Scroll to:

Simulation of structural changes in metal under high-intensity external influence

https://doi.org/10.17073/0368-0797-2024-5-567-572

Abstract

Today, researchers and industry are faced with the task of improving the physical and mechanical properties of various metal products. To strengthen the structures, there are various technologies for processing the material surface by high-temperature exposure. At the same time, the use of laser technologies is of great interest. High-speed local laser heating of the material surface followed by rapid cooling with heat removal into the volume depth, as well as the absence of mechanical action, allows us to obtain unique nonequilibrium structures with a wide range of properties. Obviously, the development of these technologies requires deep fundamental research. In this work, the molecular dynamics method revealed the features of structural changes in the surface layers of an iron crystal under high-temperature exposure. The choice of such a method is due to the fact that the phenomena under consideration are difficult to study through real experiments and direct observations. Conditions of the computer experiment were set in such a way that after the melting point is reached, a phase transition occurs in the simulated system, during which particles are separated from the surface of the liquid phase. As a result of the study, the threshold temperature of particle ejection was estimated and the mechanisms of particle cluster formation were investigated. When heated, the number of clusters increases, and when cooled, it decreases, but at the same time their sizes increase, which indicates the implementation of the condensation mechanism of ablation products. Additionally, the influence of external pressure on the simulated particle system was studied. It is shown that as the pressure increases, the number of clusters decreases.

For citations:

Gostevskaya A.N., Markidonov A.V., Starostenkov M.D., Lubyanoi D.A. Simulation of structural changes in metal under high-intensity external influence. Izvestiya. Ferrous Metallurgy. 2024;67(5):567-572. https://doi.org/10.17073/0368-0797-2024-5-567-572

Introduction

Under the influence of high temperatures, the structure of the material undergoes changes. Studying the effect of high temperatures on structural changes in metals in the field of condensed matter mechanics poses numerous challenges related to the fundamental properties and structural transformations of materials. It is worth noting that there has been growing interest in methods for producing nanoparticles through material ablation under high-temperature exposure. Irradiation with ultrashort laser pulses is of practical interest [1; 2], and both experimental and theoretical studies have been devoted to this topic [3 – 5]. Currently, theoretical methods are available that are based on the construction of thermal models [6] and the analysis of energy balance scattering during laser emission [7]. These methods allow us to evaluate the effect of laser irradiation on surface structure modifications. It should be noted that phenomena characteristic of laser irradiation of materials, such as ablation and desorption, have been studied using molecular dynamics simulations [8; 9]. Applied to solids, molecular dynamics can reveal the differences between desorption and ablation, predict the distribution of clusters in samples [10 – 12], the distribution of particles by radial and axial velocities, and explain the dependence of ablation on laser properties [13 – 15], such as energy density and pulse duration [16; 17]. It is known that for many materials, the ablation process is accompanied by the formation of particle clusters. Mechanisms for their formation include condensation of the ejected particle cloud, phase explosion, hydrodynamic spraying, and photomechanical effects [18; 19]. As part of this study, the mechanisms of particle cluster formation were investigated.

Research methodology

To conduct the numerical experiment, the molecular dynamics method was chosen, which allows for the simulation of various statistical ensembles of particles, as well as the comparison of obtained results in real time.

The implementation of the molecular dynamics simulation largely depends on the interatomic potential. For the potential calculation, the “embedded atom” model was used, based on the theory of calculating the electronic structure of many-particle systems in physics.

During the calculation of the particle system modeled in the study, metal cells (BCC lattices) with a lattice parameter of а0 = 2.855 Å, were constructed and translated along the х, y and z axes. The resulting simulation cell imitated an iron crystal and contained 30,000 particles. The infinite extent of the crystal was achieved using periodic boundary conditions, and to create the surface along the y-axis, free boundary conditions were applied.

During the simulation, the computational cell was divided into regions, each assigned a specific temperature decreasing with distance from the surface. Using the semi-infinite solid body model, an analytically exact solution to the thermal problem can be obtained through integral transformations [20]. In this case, if the source intensity is constant, the temperature distribution in the depth of the sample during the heating stage is determined as a function of the coordinates using the formula:

| \[T(y,{\rm{ }}t) = \frac{{2Aq}}{\lambda }\sqrt {at} {\rm{ierfc}}\left( {\frac{y}{{2\sqrt {at} }}} \right),\] | (1) |

where A .68 is the absorptivity; q = 3.5 ÷ 6.5 MW/cm2 is the energy density; λ = 80 W/(m·K) is the thermal conductivity coefficient; a = 2.621·10\(^‒\)5 m2/s is the thermal diffusivity; τ = 10·10\(^‒\)12 s is the exposure duration.

The function ierfc(x) is the integral of the complementary error function:

| \[{\rm{ierfc}}(x) = \int_x^\infty {{\rm{erfc}}(x)dx} .\] | (2) |

After the laser exposure ceases, the cooling stage begins, and the temperature distribution is determined by the following formula:

| \[T(y,{\rm{ }}t) = \frac{{2Aq}}{\lambda }\left[ {\sqrt {at} {\rm{ierfc}}\left( {\frac{y}{{2\sqrt {at} }}} \right) - \sqrt {a(t - \tau )} {\rm{ierfc}}\left( {\frac{y}{{2\sqrt {a(t - \tau )} }}} \right)} \right].\] | (3) |

Results and discussion

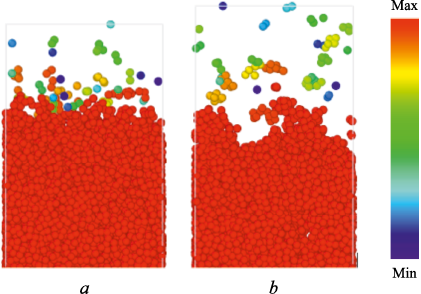

To identify clusters, the particle system was divided into separate groups based on a distance criterion, which was set to be twice the value of the lattice parameter. A cluster is defined as a group of particles where each particle is located at a distance no greater than the cutoff radius from one or more particles of the same group. Once the particle clusters are identified, they are colored according to their size. The color gradient changes from violet to red as the number of particles in the cluster increases.

The conducted research demonstrated that during the heating process, an increasing number of clusters are gradually identified, which are generally represented by individual particles (Fig. 1, a). During the cooling process, the number of identified clusters decreases while their size increases, meaning that previously ejected particles start to group together (Fig. 1, b). The condensation mechanism of ablation products is realized in the considered model.

Fig. 1. Visualization of identified clusters after 10 (a) and 18 ps (b) |

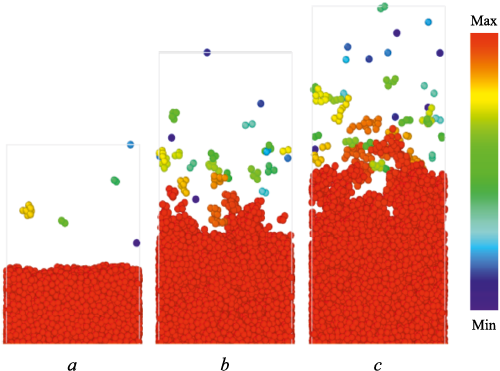

Identified clusters at different laser radiation densities are shown in Fig. 2. A higher laser energy density contributes to the formation of more clusters (for q = 3.5, 5.0, and 6.5 MW/cm2, the number of clusters is 6, 23, and 38, respectively).

Fig. 2. Visualization of identified clusters after 20 ps of model time |

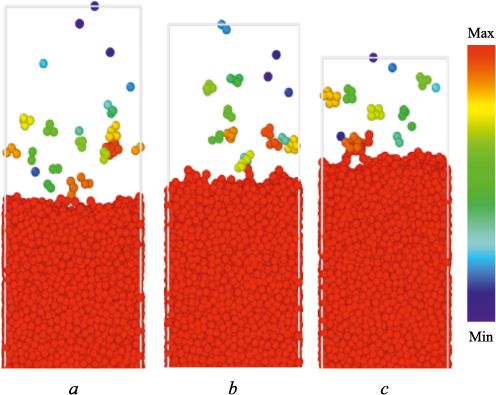

A study of the effect of system pressure on the number of forming clusters was also conducted. The barostat algorithm used in the simulation ensures that the system’s volume becomes a variable quantity, adjusting to maintain constant pressure [20]. Clusters formed under different pressure levels are shown in Fig. 3.

Fig. 3. Visualization of identified clusters after 20 ps of model time |

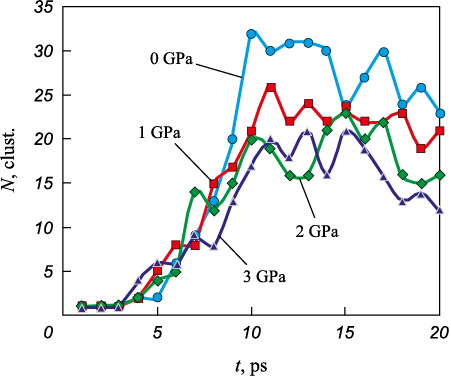

The number of clusters decreases with increasing pressure. The change in their number during the simulation process is shown in Fig. 4.

Fig. 4. Change in the number of clusters during simulation |

Conclusions

The change in their number during the simulation process is shown in Fig. 4. As a result of the conducted research, a model was developed using the molecular dynamics method, which made it possible to study the laser ablation process occurring under the influence of short pulses with low energy density. A study of the formation of particle clusters during ablation was conducted. A numerical dependence of the number of formed clusters on the pressure applied to them was established.

References

1. Gostevskaya A.N. Effect of ultra-short high power laser pulses on a solid body. In: Current Issues of Physical Metallurgy of Steels and Alloys. Abstracts of the XXVI Ural School of Metallurgists-Thermists. Ekaterinburg. 2022:259–261. (In Russ.).

2. Mazhukin V.I., Mazhukin A.V., Demin M.M., Shapranov A.V. Nonequilibrium effects accompanying the action of pulsed laser radiation on metals. Journal of Optical Technology. 2011;78(8):491–497. https://doi.org/10.1364/JOT.78.000491

3. Zhigilei L.V., Kodali P.B.S., Garrison B.J. Molecular dynamics model for laser ablation and desorption of organic solids. The Journal of Physical Chemistry B. 1997;101(11): 2028–2037. https://doi.org/10.1021/jp9634013

4. Tabetah M., Matei A., Constantinescu C. The minimum amount of “matrix” needed for matrix-assisted pulsed laser deposition of biomolecules. The Journal of Physical Chemistry B. 2014;118(46):13290–13299. http://dx.doi.org/10.1021/jp508284n

5. Bauerle D. Laser Processing and Chemistry. Luxembourg: Springer Science Business Media; 2011:851.

6. Gostevskaya A.N., Markidonov A.V. Changes in the internal structure of metals when exposed to laser pulses. In: Innovative Technologies in Materials Science and Mechanical Engineering. Materials of the 5th All-Russian Sci. and Pract. Conf. with Int. Participation. Perm: Publ. of the Perm National Research Polytechnic University; 2021:60–63. (In Russ.).

7. Gostevskaya A.N., Markidonov A.V., Kovalenko V.V. Molecular dynamic modeling of laser ablation. In: Promising Materials and Technologies: Proceedings of the Int. Symp., Minsk, August 23–27, 2021. Rubanik V.V. ed. Minsk: Belarusian State Institute of Standardization and Certification; 2021:21. (In Russ.).

8. Willis D.A., Grosu V. The effect of melting-induced volumetric expansion on initiation of laser-induced forward transfer. Applied Surface Science. 2007;253(10):4759–4763. https://doi.org/10.1016/j.apsusc.2006.10.046

9. Fardel R., Nagel M., Nuesch F. Energy balance in a laser-induced forward transfer process studied by shadowgraphy. Journal of Physical Chemistry C. 2009;113(27):11628–11633. http://dx.doi.org/10.1021/jp901340s

10. Zhigilei L. Yingling Ya., Itina T., Schoolcraft T., Garrison B. Molecular dynamics simulations of matrix-assisted laser desorption-connections to experiment. International Journal of Mass Spectrometry. 2003;226(1):85–106. https://doi.org/10.1016/S1387-3806(02)00962-4

11. Anisimov S.I., Luk’yanchuk B.S. Selected problems of laser ablation theory. Physics – Uspekhi. 2007;45(3):293. (In Russ.). https://doi.org/10.1070/pu2002v045n03abeh000966

12. Zavyalova M.A. Surface modification of quartz glass by picosecond laser pulses. Computer Optics. 2016;40(6): 863–870. (In Russ.). https://doi.org/10.18287/2412-6179-2016-40-6-863-870

13. Kuznetsov P.M., Fedorov V.A. Formation of crater relief under laser radiation on Fe ‒ Si alloy surface. Vestnik TGU. 2010;15(6):1790–1793. (In Russ.).

14. Yavtushenko T.O., Kadochnikov A.S., Novikov S.G., Berintsev A.V., Stolyarov D.A. Experimental research of metal surface structuring via high power femtosecond laser pulses. Izvestiya Samarskogo nauchnogo tsentra Rossiiskoi akademii nauk. 2013;15(4-5):1033–1037. (In Russ.).

15. Kuo J.-K., Huang P.-H., Chien S.-K., Huang K.-Y., Chen K.-T. Molecular dynamics simulations of crater formation induced by laser ablation on the surface of α-Fe substrate. MATEC Web of Conferences. 2018;167:03011. https://doi.org/10.1051/matecconf/201816703011

16. Gong X.-F., Yang G.-X., Li P., Wang Y., Ning X.-J. Molecular dynamics simulation of pulsed laser ablation. International Journal of Modern Physics B. 2011;25(4):543–550. http://dx.doi.org/10.1142/S0217979211058122

17. Cheng C., Wu A.Q., Xu X. Molecular dynamics simulation of ultrafast laser ablation of fused silica. Journal of Physics: Conference Series. 2007;59:100–104. http://dx.doi.org/10.1088/1742-6596/59/1/022

18. Rykalkin N.N., Uglov A.A., Zuev I.V., Kokora A.N. Laser and Electron Beam Processing of Materials: Reference Book. Moscow: Mashinostroenie; 1985:496. (In Russ.).

19. Zhigilei L.V., Levegl’ E., Ivanov D.S., Lin Zh., Volkov A.N. Modeling of Short-Pulse Laser Ablation by Molecular Dynamics: Mechanisms of Material Ejection and Formation of Nanoparticles. Novosibirsk: IT SB RAS; 2009:147–220.

20. Andersen H.C. Molecular dynamics simulations at constant pressure and/or temperature. The Journal of Chemical Physics. 1980;72(4):2384–2393. https://doi.org/10.1063/1.439486

About the Authors

A. N. GostevskayaRussian Federation

Anastasia N. Gostevskaya, Postgraduate of Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. V. Markidonov

Russian Federation

Artem V. Markidonov, Dr. Sci. (Phys.-Math.), Assist. Prof. of the Chair of Science named after V.M. Finkel’, Siberian State Industrial University; Head of the Chair of Informatics and Computer Engineering named after V.C. Butorin, Kuzbass Humanitarian Pedagogical Institute of Kemerovo State University

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

23 Tsiolkovskogo Str., Novokuznetsk, Kemerovo Region – Kuzbass 654041, Russian Federation

M. D. Starostenkov

Russian Federation

Mikhail D. Starostenkov, Dr. Sci. (Phys.-Math.), Prof., Head of the Chair of Physics

46 Lenina Ave., Barnaul, Altai Territory 656038, Russian Federation

D. A. Lubyanoi

Russian Federation

Dmitrii A. Lubyanoi, Cand. Sci. (Eng.), Assist. Prof. of the Chair of Technology and Integrated Mechanization of Mining

32 Nogradskaya Str., Prokop’evsk, Kemerovo Region – Kuzbass 653039, Russian Federation

Review

For citations:

Gostevskaya A.N., Markidonov A.V., Starostenkov M.D., Lubyanoi D.A. Simulation of structural changes in metal under high-intensity external influence. Izvestiya. Ferrous Metallurgy. 2024;67(5):567-572. https://doi.org/10.17073/0368-0797-2024-5-567-572