Scroll to:

Ways to improve the properties of high-entropy alloys Cantor CoCrFeNiMn and CoCrFeNiAl

https://doi.org/10.17073/0368-0797-2024-3-283-292

Abstract

Created one of the first and studied more than 20 years ago, high-entropy five-component alloys CoCrFeNiMn (Cantor alloy) and CoCrFeNiAl still attract the attention of researchers in the field of physical materials science due to their possible application in various industries because of their successful combination of strength and plastic properties. To date, a large amount of experimental materials has been accumulated on the ways to control the properties of these alloys. This article reviews the publications of domestic and foreign authors in two areas of improving the properties of these alloys: alloying, precipitation and heat treatment, and the use of CALPHAD phase diagrams. In the first direction, the role of alloying with B, Al, V, Si, Nb is analyzed; γ and γ′ nanoprecipitations, various modes of thermal and deformation processing. It was concluded that it is necessary to conduct experiments on the alloying of HEAs with Zr and Nb, which have proven themselves well in hardening steels. Creation and modification of the properties of five-component HEAs is possible using the CALPHAD computer programs developed for calculating state diagrams. The results of publications on the thermodynamic description of five-component alloys analyzed in the article are confirmed by comparing the phase diagrams with the available experimental data. In one of the analyzed works on the phase formation of five-component HEAs consisting of Co, Cr, Fe, Ni, Al, Mn, Cu, 2436 compositions were considered, which made it possible to determine 1761 variants of reliable prediction of the formation of bcc/B2 and fcc phases, bypassing amorphous phases and intermetallic compounds, thereby designing a certain level of mechanical properties. It is shown that the design of a new generation of HEAs is possible based on calculation of the CALPHAD phase diagrams.

For citations:

Gromov V.E., Konovalov S.V., Efimov M.O., Panchenko I.A., Shlyarov V.V. Ways to improve the properties of high-entropy alloys Cantor CoCrFeNiMn and CoCrFeNiAl. Izvestiya. Ferrous Metallurgy. 2024;67(3):283-292. https://doi.org/10.17073/0368-0797-2024-3-283-292

Introduction

Created in the early 21\(^\rm{st}\) century, a new class of metallic materials known as high-entropy alloys (HEAs) has attracted the attention of researchers in the field of physical materials science due to their superior properties compared to conventional alloys [1 – 5]. Among the first five-component HEAs studied were the CoCrFeNiMn (Cantor alloy) and CoCrFeNiAl HEAs [5 – 10], which exhibit a successful combination of strength and plasticity.

Discussion on improving the mechanical and operational properties of these HEAs began shortly after their creation and continues actively to this day. Reviews [11 – 14] have analyzed methods for enhancing the mechanical properties of the CoCrFeNiAl and CoCrFeNiMn HEAs, considering their potential industrial applications. Approaches to solving this problem include grain boundary strengthening [10], solid solution strengthening, creating a nanocrystalline state, strengthening through precipitates, partial amorphization, surface strengthening treatments, developing new production methods for HEAs [14 – 19], ultrasonic treatment [20], and the formation of structure gradients [21]. These methods can significantly expand the application areas of these HEAs. Based on the analysis of experimental results, it has been noted [22] that there are several hundred five-component HEAs containing over 40 different elements. All HEAs are conventionally divided into nine families: 1 – transition 3d-metals Al, Co, Cr, Fe, Ni, Mn, Cu, Ti; 2 – refractory metals Hf, Mo, Nb, Ta, Ti, V, W, Zr; 3 – Al, Be, Li, Mn, Se, Sn, Ti, Zn; 4 – transition 4f-metals Dy, Gd, Lu, Tb, Tm, Y; 5 – bronzes and brasses; 6 – Ag, Au, Co, Cr, Cu, Ni, Pd, Pt, Rh, Ru with catalytic properties; 7 – high-entropy metallic glasses of the Fe26.7Co26.7Ni26.7Si9B11 type; 8 – high-entropy borides, carbides, nitrides, oxides, silicides; 9 – HEA films and coatings.

Due to the extensive volume of information, the authors limited their analysis to experimental works from the last three years on strengthening and modifying the properties of CoCrFeNiMn and CoCrFeNiAl HEAs, as well as those with similar compositions using CALPHAD. The second research approach involved analyzing works on predicting the composition of HEAs with specific high functional properties using CALPHAD software developed for phase diagram calculations [23 – 26]. These calculations are often combined with experimental verification of the created materials at the final stage known as integrated computational materials engineering – IСME. It is believed that this approach can lead to further progress in creating HEAs with desired industrial properties [22]. The need for such analysis is justified by the fact that the most detailed examination of the properties and prospects of HEAs was conducted 3 – 4 years ago [27 – 29], which is a significant period given the pace of publication activity.

In the past 2 – 3 years, there has been an exponential growth in the number of publications dedicated to high-entropy alloys (HEAs) CoCrFeNiAl and CoCrFeNiMn. Consequently, there is a need to identify and analyze the most promising directions for predicting ways to improve the mechanical and operational properties of these HEAs, which is the objective of this work.

Results and discussion

For Cantor CoCrFeNiMn and CoCrFeNiAl alloys, the main approaches to solving the fundamental problem of solid-state physics – improving their mechanical properties – can be identified as follows: analysis of heat treatment, plastic deformation, and external influences; quantum mechanical calculations of crystalline and electronic structure; computer simulation; and the use of phase diagram calculations (CALPHAD), among others [22].

Improvement of mechanical properties of HEAs by alloying, precipitation, and heat treatment

The first approach involves searching for patterns among a large amount of fresh experimental data and forming criteria for improving the strength and plastic properties of HEAs.

Optimally, in terms of strengthening effect for Cantor alloys with FCC and BCC lattices, is vanadium. This is due to its atomic size: it is large for BCC alloys and small for FCC alloys. There is both quantitative and qualitative evidence for this across a large number of alloys. According to the authors of a study, the optimum concentration of vanadium should be approximately 25 at. %.

By varying the annealing temperature conditions (720 h at 800 °C), it is possible to achieve the precipitation of an FCC phase enriched with chromium and a sigma (σ) phase in the Cantor alloy with manganese content of 10 – 15 and 25 – 30 at. %, respectively. These precipitates do not have an orientation relationship with the BCC matrix. Comparisons with a calculated phase diagram based on a thermodynamic database confirmed the stability prediction of the BCC phase but did not predict the stability of the σ and FCC phases [11; 12; 22]. Microhardness measurements showed that the precipitation of the σ phase significantly strengthens the CoCrFeMnNi2 – x (x = 1.25; 1.50) alloy. The obtained results serve as a basis for the development of the composition and heat treatment of the Cantor alloy.

In recent years, attempts have also been made to improve the mechanical properties of the Cantor alloy through alloying with various elements. In a study by Japanese researchers, the role of titanium and silicon in the phase equilibrium and changes in the mechanical properties of the equiatomic Cantor alloy was analyzed. It was shown that titanium stabilizes the σ phase, A12, and C14 Laves phases, while silicon stabilizes the A13 phase. Phase relationships were presented as projections on the isothermal cross section of (CoFeMnNi)-C2 – x at 1000 °C of the Cantor alloy. Mechanical tests showed an increase in ultimate strength and yield strength with the addition of titanium and silicon, with the effect of titanium additives being more significant. This may be attributed to the different deformation strengthening of the Cantor alloy with these additives.

In a brief overview, it is not possible to provide a comprehensive analysis of the state of the problem of improving the properties of even two HEAs, but the main trends and approaches can be noted based on the review of the most significant recent publications.

One of the most discussed issues in strengthening these equiatomic alloys is the role of γ and γ′ nanoscale precipitates. In [32], a series of Ni60 – xCoxCr10Fe10Al18Mo2 HEAs (x = 30; 20; 10; 0) with enhanced strength and plastic properties was presented. Increasing the nickel concentration and decreasing the cobalt concentration resulted in the formation of a BCC phase with γ′ particles within it. In the as-cast state, the Ni60Cr10Fe10Al18Mo2 alloy with BCC/γ′ + B2 phase structure exhibited very high values of σ0.2 (831 MPa).

A systematic study was conducted on the influence of temperature (660 – 960 °C) and time (1 – 48 h) of aging on the mechanical properties of niobium-containing HEAs such as CoCrNi1.5Nb0.2 . It was observed that aging at 660 °C led to the formation of nanoscale γ″ precipitates with a DO22 superlattice, which strengthened the HEAs through a dislocation slip mechanism [33]. The ultimate strength and yield strength increased with increasing aging time, resulting in an increase in the volume fraction and size of γ″ precipitates, while the elongation decreased. Aging at 860 and 960 °C for 1 h resulted in the formation of semi-coherent ε precipitates with a DO19 structure, changing the strengthening mechanism to the Orowan one.

For the design of microstructure and corresponding properties of nearly equiatomic HEAs such as AlCoCrFeNi, the development of next-generation dispersion-strengthened alloys, a template based on an FCC matrix reinforced with ordered B2 precipitates, was proposed [34]. Using thermodynamic modeling of Al0.5CoCrFeNi HEA solutions, isothermal solid-state aging was performed to precipitate fine-scale intragranular B2 phases. Previous studies by these authors have already analyzed the positive role of the B2 phase in ultimate strength and deformation strengthening. In this work, the positive influence of the fine-scale B2 phase on wear resistance and dynamic compression was noted. The yield stress at a true strain of 0.02 % increased more than two times from 670 to 1350 MPa, and the compressive strength increased by 20 % from 1160 to 1500 MPa. Moreover, the wear resistance increased more than fivefold. This result is considered exceptionally important within the proposed approach to improving mechanical properties.

The role of boron in increasing the strength of steel and wear resistance of overlay coatings by forming high-hardness compounds is well-known in classical metallurgy. However, the number of studies on the influence of boron on the structural-phase state and mechanical properties of five-component HEAs is extremely limited. In [35], this gap was addressed for CoCrFeNiCuBx (x = 0 – 5 at. %) samples obtained by two-stage sintering and vacuum arc melting, using modern methods of physical materials science. It was shown that HEAs based on an FCC matrix contain dendritic phase with a high content of FeCrCoNi and interdendritic phase with a high content of copper. The hardness increased to 337 HV with increasing boron content. At 3 at. % B, the maximum strength of 1900 MPa was achieved in bending tests with good ductility.

In the creation and investigation of strengthening new HEAs, the role of heat treatment is more important than ever. This is demonstrated in [36], where a sample was fabricated using the combined method of cable-pulse arc additive manufacturing (CCW-AAM), and the evolution of microstructure and mechanical properties of the dual-phase CoCrFeNiAl alloy (FCC + ordered B2 phase) was studied during an 8 h heat treatment. At 600 °C, the formation of a large amount of chromium-rich σ-phase was observed in the B2 matrix, and nanoscale ordered L12 phase was observed in the FCC matrix, resulting in an increase in hardness from 338 to 420 HV, yield strength from 654 to 810 MPa, and ultimate strength from 876 to 1115 MPa, while the elongation decreased from 3.11 to 2.46 %. With an increase in heat treatment temperature to 800 °C, the size of the σ-phase particles increased, and the L12 phase transformed into a B2 phase with high AlNi content. The tensile properties remained unchanged, but the elongation increased by 176 %. Heat treatment at 1000 °C led to significant coarsening of the dissolved σ-phase in the B2 matrix and rod-like precipitates of B2, resulting in strengthening of the alloy. Hardness (308 HV) and yield strength (542 MPa) noticeably decreased, but the elongation increased significantly to 14.2 %. Analysis of these results suggests the potential for creating CoCrFeNiAl HEAs with a combination of high mechanical properties and control over the physical nature of these properties through heat treatment conditions.

One attractive strategy for creating multicomponent cast HEAs is the separation (and/or precipitation) induced by decreasing the configurational entropy during cooling and solidification, as proposed in [37]. It has been noted that the presence of copper in alloys similar to the Cantor alloy expands the phase separation (and precipitation) due to the high positive enthalpy of mixing between copper and various transition metals. It has been suggested that reducing the enthalpy of mixing through the separation of the copper-enriched phase from the Co – Cr or Fe– Cr enriched phases induces two- or three-phase structures. Previous work by the authors of [37] has shown that the hierarchically structured CrFeNiMn0.5Cu0.5 HEA exhibited an excellent combination of strength and ductility (1.02 GPa, 28 %), suggesting its potential for industrial applications. However, the deformation mechanisms of this cast alloy with micro- and nano-precipitates are not yet fully understood.

Dispersion strengthening and quasi-linear deformation strengthening in the cast CoCrCu1.5MnNi HEA provide an excellent combination of yield strength and ductility at both room temperature (431.5 MPa, 55 %) and cryogenic conditions (600 MPa, 67 %) [37]. This alloy has a dual FCC phase structure with dendritic regions enriched in Co – Cr and interdendritic regions enriched in Cu – Mn. These regions contain submicron and nanoscale precipitates, respectively, due to the reduced solubility of elements in the two phases. The nature of the quasi-linear deformation strengthening is associated with the accumulation of dislocation-related defects, packing defects, and twins induced by deformation.

The design of the eutectic AlCoCrFeNi2.1 HEA is considered in [38] based on the analysis of mechanical properties and mechanisms of cold and hot deformation. This HEA has a typical eutectic microstructure and consists of an FCC phase and eutectic B2 phases with nanoscale precipitates. The yield strength and elongation are 1.2 GPa and 22.8 %, respectively. At –196 °C, the yield strength is 857 MPa, the ultimate strength is 1.48 GPa, and the elongation is ~20 %. This good ductility may be related to the transformation of the L12 phase into a disordered solid solution phase during low-temperature deformation. At high temperatures, the strengthening of the nanoscale B2 and L12 phases occurs through the Orowan mechanism and dislocation cutting. It is noted that the plate-like structure in the as-cast state transformed into a fine equiaxed structure, resulting in improved strength and ductility. The authors considered the construction of HEAs comprehensively from four perspectives. The first method was based on the phase diagram and its modeling, where CoCrFeNi was considered as one of the elements in pseudo-binary eutectic alloys. The second method considered the enthalpy of mixing in multi-component alloys, with AlCoCrFeNi2.1 as a reference. Elements with a large negative enthalpy of mixing, such as zirconium, niobium, and hafnium, were selected to replace aluminum. The third method considered valence electrons. The fourth approach focused on creating HEAs without cobalt due to its weak influence on microstructure and phase composition. The importance of the results in [38] lies in the necessity of considering all four perspectives when designing eutectic HEAs with superior properties.

A new paradigm of low-cost Cantor HEA development was proposed in [39]. The strategy of designing super-strong and ductile multi-component BCC alloys involves introducing the so-called “local chemical order” controlled by interstitials and created through simple thermomechanical processing. In the experimental multi-component CoCrFeMnNi alloy, processed by partial recrystallization annealing, a high density of thin racks containing domains of close and medium order predominates. These racks develop from flat dislocation slip bands caused by the internal close order of the alloy during prior cold deformation. In the multi-component metastable alloy Fe30Mn30Co10Cr10 (at. %) with reduced content of expensive nickel and cobalt (compared to the Cantor alloy), the local chemical order consisted of forming heterostructures with non-recrystallized grains with thin racks and a small amount of recrystallized submicron-sized grains with nanonitrides. Due to the strengthening effect of racks, the local chemical order provides an ultra-high yield strength of 1.34 GPa, and deformation twinning contributes to a relative elongation of 13.9 %. The universality of the design strategy is confirmed in multi-component austenitic steel. Using the example of the CoCrNiMnAl HEA, it is shown that one way to achieve a good combination of strength and ductility is by changing the chemical composition. In HEA without iron, this is largely determined by the absence of brittle σ-phase. Based on thermodynamic predictions, three single-phase BCC HEAs were proposed: Co25Ni30Mn30Cr10Al15 , Co30Ni25Mn30Cr10Al15 , and Co30Ni30Mn25Cr10Al15 , which do not contain the σ-phase. It is shown that the addition of a minimal amount of aluminum provides a strengthening effect due to the formation of a controlled amount of NiAl-B2 precipitates in the microstructure. The alloys, subjected to intensive cold rolling with subsequent short annealing at 1000 °C, achieved high strength values without loss of ductility. The Co30Ni25Mn30Cr10Al15 high-entropy alloy, with low defect packing energy, fine grain size, a large volume fraction of twinning, and the formation of small-scale precipitates, represents a HEA with the best combination of strength and ductility.

In summary, considering the publications on the strengthening of five-component HEAs, it can be noted that the number of articles on all HEA families strengthened by vanadium, zirconium, and niobium is limited [41; 42]. From works on classical metallurgy dedicated to studying the effect of microalloying on the properties of steels, the positive role of vanadium, zirconium, and niobium in strengthening, such as in pearlitic steels, is well known. This suggests the need to clarify their role in HEA strengthening, which should become a priority area for further research. Breakthrough achievements can be expected in this field.

Using CALPHAD software

According to its chemical composition, the equiatomic Cantor alloy is expensive for practical applications. In [43], an analysis of alloys with a composition of Co10Cr12Fe43Mn18Ni17 was conducted using CALPHAD (Calculation Phase Diagram) software, revealing a cost 40 % lower than that of the equiatomic Cantor alloy. Although these alloys had reduced strength compared to the equiatomic BCC structure at room temperature, they exhibited significantly higher strength at 873 K. This can be largely attributed to deformation twinning due to low defect energy in packing at room temperature. The Labusch model was used to calculate the “softening” effect in the solid solution strengthening of the Cantor alloy. Such calculations allow for the development of an algorithm for designing alloys with specific mechanical properties.

The attempt to automate the evaluation of the kinetic database for BCC equiatomic HEAs seems justified. The development of accurate kinetic databases through parameterization of composition and temperature-dependent atomic mobilities is necessary for correcting multicomponent calculations and CALPHAD modeling. Using the example of the CoCrFeNiMn HEA, an automated evaluation procedure is proposed, which includes storing raw data and evaluation results, automatic weighting, parameter selection, and re-evaluation. The proposed software, written in Python, only uses diffusion indicator data for clear separation of thermodynamic and kinetic data. The created database is valid for the entire composition range of five-component HEAs.

Based on experimental data, the authors of [45] were able to obtain a polynomial equation for strength (hardness) for BCC HEAs containing 4 – 5 elements of the Cantor alloy system. An important conclusion of the study is that as the iron content increases, the strength of the five-component Cantor alloy decreases. This is due to a decrease in the shear modulus with decreasing iron concentration. The role of mixing enthalpy and electron concentration is also important. It is shown that the strength in Cantor alloys increases with decreasing mixing enthalpy and increasing concentration of valence electrons. This is particularly important for controlling mechanical properties, as it allows for purposefully increasing or decreasing their values.

The CALPHAD thermodynamic calculation program can be very useful for the development of new CoCrFeNiMn HEAs with increased strength. Computerized thermodynamic prediction of phase equilibria is the basis for this, as mechanical properties are largely determined by the phase composition of alloys. This task is quite complex due to the incomplete description of ternary systems. In [46], a successful attempt was made to develop a self-consistent thermodynamic description of the five-component Cantor alloy system by completing the description for all triple subsystems and making new thermodynamic assessments for CoCrNi and CoCrMn.

The reliability of the developed thermodynamic description of the five-component Cantor alloy is confirmed by comparing the calculated vertical sections of the five-component phase diagram with available experimental data. This provides a basis for higher-order thermodynamic descriptions of systems with various additional elements.

To improve the strength characteristics of the Cantor alloy, various alloying elements have been and are being introduced [47 – 52]. When designing a new Cantor alloy, it is necessary to consider the possibility of forming intermetallic σ- and B2-phases [53 – 55]. The influence of alloying elements on phase stability is very complex, and their individual contributions to a multi-component alloy like Cantor are small, which makes reliable prediction difficult.

The way forward lies in considering the simultaneous influence of various alloying elements. This can be achieved within the framework of CALPHAD (Calculation of Phase Diagram) [56]. Commercial databases (TCHEA and PanHEA) do not allow for the reproduction of experimental vertical sections of five-element HEAs and, consequently, cannot adequately predict phase equilibrium between FCC, BCC, and σ-phases. To achieve this, thermodynamic descriptions are needed for all binary and ternary systems. Unfortunately, for most multicomponent HEAs, these have not been developed. According to publications, alloying of HEAs is carried out over a wide range of concentrations, which highlights the importance of developing thermodynamic descriptions for all ternary systems that significantly impact the prediction of phase equilibrium.

The most detailed analysis of phase formation in five-component HEAs consisting of cobalt, chromium, iron, nickel, manganese, aluminum, and copper was conducted in a particular study [57]. A total of 2436 compositions were considered, of which CALPHAD selected 1761 variants for reliable prediction of FCC/B2 and BCC phase formation, excluding the amorphous phase and intermetallics. It was shown that thermodynamic calculations and experimental data closely matched. As the atomic size difference between elements increases, more FCC/B2 phase alloys are formed compared to HEAs with BCC structures. It was found that the concentration of valence electrons is the most important parameter for predicting FCC/B2, BCC, and FCC/B2 + BCC phases. These results are crucial for designing HEAs with specific structures and, consequently, properties.

A new approach to creating five-element eutectic HEAs is proposed in [58]. It is based on the possibility of using composite phase diagrams and the mixing entropy of two- and three-component eutectic alloys in the development of new HEAs. The search for such HEAs is justified, as five-component eutectic HEAs demonstrate a successful combination of high strength and plastic properties [59 – 62] due to their lamellar composite microstructures.

Reliable phase diagrams for five-element alloys are clearly insufficient, so the approach proposed in [58] looks promising. This is confirmed by experimental results in creating eutectic alloys in the AlCoCrFeNi and CoCrFeNiTi systems.

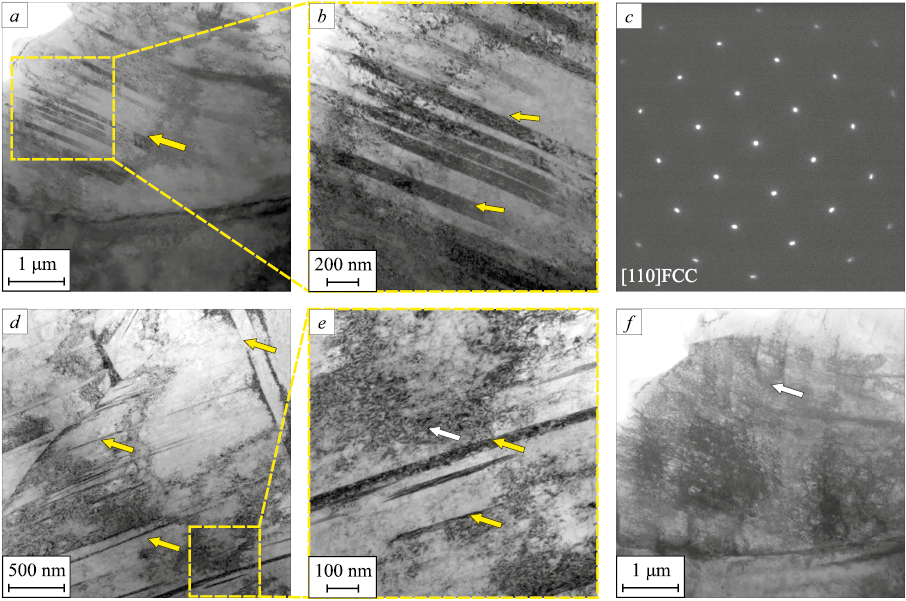

To develop new HEAs with high yield strength, a method combining CALPHAD phase diagram calculations, electronegativity differences, and machine learning [63] is proposed. In the first stage, this method allows avoiding the formation of undesirable brittle phases. Following the trend of creating new HEAs, points with high yield strength and elemental ranges are identified in the single-phase region. Additionally, if the content of molybdenum and iron is 6 and 0 at. % respectively, the ranges for nickel and cobalt are expanded. The next step is the experimental verification of the developed alloy. It is shown that the yield strength of the single-phase Co14Cr30Ni50Mo6 HEA with a grain size of 17.1 µm was 472 MPa with an electronegativity difference of 0.136. The high ductility and deformation strengthening ability of the alloy are due to the high density of dislocation slip bands and their interaction. The distance between slip bands is about 100 nm (refer to Figure, b). The contrast from the slip bands is darker than the FCC matrix, and the presence of high-density dislocation tangles in the slip bands (refer to Figure, f). indicates intensive deformation.

TEM images of the destroyed alloy Co14Cr30Ni50Mo6 [63]: |

For the aerospace industry, the Al10Co19Cr16Fe20Ni35 HEA, obtained in the cast state, homogenized at 1200 °C for 8 h, and subjected to step annealing at (24 h) and 590 °C (120 h) [64], can be useful. This provided an FCC matrix microstructure with B2 precipitates and chromium-enriched carbide. The design of this HEA was based on CALPHAD phase diagram calculations. Mechanical testing showed an excellent combination of strength and ductility: the yield strength was 470 MPa, the ultimate strength was 790 MPa, and the elongation was 48 %. The results of this study vividly demonstrate the possibilities of creating next-generation HEAs based on phase diagrams.

Conclusions

Due to the large number of publications accumulated on various directions for improving the mechanical properties of the CoCrFeNiMn (Cantor alloy) and CoCrFeNiAl HEAs, an analysis of works from the last three years on alloying, strengthening by precipitations, heat treatment, and the use of CALPHAD phase diagrams has been carried out.

References

1. Yeh J.W. Recent progress in high-entropy alloys. Annales de Chimie – Science des Matériaux. 2006;31(6):633–648. http://dx.doi.org/10.3166/acsm.31.633-648

2. Ma L.-S., Fu G.-L., Tian F.-C., Zhang T.-Y. Recent progress in high-entropy alloys. Advanced Materials Research. 2013;631-632:227–232. https://doi.org/10.4028/www.scientific.net/AMR.631-632.227

3. Zhang Y., Zuo T.T., Tang Z., Gao M.C., Dahmen K.A., Liaw P.K., Lu Z.P. Microstructures and properties of high-entropy alloys. Progress in Materials Science. 2014;61:1–93. https://doi.org/10.1016/j.pmatsci.2013.10.001

4. Cantor B., Chang I.T.H., Knight P., Vincent A.J.B. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A. 2004;375-377: 213–218. https://doi.org/10.1016/j.msea.2003.10.257

5. George E.P., Curtin W.A., Tasan C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Materialia. 2020;188:435–474. https://doi.org/10.1016/j.actamat.2019.12.015

6. Osintsev K.A., Konovalov S.V., Glezer A.M., Gromov V.E., Ivanov Yu.F., Panchenko I.A., Sundeev R.V. Research on the structure of Al2.1Co0.3Cr0.5FeNi2.1 high-entropy alloy at submicro- and nano-scale levels. Materials Letters. 2021;294: 129717. https://doi.org/10.1016/j.matlet.2021.129717

7. Li Z., Zhao S., Ritchie R.O., Meyers M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Progress in Materials Science. 2019;102: 296–345. https://doi.org/10.1016/j.pmatsci.2018.12.003

8. Cantor B., Chang I.T.H., Knight P., Vincent A.J.B. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A. 2004;375-377: 213–218. https://doi.org/10.1016/j.msea.2003.10.257

9. Otto F., Dlouhy A., Somsen C., Bei H., Eggeler G., George E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Materialia. 2013;61(15):5743–5755. https://doi.org/10.1016/j.actamat.2013.06.018

10. Schuh B., Mendez-Martin F., Volker B., George E.P., Clemens H., Pippan R., Hohenwarter A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Materialia. 2015;96:258–268. https://doi.org/10.1016/j.actamat.2015.06.025

11. Gromov V.Е., Konovalov S.V., Ivanov Yu.F., Osintsev K.A. Structure and Properties of High-Entropy Alloys. Springer, Advanced structured materials; 2021:110.

12. Gromov V.E., Ivanov Yu.F., Osintsev K.A., Shlyarova Yu.A., Panchenko I.A. Structure and Properties of High-Entropy Alloys. Moscow: RuScience; 2021:203.

13. Osintsev K.A., Gromov V.E., Konovalov S.V., Ivanov Yu.F., Panchenko I.A. High-entropy alloys: Structure, mechanical properties, deformation mechanisms and application. Izvestiya. Ferrous Metallurgy. 2021;64(4):249–258. (In Russ.). https://doi.org/10.17073/0368-0797-2021-4-249-258

14. Gromov V.E., Rubannikova Yu.A., Konovalov S.V., Osintsev K.A., Vorob’ev S.V. Generation of increased mechanical properties of Cantor high-entropy alloy. Izvestiya. Ferrous Metallurgy. 2021;64(8):599–605. (In Russ.). https://doi.org/10.17073/0368-0797-2021-8-599-605

15. Coury F.G., Kaufman M., Clarke A.J. Solid-solution strengthening in refractory high entropy alloys. Acta Materialia. 2019;175:66–81. https://doi.org/10.1016/j.actamat.2019.06.006

16. Ikeda Y., Tanaka I., Neugebauer J., Kormann F. Impact of interstitial C on phase stability and stacking-fault energy of the CrMnFeCoNi high-entropy alloy. Physical Review Materials. 2019;3:113603. https://doi.org/10.1103/PhysRevMaterials.3.113603

17. Li F., Zhao H., Yue Y., Yang Z., Zhang Y., Gou L. Dual-phase super-strong and elastic ceramic. ACS Nano. 2019;13(4): 4191–4198. https://doi.org/10.1021/acsnano.8b09195

18. Li Z., Kormann F., Grabowski B., Neugebauer J., Raabe D. Ab initio assisted design of quinary dual-phase high-entropy alloys with transformation-induced plasticity. Acta Materialia. 2017;136:262–270. https://doi.org/10.1016/j.actamat.2017.07.023

19. Gromov V.E., Ivanov Yu.F., Glezer A.M., Konovalov S.V., Alsaraeva K.V. Structural evolution of silumin treated with a high-intensity pulse electron beam and subsequent fatigue loading up to failure. Bulletin of the Russian Academy of Sciences. Physics. 2015;79(9):1169–1172. https://doi.org/10.3103/S1062873815090087

20. Listyawan T.A., Lee H., Park N., Lee U. Microstructure and mechanical properties of CoCrFeMnNi high entropy alloy with ultrasonic nanocrystal surface modification process. Journal of Materials Science and Technology. 2020;57: 123–130. https://doi.org/10.1016/j.jmst.2020.02.083

21. Guo L., Wu W., Ni S., Yuan Z., Cao Y., Wang Z., Song M. Strengthening the FeCoCrNiMo0.15 HEA by gradient structure. Journal of Alloys and Compounds. 2020;841:155688. https://doi.org/10.1016/j.jallcom.2020.155688

22. Rogachev A.S. Structure, stability and properties of high entropy alloys. Fizika metallov i metallovedenie. 2020; 121(8):807–841. (In Russ.). https://doi.org/10.31857/S0015323020080094

23. Raturi A., Aditya C.J., Gurao N.P., Biswak K. ICME approach to explore equiatomic and non-equiatomic single phase BCC refractory high entropy alloys. Journal of Alloys and Compounds. 2019;806:587–595. https://doi.org/10.1016/j.jallcom.2019.06.387

24. Senkov O.N., Zhang C., Pilchak A.L., Payton E.J., Woodward C., Zhang F. CALPHAD-aided development of quaternary multi-principal element refractory alloys based on NbTiZr. Journal of Alloys and Compounds. 2019;783: 729–742. https://doi.org/10.1016/j.jallcom.2018.12.325

25. Menou E., Tancret F., Toda-Caraballo I., Ramstein G., Castany P., Bertrand E., Gautier N., Rivera Díaz-Del-Castillo P.E.J. Computational design of light and strong high entropy alloys (HEA): Obtainment of an extremely high specific solid solution hardening. Scripta Materialia. 2018;156:120–123. https://doi.org/10.1016/j.scriptamat.2018.07.024

26. Tapia A.J.S.E, Yim D., Kim H.S., Lee B.-J. An approach for screening single phase high-entropy alloys using an in-house thermodynamic database. Intermetallics. 2018;101:56–63. https://doi.org/10.1016/j.intermet.2018.07.009

27. Alaneme K.K., Bodunrin M.O., Oke S.R. Processing, alloy composition and phase transition effect on the mechanical and corrosion properties of high entropy alloys: a review. Journal of Materials Research and Technology. 2016;5(4):384–393. https://doi.org/10.1016/j.jmrt.2016.03.004

28. Murty B.S., Yeh J.W., Ranganathan S., Bhattacharjee P.P. High-Entropy Alloys. 2nd ed. Amsterdam: Elsevier; 2019:374.

29. Zhang Y. High-Entropy Materials. A Brief Introduction. Singapore: Springer Nature; 2019:159.

30. Yin B., Maresca F., Curtin W.A. Vanadium is an optimal element for strengthening in both fcc and bcc high-entropy alloys. Acta Materialia. 2020;188:486–491. https://doi.org/10.1016/j.actamat.2020.01.062

31. Yamanaka S., Ikeda Ki., Miura S. The effect of titanium and silicon addition on phase equilibrium and mechanical properties of CoCrFeMnNi-based high entropy alloy. Journal of Materials Research. 2021;36:2056–2070. https://doi.org/10.1557/s43578-021-00251-0

32. Jia Y., Wang Z., Wu Q., He F., Li J., Wang J. Enhancing the yield strength of Ni-Co-Cr-Fe-Al as-cast hypoeutectic high-entropy alloys by introducing γ′ precipitation. Materials Science and Engineering: A. 2022;858:144190. https://doi.org/10.1016/j.msea.2022.144190

33. Zhou H., Lin Y., Chen F., Shen Q. Effect of precipitation behavior on mechanical properties of a Nb-containing CoCrNi-based high-entropy alloy. Metals and Materials International. 2023;29:674–692. https://doi.org/10.1007/s12540-022-01265-x

34. Gwalani B., Torgerson T., Dasari S., Jagetia A., Nartu M.S.K.K.Y., Gangireddy S., Pole M., Wang T., Scharf T.W., Banerjee R. Influence of fine-scale B2 precipitation on dynamic compression and wear properties in hypo-eutectic Al0.5CoCrFeNi high-entropy alloy. Journal of Alloys and Compounds. 2021;853:157126. https://doi.org/10.1016/j.jallcom.2020.157126

35. Algan Şimşek İ.B., Arık M.N., Talaş Ş., Kurt A. The effect of B addition on the microstructural and mechanical properties of FeNiCoCrCu high entropy alloys. Metallurgical and Materials Transactions A. 2021;52:1749–1758. https://doi.org/10.1007/s11661-021-06186-9

36. Shen Q., Kong X., Chen X. Significant transitions of microstructure and mechanical properties in additively manufactured Al-Co-Cr-Fe-Ni high-entropy alloy under heat treatment. Materials Science and Engineering: A. 2021;815:141257. https://doi.org/10.1016/j.msea.2021.141257

37. Shim S.H., Pouraliakbar H., Lee B.J., Kim Y.K., Rizi M.S., Hong S.I. Strengthening and deformation behavior of as-cast CoCrCu1.5MnNi high entropy alloy with micro-/nanoscale precipitation. Materials Science and Engineering: A. 2022;853:143729. https://doi.org/10.1016/j.msea.2022.143729

38. Xie X., Li N., Liu W., Huang S., He X., Yu Q., Xiong H., Wang E., Hou X. Research progress of refractory high entropy alloys: A review. Chinese Journal of Mechanical Engineering. 2022;35:142. https://doi.org/10.1186/s10033-022-00814-0

39. He Z., Guo Y., Sun L., Yan H.-L., Guan X., Jiang S., Shen Y., Yin W., Zhao X., Li Z., Jia N. Interstitial-driven local chemical order enables ultrastrong face-centered cubic multicomponent alloys. Acta Materialia. 2023;243:118495. https://doi.org/10.1016/j.actamat.2022.118495

40. Mehranpour M.S., Shahmir X., Kim H.S. Microstructure tailoring by manipulating chemical composition in novel CoNiMnCrAl high-entropy alloys. Journal of Alloys and Compounds. 2023;944:169207. https://doi.org/10.1016/j.jallcom.2023.169207

41. Knieps M.S., Messe O.M.D.M., Barriobero-Vila P., Hecht U. Advanced characterization of two novel Fe-rich high entropy alloys developed for laser powder bed fusion in the Al-Co-Cr-Fe-Ni-Zr system. Materialia. 2022;26:101615. https://doi.org/10.1016/j.mtla.2022.101615

42. Abbasi E., Dehghani K. Phase prediction and microstructure of centrifugally cast non-equiatomic Co-Cr-Fe-Mn-Ni(Nb,C) high entropy alloys. Journal of Alloys and Compounds. 2019;783:292–299. https://doi.org/10.1016/j.jallcom.2018.12.329

43. Conway P.L.J., Klaver T.P.C., Steggo J., Ghassemali E. High entropy alloys towards industrial applications: High-throughput screening and experimental investigation. Materials Science and Engineering: A. 2022;830:142297. https://doi.org/10.1016/j.msea.2021.142297

44. Abrahams K., Zomorodpoosh S., Khorasgani A., Roslyakova I., Steinbach I., Kundin J. Automated assessment of a kinetic database for fcc Co-Cr-Fe-Mn-Ni high entropy alloys. Modelling and Simulation in Materials Science and Engineering. 2021;29:055007. https://doi.org/10.1088/1361-651X/abf62b

45. Shafiei A. Simple approach to model the strength of solid-solution high entropy alloys in Co-Cr-Fe-Mn-Ni system. Strength of Materials. 2022;54:705–716. https://doi.org/10.1007/s11223-022-00448-6

46. Do H.-S., Choi W.-M., Lee B.-J. A thermodynamic description for the Co–Cr–Fe–Mn–Ni system. Journal of Materials Science. 2022;57:1373–1389. https://doi.org/10.1007/s10853-021-06604-8

47. Li Z., Pradeep K.G., Deng Y., Raabe D., Tasan C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature. 2016;534:227–230. https://doi.org/10.1038/nature17981

48. Gao N., Lu D.H., Zhao Y.Y., Liu X.W., Liu G.H., Wu Y., Liu G., Fan Z.T., Lu Z.P., George E.P. Strengthening of a CrMnFeCoNi high-entropy alloy by carbide precipitation. Journal of Alloys and Compounds. 2019;792:1028–1035. https://doi.org/10.1016/j.jallcom.2019.04.121

49. Wang Z., Baker I., Guo W., Poplawsky J.D. The effect of carbon on the microstructures, mechanical properties, and deformation mechanisms of thermo-mechanically treated Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys. Acta Materialia. 2017;126:346–360. https://doi.org/10.1016/j.actamat.2016.12.074

50. Peng H., Hu L., Li L., Gao J., Zhang Q. On the correlation between L12 nanoparticles and mechanical properties of (NiCo)52+2x(AlTi)4+2xFe29–4xCr15 (x=0–4) high-entropy alloys. Journal of Alloys and Compounds. 2020;817:152750. https://doi.org/10.1016/j.jallcom.2019.152750

51. Jo Y.H., Jung S., Choi W.-M., Sohn S.S., Kim H.S., Lee B.-J., Kim N.J., Lee S. Cryogenic strength improvement by utilizing room-temperature deformation twinning in a partially recrystallized VCrMnFeCoNi high-entropy alloy. Nature Communications. 2017;8:15719. https://doi.org/10.1038/ncomms15719

52. Lu Y., Dong Y., Guo S., Jiang L., Kang H., Wang T., Wen B., Wang Z., Jie J., Cao Z., Ruan H., Li T. A promising new class of high-temperature alloys: Eutectic high-entropy alloys. Scientific Reports. 2014;4:6200. https://doi.org/10.1038/srep06200

53. Zhang Y., Chen Z., Cao D., Zhang J., Zhang P., Tao Q., Yang X. Concurrence of spinodal decomposition and nano-phase precipitation in a multi-component AlCoCrCuFeNi high-entropy alloy. Journal of Materials Research and Technology. 2019;8(1):726–736. https://doi.org/10.1016/j.jmrt.2018.04.020

54. Otto F., Dlouhý A., Pradeep K.G., Kuběnová M., Raabe D., Eggeler G., George E.P. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Materialia. 2016;112: 40–52. https://doi.org/10.1016/j.actamat.2016.04.005

55. Stepanov N.D., Shaysultanov D.G., Ozerov M.S., Zherebtsov S.V., Salishchev G.A. Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing. Materials Letters. 2016;185:1–4. https://doi.org/10.1016/j.matlet.2016.08.088

56. Lukas H.L., Fries S.G., Sundman B. Computational Thermodynamics: The Calphad Method. Cambridge: Cambridge University Press; 2007:313. https://doi.org/10.1017/CBO9780511804137

57. Wang C., Zhong W., Zhao J. Insights on phase formation from thermodynamic calculations and machine learning of 2436 experimentally measured high entropy alloys. Journal of Alloys and Compounds. 2022;915:165173. https://doi.org/10.1016/j.jallcom.2022.165173

58. Shafiei A. Design of Eutectic high entropy alloys. Metallurgical and Materials Transactions A. 2022;53:4329-4361. https://doi.org/10.1007/s11661-022-06831-x

59. Gao X., Lu Y., Zhang B., Liang N., Wu G., Sha G., Liu J., Zhao Y. Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy. Acta Materialia. 2017;141:59–66. https://doi.org/10.1016/j.actamat.2017.07.041

60. Wani I.S., Bhattacharjee T., Sheikh S., Bhattacharjee P.P., Guo S., Tsuji N. Tailoring nanostructures and mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy using thermo-mechanical processing. Materials Science and Engineering: A. 2016;675:99–109. https://doi.org/10.1016/j.msea.2016.08.048

61. Zhang P.C., Zhai B., Wang H.P. Effect of microstructure, strain rate, and elevated temperature on the compression property of Fe-Co-Ni-Cr-Zr alloy. Metallurgical and Materials Transactions A. 2023;54:346–357. https://doi.org/10.1007/s11661-022-06887-9

62. Wu M., Wang S., Huang H., Shu D., Sun B. CALPHAD aided eutectic high-entropy alloy design. Materials Letters. 2020;262:127175. https://doi.org/10.1016/j.matlet.2019.127175

63. Yan J., Song Z., Fang W., He X., Chang R., Huang S., Huang J., Yu H., Yin F. Composition design of high yield strength points in single-phase Co-Cr-Fe-Ni-Mo multi-principal element alloys system based on electronegativity, thermodynamic calculations, and machine learning. Tungsten. 2023;5:169–178. https://doi.org/10.1007/s42864-021-00129-y

64. Yen S., Liu Y., Chu S., Chang C., Lin S., Tsai M. B2-strengthened Al-Co-Cr-Fe-Ni high entropy alloy with high ductility. Materials Letters. 2022;325:132928. https://doi.org/10.1016/j.matlet.2022.132828

About the Authors

V. E. GromovRussian Federation

Viktor E. Gromov, Dr. Sci. (Phys.-Math.), Prof., Head of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

S. V. Konovalov

Russian Federation

Sergei V. Konovalov, Dr. Sci. (Eng.), Prof., Vice-Rector for Research and Innovation

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

M. O. Efimov

Russian Federation

Mikhail O. Efimov, Candidates for a degree of Cand. Sci. (Eng.) of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

I. A. Panchenko

Russian Federation

Irina A. Panchenko, Cand. Sci. (Eng.), Head of the Laboratory of Electron Microscopy and Image Processing

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

V. V. Shlyarov

Russian Federation

Vitaly V. Shlyarov, Postgraduate of the Chair of Science named after V.M. Finkel’, Research Associate of the Laboratory of Electron Microscopy and Image Processing

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Gromov V.E., Konovalov S.V., Efimov M.O., Panchenko I.A., Shlyarov V.V. Ways to improve the properties of high-entropy alloys Cantor CoCrFeNiMn and CoCrFeNiAl. Izvestiya. Ferrous Metallurgy. 2024;67(3):283-292. https://doi.org/10.17073/0368-0797-2024-3-283-292