Scroll to:

Improving the design and thermal operation of a rotary kiln for production of metallurgical lime from chalk

https://doi.org/10.17073/0368-0797-2025-4-395-401

Abstract

The article is devoted to the topical issue of increasing the efficiency of rotary kilns used in the production of metallurgical lime from chalk. Methods of improving the structures and thermal operation of these units are considered, which is especially important in modern production conditions. The work begins with a description of the importance of lime in the metallurgical industry and the specifics of using rotary kilns as the main units for its production. There is a need to increase productivity and reduce energy consumption. The article provides an overview of promising technical solutions, such as: design changes, optimization of heat exchange devices, improvement of burner mechanisms, introduction of automatic control and process control systems. The results of tests confirming the expediency of using chalk of certain brands are also considered. Attention is drawn to the importance of factors such as the quality of raw materials and the qualifications of service personnel that affect the firing efficiency. The authors proposed new technical solutions to increase the efficiency of roasting process and reduce energy consumption. The article discusses the main problems associated with the production of lime from chalk. The proposed improvements are aimed at solving the mentioned problems and improving the quality of the final product. Special attention is paid to optimizing the thermal mode of the furnace; this will make it possible to use thermal energy more efficiently and reduce fuel consumption, which in turn will lead to reduction in the cost of lime production. Implementation of the proposed technical solutions will significantly increase the economic and environmental efficiency of lime production. The article emphasizes that continued research in this area is promising for improving the performance of rotary furnaces and, consequently, the quality of the resulting product.

Keywords

For citations:

Sivkov A.S., Chibizova S.I., Apasova A.D. Improving the design and thermal operation of a rotary kiln for production of metallurgical lime from chalk. Izvestiya. Ferrous Metallurgy. 2025;68(4):395-401. https://doi.org/10.17073/0368-0797-2025-4-395-401

Introduction

In today’s world, lime is one of the key materials used in the metallurgical industry, and the rotary kiln remains one of the most efficient and widely adopted process units for its production. The need to enhance the performance of rotary kilns employed in the technology of producing metallurgical lime from chalk is a pressing challenge. Improving the design and thermal operation of these kilns will enable increased productivity, reduced energy consumption, and improved quality of the final product [1; 2].

An overview is provided of the most relevant and promising technical solutions whose implementation would enhance the efficiency of rotary kilns used for the production of metallurgical lime from chalk, reduce energy consumption, and improve the environmental performance of the process [3].

Classification and main design features of rotary kilns

The rotary kiln is one of the most widely used types of thermal units employed in metallurgy, as well as in the production of cement, lime, ceramics, refractories, and other materials [4; 5]. The design features and operating principles of rotary kilns account for their broad application in carrying out high-temperature processes such as drying, roasting, reduction, sintering, and more. The key advantages of rotary kilns over other types of thermal units include:

– continuous process operation (the material loaded into the loading device at the upper end of the kiln gradually moves along the inclined rotating drum toward the discharge device at the lower end, thereby ensuring continuity of the process and the ability to regulate the material’s residence time within the working space);

– intensive heat and mass transfer (the rotation of the drum, along with internal lifting blades mounted on the inner surface, ensures thorough mixing of the material, which promotes efficient heat and mass exchange between the solid and gas phases);

– fuel flexibility (rotary kilns can operate on solid, gaseous, or liquid fuels), which enhances the adaptability of the production process);

– relative simplicity of design and operation (compared to other types of thermal units – such as shaft and chamber kilns – rotary kilns have a simpler structure, which facilitates maintenance and repair);

– high productivity (due to the continuous operation and intensive heat and mass transfer, rotary kilns can deliver production capacities reaching hundreds or even thousands of tons per day).

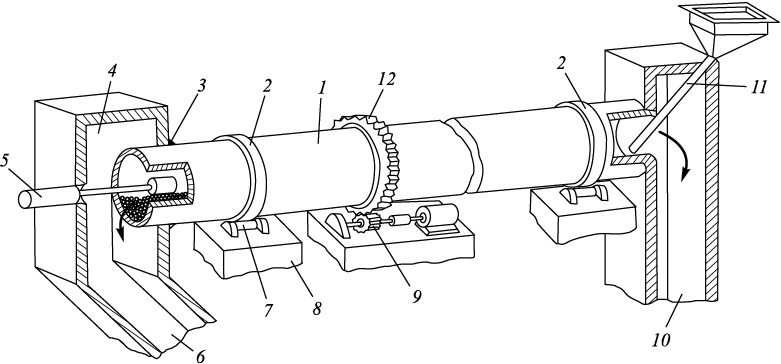

The specific design solutions and configuration of rotary kiln components are determined by the characteristics of the technological process, the physical and chemical properties of the raw materials, the quality requirements for the final product, and energy and environmental considerations. The rotary kiln design is shown in Fig. 1 [6; 7].

Fig. 1. Rotary kiln design: |

Key areas for improving rotary kiln design for lime production

Tests carried out on a laboratory-scale model at NUST “MISIS” for the production of metallurgical lime from chalk confirmed the feasibility and expediency of using chalk from Lebedinsky Mining and Processing Combine (LGOK) at Oskol Electrometallurgical Combine (OEMK). Both enterprises are part of the Metalloinvest holding company [8].

The rotary kiln is a heat exchange unit in the form of an inclined rotating tube, in which hot gases flow countercurrent to the movement of limestone. The size of the material loaded into the kiln ranges from 20 to 60 mm. The kiln has a nominal capacity of 360 tons per day.

The main component of the rotary kiln is a steel cylindrical drum, with a diameter of 3.6 m and a length of 75 m. The diameter of the drum remains constant along the entire length of the kiln.

An analysis of the operational characteristics of existing rotary kiln designs used for lime production makes it possible to identify several key areas for improvement aimed at increasing the energy efficiency, environmental performance, and economic viability of this technological process. A number of foundational studies have been devoted to enhancing the efficiency of technological processes in lime roasting units, particularly in rotary kilns.

In the monograph Lime Production by A.V. Monastyriev [9], the design features and thermal operating modes of various types of firing kilns, including rotary kilns, are examined in detail. The author identifies the key factors influencing fuel efficiency in lime production: raw material quality and preparation, kiln design solutions, operation of auxiliary equipment, and qualifications of service personnel. The book presents technical solutions for improving rotary kiln design, such as the use of in-kiln heat exchange devices, optimization of raw material loading and discharge systems, and modernization of burner mechanisms.

In the monograph Kilns for Lime Production by A.V. Monastyriev and R.F. Galiahmetov [10], the structural features and operating modes of rotary kilns are considered in greater detail, particularly those affecting fuel efficiency. The authors analyze the influence of factors such as kiln drum length and inclination, the presence of internal heat exchangers, and loading and unloading modes of the raw materials.

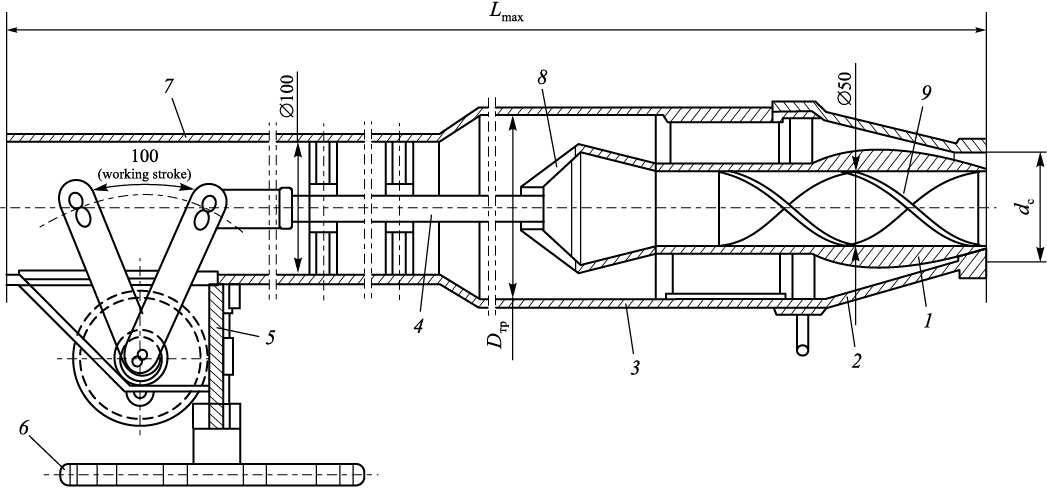

Patent RF No. 2079785 Gas Burner [11], by L.V. Kalashnikov and G.L. Kalashnikov, proposes a design for a adjustable gas burner that allows regulation of the flame parameters and the intensity of heat exchange within the working space of the kiln. This innovation contributes to more efficient fuel combustion in firing units (Fig. 2).

Fig. 2. Single-channel adjustable cement burner [11]: |

In the monograph by N.P. Tabunshchikov Lime Production, the issues of proper kiln operation, maintaining optimal process conditions, and monitoring the composition of off-gases are discussed. These factors are noted to significantly affect fuel efficiency in lime production.

One of the main factors limiting the efficiency of rotary kilns is the uneven distribution and movement of raw materials inside the kiln drum [12]. To address this issue in the studied kiln, a promising direction is the development of advanced loading and discharge devices that ensure optimal distribution and transport of raw material along the kiln length. A key area for improving the energy efficiency of rotary kilns used for lime production is the enhancement of heat and mass transfer systems. The kiln under consideration is characterized by significant heat losses with exhaust gases, as well as insufficient utilization of the thermal potential of calcined products for preheating the raw materials [13].

The efficiency of heat exchange processes can be increased by:

– installing high-efficiency regenerative or recuperative heat exchange devices (such as rotary air preheaters and tubular heat exchangers);

– implementing multi-stage heat exchange schemes with recirculation and cascade utilization of thermal energy.

The introduction of these technical solutions will reduce fuel consumption, decrease heat losses, and increase the temperature of the air supplied to the combustion zone, ultimately leading to higher thermal efficiency of the rotary kiln.

Studying combustion processes and flame heat transfer in the working space of kilns used for lime production is a critical task, as it determines the size of the firing zone, the intensity of thermal impact on the material, and the condition of the lining.

A.A. Anisimov et al. [14] developed a mathematical model and a calculation algorithm for evaluating the thermal characteristics of limestone firing in a rotary kiln. The authors established an empirical relationship for determining the length of the gas burner flame, taking into account parameters such as burner diameter, inner kiln diameter, and fuel and air flow rates. A method was proposed for calculating the average effective temperature of the gas stream in the contact zone with the surface of the fired limestone.

Based on the developed model, a numerical study was conducted on the influence of various factors on flame heat transfer and the temperature state of the calcined material. It was shown that the flame heat transfer is significantly affected by the excess air ratio, preheated air temperature, lining emissivity, and the lower heating value of the fuel [14]. At the same time, the thickness of the lining has a lesser effect. To optimize the firing mode, an algorithm was proposed for calculating the resulting thermal flux of the flame into the firing zone. This algorithm allows for achieving the required calcination temperature by adjusting the fuel flow rate, excess air ratio, and air preheating temperature, thereby preventing overheating of the kiln lining.

E.E. Merker et al. [15] also addressed the issue of improving fuel combustion efficiency in rotary kilns for lime production. The authors emphasize that key factors determining heat transfer in the working space of the kiln include the flame length and temperature. Flame characteristics, in turn, depend on the design and operating modes of the burner devices.

Studies have shown that optimizing fuel combustion conditions and heat transfer in the firing zone of rotary kilns used for lime production is a relevant and important task. The developed mathematical models and calculation algorithms make it possible to determine optimal operating parameters that ensure the required quality of lime while minimizing energy consumption.

Existing kiln designs are characterized by high emissions of nitrogen and sulfur oxides, as well as significant heat losses with flue gases [16].

To address these issues, the following technical solutions can be applied:

– use of staged or two-stage fuel combustion to reduce NOx formation;

– implementation of flue gas recirculation to limit excess air and lower the temperature in the firing zone;

– application of low-emission burner mechanisms equipped with automatic air and fuel control systems;

– introduction of catalytic or selective non-catalytic treatment systems for removing nitrogen and sulfur oxides from exhaust gases.

The integrated implementation of these measures will help reduce fuel consumption during the roasting process and significantly lower atmospheric emissions of harmful substances. A key factor affecting the operational performance of rotary kilns is the reliability and durability of their main structural components, such as the drum and lining [17].

The implementation of these technical solutions will help extend kiln service life, reduce maintenance and repair costs, and improve the overall reliability and economic efficiency of lime production [18]. An important direction for improving the performance of rotary kilns is the introduction of automatic control and process management systems. This will make it possible to maintain optimal operating conditions, ensure stable firing conditions, and thereby achieve high and consistent lime quality. In addition to improving traditional rotary kiln designs to enhance their performance characteristics, a promising direction is the development and implementation of nontraditional technical solutions [19; 20]. The main directions for improving the design of rotary kilns for lime production include:

– enhancing raw material loading and discharge systems;

– improving the efficiency of heat exchange processes;

– optimization of fuel combustion systems;

– improving the design of the drum and lining;

– automating process control;

– developing and applying nontraditional design solutions.

The implementation of these measures will improve the energy efficiency, environmental performance, and cost-effectiveness of lime production in rotary kilns, while also ensuring high and stable quality of the final product.

Conclusions

An analysis of the operational characteristics of the existing rotary kiln design with a diameter of 3.6 m and a length of 75 m, used for producing 360 tons of lime per day, revealed a number of deficiencies and issues that negatively affect the technical, economic, and environmental performance of this technological process. The main problematic aspects include: limited potential for increasing productivity, low energy efficiency, challenges in ensuring consistent quality of limestone firing, accelerated wear of main structural components, and significant emissions of carbon dioxide and other pollutants.

The main directions for improving the rotary kiln design for lime production are identified. Their implementation will enhance the energy and economic efficiency of lime production in rotary kilns, ensure high and stable product quality, and support compliance with environmental standards.

A review of the current state of lime production and existing rotary kiln designs has confirmed the relevance of improving kiln construction and thermal operation in the context of lime production from chalk. Addressing this challenge is of significant practical importance for improving both the efficiency and environmental safety of the production process.

References

1. Sivkov A.S., Shumakov V.V. Production of lime for metallurgical industry. In: Scientific Community of Students of the XXI Century. Natural Sciences: Proceedings of the XLV Int. Student Sci.-Pract. Conf. 2016;9(44). Available at: https://sibac.info/archive/nature/9(44).pdf (Accessed 07.06.2025). (In Russ.).

2. Sivkov A.S., Shumakov V.V., Mamonov R.I. Study of properties of chalk from LGOK. In: Scientific Community of Students of the XXI Century. Natural Sciences: Proceedings of the XLV Int. Student Sci.-Pract. Conf. 2016;11(47). Available at: https://sibac.info/archive/technic/11(47).pdf (Accessed 07.06.2025). (In Russ.).

3. Sivkov A.S., Shilov A.A. Study of physical and mechanical characteristics of chalk and limestone, with the aim of using chalk as a raw material for lime production. In: Scientific Community of Students of the XXI Century. Natural Sciences: Proceedings of the XLV Int. Student Sci.-Pract. Conf. 2018;1(60). Available at: https://sibac.info/archive/technic/1(60).pdf (Accessed 07.06.2025). (In Russ.).

4. Mikulcic H., Berg E.V., Vujanovic M., Priesching P., Perkovic L., Tatschl R., Duic N. Numerical modelling of calcination reaction mechanism for cement production. Chemical Engineering Science. 2012;69(1):607–615. https://doi.org/10.1016/j.ces.2011.11.024

5. Sinhal K., Ghoshdastidar P.S., Dasgupta B. Computer simulation of drying of food products with superheated steam in a rotary kiln. ASME Journal of Thermal Science and Engineering Applications. 2012;4(1):011009. https://doi.org/10.1115/1.4005256

6. Li S.Q., Ma L.B., Wan W., Yao Q. A mathematical model of heat transfer in a rotary kiln thermo-reactor. Chemical Engineering Technology. 2005;28(12):1480–1489. https://doi.org/10.1002/ceat.200500241

7. Guo Y.C., Chan C.K., Lau K.S. Numerical studies of pulverized coal combustion in a tubular coal combustor with slanted oxygen jet. Fuel. 2003;82(8):893–907. https://doi.org/10.1016/S0016-2361(02)00367-8

8. Sivkov A.S., Shumakov V.V., Mamonov R.I. Possibility of using chalk for the production of lime used in metallurgy. In: Scientific Community of Students of the XXI Century. Natural Sciences: Proceedings of the XLV Int. Student Sci.-Pract. Conf. 2016;9(45). Available at: https://sibac.info/archive/technic/9(45).pdf (Accessed 07.06.2025). (In Russ.).

9. Monastyrev A.V. Lime Production. Moscow: Vysshaya shkola; 1971:272. (In Russ.).

10. Monastyrev A.V., Galiakhmetov R.F. Kilns for Lime Production. Voronezh: Istoki; 2011:392. (In Russ.).

11. Kalashnikov L.V., Kalashnikov G.L. Gas burner. Patient RF no. 2079785 1997 (In Russ.).

12. Selivanov N.I. Technology and Equipment for Production of Building Materials. Moscow: Vysshaya shkola; 2005:366. (In Russ.).

13. Alekseev A.D. Theory and Practice of Limestone Roasting in Rotary Kilns. Moscow: Metallurgiya; 1973:344. (In Russ.).

14. Ansimov A.A., Merker E.E., Kharlamov D.A., Kochetov A.I., Kazartsev V.O. Studying the heat transfer of the torch and optimization of the regime of firing in the revolver. Bulletin of Cherepovets State University. 2013; (2-1(47)):5–9. (In Russ.).

15. Merker E.E., Kharlamov D.A., Ansimov A.A. Increasing the efficiency of fuel combustion in rotary kilns for lime roasting. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 1995;(5):28–30. (In Russ.).

16. Sheludyak B.L. Technology of Lime Production. Moscow: Stroyizdat; 1988:272. (In Russ.).

17. Alekseev A.D. Theory and Practice of Limestone Roasting in Rotary Kilns. Moscow: Metallurgiya; 2018:344. (In Russ.).

18. Kuznetsov N.V., Baskakov A.P. Thermal Engineering. Moscow: Energoatomizdat; 2018:479. (In Russ.).

19. Mastorakos E., Massias A., Tsakiroglou C.D., Goussis D.A., Burganos V.N. CFD predictions for cement kiln including flame modelling, heat transfer and clinker chemistry. Applied Mathematical Modelling. 1999;23(1):55–76. https://doi.org/10.1016/S0307-904X(98)10053-7

20. Mujumdar K.S., Ganesh K.V., Kulkarni S.V., Ranade V.V. Rotary cement kiln simulator (RoCKS): Integrated modeling of pre-heater, calciner, kiln and clinker cooler. Chemical Engineering Science. 2007;62(9):2590–2607. https://doi.org/10.1016/j.ces.2007.01.063

About the Authors

A. S. SivkovRussian Federation

Aleksandr S. Sivkov, Postgraduate of the Chair “Energy-Efficient and Resource-Saving Industrial Technologies”

4 Leninskii Ave., Moscow 119049, Russian Federation

S. I. Chibizova

Russian Federation

Svetlana I. Chibizova, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Energy-Efficient and Resource-Saving Industrial Technologies”

4 Leninskii Ave., Moscow 119049, Russian Federation

A. D. Apasova

Russian Federation

Anna D. Apasova, Postgraduate of the Chair “Energy-Efficient and Resource-Saving Industrial Technologies”

4 Leninskii Ave., Moscow 119049, Russian Federation

Review

For citations:

Sivkov A.S., Chibizova S.I., Apasova A.D. Improving the design and thermal operation of a rotary kiln for production of metallurgical lime from chalk. Izvestiya. Ferrous Metallurgy. 2025;68(4):395-401. https://doi.org/10.17073/0368-0797-2025-4-395-401