Scroll to:

History and current state of metallurgy in St. Petersburg

https://doi.org/10.17073/0368-0797-2024-5-500-508

Abstract

Development of the metallurgical industry in St. Petersburg played an outstanding role in the history of world and domestic science and technology. The founding fathers of domestic metallurgy: D.K. Chernov and his contemporaries had such a strong influence on the development of metal science that metallurgical science in Russia continued to develop successfully throughout the century and achieved impressive results in the 20th century and the beginning of the 21st century both in theoretical and in applied areas. However, the history of metallurgy in St. Petersburg wasn’t systematically covered in scientific and technical periodicals in recent years. Publishing this article in the year of the 300th anniversary of the Russian Academy of Sciences, we highlight current issues of history, continuity of traditions and prospects for the development of metallurgy in one of the leading regions of our country.

Keywords

For citations:

Rudskoi A.I., Kodzhaspirov G.E. History and current state of metallurgy in St. Petersburg. Izvestiya. Ferrous Metallurgy. 2024;67(5):500-508. https://doi.org/10.17073/0368-0797-2024-5-500-508

History of enterprises in the industry

One of the first metallurgical enterprises in St. Petersburg and Russia are the Izhora, Kirov (formerly Putilov), and Obukhov plants [1 – 4].

The history of the Izhora Plants began in the 18\(^{th}\) century with a sawmill that processed timber for shipbuilding. The enterprise was officially established in 1722 by decree of Peter I, the first emperor of Russia. Since then, the Izhora Plants were pioneers in many areas: the first steamship, the first mine sweepers, and the first tank [3]. It was here that the pride of Russia – the Baltic Fleet – was created. By the beginning of the 21\(^{st}\) century, the plant’s main focus had become the production of equipment for the nuclear industry and oil and gas refining. The modernization of the enterprise transformed the Izhora Plants into a unique industrial cluster, where equipment is produced for the most complex industries. More than sixty power units of both Russian and foreign nuclear power plants operate on equipment manufactured in Kolpino, and over a hundred high-pressure vessels are in use at oil and gas refineries across the country. Today, the Izhora Plants are capable of producing unique units of any complexity.

The Kirov Plant (formerly Putilov), founded in 1801 as an iron foundry for casting shells, became, during Soviet times, the largest plant for tractor and special machinery manufacturing, with almost a full cycle of metallurgical production [2; 3]. In 1868, the plant was purchased from state ownership by engineer and mathematician N.I. Putilov, who quickly organized the rolling of rails, which were of better quality compared to the English and Belgian ones. In 1868, the plant was purchased from the treasury by engineer and mathematician N.I. Putilov, who quickly organized the rolling of rails, which were of better quality compared to English and Belgian ones. The plant produced locomotives, wagons, dredgers, tool steels, and the famous 76-mm regimental gun. Already at that time, Russian engineers were conducting serious scientific research and developing original designs. The chemical and metallographic laboratories played an outstanding role in the creation of new steel grades and in improving technology. Famous metallurgists such as A.A. Rzheshotarsky, N.I. Belyaev, N.T. Gudtsov, and others worked here, developing the theory of steel alloying. There were no automobile factories in Leningrad (St. Petersburg). Tractors “Kirovets” were produced at the Kirov Plant. The plant had and still has a metallurgical production facility (now JSC Metallurgical Works “Petrostal”), including steel production, rolling mills (billet and section), forging and stamping production, thermal treatment workshops, and a well-equipped central factory laboratory with highly qualified personnel (highly skilled engineers, doctors, and candidates of sciences). One of the founders of this laboratory was Academician N.T. Gudtsov, who worked at the Putilov (later Kirov) Plant from 1913 to 1928 as its head. During this period, under his leadership, the structure and properties, as well as the heat treatment regimes, of special structural and tool steels were analyzed [2 – 4]. During the war, N.T. Gudtsov led work on the creation of special steels for the defense industry, and the Kirov Plant carried out work on the creation and production of steels for tanks, which were also manufactured there. In the post-war period, the laboratory became a scientific-production center for mastering steels and alloys, as well as products made from them, for tanks, military shipbuilding, tractors, and other products. After a prolonged stagnation (in the post-Soviet period), JSC Metallurgical Works “Petrostal” began producing modern steel products and is currently in a development stage, manufacturing carbon and highly alloyed special steels and alloys, including for special purposes.

In 2019 – 2020, technical upgrades were carried out at the enterprise, resulting in the creation of a new metallurgical complex, LLC “NPO Laboratory of Special Steels and Alloys”, capable of producing new steel grades for key industries, namely: the nuclear and defense industries, medicine, shipbuilding and aerospace, instrumentation, special machinery manufacturing, and electrical engineering.

In 2020, to produce higher-quality metallurgical products, the enterprise launched an electro-slag remelting (ESR) facility. Rolling is produced from carbon, alloyed structural, stainless corrosion-resistant, heat-resistant, and tool steels and alloys.

The Obukhov Plant was at the forefront of Russian steelmaking, built the first Soviet aircraft engine, and “turned the angel weathervane” on the spire of the Peter and Paul Fortress [5]. In 2020, the enterprise with its 157-year history celebrated a special anniversary – 200 years since the birth of its founder, metallurgist Pavel Obukhov. The Obukhov Plant was established on May 16, 1863, by agreement with the Naval Ministry, but at its origins stood a partnership of three private individuals: metallurgist Pavel Obukhov, industrialist Nikolai Putilov, and merchant Sergey Kudryavtsev. Alexander II allocated part of the land of the former Imperial Alexandrovskaya Manufactory, with residential buildings and structures, for the new production. The main task of the plant was to produce steel for manufacturing artillery guns. The state urgently needed to rearm the army and navy, but replacing obsolete bronze cannons with foreign designs would have been very costly for the treasury. Import substitution was required. The plant was built very quickly. On April 17, 1864, it produced its first 294 poods of steel, and on May 12, in the presence of the emperor, a blank for an eight-foot cannon was cast. The full launch of production took about a year, during which time the partnership had to take a loan from the Naval Ministry to purchase equipment abroad, and until the debt was repaid, the Obukhov Steel and Gun Plant was under the control of this department.

Obukhov steel was used to manufacture not only artillery guns but also wheels, tires, and axles for railway cars, armor and parts of steam engines for ships, surgical, drafting, and locksmith tools, as well as barrels and magazine boxes for Berdan rifles. Moreover, Russian steel began to be sold to England and Germany, as it was not inferior in quality to foreign steel but was several times cheaper.

In 1886, the plant was transferred to state ownership with the buyout of shares from the owners. It was a profitable and well-equipped enterprise, consisting of five workshops (crucible, steelmaking, hammering, iron casting, and gun finishing), as well as a forge, laboratory, gas plant, and wood drying facility. Even after transitioning to state ownership, the plant operated on its own funds, allowing it to invest relatively freely in modern equipment, capacity expansion, foreign trips for engineers and technicians, and so on. By 1913, at its 50th anniversary, Obukhov Plant had become one of the largest gun and steelmaking enterprises in Russia and Europe, a major competitor of the German Krupp firm and the British Armstrong. During this period, it produced more than 90 % of the armament of the Russian navy and more than 50 % of army guns, including the legendary gun of the cruiser “Aurora.” By 1914, the plant employed more than 10,000 workers. For its employees, a stone church and residential houses were built, a vocational school and a general school were established, and a library and a hospital with an outpatient clinic were organized. In December 1917, the Obukhov Plant stopped working, and all 12,000 workers were laid off. After 2.5 months of inactivity, the plant received its first large order in the new reality: the production of 1,000 “Holt” system tracked tractors with engines of 40 and 75 horsepower. The first three units were completed in 1919 and sent to the front for transporting large guns.

In 1921, the steel production was revived, and the following year, the plant received a new name – ”Bolshevik,” which it bore until 1992. By November 7, 1923, the first Soviet aircraft engine was assembled here. In 1935, the “Sickle and Hammer” emblems were created with inlaid gemstones for the first Kremlin stars – one of which later adorned the spire of the Northern River Terminal in Moscow. In 1937, “Bolshevik” produced the steel frames for the glowing ruby stars.

Between 1929 and 1937, the plant participated in the construction of the Magnitogorsk and Kuznetsk metallurgical complexes, supplying tunnel segments, escalators, and shield tunneling machines for the Moscow Metro.

During World War II, “Bolshevik” produced more than 20,000 armor-piercing and high-explosive shells, 125,000 mines, over 90,000 parts for “Katyusha” rocket launchers, and 11,000 parts for Maxim machine guns. Additionally, 30 artillery batteries were created on railway platforms, and serial production of a 100-mm caliber anti-tank gun was established. Around 6,000 plant employees went to the front. From the factory volunteers, a worker battalion, five partisan units, a fighter battalion, and a people’s militia regiment were formed. Women and teenagers replaced men at the machines and open-hearth furnaces, and veterans returned to the production lines. The work did not stop day or night. Despite all the hardships, in just July and August 1941, as much metal was smelted as during the entire first half of the pre-war year.

In the summer of 1941, part of the workers and technical specialists, along with equipment, were sent to Stalingrad, then to the Urals and Siberia, where they worked at various enterprises in the rear. The damage inflicted on the plant by the war and blockade was immense. The repair of workshops and the restoration of production were completed only by the end of 1948. By this time, the plant had mastered the production of oil pumps for the chemical industry and resumed the production of tunnel segments for the Moscow and later Leningrad metro systems. In 1957, the open-hearth furnaces were automated, making the work of steelmakers easier and more productive.

In the 1960s and 1970s, “Bolshevik” created launch systems for the “Sopka,” “Shtorm,” S-300F “Fort” anti-aircraft and cruise missiles, as well as containers for silo-based intercontinental ballistic missiles. The plant also produced equipment for nuclear reactors at the Leningrad, Ignalina, and Kursk nuclear power plants. In the 1980s, the enterprise continued to produce steel of various grades, cast and forged products, shafts for ships, sucker rod pumps for oil production, components and parts for nuclear power plants, and agricultural machinery.

The plant also manufactured long-range space communication antenna systems with a mirror diameter of up to 70 m, and in 1982, it produced ground equipment for the “Energia-Buran” space system.

In 1992, seventy years after its renaming, the plant once again became the State Obukhov Plant (GOZ). Despite the difficulties experienced by industry after the collapse of the USSR, it continued to operate, striving to preserve its workforce and production capacities. In 1996, the enterprise won several international quality awards: the 10\(^{th}\) Anniversary Golden European Award (France) and the 21\(^{st}\) International Prize (USA). Additionally, the plant received a German TUV quality certificate. Besides manufacturing traditional machinery products, the enterprise also fulfilled unique orders for St. Petersburg. The State Obukhov Plant chromed the spheres for the Pulkovo Observatory, galvanized the axes of the Rostral Columns, and restored the lost technology for making the bearings of the turning mechanism of the angel on the spire of the Peter and Paul Fortress. In 2002, the plant was incorporated into the Almaz-Antey Air Defense Concern, and in 2003, the Federal State Unitary Enterprise “State Obukhov Plant” was reorganized into the Open Joint-Stock Company “GOZ Obukhov Plant.” In 2004, by decree of the President of the Russian Federation, the plant was included in the list of the 100 most important strategic enterprises of the country. In 2008, a unique defense-industrial technopark was established on the basis of GOZ, uniting seven leading St. Petersburg enterprises of the Almaz-Antey concern.

Today, the Obukhov Plant is one of the leading enterprises in Russia’s military-industrial complex. Along with civilian products for the nuclear power industry, shipbuilding, and other sectors, the plant designs, manufactures, and services various weapons systems and military equipment. The plant’s traditional customers are the navy, aviation, missile forces, and aerospace forces. Equipment for missile complexes, launch and antenna systems, and damping systems are just part of its product range. The equipment designed and manufactured at the Obukhov Plant is successfully operated in Russia and abroad.

In addition to the aforementioned major enterprises, metallurgy also developed in St. Petersburg (Leningrad) at other plants, including Krasny Vyborzhets (non-ferrous metal production), the Metal Plant, and the Turbine Blade Plant (now part of JSC “Power Machines”), as well as the steel rolling plant. The latter ceased to exist in 2007, but the remaining part of the plant continues to operate under the name LLC “Petersburg Precision Alloys Plant”, producing items for the energy machinery industry (manufacturing flat and round rolled products).

History in persons

Dmitry Konstantinovich Chernov is rightfully considered the founding father of Russian metallurgy [4; 5]. He graduated from the St. Petersburg Technological Institute in 1858 with a silver medal and began working there. Dmitry Konstantinovich initially worked at the Technological Institute as a lecturer and later as a museum curator and librarian. Three years later, he became actively involved in the creation of the Russian Technical Society, which was inaugurated on May 24, 1866. D.K. Chernov’s entire subsequent scientific and public career was closely linked to this society. In 1866, he resigned from the institute and took a position as a technician in the hammer shop of the Obukhov Plant, eventually becoming a metallurgical engineer.

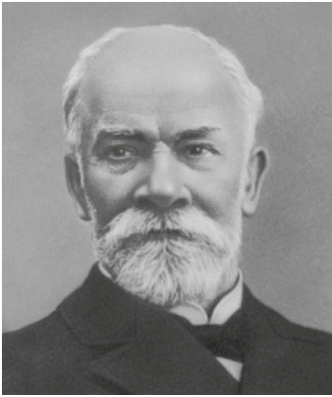

Fig. 1. Dmitrii Konstantinovich Chernov |

A task was set before the young engineer: to identify and explain the reason for the unsatisfactory quality of some cannons compared to the superior quality of others, cast from the same steel grade under what were thought to be identical conditions at the time. Chernov began his work with great enthusiasm, spending sleepless nights in mechanical and chemical laboratories, staying by the furnaces late into the night, learning from experienced workers how to determine the temperature of red-hot steel forgings by sight. Dmitrii Konstantinovich noticed changes in the structure of fractured surfaces of failed items. He examined the fracture points using a magnifying glass and a microscope and found that their structures were significantly different. He thus established that fine-grained steel could withstand much higher tensile stress. Following this, Chernov set out to discover how steel with a fine-grained structure was formed. Using the method of rapid forging with a heavy hammer, the scientist concluded that changes in steel structure occur under the influence of temperature, and that this temperature differs for each steel grade. There were no pyrometers to measure high temperatures at that time, so the engineer learned to determine the temperature by the color of the steel blank. It turned out that if steel is cooled slowly in air, the gradually darkening mass of metal would suddenly heat up, almost as if it had ignited, before darkening again. No one could explain this phenomenon, nor did it occur during rapid cooling. The strange occurrence piqued the researcher’s interest. Upon examining two blanks, one that had passed through the “special” point and one that had not, it was found that the first sample did not harden and remained soft. This was a discovery. Dmitrii Konstantinovich continued his research and found that there was yet another special point, corresponding to a different specific temperature. These points became known as “Chernov points” – critical temperatures at which phase changes occur in steel during heating and cooling in its solid state. In this way, “by sight”, the herald of a new school of metallurgy, the founder of metallography, was able to confirm the occurrence of phase transformations in steel during its crystallization.

From 1866, Chernov worked as an engineer in the hammer shop of the Obukhov Steel Plant in St. Petersburg, and from 1884, he was employed at the Naval Technical Committee. In 1886, he also became the chief inspector of the Ministry of Railways, responsible for overseeing the execution of orders at metallurgical plants, and from 1889, he served as a professor of metallurgy at the Mikhailov Artillery Academy. Dmitrii Konstantinovich discovered the existence of phase transformations in steel as a result of heating or cooling in its solid state (1866 – 1868), and he established the critical temperatures (the so-called Chernov points) at which internal transformations occur, determining the structure and properties of steel. In 1879, he presented the theory of the crystallization of steel ingots (dendritic steel crystals are sometimes called Chernov crystals). He thoroughly studied the defects in cast steel and suggested methods to combat them. Chernov substantiated the importance of complete deoxidation of steel during smelting, proposed an original design for a furnace to convert iron ore into steel, and worked on producing high-quality steel gun barrels, steel armor-piercing shells, and other items. Chernov’s research greatly contributed to the transformation of metallurgy from a craft into a theoretically grounded scientific discipline.

The creators of the first scientific schools of metallurgists and metallographers in the post-Chernov period were N.S. Kurnakov (1860 – 1941), who later became an academician of the USSR Academy of Sciences and founded a scientific school in the field of physicochemical processes. He chaired the Department of General Chemistry at the Polytechnic Institute from 1902 to 1930. Chernov’s students also included A.A. Baikov (1870 – 1946), later an academician of the USSR Academy of Sciences, and A.A. Rzheshotarskii (1847 – 1904). Baikov’s students, in turn, were metallurgists such as N.T. Gudtsov and N.V. Ageev (academicians of the USSR Academy of Sciences), B.V. Stark (corresponding member of the USSR Academy of Sciences), and professors M.G. Oknov, M.P. Slavinskii, G.A. Kashchenko, and others. In 1902, A.A. Rzheshotarskii headed the Department of Metallurgy at the Metallurgical Faculty (which had been part of the Polytechnic Institute since its founding in 1899, along with three other faculties: Naval Architecture, Electrical Engineering, and Commerce) (now Peter the Great St. Petersburg Polytechnic University).

A.A. Baikov was invited to work at this institute in 1903 and was immediately sent abroad to prepare for a professorial position. Upon his return in 1904, he was elected associate professor of metallurgy and chemistry. He took on the organization of laboratories and lecturing on general metallurgy and metallography. However, his main achievement was the development of active scientific research.

Fig. 2. Academician Baikov A.A. with his followers – teachers and students |

The industrialization of the young Soviet republic created the conditions for the establishment of new scientific schools. In 1930, at the Metallurgical Faculty of the Polytechnic Institute, which was the main training ground for specialists, two independent departments were formed from the Department of General Metallurgy, headed by A.A. Baikov: the Department of Metallography (non-degree-granting), led by Professor Mikhail Grigorievich Oknov (1930 – 1942), and the Department of Heat Treatment (degree-granting), under the leadership of Professor Nikolai Timofeevich Gudtsov, later an academician of the USSR Academy of Sciences (1930 – 1942). From 1912 to 1928, N.T. Gudtsov worked at the Putilov (later Kirov) Plant as the head of the central factory laboratory, and from 1924, he became an associate professor, and later a professor, at the Metallurgical Faculty of the Leningrad Polytechnic Institute (now Peter the Great St. Petersburg Polytechnic University). In 1926, N.T. Gudtsov, together with prominent scientists of the time, G.V. Kurdyumov (later an academician of the USSR Academy of Sciences, the founder of the Soviet school of metal physicists) and N.Ya. Selyakov, applied X-ray analysis to the study of metals for the first time, making him the founder of the Leningrad (St. Petersburg) school of metallurgists-metallographers-heat treaters. His research on martensite structure, the basics of the theory of the effect of alloying elements on the structure and properties of steel, and his fundamental works: “Physical Metallography”, “Special Steels”, and “Metallography and Heat Treatment of Steel” – are only some of N.T. Gudtsov’s major contributions.

A separate page should be dedicated to the great scientist Andrey Sergeevich Zav’yalov, whose 100\(^{th}\) birthday was celebrated by the scientific community in 2005. A brilliant scientist and organizer, A.S. Zav’yalov made a significant mark on the history of our country and the Leningrad school of metallurgists. Moreover, he nurtured a large number of students, the most prominent of whom was the renowned Igor Vasil’evich Gorynin, academician of the Russian Academy of Sciences, who for many years headed the country’s largest materials science research center – TsNII KM “Prometey” (now part of the Kurchatov Institute). The scientists of this institute made enormous contributions to the development of steels for shipbuilding and nuclear power, titanium, aluminum, and nickel alloys for new technologies, and a wide range of modern functional materials.

Let us provide some historical information, including the current state of this scientific center. The institute was founded in January 1939, based on the armor laboratory of the Izhora Plant. In its early years, the institute was tasked with creating and mastering the production of anti-shell armor for tanks, ships, and aircraft. The armor developed by the institute and put into production was used to protect the globally famous T-34 medium tanks, IS and KV heavy “breakthrough” tanks, self-propelled artillery systems, and the IL-2 attack aircraft.

In 1947, TsNII KM “Prometey” became the leading research institute in the field of metallurgy, metallography, casting technology, hot plastic working, and welding for all structural metallic materials used in military shipbuilding, civil shipbuilding, and the production of various marine equipment. Starting in the late 1940s, the institute carried out large-scale developments to create a series of new high-strength, cold-resistant, weldable hull steels for surface and submarine naval fleets that do not require subsequent heat treatment. These steels were later used to manufacture the hulls of a new generation of civilian fleet vessels (lighter carriers, icebreakers, tankers, gas carriers, marine floating self-elevating and semi-submersible drilling rigs of the “Shelf” type, and unique stationary ice-resistant platforms). A series of Navy submarines and manned and unmanned deep-sea vehicles were built using the high-strength, weldable titanium alloys developed by the institute’s specialists. With the onset of nuclear energy development in 1955, the institute began developing structural materials for nuclear power equipment. From 1981 to 1999, in addition to its traditional areas of focus, the institute also worked on the creation of materials for equipment used in the oil and gas extraction and processing industries, rail transportation, the automotive industry, the agro-industrial complex, medicine, and other sectors.

Today, TsNII KM “Prometey” has a strong scientific, technical, human, and technological capacity, as well as a material and technical base, allowing it to tackle complex tasks in the development of new advanced materials and production technologies. It is headed by a student of Academician I.V. Gorynin, Corresponding Member of the Russian Academy of Sciences A.S. Oryshchenko.

Another major scientific center of St. Petersburg metallurgy is the TsNIIM (Central Research Institute of Materials), whose scientists have made a significant scientific contribution to the creation of new steels and alloys for defense technology. This center began its activity as the Central Scientific and Technical Laboratory of the Military Department (CSTL), which was established in 1914. This laboratory was later transformed into Research Institute 13 and then into TsNIIM. Scientists and specialists at TsNIIM developed high-strength corrosion-resistant weldable steels, titanium and aluminum alloys, and technologies for manufacturing a wide range of parts based on tungsten, molybdenum, ceramics, and heat-protective coatings capable of withstanding gas flow temperatures of 3000 °C and above, as well as exposure to thermal shock and gun steels.

One of the leading research institutes in the field of power engineering in the country is NPO CKTI (I.I. Polzunov Scientific and Development Association on Research and Design of Power Equipment), which celebrated its 90\(^{th}\) anniversary several years ago. Throughout the institute’s history, the focus of its scientists and specialists has been on both theoretical work (developing new calculation methods and new power machine schemes) and experimental work, including the creation of new test stands and machines. The institute developed new grades of heat-resistant steels and alloys, new sector-specific federal and industry regulations, and created new testing methods and equipment, conducting systematic research on them. Additionally, experimental work is ongoing, including the examination of the condition of metal parts during their operation in the field of power machine strength.

Along with the giants of Leningrad (St. Petersburg) mechanical engineering and metallurgy, the industry was represented by a series of shipbuilding plants and power engineering plants (turbine manufacturing, compressor manufacturing, diesel engine manufacturing), where the metallurgical field held a significant place. In addition to large factory laboratories, science was developed in a number of industry-specific institutes: besides the aforementioned TsNII KM “Prometey” and TsNIIM (Central Research Institute of Materials), there were also TsKTI (Central Boiler and Turbine Institute), VPTI Elektro (All-Union Design and Engineering Institute of Electrical Engineering Production Technology), VPTI Energomash (All-Union Design and Technology Institute of Power Engineering Machinery), VNITI (All-Union Scientific Research Institute of Technology), and TsNIITS (Central Institute of Transport Construction) [6 – 8]. Analyzing the activities of St. Petersburg (Leningrad) metallurgists, it is essential to note the role of the House of Scientific and Technical Propaganda, which for several decades played a significant organizational role in conducting ongoing seminars in the fields of metallurgy of steel and alloys, physics of metals, metallography, and plastic metal processing (chaired by Professors A.S. Zav’yalov, Yu.V. Shakhnazarov, A.M. Parshin, L.I. Vasil’ev, and G.E. Kodzhaspirov).

Fig. 3. Bureau of the Section of Metal Science and Heat Treatment |

The seminars were held twice a month, and in addition, annual conferences were organized, attracting scientists and manufacturers from all regions of the former USSR. Unfortunately, during the collapse of the USSR, the House of Scientific and Technical Propaganda ceased to exist.

Traditionally, universities have played and continue to play a special role in the organization of science in our country. Undoubtedly, the main center is the Peter the Great St. Petersburg Polytechnic University (formerly the Polytechnic Institute and Leningrad Polytechnic Institute named after M.I. Kalinin) [4; 9]. The polytechnic school of metallurgists has trained and continues to train highly qualified production and pedagogical specialists not only for the region, but in the past for the entire former Soviet Union, and now for Russia, neighboring countries, and beyond. As mentioned at the beginning of the article, this school was headed by prominent scientists with worldwide recognition. TsNII KM “Prometey” has a special department at SPbPU dedicated to training its personnel.

At the Kalinin Leningrad Polytechnic Institute (now Peter the Great St. Petersburg Polytechnic University), several departments were dedicated to metallurgy: cast iron and steel, non-ferrous metals, foundry production, metallography and heat treatment, metal forming, physical chemistry, analytical chemistry, and others. These departments were created within the foundational Faculty of Technology and Materials Research (FTMR), formerly known as the Metallurgical and Physical-Metallurgical Faculty. In addition to the aforementioned professors, significant contributions to the development of metallurgical research were made by professors of the Polytechnic: N.A. Menshutkin, N.S. Kurnakov, A.A. Rzheshotarskii, V.E. Grum-Grzhimailo, A.A. Baikov, M.A. Pavlov, F.Yu. Levinson-Lessing, V.A. Kistyakovskii, A.N. Ramm, P.Ya. Ageev, V.S. Smirnov, and others. In addition to the Polytechnic Institute (SPbPU), departments of materials science existed at the Shipbuilding Institute (now St. Petersburg State Marine Technical University, SPbGMTU) and the Refrigeration Institute (now St. Petersburg State University of Low-Temperature and Food Technologies, SPbGUNiPT), where work was conducted on cold-resistant steels and alloys, among others.

In 2013, the Institute of Metallurgy, Mechanical Engineering, and Transport was established at Peter the Great St. Petersburg Polytechnic University, based on the Faculty of Physical Metallurgy (later the Faculty of Technology and Materials Research) and the Faculty of Mechanical Engineering. Later, it became the Institute of Mechanical Engineering, Materials, and Transport (IMMiT), which now implements programs for modern development in the fields of metallurgy and materials science.

Since 1993, SPbPU has hosted several international conferences, which have become a tradition: “High-Efficiency Technologies in Pre-Form Production” (St. Petersburg, 1993), “Plastic and Heat Treatment of Modern Metallic Materials” (St. Petersburg, 1995), “High Technologies in Modern Materials Science and Engineering” (St. Petersburg, 1997), “Plastic, Heat, and Thermomechanical Treatment of Modern Metallic Materials” (St. Petersburg, 1999), “Modern Metallic Materials and Technologies and Their Use in Engineering” (St. Petersburg, 2001, 2006, 2009, 2011, 2013, 2015, 2017), “Modern Achievements in the Theory and Technology of Metal Forming” (SPbPU, 2005, 2007), “Nanotechnologies of Functional Materials” (NFM’2010) (St. Petersburg, SPbPU, 2010, 2012), and “Modern Materials and Advanced Manufacturing Technologies” (SMPPT–2019) (2019, 2021, 2023). Leading scientists and specialists in the fields of materials science, plastic, heat, and thermomechanical treatment, powder metallurgy, and in recent years, the promising field of additive technologies, have participated in these conferences. Peter the Great St. Petersburg Polytechnic University is one of the leading research centers in the country in this area.

Fig. 4. Participants of the Conference “Modern Metal Materials and Technologies – 2013” |

In conclusion, it should be noted that the high level of the St. Petersburg school of metallurgists, metallographers, and metal physicists remains strong despite difficult times for our science, and our scientists are in demand not only in our country but also abroad. The main scientific contributions of St. Petersburg scientists to metallurgy can be summarized as follows: D.K. Chernov – discovery of critical points; A.A. Baikov – development of the theory of metallurgical processes and transformations in metals and alloys, creator of one of the first schools of metallographers; N.T. Gudtsov – development of the theory of martensite structure and steel alloying, founder of the school of metallographers and heat treaters; N.V. Ageev – theory of interatomic bonds and the electronic structure of metals; M.G. Oknov – metallography of iron-carbon alloys; G.A. Kashchenko – development of metallographic analysis methods; A.S. Zav’yalov – development of some aspects of the theory of phase transformations in iron-carbon alloys; V.I. Vladimirov – development of the theory of dislocations and disclinations; V.A. Likhachev – development of the structural-analytical theory of strength and the design of shape-memory alloys; A.N. Orlov – development of the theory of dislocations; I.V. Gorynin – development of the theoretical foundations for creating high-strength weldable structural materials for use in extreme conditions, creator and leader of the scientific school of metallographers at TsNII KM “Prometey” (Central Research Institute of Structural Materials “Prometey”); Yu.P. Solntsev – development of the scientific foundations for creating cold-resistant materials and methods for assessing resistance to brittle fracture; A.M. Parshin – development of the theory of structural recombination of radiation defects during the decomposition of solid solutions (problems of radiation materials science); Yu.V. Shakhnazarov – development of the physico-technological foundations for creating martensitic-aging and tool steels [4; 9].

Listing the scientific contributions of each prominent St. Petersburg scientist currently working would take up too much space. Therefore, we will mention only the most well-known scientists to the academic community, as well as those who have led and continue to lead scientific schools: RAS Academician A.I. Rudskoi – development of the scientific foundations for structure formation and modeling of steels and a wide range of modern materials during thermomechanical processing and in the field of powder metallurgy; RAS Corresponding Member A.S. Oryshchenko – development of the theoretical foundations for creating new heat-resistant and heat-resistant alloys based on Fe – Cr – Ni, technologies for their cast production for high-temperature pyrolysis oil equipment, the creation of corrosion-resistant titanium and aluminum alloys and materials for the hulls of marine nuclear reactors and nuclear power plants, and the creation of an original steel with elements of nanostructuring that increases the power of nuclear reactors by 30 – 40 %; RAS Corresponding Member V.V. Rybin – development of the scientific foundations of the physics of advanced plastic deformation of crystals and the structural-kinetic concept of metal fracture; RAS Corresponding Member Yu.K. Petrenya – theoretical and technological aspects of the development of alloys for power engineering; Professors, Doctors of Technical and Physical-Mathematical Sciences A.A. Popovich – development of mechanochemical synthesis of inorganic compounds, powder metallurgy, and additive technologies; V.I. Betechtin – development and advancement of the kinetic approach to the problem of solid body fracture; E.L. Gyulikhandanov – theory and technology of chemical-thermal treatment of steels, diffusion processes in metals; G.E. Kodzhaspirov – structural transformations in deformed steels and alloys, physico-technological foundations of non-isothermal thermomechanical treatment; N.G. Kolbasnikov – mechanisms of deformation and strengthening of low-plastic metals and the creation of the entropic concept of strength and plasticity.

Undoubtedly, not all St. Petersburg metallurgists who contributed to the development of domestic and world metallurgy are mentioned here, and we ask for the understanding of our colleagues who were not included in this list due to the brevity of this presentation.

References

1. Zav’yalov S. History of the Izhora Plant. Publishing House Istoriya zavodov; 1934:410. (In Russ.).

2. Lyubchenko A.A. Role of the Kirov Plant in development of Soviet mechanical engineering and metallurgy. In: Mechanical Engineering and Metallurgy of the Kirov Plant. Leningrad: Mashinostroenie; 1967:5–9. (In Russ.).

3. Aleksandrov V.P., Dysin B.G. Kirov plant – laboratory of technical progress. In: Mechanical Engineering and Metallurgy of the Kirov Plant. Leningrad: Mashinostroenie; 1967:10–13. (In Russ.).

4. Gyulikhandanov E.L., Kodzhaspirov G.E. History and current state of St. Petersburg physical metallurgy. Metal Science and Heat Treatment. 2007;(1):3–8. (In Russ.).

5. Vinogradova N.A. Obukhov Plant. Essays on the History of 1863–2008. St. Petersburg: Gumanistika; 2010:592. (In Russ.).

6. Gorynin I.V. Reflections with Optimism. St. Petersburg: Polytechnic University Publishing House; 2014:525. (In Russ.).

7. Central Research Institute of Materials – 90 Years in Materials Science. Patkin Yu.Yu. ed. Vol. 2. St. Petersburg: Polytechnic University Publishing House; 2004:228. (In Russ.).

8. High-Tech Defense Industry in Action. A Historical Sketch of the Scientific and Technical Activities of the All-Union (All-Russian) Scientific Research Institute of Technology 1947–1997. St. Petersburg: Publishing House “INTEGRAF” JSC “Kirovskii Zavod”; 1997:160. (In Russ.).

9. St. Petersburg State Polytechnic University: Biographies. St. Petersburg: Gumanistika; 2006:912. (In Russ.).

About the Authors

A. I. RudskoiRussian Federation

Andrei I. Rudskoi, Academician, Dr. Sci. (Eng.), Rector

29 Politekhnicheskaya Str., St. Petersburg 195251, Russian Federation

G. E. Kodzhaspirov

Russian Federation

Georgii E. Kodzhaspirov, Dr. Sci. (Eng.), Prof. of the Higher School of Physics and Technology of Materials

29 Politekhnicheskaya Str., St. Petersburg 195251, Russian Federation

Review

For citations:

Rudskoi A.I., Kodzhaspirov G.E. History and current state of metallurgy in St. Petersburg. Izvestiya. Ferrous Metallurgy. 2024;67(5):500-508. https://doi.org/10.17073/0368-0797-2024-5-500-508