Open-hearth furnace No. 14;

• 1941: Open-hearth furnace No. 15.

The final two open-hearth furnaces were designed for 300-ton charges. The plant had to overcome the challenges of a “growth crisis” in steel production – problems that were, to a large extent, successfully resolved. By mid-1941, the KMK had achieved stable operation and was consistently exceeding production targets across the full metallurgical cycle.

In 1941, KMK began considering the possibility of transitioning to defense production. This is confirmed by the fact that on the very day of the fascist Germany’s attack, the plant’s engineering and technical personnel convened to discuss the organization of defense production [1].

Under the conditions of the Great Patriotic War, the entire industry – particularly ferrous metallurgy – had to respond swiftly to wartime demands. This required not only increasing output volumes but also a radical restructuring of production. There was an urgent need to boost the output of high-alloy steels required for armored vehicles and other military applications. It is important to note that, at the time, most alloyed steel production was concentrated in the southern and central regions of the country – territories that were soon either occupied or under serious threat due to the enemy’s rapid advance. This created enormous challenges for the metallurgical industry, as many of its leading enterprises were either destroyed or severely damaged by air raids.

From an open-hearth furnace |

In the year preceding the war, alloy steel accounted for only 2.2 % of KMK’s total rolled metal output. However, beginning on June 22, the range of steel grades produced at the plant began to shift [2]. KMK reached its maximum pig iron output, and both open-hearth and rolling mill crews met their performance targets. Already in July 1941, open-hearth furnace No. 11 delivered its first batch of armored steel. rapid and effective transition of the national economy to a wartime footing was made possible by the mobilization-based economic model established during the first Five-Year Plans. This system demanded results from all levels of the production chain – from government officials and plant managers to engineers and workers. The socioeconomic and political structures shaped during the 1930s laid the foundation for Soviet society and gave rise to a new type of Soviet engineer-specialist: a skilled technician who was also a member of the working class.

On June 22, 1941, KMK director R.V. Belan was in Moscow. He had been on vacation and was planning a trip to Sochi. Upon learning of Germany’s invasion of the USSR, he immediately traveled that same Sunday to meet with the People’s Commissar of Ferrous Metallurgy, I.F. Tevosyan. At that point, it appears that the issue of organizing defense steel production at KMK had not yet been discussed with the plant’s leadership.

The following day, reports of the rapid advance of German forces into Soviet territory prompted the Commissar to make a strategic decision: to involve the industrial capacities of the eastern regions – the Urals and Siberia – in defense production. Upon reviewing KMK’s operational capabilities, it became clear that the existing equipment was not suited for producing armored steel. The plant would either need new open-hearth furnaces or significant upgrades to the current ones. Equally pressing was the question of whether the plant could handle the rolling of armor plate. Late in the evening of June 23, Tevosyan called chief engineer L. Vaisberg in Stalinsk and posed a key question: did KMK have the technical capacity to roll armor plate? Vaisberg requested a few hours to provide a definitive answer and, that same night, urgently organized a rolling test [3].

Chief engineer L. Vaisberg, blooming mill head V.D. Smirnov, along with the senior operator and roller, carried out a trial run: the ingots were first passed through the blooming mill and then through the sheet-rolling mill. Within a few hours, the team successfully rolled a steel ingot into a maximum-width plate. The test revealed that rolling armored steel – due to its greater mass and increased strength – would require technical modifications to the equipment. Specifically, it was necessary to reinforce the lifting tables for heavier blooms, implement autogenous cutting, and introduce other improvements. With this knowledge, a definitive answer was ready. Five hours after the last call from Moscow, Vaisberg contacted the People’s Commissariat of Ferrous Metallurgy with the positive result. At that moment, Tevosyan attending a meeting with the head of state and the Defense Committee, I.V. Stalin. In his absence, Deputy commissar P.I. Korobov received the update and was satisfied with the result.

As a consequence, the People’s Commissariat of Ferrous Metallurgy issued an order for KMK to begin producing armored steel for tanks. At that time, however, KMK had neither the necessary technology nor the proper equipment. Previously, armored steel had only been produced at specialized defense facilities using small-capacity open-hearth furnaces with acid linings. The large open-hearth furnaces at KMK were not technically suitable for smelting alloyed steel grades, and the rolling mills lacked the capacity for processing armor plate. Commissariat decided to transfer heat treatment furnaces from the Izhora Plant to Stalinsk, and a dedicated workshop section had to be built to house them.

The People’s Commissar of Ferrous Metallurgy instructed the implementation of large-scale changes to the steel production process, particularly involving the open-hearth furnaces. The top priority was to reconstruct and convert the furnaces to basic linings, which would improve both the quality and mechanical properties of the steel. This required major technological revisions, including reducing the volume of the metal charge. A fundamentally new smelting technology for armored steel had been developed at the Izhora Plant in June 1941, but there was no time for extensive testing. Complicating matters further, both the relevant classified documents and experienced personnel had already been redirected to the Magnitogorsk Metallurgical Plant. On June 26, 1941, an official order was issued instructing KMK to begin producing tank armor by August 1 of that year [4]. This urgent decision was a direct response to the intensifying war and the critical need to increase production of high-quality armored metal for tank manufacturing.

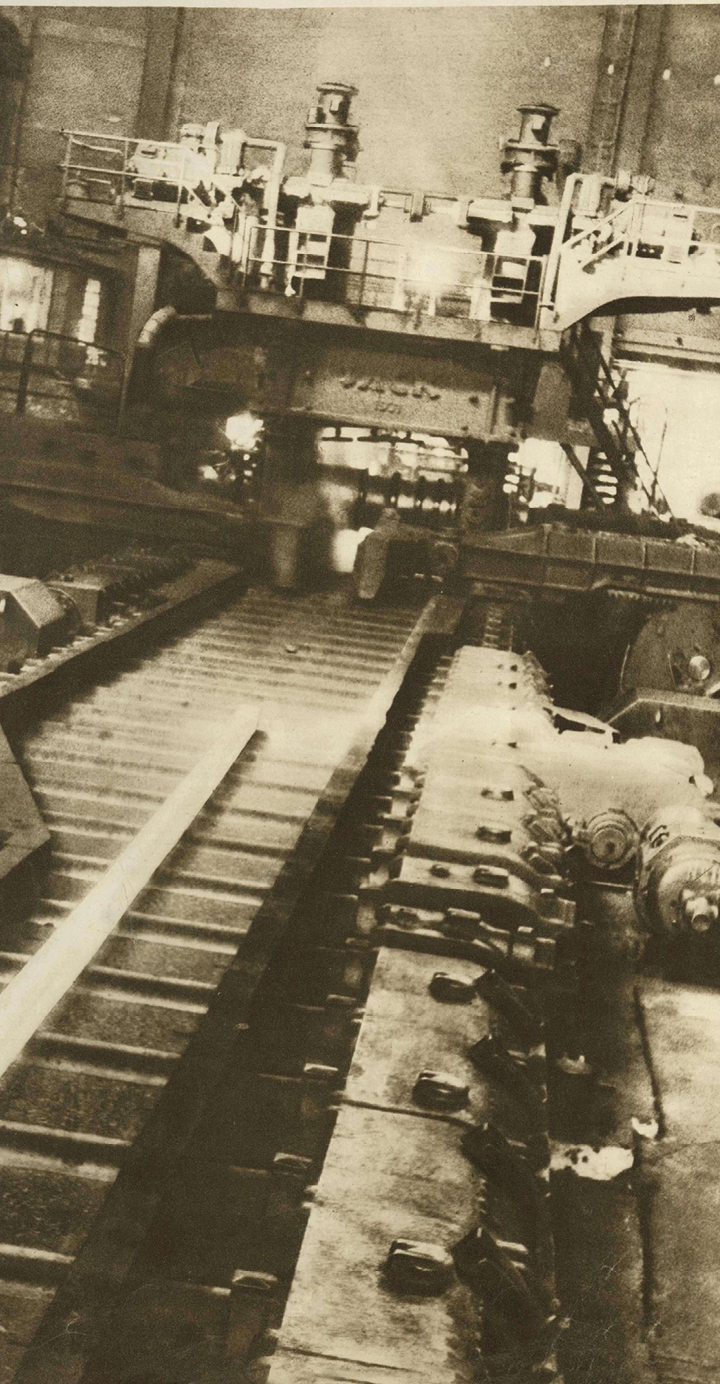

Rolling mill. KMK. 1930s |

In June 1941, a group of engineers from the Izhora Plant – including M.N. Popov, A.F. Yakimovich, D.Ya. Badyagin, I.A. Frumkin, P.A. Romanov, and Ya.I. Mashchuk – collaborated with specialists from the Central Research Institute of Structural Materials (TsNII-48, the “Armor Institute”), such as A.S. Zav’yalov, S.I. Sakhin, E.E. Levin, and A.Ya. Vergazov, to develop a new technology for smelting armored steel in basic-lined open-hearth furnaces. As previously mentioned, armored steel had traditionally been produced in acid-lined furnaces at specialized defense facilities. The new process was first tested at the Izhora Plant on Furnace No. 8 – the largest of its kind there – which allowed engineers to replicate, to some extent, the operating conditions of the high-capacity furnaces used at KMK. This innovative technology was formalized into a set of technical guidelines just as enemy forces approached the outskirts of Leningrad [5]. Due to its novelty and complexity, the technology could not be adopted immediately on a wide scale. However, as the blockade of Leningrad tightened, a crucial decision was made. On September 8, 1941, with the city under full siege, engineer I.A. Frumkin transported the technical documentation out of Leningrad via a special air mission. The availability of these instructions, developed at the Izhora Plant, enabled Soviet ferrous metallurgy facilities to promptly initiate large-scale production of tank armor in the early stages of the Great Patriotic War.

A special “armor bureau” was established, composed not only of metallurgical scientists from TsNII-48 but also of KMK plant personnel. This bureau developed a fundamentally new technology for smelting armored steel in large-capacity open-hearth furnaces with basic lining. On July 23, 1941, the first heat of armored steel using this new method was successfully carried out at the Magnitogorsk Metallurgical Plant. As a result, between September 1941 and January 1942, the output of armored steel increased almost one hundredfold. Following Magnitogorsk, the production of alloyed and armored steels using similar technologies – adapted with the support of TsNII-48 experts – was launched at both the Nizhny Tagil Metallurgical Plant and KMK [6].

On June 27, 1941, open-hearth furnace No. 11 in KMK’s second open-hearth shop was shut down for scheduled repairs. The design department promptly finalized and submitted the full technical documentation for the furnace’s reconstruction and modernization. Repair crews – comprising refractory specialists, boilermakers, and assemblers – worked around the clock to meet the urgent deadlines. First, the outdated equipment was dismantled; then the installation of new components began. These upgrades were intended to boost the furnace’s efficiency and enhance its production performance. The entire plant was gripped by a sense of shared responsibility, as every worker understood the strategic importance of their efforts. On July 4, the furnace was fired up again. Its successful adaptation to the new smelting technology was essential for maintaining the operational capacity of the entire shop. This achievement became not only a technical milestone but also a symbol of hope – marking a decisive step toward large-scale production of armored steel and, ultimately, toward victory.

Simultaneously with the furnace reconstruction, work was underway to establish a heat treatment section within the sheet-rolling mill. On the eve of the Great Patriotic War had no furnaces for the heat treatment of rolled metal – creating a major obstacle to fulfilling its new production tasks, particularly in light of the decision to launch armor plate production. Recognizing the strategic significance of the project, the People’s Commissariat of Ferrous Metallurgy ordered the dismantling of six heat treatment furnaces at the Izhora Plant in Kolpino, near Leningrad. These furnaces were to be shipped over 3,000 kilometers to KMK. On the same day the order was received, dismantling began at the Izhora Plant, while construction work commenced simultaneously at KMK. The deadlines set by the Commissariat were extremely strict: the heat treatment furnaces were to be fully operational by September 1, 1941. It was decided to install them in the fourth span of the blanking shop, which was still under construction – requiring additional effort from builders and designers. Foundations for the first two furnace blocks were laid in the completed portion of the span, while the rest of the space had to be expanded – necessitating design changes and a significantly faster pace of construction.

On July 3, 1941, KMK director R.M. Belan and N.G. Kratenko, head of the Stalinskpromstroi trust, signed an order establishing a strict project schedule. It defined the deadlines for issuing design documentation, which were subject to tight oversight. The final set of construction drawings had to be delivered to the site no later than 8:00 p.m. on July 7. The urgency of the task created a highly charged atmosphere at the construction site. Chief Mechanic I.S. Lyulenkov committed to delivering all required equipment by 10:00 a.m. on July 16. To support uninterrupted work, temporary lighting had to be installed at the site by 10:00 p.m. on the day the order was issued, and the power supply was to be connected by 8:00 p.m. on July 4.

Work continued around the clock. Both workers and engineers invested enormous effort and displayed remarkable enthusiasm throughout the construction process. Among those involved were renowned assemblers from Kuznetskstroi: V.E. Kashkarov, I.A. Dubovik, M.M. Kalyuzhnyi, S.V. Yudakov, N.I. Osipov, and G.I. Podoroga. Their professionalism and experience played a crucial role in the project’s successful execution. Engineers G.F. Rybochkin and S.Ya. Selyukov also deserve recognition for their technical supervision and quality control during the entire construction phase.

Furnace masonry foreman I.A. Klenov, actively coordinated work crews and closely monitored adherence to the construction timeline. Daily on-site meetings were held to review progress, address emerging issues, and propose practical solutions. The workers clearly understood the importance of their task: the successful completion of the heat treatment section would not only enable the plant to meet its production targets but also make a vital contribution to the country’s defense capabilities. With each passing day, the construction pace accelerated. Despite growing fatigue, the construction teams maintained high morale and unwavering commitment.

In the third ten-day period of July, smelting operations resumed in open-hearth furnace No. 11. Initially, standard heats of the plant’s existing steel grades were produced. Soon thereafter, armored steel was added to the production schedule [7]. Smelting armored steel in an acid-lined open-hearth furnace requires a specific approach. One of the key conditions was the use of exceptionally clean charge materials with reduced phosphorus and sulfur content. Unfortunately, the pig iron produced at KMK contained elevated levels of these impurities, rendering it unsuitable for smelting in acid-lined furnaces. To address this, the duplex process – a two-stage smelting method – was employed. In the first stage, a semi-finished melt was produced in a basic-lined furnace and refined to remove sulfur and phosphorus. This was followed by a transfer of the molten metal into an acid-lined furnace for final refining. However, the process necessitated a reduction in charge volume in the main 185-ton furnace, which led to decreased production capacity and significantly increased the workload on plant personnel.

Highly qualified foremen A.N. Tomilin, A.A. Akridin, and V.A. Matyushkin were assigned to open-hearth furnace No. 11, while steelmakers D.V. Merzlyakov, F.A. Ryabov, and D.P. Sinenko were appointed to conduct the melting operations. As noted in the records, “the primary role in the technical oversight and organization of armored steel production belonged to chief engineer L.E. Vaisberg” [8]. At the time, KMK steelmakers had no previous experience working with acid-lined open-hearth furnaces. During the initial heats, they received expert guidance from specialists dispatched from the Izhora Plant. This knowledge transfer played a critical role in preparing and adapting the local workforce to the new process requirements. The learning curve proved to be relatively short. The first heats were carried out by A.N. Tomilin, in collaboration with G.V. Gurskii, head of Open-Hearth Shop No. 2, a widely respected expert in the field. Gurskii, known for his technical competence and strong theoretical foundation, took a creative and systematic approach to solving emerging process challenges. His experience, combined with the determination of shift foreman A.N. Tomilin, led to rapid progress. By the third ten-day period of July, the first successful heats of armored steel had been completed – a major achievement for the plant.

The process of mastering armor plate production presented a serious challenge for KMK’s rolling mill operators. On June 26, 1941, the plant issued an internal order outlining the urgent measures required to prepare the blooming mill and the sheet-rolling mill – both of which would be adapted for armor plate production – for their new roles. This involved modifying the equipment to meet the technical demands of rolling heavy, high-strength steel, and called for intense effort across the plant’s workforce. By the time the first heats of armored steel were ready, a team of specialists had already begun developing new roll pass designs for the breakdown stand – an essential step toward launching full-scale production. Under the leadership of chief electrician V.G. Prokoshin, chief mechanic I.S. Lyulenkov, and plate mill head S.I. Pavlovskii, a modernization plan was prepared within just one month. The plan called for reinforcing several key mechanical and electrical components of the rolling equipment. Its implementation demanded not only deep technical expertise but also close coordination between departments.

In parallel, the plant’s technical department, working with alongside specialists from the Central Research Institute of Structural Materials (TsNII-48), who had arrived to assist with the transition, began developing technical guidelines for armor plate rolling. A key advantage at this stage was the prior experience accumulated at the Izhora Plant, which served as a practical foundation for creating process standards [9].

Close collaboration with faculty members from the Siberian Metallurgical Institute (SMI) also made it possible to incorporate advanced approaches and modern methods in organizing the production of this new type of defense product – armor plate – significantly improving the prospects for success [10]. Major contributions to the development of armor steel production technology were made by professor Yu.V. Grdina and Associate Professors I.S. Nazarov and E.Ya. Zarvin. SMI researchers and instructors – N.N. Shubina, D.L. Polyakova, and A.A. Govorov – worked almost continuously under real production conditions to optimize the parameters of the heat treatment process for armor plate. Associate professors E.Kh. Shamovskii and N.I. Kunitsyn designed a highly efficient gas torch specifically for cutting thick slabs of armor steel.

Finally, the long-anticipated moment arrived: the first ingot of armored steel was placed onto the blooming mill’s roller table. This ingot differed significantly from standard ones – both in mass and dimensions – creating additional challenges during rolling. It required 25 to 28 passes to achieve the desired reduction, and by the end of the process, the slab had cooled significantly, complicating further handling. It was no longer possible to cut the slab with standard shears, so a crane was used to transfer it to the plate rolling mill’s storage area, where it was cut with an oxy-fuel torch. Unfortunately, the heating and rolling temperature modes developed at the Izhora Plant proved incompatible with KMK’s equipment. As a result, the steel from this first heat exhibited surface defects that required immediate correction. The mill scale had to be removed manually using pneumatic chisels – a time-consuming and labor-intensive process. Surface defects were smoothed using handheld electric grinders, which also demanded significant time and physical effort. In this way, the introduction of armor plate production became a true test for the entire KMK workforce. Ultimately, the transition to this new production line not only expanded the workers’ knowledge and skills, but also marked a turning point in the broader evolution of Soviet steelmaking. The successful implementation of new processing methods for armored steel paved the way for continued innovation and industrial advancement.

Conquering metal |

Thanks to the extraordinary efforts of the workforce and the full mobilization of available resources, KMK surpassed the government’s August production target for armored steel – achieving an impressive 190 % of the planned volume. This accomplishment marked the plant’s first major wartime success and became a source of pride and inspiration not only for KMK employees but for the entire city of Stalinsk. The achievements of the Kuznetsk steelmakers were of national significance – especially considering that, by autumn 1941, over 48 % of rolling mills across the Soviet Union had been rendered inoperable due to bombing and destruction. Despite material shortages and mounting fatigue, KMK’s metallurgists continued to optimize production processes and increase output to meet the urgent needs of the war effort.

On August 16, 1941, the Central Committee of the All-Union Communist Party (Bolsheviks) and the Council of People’s Commissars of the USSR approved a military-economic plan for industry covering the fourth quarter of 1941 and the entirety of 1942 [11]. The plan aimed to mobilize key industrial regions – such as the Volga region, the Urals, Western Siberia, Kazakhstan, and Central Asia – for defense production. One of its top priorities was to expand the output of specialty metals critical to the war effort, particularly in response to the growing intensity of military operations. At that point, the nationwide demand for high-quality armored steel had reached an unprecedented level. However, the available technologies could not ensure the required production volumes. The widespread use of the duplex process – based on melting in separate furnaces – remained common at many facilities, but it entailed significant production losses and became increasingly inefficient under the pressure of wartime requirements. As a result of the reconstruction of open-hearth furnace No. 11, the average heat mass had to be reduced by about 65 tons – a critical limitation during wartime. Furthermore, the charge for this furnace was prepared separately in a unit with a basic hearth, which further compromised both the quality and quantity of the steel produced. Daily losses from operating a single acid-lined furnace reached approximately 450 – 460 tons of metal – an unacceptable figure, particularly under government pressure to meet armored steel production targets. Meeting those targets would have required converting several more furnaces to acid lining, which would have drastically lowered the plant’s overall steelmaking capacity – an undesirable outcome in wartime. This situation created an urgent need to optimize production processes and reduce losses wherever possible.

One of the key solutions was to use the plant’s high-capacity 185-ton open-hearth furnaces with basic lining for the production of armored steel. This strategy offered the potential to significantly increase output while minimizing material losses. In addition to increasing the mass of each heat, there was also a strong focus on improving product quality. Another critical goal was the introduction of a fundamentally new rolling technology that could enhance both productivity and the quality of finished armor plate. As a result, the steelmaking and rolling shops became the central fronts in the broader industrial campaign to supply urgently needed armored steel for tanks and military vehicles.

At KMK, alongside the conventional production of armored steel in acid-lined furnaces, experimental trials were launched to develop new melting techniques using basic-lined open-hearth furnaces. Unlike acid linings, basic linings provided more stable smelting conditions and enabled more effective removal of harmful impurities, resulting in higher-quality steel. A key element of this transition was the study of prior developments at the Izhora Plant, where metallurgists had already achieved success in this area. Their experience had been adopted at the Magnitogorsk Metallurgical Plant and served to significantly accelerate KMK’s shift toward large-scale production of alloyed steels.

The first experimental heats of armored steel in the newly retrofitted furnace were entrusted to master steelmaker P.D. Nikitin, an experienced specialist in new steel grades. However, the task before him was exceptionally demanding. Producing armored steel required not only technical knowledge and skill but also effective desulfurization and dephosphorization pig iron. It was necessary to completely drain the slag and form a new slag layer during the melting process, which complicated operations and extended the overall smelting time. By September 1941, both of KMK’s open-hearth shops had begun mass production of armored steel using 185-ton basic-lined furnaces. This milestone was made possible by successful trials and the operational experience accumulated in previous months. By that time, newly developed technologies had significantly improved both the quality and output of the steel.

The Office of the Chief Steelmaker became the center for developing and implementing these new technologies and making critical production decisions. The team shared a deep sense of urgency and responsibility. Engineers and workers not only handled everyday challenges but also actively sought ways to optimize technological processes. Thanks to their combined efforts, KMK achieved major advances in armored steel production. Under wartime conditions, these results were nothing short of heroic – attained through unity and the growing expertise of the workforce.

Beginning in October 1941, KMK achieved a major breakthrough in both armored steel and plate production, marking a significant milestone in the plant’s wartime history. In the third quarter, the plant fulfilled 112 % of its armor plate production plan – a testament to organizational effectiveness and operational discipline. In the fourth quarter, despite a nearly fivefold increase in targets, the plant exceeded the plan by reaching 125 % [7].

As production volumes increased, rolling mill specialists actively explored new ways to enhance process efficiency. Leading engineers played a central role in developing and implementing improved rolling technologies. Chief engineer L.E. Vaisberg, whose technical knowledge and experience were widely recognized, became a driving force behind these efforts. Significant contributions were also made by plate mill head S.I. Pavlovskii and blooming mill head V.D. Smirnov, both of whom played key roles in streamlining operations and achieving high-performance outcomes. Senior foreman of the plate rolling shop M.I. Korchemnyi, deputy head of the Technical Department G.V. Sharov, blooming mill operators P.A. Zavarykin and M.I. Merkulov, and plate mill rollers P.A. Novokreshchin and I.P. Maksimov ll demonstrated exceptional dedication – an essential factor in the plant’s overall success. Within a remarkably short time, a fundamentally new armor plate rolling technology was developed. It featured advanced processing techniques and improved quality control measures. Specialists identified optimal heat treatment temperature regimes, significantly improving the strength and durability of the final product. As a result of these innovations, productivity at both the blooming and plate rolling mills increased several-fold, while surface defects were reduced to a minimum.

Conclusions

The Kuznetsk Metallurgical Plant (KMK) played a critical role in supplying armored steel to the Soviet Union during the Great Patriotic War. The scale of the challenges faced by KMK was unprecedented. It was not simply a matter of increasing output – it required a complete restructuring of production to manufacture high-quality armored steel that met the extreme demands of wartime. This effort entailed solving a wide range of technical and organizational problems, many of which had previously seemed insurmountable. The launch of armored steel production at KMK in the second half of 1941 represented a major industrial breakthrough and demanded extraordinary dedication from the residents of Stalinsk. Workers often remained at the plant around the clock, fully committed to the production effort. The rapid technical re-equipment of the plant posed a particular challenge. New production technologies for armored steel had to be developed and implemented within an extremely short timeframe, including improvements under severe time constraints. This included improvements in the mechanical properties of the steel – such as hardness and strength – as well as new processes for smelting, rolling, and heat treating armor plate. The successful transition to mass production of armored steel at KMK in Stalinsk (now Novokuznetsk) in 1941 became a strategically important contribution to the defense capabilities of the country during the critical initial phase of the war.

References

1. Berlin A.B. Novokuznetsk in a Soldier’s Overcoat: In the Year of the 50th Anniversary of the Great Victory, Dedicated to the Younger Generation of Novokuznetsk Residents. Novokuznetsk: Kuznetsk Fortress: Writers’ Union; 1995:297. (In Russ.).

2. Dokuchaev G.A. The Siberian rear in the Great Patriotic War. Novosibirsk: Nauka, Siberian Branch; 1968:322. (In Russ.).

3. Weisberg L. Not a minute to rock. In: The Steel Heart of Siberia. Titova A.M. ed. Kemerovo: Kemerovskoe knizhnoe izdatel’stvo; 1982:121–125. (In Russ.).

4. Belan R. Contribution of Kuznetsk residents to the victory. In: The Steel Heart of Siberia. Titova A.M. ed. Kemerovo: Kemerovskoe knizhnoe izdatel’stvo; 1982:125–129. (In Russ.).

5. Frumkin-Rybakov Yu. The history of the creation of new armored steel grades at the Izhora plant in 1936 – 1941. Report to the plenary session “Development of Science and Technology in the USSR in the pre-war years”, section 14, at the XXXVI Int. Conf. of the St. Petersburg Branch of the Russian National Committee for the History and Philosophy of Science and Technology of the Russian Academy of Sciences. [Electronic resource]. Available at URL: https://kolpino.ru/news/1/yulian-frumkin-rybakov-istoriya-sozdaniya-novykh-bronevykh-marok-stali-na-izhorskom-zavode-v-1936-1941-gg/. (Accessed: 09.03.2025). (In Russ.).

6. Serikbol A. The military and economic task of ferrous metallurgy during the Great Patriotic War. In: Salute, Victory! Proceedings of the International Scientific and Practical Military Historical Conference, May 13, 2015, Yurga. Tomsk: TPU; 2015:134–137. (In Russ.).

7. Polyanskaya E.M., Susakin G.N., Shparog Yu.A., etc. History of the Kuznetsk Metallurgical Plant named after V.I. Lenin. Zherebin B.N. ed. Moscow: Metallurgiya; 1973:463. (In Russ.).

8. Zaparii Vl.V., Zaparii V.V., Sheshukov O.Yu. Going through old paper, or correcting an error after half a century. Problemy chernoi metallurgii i materialovedeniya. 2024;(4):122–126. (In Russ.). https://doi.org/10.52351/00260827_2024_4_122

9. Novokuznetsk is a City of Labor Valor. Lizogub P.P. ed. Novokuznetsk: Lotus Press; 2021:168. (In Russ.).

10. Gromov V. Metal and People [Electronic resource]. Available at URL: https://www.sibsiu.ru/news/?ELEMENT_ID=13351. (Accessed: 09.03.2025). (In Russ.).

11. Butakov P.V. The industrial policy of the USSR during the Great Patriotic War. Problemnyi analiz i gosudarstvennoe upravlencheskoe proektirovanie: politologiya, ekonomika, pravo. 2013;6(4):61–72. (In Russ.).

About the Authors

L. A. TresvyatskiiRussian Federation

Lev A. Tresvyatskii, Dr. Sci. (Cultural), Assist. Prof., Prof. of the Chair of Pedagogical Education

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

E. V. Protopopov

Russian Federation

Evgenii V. Protopopov, Dr. Sci. (Eng.), Prof. of the Chair of Ferrous Metallurgy and Chemical Technology

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. A. Umanskii

Russian Federation

Aleksandr A. Umanskii, Dr. Sci. (Eng.), Prof. of the Chair of Ferrous Metallurgy and Chemical Technology

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. N. Khudoleev

Russian Federation

Aleksei N. Khudoleev, Dr. Sci. (Historical), Assist. Prof., Prof. of the Chair of History and Social Sciences

23 Tsiolkovskogo Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Tresvyatskii L.A., Protopopov E.V., Umanskii A.A., Khudoleev A.N. Kuznetsk armor: The first frontiers of victory. Izvestiya. Ferrous Metallurgy. 2025;68(2):114-123. https://doi.org/10.17073/0368-0797-2025-2-114-123