Scroll to:

On the results of tribological studies of railway rails

https://doi.org/10.17073/0368-0797-2024-6-653-659

Abstract

Metal resistance to the formation of contact fatigue defects and wear development has a great influence on the consumer properties of rails. The most significant factors limiting the service life of rails in curved sections of the railway track are wear of rails of the outer threads and development of contact fatigue defects in the inner threads of the track. In this regard, methods of reliable laboratory assessment of the rail metal resistance become important in the development of new products. The paper describes the change in the nature of damage to rails of various hardness categories by contact fatigue defects, and evaluates their wear resistance. The study of defects and forecasting of the rail resource require an integrated approach. The paper provides a brief description of modeling the conditions of formation and accumulation of contact fatigue defects. The parameters under consideration have an effect on the wear resistance of rail metal of various chemical compositions. During the testing, the rails microstructure and the nature of crack growth change. The authors made a comparative analysis of the data obtained characterizing the wear resistance of rail steels of various hardness categories. The basis of the methodology for assessing the wear resistance of railway rails is the physical modeling of adhesion-deformation mechanism of friction of the samples on a roller friction machine (tribometer). During laboratory tests of the studied categories of rails, the friction machine automatically outputs and records a number of computational parameters shown in the work. The conducted research is promising from a practical point of view. The results obtained can be used to develop a theory to increase the service life of differentially hardened rails produced by JSC EVRAZ United West Siberian Metallurgical Plant.

Keywords

For citations:

Olifirenko I.A., Oskolkova T.N., Polevoi E.V. On the results of tribological studies of railway rails. Izvestiya. Ferrous Metallurgy. 2024;67(6):653-659. https://doi.org/10.17073/0368-0797-2024-6-653-659

Introduction

According to GOST R 51685, the quality of rail steel is evaluated based on a range of mechanical properties, including yield strength (σy ), ultimate tensile strength (σt ), elongation (δ5 ), reduction of area (φ), impact toughness, impact toughness, hardness of the running surface and cross-section, and the level of residual stresses. Additionally, compliance with requirements for micro- and macrostructure, non-metallic inclusions, surface quality, straightness, and other parameters is assessed. These factors influence the operational properties of rails; however, similar characteristics can be achieved through different approaches, such as alloying, heat treatment, and variations in force and temperature modes during rolling. Each treatment method activates distinct mechanisms of strengthening and structure formation, which directly impact resistance to contact fatigue defects and wear resistance. These differences become especially pronounced when rails are used on curved sections of the track. Rails on the outer threads of curves experience significant wear due to lateral forces from the wheel flanges of rolling stock. These forces arise from the interaction between the rotating wheels and the tangent to the curve of the rails [1 – 3].

Historically, hardness was considered the primary indicator of wear resistance in steel. However, recent studies [4; 5] suggest that the nature of wear is much more complex, and wear resistance cannot be evaluated solely based on hardness. Abrasive wear is influenced by the hardness, strength, and plasticity of the steel. Additionally, wear resistance depends on the chemical composition, production technology, and microstructure of the rails [6 – 8].

With the growth of heavy-duty transportation and the general trend toward increasing freight intensity, the issue of rail wear in curved sections and the formation of contact fatigue defects has become increasingly significant. Numerous studies [10 – 15] have been devoted to identifying the mechanisms of defect formation and progression, as well as understanding the structural changes in rails during operation. Additional research has focused on evaluating the operational properties of rails either directly in service [16 – 21] or through the use of specialized test rigs [22; 23] that simulate the wheel-rail interaction on a full scale. Full-scale wheel-rail test rigs provide precise assessments of rail wear resistance by testing the rail as an integrated structure, accounting for variations in structure and properties across the cross-section. These tests offer insights into rail performance at different stages of its life cycle. However, direct in-service measurements have significant limitations, including the substantial influence of specific operating conditions during field tests and the lengthy duration required for both field (~2.0 – 2.5 years) and laboratory stand (~0.5 – 1.0 years) tests. Furthermore, wheel-rail test rigs are expensive and currently unavailable in Russia.

Thus, a key challenge in modern railway rail production is developing and implementing new laboratory methods to assess the resistance of rail steel to wear and contact fatigue defects. These methods will allow for evaluating the effectiveness of technological solutions and expedite the development of high-demand products. Establishing a scientifically grounded methodology for assessing rail wear resistance is a priority, as no standardized approach currently exists in the available technical documentation.

Materials and methods

In this study, the focus was on differentially hardened R65 rails of compositions 1 and 2, produced by JSC EVRAZ United West Siberian Metallurgical Plant (JSC EVRAZ ZSMK) using 76KhF steel in accordance with GOST R 51685 – 2022. The chemical composition of 76KhF steel, as per GOST R 51685 – 2022, is as follows (wt. %): C 0.71 – 0.84; Mn 0.75 – 1.25; Si 0.25 – 1.00; P ≥ 0.020; S ≥ 0.020; Al ≥ 0.004; Cr 0.20 – 0.60; V 0.03 – 0.15. The grades differ in carbon and manganese content: grade 1 – 0.76 % C, 0.79 % Mn; grade 2 – 0.81 % C, 0.97 % Mn.

Friction tests were performed using a roller friction machine with the following specifications:

– load: up to 5 kN;

– sample rotation speed: up to 3000 rpm;

– ability to test with or without lubricants, with heating of lubricants up to 100 °C 100 °С.

The machine is equipped with wear sensors, an eddy current sensor, and two vibration sensors measuring in three planes (х, у, z).

All samples were tested under consistent conditions:

– load: 1.2 kN;

– rail roller rotation speed: 217 rpm;

– slip ratio: ~10 %;

– test duration: 120 min;

– contact roller hardness: HRC 59;

– no lubricants used.

The machine also recorded several computational parameters in the form of graphs, including the coefficient of friction, slip ratio, friction force, sliding speed, speed of increase, and the relationship between slip and roller diameter. Parameters were dynamically adjusted to reflect changes introduced during the tests.

During the experiments, the sliding speed of the contact roller was varied to maintain a consistent slip ratio of 10 %, accounting for changes in roller diameter due to friction.

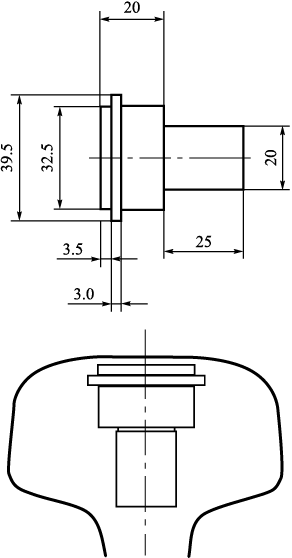

For the laboratory evaluation of wear resistance, one sample was cut from rails of compositions 1 and 2 from current production according to the specified design (Fig. 1).

Fig. 1. Scheme and place of cutting samples |

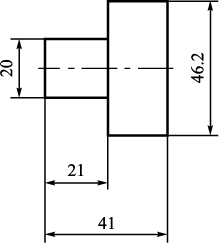

A thermally strengthened roller made of 31Mn4 steel with a hardness of (59 ÷ 59) ± 2 HRС in accordance with the European standard DIN 1544, was used as the contact sample. The diagram of the contact sample is shown in Fig. 2.

Fig. 2. Diagram of the contact sample |

The evaluation of the wear rate of rail rollers was conducted over 52,000 to 156,000 revolutions to eliminate the influence of surface quality at the beginning of the tests and the effect of metal delamination during the final test cycles.

Wear resistance was determined as the reciprocal of wear rate. Due to the minimal mass loss during testing, laboratory analytical scales with an accuracy of up to 0.0001 g were used:

\(W = \frac{{{m_1} - {m_2}}}{{{N_{{\rm{cycle}}}}}} \cdot {10^{ - 5}},\)

where W is the wear resistance, g/cycle; m1 and m2 are sample masses before and after testing, g; Ncycle is the number of revolutions (1 cycle = 2600 revolutions).

The factors influencing the wear resistance of rail steel include a combination of several characteristics that allow for the assessment and improvement of rail steel performance in terms of wear resistance. These characteristics are: material hardness; chemical composition (carbide-forming carbon) and sulfur content (which determines the quantity of manganese and iron sulfides that act as stress concentrators in micro-damage zones during wear) [16]; microstructure parameters (interlamellar spacing, grain diameter, size of pearlite colonies, volumetric fraction of cementite); influence of carbides and carbonitrides (their quantity, shape, and distribution) [4].

Comparative analysis of the results

The hardness of the metal in the tested samples was measured using the Vickers method on a “Qness Q10A+” microhardness tester at seven points on the sample surface under a load of 50 N. The measurement results are presented in Table 1.

Table 1. Results of hardness measurements of the samples

| ||||||||||||||||||||||||||||||||||

The data show that the hardness of the samples from rails with composition 2 is 7.85 % higher compared to those with composition 1.

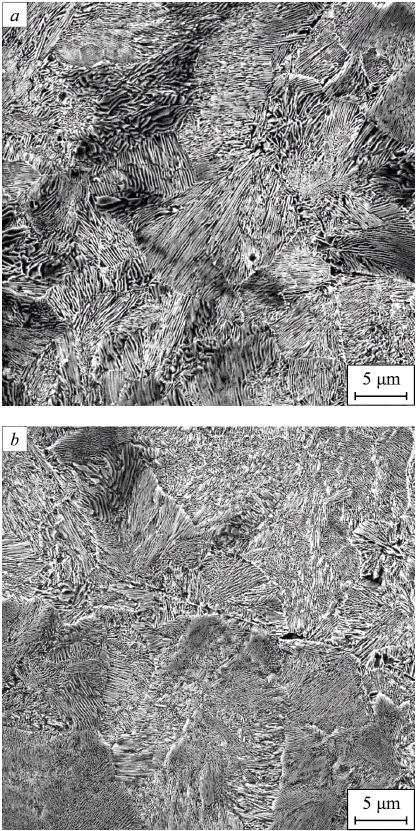

The microstructure of the rail steel was studied on transverse polished sections prepared from the fillet zone of the rail head after electropolishing and etching in a 4 % ethanol solution of nitric acid. The investigations were conducted using a scanning electron microscope (SEM). The analyzed area was located 2 – 4 mm from the running surface of the rail head.

The results of these measurements are presented in Table 2 and Fig. 3.

Table 2. Parameters of the rail microstructure

Fig. 3. Microstructure of metal of the rails of composition 1 (a) |

The analysis of the data indicates that the interlamellar spacing in the microstructure of the steel from rails with composition 1 slightly exceeds that of rails with composition 2. At the same time, the grain diameter in the steel of rails with lower carbon and manganese content (composition 1) is 1.0 grade larger than that of rails with composition 2. The grain sizes correspond to 24.20 µm (grain number 8) for composition 1 and 19.50 µm (grain number 9) for composition 2.

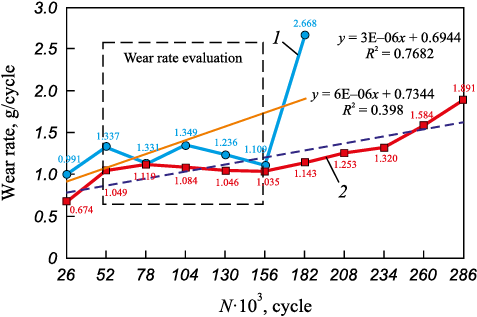

The average wear rate of samples from rails with composition 2 was 1.0665·10–5 g/cycle, which is 13.5 % lower than the wear rate of samples from rails with composition 1, measured at 1.2324·10–5 g/cycle.

It is worth noting that after 182,000 revolutions, the samples cut from rails with composition 1 exhibited a sharp increase in mass loss (Fig. 4).

Fig. 4. Wear rate of the rail samples of composition 1 ( |

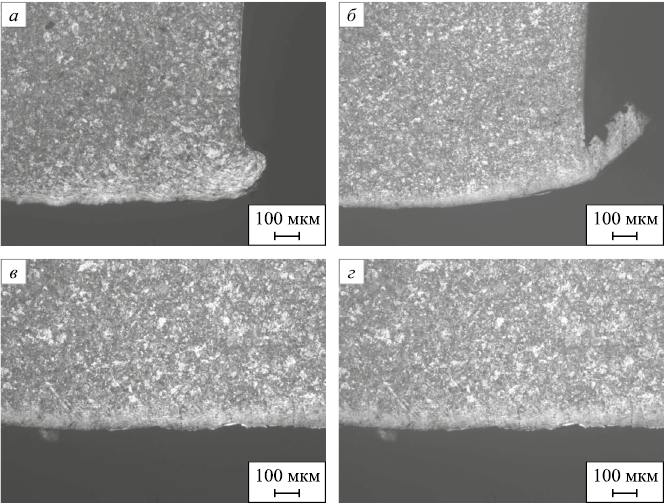

The microstructure of the samples after the friction test cycle was studied using an Olympus JX71 optical inverted microscope. Microstructural analysis revealed a fibrous-deformed structure with a layer thickness of up to 82.4 µm on the edges of samples with composition 2 and up to 103.9 µm on the edges of samples with composition 1 (Figs. 5, a, b). In the central part of the samples, the layer thickness reached up to 67.7 µm for composition 2 and up to 77.6 µm for composition 1 (Figs. 5, c, d).

Fig. 5. Fibrous-deformed structure along the edges of the rail samples (a, b) |

Conclusions

An increase in carbon and manganese content in rail steel enhances its wear resistance and resistance to contact fatigue defects.

The scientific findings of this study can be used to advance the theory of extending rail service life, reducing maintenance costs, and improving the reliability of differentially hardened rails produced by JSC EVRAZ United West Siberian Metallurgical Plant.

References

1. Yokoyama H., Mitao S., Yamamoto S. Wear and rolling contact fatigue behavior in pearlitic and bainitic rail steels. In: 7th International Heavy Haul Conf. Fukuyama, Japan: Materials & Processing Research Center; 2001:551–557.

2. Goryacheva I.G., Shur E.A., Bortz A.I., Zakharov S.M. New generation rails damageability mechanisms evaluation and damage occurrence design. Bulletin of the Joint Scientific Council of Russian Railways. 2017;(4):25–27. (In Russ.).

3. Goryacheva I.G., Zakharov S.M., Kogan A.Ya., Torskaya E.V., Shur E.A., Abdurashitov A.Yu., Borts A.I., Zagranichek K.L. Complex approach to forecasting the operability and resource of new generation rails. Bulletin of the Joint Scientific Council of Russian Railways. 2017;(5-6): 16–26. (In Russ.).

4. Polevoy E.V., Yunin G.N., Yunusov A.M., Dobuzhskaya A.B., Golitsyn G.A. On the issue of wear resistance of rails. Stal’. 2019;(7):62–65. (In Russ.).

5. Jendel T. Prediction of wheel profile wear – comparisons with field measurements. Wear. 2002;253(1-2):89–99. https://doi.org/10.1016/S0043-1648(02)00087-X

6. Zagranichek K.L., Bortz A.I., Peshkov I.E. Comparative assessment of wear resistance of differentially heat-strengthened rails for general and special purposes in laboratory conditions. In: Improving the Quality and Operating Conditions of Rails and Rail Fasteners. Collection of Scientific Reports based on the Materials of the Meeting of the Non-Profit Partnership “Rail Commission” (Novokuznetsk, September 26-27, 2019). Yekaterinburg: UIM; 2020:94-114. (In Russ.).

7. Shur E.A., Borts A.I., Bazanova L.V. Fatigue life of damaged rails. Journal of Physics: Conference Series. 2020;1431(1):012071. https://doi.org/10.1088/1742-6596/1431/1/012071

8. Improvement of rail steels. Zheleznye dorogi mira. 2016;(1): 74–76. (In Russ.).

9. Generalization of the World Experience of Heavy-Weight Movement: Control of the Wheel – Rail System. Trans. from Eng. Zakharov S.M. ed. Moscow: Intext; 2017:420. (In Russ.).

10. Dang Van, Maitournam M.H., Moumni Z., Roger F. A comprehensive approach for modeling fatigue and fracture of rails. Engineering Fracture Mechanics. 2009;76(17):2626–2636. https://doi.org/10.1016/j.engfracmech.2008.12.020

11. Goryacheva I.G., Zakharov S.M., Torskaya E.V. Rolling contact fatigue and wear of wheel/rail simulation. In: Proceedings of the Second Int. Conf. on Railway Technology Research Development and Maintenance. Stirlingshire, Scotland: Civil-Comp Press; 2014:0123456789.

12. Kabo E., Ekberg A. Prediction of RCF from laboratory tests. In: INNOTRACK Concluding Technical Report. 2010:131–133.

13. Rodríguez-Arana B., Emeterio A.S., Panera M., Montes A., Alvarez D. Investigation of a relationship between twin-disc wear rates and the slipping contact area on R260 grade rail. Tribology International. 2022;168:107456. https://doi.org/10.1016/j.triboint.2022.107456

14. Kuznetsov R.V., Gromov V.E., Polevoy E.V., Rubannikova Yu.A., Kormyshev V.E. Evolution of structural-phase states and properties of differentially hardened 100-meter rails during extremely long-term operation. Message 3. Structure and properties of rails after the transported tonnage of 1.77 billion tons. Problemy chernoi metallurgii i materialovedeniya. 2021;(2):81–87. (In Russ.).

15. Pacey M.N., James M.N., Patterson E.A. A new photoelastic model studying fatigue cracks closure. Experimental Mechanics. 2005;45(1):42–45. https://doi.org/10.1007/BF02428989

16. Shur E.A., Tsvigun V.N., Koinov R.S. Models of formation of factographic reliefs on fatigue cracks. Vestnik gorno-metallurgicheskoi sektsii Rossiiskoi akademii nauk. Otdelenie metallurgii. 2018;(40):118–135. (In Russ.).

17. Goryacheva I.G., Bortz A.I., Zakharov S.M., Zagranichek K.L., Shur E.A. Investigation and modeling of the occurrence of surface contact fatigue damage in rails. In: Tribology – machine structure. Proceedings of the XII Int. Sci. and Tech. Conf. dedicated to the 80th anniversary of IMASH RAS. 2018:146–149. (In Russ.).

18. Nekrasov D.B., Palagin S.V., Lykov K.Yu. On the expansion of landfills and the improvement of methods for monitoring and testing rails. Railway Track and Facilities. 2023;(4): 29–31. (In Russ.).

19. Shur E.A. How to compare the wear resistance of different rails correctly. RSP Expert. 2018;(1-2):20-25. (In Russ.).

20. Nekrasov D.B., Borts A.I., Becher S.A., Bobrov A.L., Palagin S.V., Shlyakhtenko S.P. Ensuring the effectiveness of grinding based on the diagnosis of pre-defective conditions. Railway Track and Facilities. 2024;(3):17–19. (In Russ.).

21. Nekrasov D.B., Palagin S.V., Lykov K.Yu. Test results of rails of the DT400IK category. Railway Track and Facilities. 2023;(2):20–22. (In Russ.).

22. Burstow M. A whole life rail model application and development for RSSB – Continued development of an RCF damage parameter. London: Rail Safety and Standards Board; 2004:74.

23. Chen Y.-T., Liu D.-Y., Fang H.-S., Bai B.-Z. Rolling contact fatigue of rail steel. Journal of Iron and Steel Research International. 2000;12(5):50–53.

About the Authors

I. A. OlifirenkoRussian Federation

Ivan A. Olifirenko, Chief Specialist in Physical Research Methods, Directorate for Rail Production of the Research and Production Center, JSC EVRAZ United West Siberian Metallurgical Plant; Postgraduate of the Chair of Ferrous Metallurgy and Chemical Technology, Siberian State Industrial University

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

16 Kosmicheskoe Route, Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

T. N. Oskolkova

Russian Federation

Tat’yana N. Oskolkova, Dr. Sci. (Eng.), Prof. of the Chair of Ferrous Metallurgy and Chemical Technology

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

E. V. Polevoi

Russian Federation

Egor V. Polevoi, Cand. Sci. (Eng.), Head of Bureau of Metal Science and Heat Treatment of Technical Department of the Rail Site

16 Kosmicheskoe Route, Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Olifirenko I.A., Oskolkova T.N., Polevoi E.V. On the results of tribological studies of railway rails. Izvestiya. Ferrous Metallurgy. 2024;67(6):653-659. https://doi.org/10.17073/0368-0797-2024-6-653-659