Scroll to:

Structure and properties of coatings obtained by gas-thermal spraying

https://doi.org/10.17073/0368-0797-2024-6-710-715

Abstract

The authors investigated the microstructure and mechanical properties of wear-resistant coatings applied by the method of gas-thermal spraying with heating of the metal to a liquid state and its subsequent spraying with a gas jet. Nowadays, thermal spraying is increasingly an alternative to various methods of surfacing due to the high costs of consumables, the complexity of maintenance and safety during repairs. By this method, it is possible to reliably solve a variety of technological tasks, which include spraying of wear-resistant, antifriction and corrosion-resistant coatings; alitizing by spraying (increasing heat resistance); increasing the size of products; surfacing and soldering; elimination of casting defects; manufacture of molds, etc. The tribotechnical properties of the vibration damper rod of a railway carriage with reinforcing surface layers applied to the working surface by methods of gas-thermal spraying with 40Kh13 steel and galvanic chromium plating were investigated. Structure and thickness of the coatings, microhardness distribution in the coating-substrate zone, as well as the features of the coatings destruction under the same test conditions were studied. The criterion for comparing the coatings’ wear resistance was the operating time of the samples before the beginning of the coating destruction. Wear of the rollers was determined by the change in diameter, and wear of the pads – by the depth and width of the grooves formed on their surface during the experiment. The coating applied to the vibration damper rod by spraying 40Kh13 steel wire has high wear resistance in conditions of boundary friction with grease and can be an alternative to electroplated chrome coating. The high wear resistance of the coating makes it possible to recommend it for restoring the dimensions of worn parts and increasing the durability of new ones, as well as for replacing special anti-friction bearing alloys.

Keywords

For citations:

Kolubaev A.V., Sizova O.V. Structure and properties of coatings obtained by gas-thermal spraying. Izvestiya. Ferrous Metallurgy. 2024;67(6):710-715. https://doi.org/10.17073/0368-0797-2024-6-710-715

Introduction

Structural steels of various chemical compositions are traditional materials for manufacturing components of mechanisms and equipment. During operation, under conditions of sliding friction on working surfaces, the geometric dimensions of such components change, which consequently leads to disruptions in the operating modes of mechanisms and the occurrence of hazardous situations. The intensity of the wear process depends on several factors: chemical composition of the steel, its operational characteristics, load, and sliding speed of the working surface against the counterbody. A critical task in modern mechanical engineering is to develop a scientifically grounded set of measures for creating technologies to restore the working surfaces of machine components and tooling. One of the most promising methods is gas-thermal restoration of worn surfaces by applying metallic, non-metallic, and composite coatings. This involves heating the source material to a liquid or plastic state and spraying it with a gas jet. This method includes the previously known metallization process by spraying and similar processes for applying various materials. The spraying process consists of several stages: the initial stages ensure the atomization of the source materials, and in the final stage, they are deposited onto a target.

The gas-thermal spraying process is defined by distinct thermodynamic and aerodynamic characteristics [1], which are of practical importance as they directly influence the quality of the deposited material layer and its functional performance [2 – 9].

The gas-thermal spraying (GTS) process consists of four sequential stages: melting the source material in quantities sufficient to ensure continuous and uninterrupted spraying; atomizing the molten material into fine particles using jets of compressed air or other gases; creating a directed flow (spray plume) of these molten and atomized particles; and depositing the particles to form a material layer. During deposition, the particles, propelled by their kinetic energy, bombard the target surface, embedding themselves in its irregularities and adhering to previously deposited particles. Gas-thermal spraying is increasingly emerging as an alternative to traditional surfacing methods, which are often associated with high consumable costs, complex maintenance requirements, and significant safety challenges during repairs [10 – 16].

This study presents a comparative analysis of the structure and properties of gas thermal coatings made from high-chromium steel, applied to the working surface of a vibration damper rod in a passenger railway carriage. The coatings were applied using GTS, where the metal was heated to a liquid state and sprayed with a gas jet, and electroplated chrome coatings for comparison.

Materials and methods

The tribotechnical properties of the vibration damper rod of a railway carriage were investigated, with reinforcing surface layers applied to the working surface using gas-thermal spraying with 40Kh13 steel and electroplated chrome coatings. The chemical composition of the coatings was determined by X-ray fluorescence analysis, and the results were compared with the chemical composition of 40Kh13 steel according to GOST 5632 – 72. The study examined the structure and thickness of the coatings, the distribution of microhardness in the coating-substrate zone, and the characteristics of coating destruction under identical test conditions. Metallographic studies of the friction surfaces were conducted using a NEOPHOT-21 optical microscope, and the microhardness was measured with a PMT-3 microhardness tester.

The chemical composition of the coating obtained by gas-thermal spraying of 40Kh13 wire was as follows (wt. %): C 0.38, Si 0.21, Mn 0.64, Cr 0.87. A comparison of the primary element content, particularly chromium, showed that the coating material after spraying corresponded to the standard composition of 40Kh13 steel as per GOST 4543 – 71.

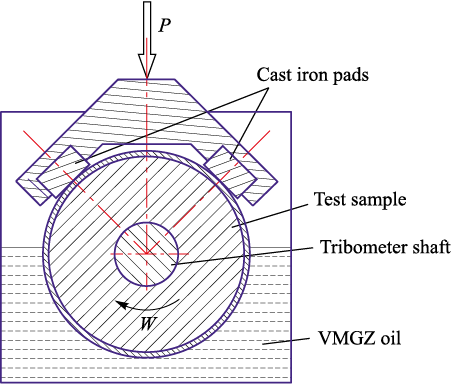

The wear of the rollers was determined by measuring the change in diameter, while the wear of the pads was evaluated based on the depth and width of the grooves formed on their surface during the experiment. A comparative analysis of the tribotechnical properties of electroplated and gas-thermal coatings was performed using a SMT-1 tribometer, following a roller-to-pad configuration. The rollers were the test samples, and the pads were made of SCh 32-52 grade cast iron. The test conditions closely simulated the real operating conditions of vibration dampers, including the lubricant used in this design (VMGZ oil). Tests were conducted until the onset of coating destruction, which was monitored by observing changes in surface topography and detecting initial signs of coating failure. After every three hours of experimentation, the structure of the coating and substrate was analyzed, microhardness was measured, and changes in the dimensions of rollers and pads were recorded.

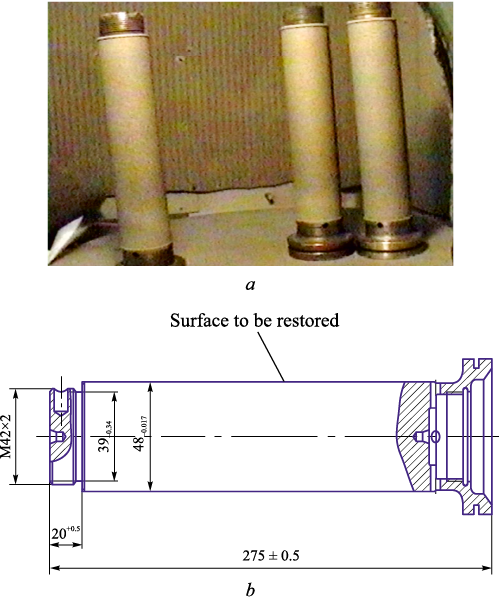

The implementation of new high-velocity gas-flame spraying systems offers significant potential for further development of this method, particularly in protecting critical machine and mechanism components from abrasive wear, corrosion, and other types of degradation [6 – 12]. One such critical component is the vibration damper of a railway carriage (Fig. 1), a large oilfilled shock absorber designed to dampen carriage oscillations during motion. A passenger carriage typically has four vibration dampers. Generally, within six months of oper-ation, these dampers begin to fail due to the destruction of the chrome coating and oil leakage. The cumulative costs of oil loss, rod replacement, and carriage downtime are substantial. It should be noted that worn rods are typically not repaired but discarded. Improving the wear resistance of these critical components can significantly reduce railway maintenance costs and enhance the safety of railway operations [13 – 16].

Fig. 1. General view (а) and diagram (b) of the vibration damper rod |

Samples for the structural and tribotechnical studies were prepared from two types of vibration damper rods: the first was a worn rod restored using GTS with 40Kh13 steel wire, and the second was a rod coated with a protective layer applied through standard electroplating in a liquid electrolyte.

The wear rates of the electroplated and gas-thermal coatings on the test samples were determined through comparative wear tests conducted on a 2070 SMT-1 tribometer, following the previously described roller-to-pad configuration. The experimental scheme is shown in Fig. 2.

Fig. 2. Experimental scheme |

The performance criterion for comparison was the duration of sample operation until the onset of coating failure under a load of P = 400 N and a shaft rotation speed of ω = 350 rpm. The degree of wear was evaluated using the following parameters: for the rollers, by the change in diameter; and for the pads, by the depth and width of the grooves formed on their surface during the experiment.

Results

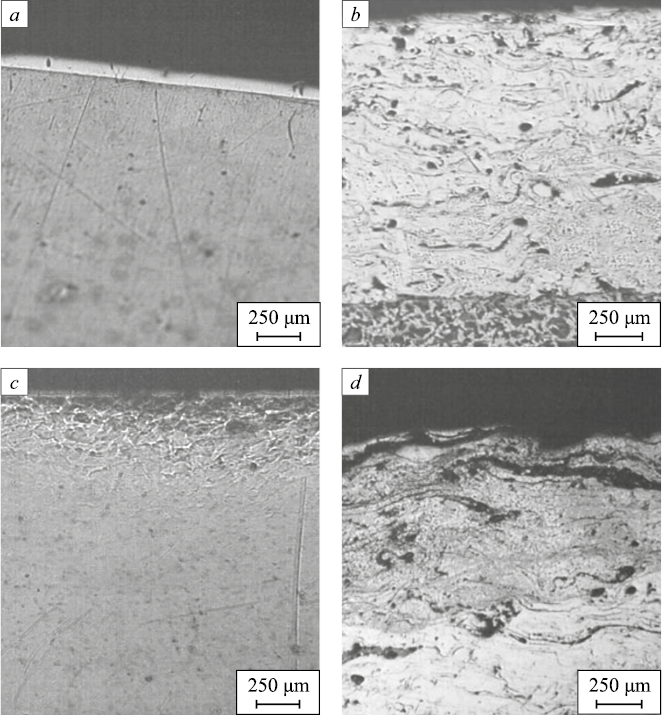

The structural analysis of the coatings revealed notable differences. The thickness of the dense electroplated chrome coating did not exceed 0.1 mm, with a sharp and well-defined boundary observed between the coating and the substrate (Fig. 3, а). In contrast, the thickness of the coating applied through GTS reached approximately 2 mm, with a similarly distinct boundary evident in this case. The metal structure within the gas thermal sprayed coating zone comprised mixed layers of the sprayed metal, varying in thickness (Fig. 3, b). Discontinuities, such as cracks and pores, were observed at the boundaries between these layers. The calculated porosity of the material was determined to be 5 – 6 %. Microhardness measurements indicated that the chrome coating exhibited a hardness of approximately 700 HV, while the gas-thermal sprayed coating demonstrated a hardness range of 340 – 400 HV. The substrate material (45 steel) had a hardness within the range of 150 – 180 НV.

Fig. 3. Microstructure of the samples in cross section: |

During the first three hours of testing, no significant changes were observed in either sample. However, after six hours of testing, the sample with the chrome coating began to exhibit the initial signs of substrate material deformation and localized chipping of the coating. These signs included the formation of a deformed layer beneath the coating, measuring 0.8 – 0.9 mm in depth, and the detachment of coating fragments along the boundary (Fig. 3, c). The image clearly illustrates that the failure of the chrome coating occurred through the detachment of small particles in areas where substrate material (the rod) deformation had occurred beneath the coating.

The coating applied through GTS retained its original structure throughout the entire testing period (9 h) without any visible signs of damage. Wear occurred gradually, with the removal of thin surface layers, avoiding the formation of localized areas with significant material loss.

Analysis and discussion of results

The analysis of the results revealed that the coating applied to the vibration damper rod through GTS of 40Kh13 steel wire demonstrated excellent wear resistance under conditions of boundary friction with lubrication. This highlights its potential as a viable alternative to electroplated chrome coatings. The exceptional wear resistance of the gas thermal coating makes it suitable not only for restoring the dimensions of worn components and enhancing the durability of new ones but also as a replacement for specialized anti-friction bearing alloys. The findings suggest that, in most cases, GTS is the most economically viable method for applying anti-friction coatings on components operating under sliding friction with either limited or abundant liquid lubrication [17 – 20].

Conclusions

It has been established that the GTS method, which involves heating the metal to a liquid state followed by its atomization using a gas jet, can be effectively employed to restore the worn surfaces of steel components.

Comparative studies of the tribotechnical properties of coatings applied through GTS and electroplating indicate that the gas thermal method reliably addresses a wide range of technological applications, including application of wear-resistant, anti-friction, and corrosion-resistant coatings; alitizing through spraying (to enhance heat resistance); increasing the dimensions of components; surfacing and soldering through spraying; rectification of casting defects.

References

1. Belotserkovskii M.A. Tribotechnical characteristics of gas-flame coatings. Friction and Wear. 2000;21(5):534–539. (In Russ.).

2. Vityaz P.A., Belotserkovskii M.A., Kukareko V.A., Kalinovskii D.M., Sukhotskii P.G., Kovalevskaya Zh.G. Structure and properties of 40Kh13 steel coatings obtained using various methods of gas-thermal spraying. Fizicheskaya Mezomekhanika. 2002;5(1):29–36. (In Russ.). https://doi.org/10.24411/1683-805X-2002-00072

3. Baldaev P.Kh., Shesterkin N.G., Lupakov V.I., Shatov A.P. Features of high-speed gas plasma spraying processes. Svarochnoe proizvodstvo. 2003;(5):43–46. (In Russ.).

4. Belotserkovskii M.A., Pryadko A.S. Activated plasma gas and electric arc spraying of coatings with conductive materials. Uprochnyayushchie tekhnologii i pokrytiya. 2006;(12):17–23. (In Russ.).

5. Zavareh M.A., Sarhan A.A.D.M., Binti A.R.B., Basirun W.J. Plasma thermal spray of ceramic oxide coating on carbon steel with enhanced wear and corrosion resistance for oil and gas applications. Ceramics International. 2014;40(9A): 14267–14277. https://doi.org/10.1016/j.ceramint.2014.06.017

6. Belotserkovskii M.A. Strength reliability and tribotechnical properties of gas-thermal coatings used in friction units. Fizicheskaya Mezomechanika. 2007;10(2):103–108. (In Russ.). https://doi.org/10.24411/1683-805X-2007-00037

7. Chu Z., Yang Y., Chen X., Yan D., Huang D., Lei W., Liu Z. Characterization and tribology performance of Fe-based metallic glassy composite coatings fabricated by gas multiple-tunnel plasma spraying. Surface and Coatings Technology. 2016;292:44–48. https://doi.org/10.1016/j.surfcoat.2016.03.024

8. Kolubaev A.V., Belyi A.V., Buyanovskii I.A. Mechanisms of deformation and destruction of hard coatings under frictional heating conditions. Izvestiya vuzov. Fizika. 2019;62(8): 53–75. (In Russ.). http://doi.org/10.17223/00213411/62/8/52

9. Gusev A.I., Usol’tsev A.A., Kozyrev N.A., Kibko N.V., Bashchenko L.P. Development of flux-cored wire for surfacing of parts operating under conditions of wear. Izvestiya. Ferrous Metallurgy. 2018;61(11):898–906. (In Russ.). https://doi.org/10.17073/0368-0797-2018-11-898-906

10. Belotserkovskii V.A., Grigorchik A.N., Kukareko V.A., Konstantinov V.M. The structural and phase state and wear resistance of nitrogen ion-modified thermal gas coatings made of high-chromium steels applied using high-enthalpy combustible gas. Metallovedenie i termicheskaya obrabotka. 2019;(9(771)):46–54. (In Russ.).

11. Kolubaev A.V., Sizova O.V., Fortuna S.V., Vorontsov A.V., Ivanov A.N., Kolubaev E.A. Weld structure of low-carbon structural steel formed by ultrasonic-assisted laser welding. Journal of Constructional Steel Research. 2020;172:160190. https://doi.org/10.1016/j.jcsr.2020.106190

12. Kukareko V.A., Belotserkovskii V.A., Grigorchik A.N., Sosnovskii A.V. Structure and tribological properties of the coating Ti–TiN, obtained by high-speed deposition. Friction and Wear. 2022;43(5):458–465. (In Russ.). https://doi.org/10.32864/0202-4977-2022-43-5-458-465

13. Artemenko S.A., Orlik G.V., Orlik A.G. The use of wear-resistant cord material for the restoration of worn teeth of a quarry excavator. Svarochnoe proizvodstvo. 2021;(10):63–69. (In Russ.). https://doi.org/10.26160/2658-3305-2021-10-63-69

14. Zharkevich A.M., Nurzhanova O.A., Bessonov A.V. Determination of the optimal technological modes of surfacing when restoring parts such as bodies of revolution. Svarochnoe proizvodstvo. 2022;(5):35–40. (In Russ.).

15. Liu S.-H., Trelles J.P., Li C.-J., Li C.-X., Guo H.-B. A review and progress of multiphase flows in atmospheric and lowе pressure plasma spray advanced coating. Materials Today Physics. 2022;27:100832. https://doi.org/10.1016/j.mtphys.2022.100832

16. Singh S., Goyal K., Bhatia R. A review on protection of boiler tube steels with thermal spray coatings from hot corrosion. Materials Today: Proceedings. 2022;56(1):379–383. https://doi.org/10.1016/j.matpr.2022.01.219

17. Li N., Tariq N. ul H., Che Y., Liu S., Wang J., Cui X., Xiong T. Corrosion-resistant thermal spray coatings for low-alloy steel in contact with molten nitrate salts in solar power plants. Solar Energy Materials and Solar Cells. 2023;59:112432. https://doi.org/10.1016/j.solmat.2023.112432

18. Samal S., Zeman J., Kopeček J., Šittner P. Thermal plasma spraying of NiTi powder for thick coating of shape memory alloy. Journal of Alloys and Compounds. 2024;984:173962. https://doi.org/10.1016/j.jallcom.2024.173962

19. Gupta M., Li X.-H., Peng R., Ottosson A., Gillbergе P., Girgulisf J. Understanding the effect of bondcoat surface treatment on enhanced lifetime of suspension plasma sprayed thermal barrier coatings. Surface and Coatings Technology. 2024;482:130716. https://doi.org/10.1016/j.surfcoat.2024.130716

20. Lakkannavar V., Yogesha K.B., Prasad C.D., Phanden R.K., Srinivasa G., Prasad S.C. Thermal spray coatings on high-temperature oxidation and corrosion applications – A comprehensive review. Results in Surfaces and Interfaces. 2024;16:100250. https://doi.org/10.1016/j.rsurfi.2024.100250

21.

22.

About the Authors

A. V. KolubaevRussian Federation

Aleksandr V. Kolubaev, Dr. Sci. (Phys.-Math.), Chief Researcher

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

O. V. Sizova

Russian Federation

Ol’ga V. Sizova, Dr. Sci. (Phys.-Math.), Chief Researcher

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

Review

For citations:

Kolubaev A.V., Sizova O.V. Structure and properties of coatings obtained by gas-thermal spraying. Izvestiya. Ferrous Metallurgy. 2024;67(6):710-715. https://doi.org/10.17073/0368-0797-2024-6-710-715