Scroll to:

Kinetics of deformation fronts during serrated Lüders deformation in α-iron at high temperature

https://doi.org/10.17073/0368-0797-2024-3-325-331

Abstract

At room temperature, the deformation of most bcc metals, which contain a small amount of interstitial elements, is accompanied by the formation of a Lüders band and its monotonic propagation over the tensile yield area. Within the framework of the autowave concept, front of the Lüders band is a switching autowave, which realizes the transition from a metastable elastically deformable state to a stable plastically deformable state. However, in the temperature range of blue brittleness of mild steels of 423 – 510 K, when the interaction of atoms of the dissolved substance with mobile dislocations takes place, propagation of the Lüders band is accompanied by a discrete flow. The patterns of propagation of the Chernov-Lüders fronts in ARMCO iron in the temperature range from 296 to 503 K and strain rates from 6.67·10–6 to 3.7·10–2 s–1 are considered in this paper. It was established that under these conditions both monotonic and discrete kinetics of front movement can be realized. Regardless of the movement nature, the Lüders deformation and width of the front remain unchanged throughout the entire process. The local strain rate at the front depends on magnitude of the effective stress, and with monotonic kinetics it increases with stress according to an exponential law, and with discrete kinetics it increases according to a linear law. This difference is due to different autowave modes that are formed in this case. The autowave of localized plasticity switching corresponds to monotonic kinetics, and the autowave of excitation – to discrete kinetics.

Keywords

For citations:

Orlova D.V., Danilov V.I., Gorbatenko V.V., Danilova L.V., Bochkareva A.V. Kinetics of deformation fronts during serrated Lüders deformation in α-iron at high temperature. Izvestiya. Ferrous Metallurgy. 2024;67(3):325-331. https://doi.org/10.17073/0368-0797-2024-3-325-331

Introduction

At room temperature, deformation of most BCC metals containing small amounts of interstitial elements is accompanied by the formation of a Chernov–Lüders band, which propagates monotonically across the yield plateau during tension [1 – 4]. The propagation behavior of the Lüders band can vary depending on grain size, temperature, applied stress, and strain rate. The band expands uniformly across the yield plateau, with all deformation concentrated at its boundaries, or deformation fronts, at any given moment. The velocities of front movement are proportional to the velocity imposed by the loading device. According to the autowave concept [5 – 7], the Chernov–Lüders band front represents an autowave switch that transitions from a metastable elastically deformable state to a stable plastically deformable state [8; 9]. However, within the blue brittleness temperature range for mild steels (423 – 510 K) [10 – 12], where dislocation movement is influenced by dynamic strain aging, the propagation of the Lüders band is characterized by discrete flow. In [13], it was established that within the temperature range of 393 – 503 K in ARMCO iron, the stationary kinetics of Lüders front movement is replaced by serrated behavior. The temperature at which Lüders deformation becomes serrated increases with increasing deformation rate. On the serrated yield plateau, the discretely propagating Lüders band front represents an autowave of localized plasticity excitation. Notably, front movement in this case only occurs during the stress relaxation process associated with serration. This raises a question about the nature of dependence of the local deformation rate in front region on the applied stress during the serrated process.

This study is dedicated to establishing the kinetic regularities of deformation front propagation during serrated Lüders deformation in α-iron at elevated temperatures.

Materials and methods

The material used for the study was ARMCO iron with the following composition (wt. %): C 0.025; Si 0.05; Cu 0.05; Mn 0.035; S 0.025; P 0.015; Fe – remainder. Test samples in the form of double-sided blades were laser-cut from hot-rolled sheet with a thickness of 1.5 mm. The working area of the sample was 50×10 mm. To standardize the stress and structural states before testing, the samples were annealed in a vacuum according to the following regime: 1233 K for 1 h, followed by cooling with the furnace to room temperature.

The prepared samples were subjected to uniaxial tension using an LFM-125 testing machine at speeds ranging from 0.02 to 10 mm/min. Tests were conducted at temperatures ranging from 296 to 503 K. The STE-12H furnace (Walter + Bai) with independent temperature control in three zones was used. The sample temperature was measured using three thermocouples installed along the sample axis at a distance of 20 mm from each other.

Analysis of the kinetics of Lüders deformation fronts was performed using digital image correlation [14; 15] and digital statistical speckle photography [16; 17]. To form the speckle structure, the sample was illuminated with coherent light from a semiconductor laser (635 nm, 15.0 mW). The sample images were captured using a Point Grey FL3-GE-50S5MC digital video camera with a resolution of 2448×2048 pixels at a frame rate of 2 to 25 fps, depending on the stretching speed. Chronograms [18] were constructed from the obtained data arrays, which allowed for the identification of Lüders band nucleation regions and determination of the kinetic characteristics of their fronts.

Results and discussion

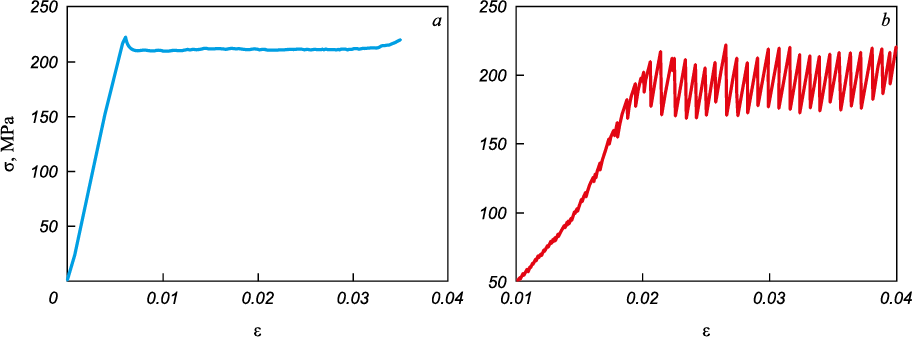

Fig. 1 shows the yield plateaus of the stress-strain curves of ARMCO iron obtained at room temperature and elevated temperatures. At room temperature, the strain curve exhibits a typical tooth and smooth yield plateau characteristic of low-carbon steels. At a test temperature of 423 K and a deformation rate of 6.67·10\(^–\)5 s\(^–\)1, periodic stress jumps occur on the yield plateau.

Fig. 1. Yield plateau in α-iron samples at T = 295 K, |

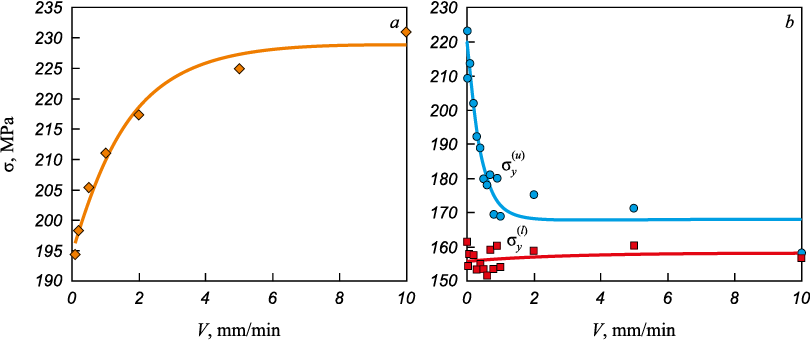

It is known that at temperatures below 393 K, ARMCO iron exhibits normal strain rate sensitivity, meaning that the yield stress on the yield plateau (lower yield strength \(\sigma _y^{(l)}\) ) increases with increasing deformation rate and decrease with increasing temperature [19]. As shown in Fig. 2, a, at room temperature, the lower yield strength increases non-linearly with increasing deformation rate.

Fig. 2. Strain rate dependence of the lower yield strength at T = 295 K (a) |

Studies in the temperature region of the serrated development of the Lueders strain have shown that with increasing deformation rate, the amplitude of stress jumps decreases, while the stress level \(\sigma _y^{(l)}\), at which the drop occurs remains constant (Fig. 2, b). Thus, in the temperature range of serrated flow, the strain rate sensitivity of the lower yield strength is absent. At the same time, the stress at the onset of the jump (upper yield strength \(\sigma _y^{(u)}\)) monotonically decreases with increasing deformation rate.

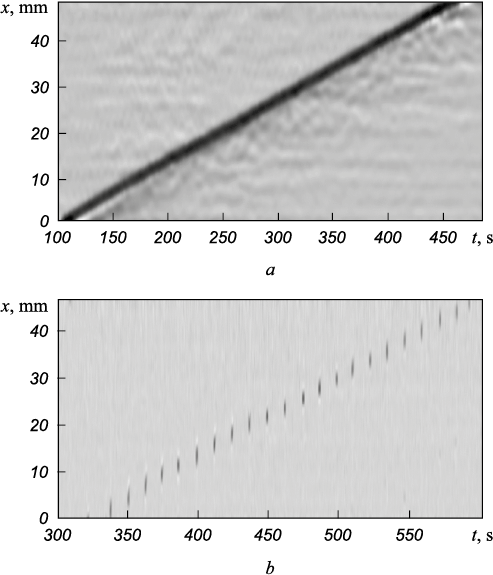

Studies on the nature of deformation localization using digital statistical speckle photography identified that fronts of localized plastic deformation form and move both on the smooth (Fig. 3, a) and serrated (Fig. 3, b) yield plateaus. However, in the former case, the front moves monotonically at a constant velocity Vf , while in the latter case, it moves discretely, only during the stress drop in the serration process.

Fig. 3. Chronograms of deformation fronts movement |

Based on the fact that the deformation front passes through the entire length of the sample L during the observed yield plateau Δt, then L = Vf Δt. During this time, the sample undergoes elongation expressed as ∆L = Vd ∆t (where Vd is the deformation rate set by the loading device). Therefore, the deformation acquired by the sample on the yield plateau can be represented as

| \[{\varepsilon _L} = \frac{{\Delta L}}{L} = \frac{{{V_d}}}{{{V_f}}}.\] | (1) |

From this, it follows that the front velocity and deformation rate are interrelated by the equation Vd = εLVf . If this relationship is normalized by the front width δ, then the relative deformation velocity is expressed as

| \[\dot \varepsilon = \frac{{{V_d}}}{\delta } = {\varepsilon _L}\frac{{{V_f}}}{\delta } = \frac{{{\varepsilon _L}}}{{{t_f}}},\] | (2) |

where tf is the time of front motion during a jump at a certain velocity Vf .

Thus, the relative deformation velocity \(\dot \varepsilon\) and front velocity Vf must be linearly related if the deformation εL at any given time is constant and concentrated at the front. Furthermore, for this equation to hold, the width of the deformation front δ during motion must also remain constant.

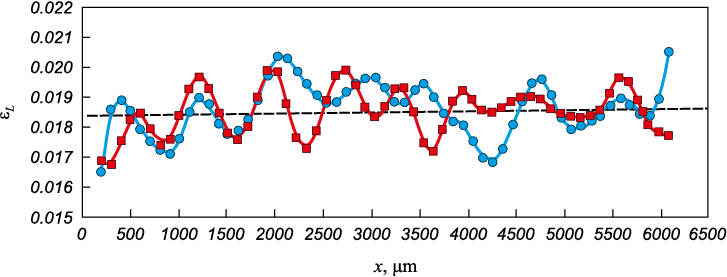

To test the first postulate of εL constancy, measurements of marker displacements on the surface of the sample were conducted during deformation on a serrated yield plateau. Markers were applied to the surface of the sample in three rows, spaced 100 μm apart, using a PMT-3M microhardness tester. Two series of images of these markers were then taken before and after deformation using a NEOPHOT-21 optical microscope. Measurements of the distance between the centers of two adjacent markers before deformation (l) and after deformation (l1 ) allowed for the determination of the displacement of each marker ∆l = l1 – l, thus obtaining the displacement field ∆l(x) (where x is the marker coordinate). By numerically differentiating this field, the local deformation at each point was calculated as εL = Δl / l. Fig. 4 shows the distribution of εL along the length of the sample. The application of the hypothesis of a normally distributed population [20] showed that changes in εL are random in nature, with the magnitude being considered constant and its average value being εL = 0.0184 ± 0.0003.

Fig. 4. Dependence of local deformation εL on yield plateau on the position of markers x |

As stated in [17], when using the digital statistical speckle photography method to visualize deformation fronts, the brightness of the front image is proportional to the deformation within it. From this, the average width of the front δ can be determined. Measurements for fronts moving during all jumps (Figs. 1, b and 3, b) showed that their width is constant and equal to 105 ± 7 μm. Thus, the second postulate of front width constancy is also fulfilled, and equation (2) can be used to investigate the relationship between local deformation rate and stress in the during a jump.

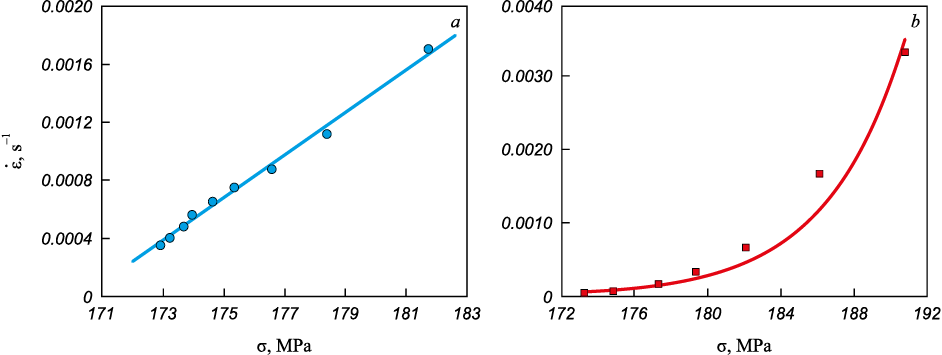

Fig. 5, a shows this dependence. It can be seen that \(\dot \varepsilon\) increases linearly with increasing stress. The correlation coefficient of the interpolating relationship is ρ = 0.99. On the other hand, in the case of a monotonically moving front, based on the correlation relationship (Fig. 2) and equations (1) and (2), the strain rates at the front can be calculated for each \(\sigma _y^{(l)}\) (Fig. 5, b). It is evident that it cannot be interpolated by a linear function. In other words, the strain rates in the monotonically moving front and the serrated moving front react differently to changes in the stress state.

Fig. 5. Change of strain rate during serrated movement of the front (a) |

The reason for this difference may be the change in the deformation autowave mode from the autowave of switching to the autowave of excitation. In [13], it is shown that the kinetics of Lüders front motion in ARMCO iron is indeed controlled by the effect of dynamic strain aging, i.e., the delay time tw of mobile dislocations at barriers overcome by thermally activated processes, and the time ta of carbon impurity deposition on these dislocations. At temperatures below 393 K, when ta \( \gg \) tw , front moves monotonically and represents an autowave of localized plasticity switching. In this case, the local strain rate increases non-linearly with stress according to a parabolic law. The discrete nature of the deformation front movement occurs under temperature-rate conditions where tw and ta are comparable. The serrated moving deformation front represents an autowave of localized plasticity excitation. In this case, the local strain rate depends linearly on the applied stress.

Conclusion

The deformation accumulated on the serrated yield plateau in α-iron is constant. Under these conditions, the width of the front is also a constant in the first approximation.

The local strain rate during the monotonic movement of the front (296 – 393 K) increases with stress according to a power law. In the case of serrated Lüders deformation (393 – 503 K), the local strain rate is directly proportional to the applied stress.

The difference in front kinetics is determined by the reaction characteristics of active deformable media to external mechanical action and is controlled by the effect of dynamic strain aging.

References

1. Hall E.O. Yield Point Phenomena in Metals and Alloys. New York: Plenum Press; 1970:296.

2. Seeger A., Frank W. Non Linear Phenomena in Materials Science. New York: Trans. Tech. Publ.; 1988:125–137.

3. Fridel J. Dislocations. Oxford – London –Edinburg – N. Y. – Paris – Frankfurt: Pergamon Press; 1964:576.

4. Cottrell A.H. Dislocation and Plastic Flow in Crystals. New York: Oxford Univ. Press.; 1953:223.

5. Zuev L.B. Using a crystal as a universal generator of localized plastic flow autowaves. Bulletin of the Russian Academy of Sciences: Physics. 2014;78(10):957–964. https://doi.org/10.3103/S1062873814100256

6. Zuev L.B., Barannikova S.A., Danilov V.I., Gorbatenko V.V. Plasticity: from crystal lattice to macroscopic phenomena. Progress in Physics of Metals. 2021;22(1):3–57. https://doi.org/10.15407/ufm.22.01.003

7. Krinsky V.I. Self-Organization: Autowaves and Structures Far from Equilibrium. Berlin: Springer-Verlag; 1984:270.

8. Danilov V.I., Gorbatenko V.V., Danilova L.V. Kinetics of Lüders deformation as an autowave process. Izvestiya. Ferrous Metallurgy. 2022;65(4):261–267. (In Russ.). https://doi.org/10.17073/0368-0797-2022-4-261-267

9. Zuev L.B., Danilov V.I., Danilova L.V. Gorbatenko V.V. Deformable material as a nonlinear active medium. Izvestiya vuzov. Fizika. 2022;65(2):89–97. (In Russ.). https://doi.org/10.17223/00213411/65/2/89

10. Babich V.K., Gul’ Yu.P., Dolzhenkov I.E. Strain aging of steel. Moscow: Metallurgiya; 1972:320. (In Russ.).

11. Liu W., Lian J. Stress-state dependence of dynamic strain aging: Thermal hardening and blue brittleness. International Journal of Minerals, Metallurgy and Materials. 2021;28(5):854–866. https://doi.org/10.1007/s12613-021-2250-1

12. Prokhorov A., Vshivkov A., Plekhov O., Kashaev N., Fomin F., Ozerov M., Zherebtsov S. The effect of LSP on the structure evolution and self‐heating of ARMCO-iron under cyclic loading. Metals. 2021;11(8):119. https://doi.org/10.3390/met11081198

13. Danilov V.I., Orlova D.V., Gorbatenko V.V., Danilova L.V. Effect of temperature on the kinetics of localized plasticity autowaves in Lüders deformation. Metals. 2023;13(4):773. https://doi.org/10.3390/met13040773

14. Sutton M.A. Digital Image Correlation for Shape and Deformation Measurements. Springer Handbooks. Boston MA: Springer; 2008:1100.

15. Briers J.D., Webster S. Quasi real-time digital version of single-exposure speckle photography for full-field monitoring of velocity or flow fields. Optics Communication. 1995;116(1-3): 36–42. https://doi.org/10.1016/0030-4018(95)00042-7

16. Erbeck R., Merzkirch W. Speckle photographic measurements of turbulence in an air stream with fluctuating temperature. Experiments in Fluids. 1988;6(2):89–93. https://doi.org/10.1007/BF00196458

17. Zuev L.B., Gorbatenko V.V., Pavlichev K.V. Elaboration of speckle photography techniques for plastic flow analyses. Measurement Science and Technology. 2010;21(5):054014. http://dx.doi.org/10.1088/0957-0233/21/5/054014

18. Sun H.B., Yoshida F., Ohmori M., Ma X. Effect of strain rate on Lüders band propagating velocity and Lüders strain for annealed mild steel under uniaxial tension. Materials Letters. 2003;57(29):4535–4539. https://doi.org/10.1016/S0167-577X(03)00358-6

19. Estrin Yu., Kubin L.P. Plastic instabilities: phenomenology and theory. Materials Science and Engineering: A. 1991;137: 125–134. https://doi.org/10.1016/0921-5093(91)90326-I

20. Zazhigaev L.S., Kish’yan A.A., Romannikov Yu.I. Methods for Planning and Processing the Results of a Physical Experiment. Moscow: Atomizdat; 1978:232.

About the Authors

D. V. OrlovaRussian Federation

Dina V. Orlova, Cand. Sci. (Phys.-Math.), Research Associate of the Laboratory of Strength Physics

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

V. I. Danilov

Russian Federation

Vladimir I. Danilov, Dr. Sci. (Phys.-Math.), Prof., Chief Researcher of the Laboratory of Strength Physics

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

V. V. Gorbatenko

Russian Federation

Vadim V. Gorbatenko, Cand. Sci. (Phys.-Math.), Senior Researcher of the Laboratory of Strength Physics

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

L. V. Danilova

Russian Federation

Lidiya V. Danilova, Cand. Sci. (Phys.-Math.), Junior Researcher of the Laboratory of Strength Physics

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

A. V. Bochkareva

Russian Federation

Anna V. Bochkareva, Cand. Sci. (Eng.), Research Associate of the Laboratory of Strength Physics

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

Review

For citations:

Orlova D.V., Danilov V.I., Gorbatenko V.V., Danilova L.V., Bochkareva A.V. Kinetics of deformation fronts during serrated Lüders deformation in α-iron at high temperature. Izvestiya. Ferrous Metallurgy. 2024;67(3):325-331. https://doi.org/10.17073/0368-0797-2024-3-325-331