Scroll to:

Influence of copper and silicon on phase transformations in the iron – carbon system

https://doi.org/10.17073/0368-0797-2024-1-73-75

Abstract

To evaluate the phase and structural components of grinding media made of cast iron with a high content of copper and silicon obtained by extracting iron from copper-smelting slags, phase equilibria in the iron – carbon system were calculated with the addition of copper and silicon in various concentrations. The calculation was carried out using the ThermoCalc software package with construction of phase diagrams by the Calphad method. At the same time, temperatures of the beginning of phase transformations were estimated taking into account the presence of all thermodynamically possible phases in the system at various combinations of copper and silicon concentrations.

Keywords

For citations:

Adilov G., Kareva N.T., Roshchin V.E. Influence of copper and silicon on phase transformations in the iron – carbon system. Izvestiya. Ferrous Metallurgy. 2024;67(1):73-75. https://doi.org/10.17073/0368-0797-2024-1-73-75

Introduction

Large quantities of copper-smelting slag, primarily composed of iron, silicon, calcium, and aluminum oxides, have accumulated in waste dumps in areas where the non-ferrous metallurgy industry is well-developed. The slag also contains small amounts of compounds of copper, zinc, selenium, arsenic, and other elements. Among the elements present, iron has the highest value in the slag. When iron is reduced by carbon under certain process conditions, alloys of iron-carbon or iron-carbon-silicon with high copper and sulfur content are produced. The high copper content, which traditional methods cannot remove, prevents the use of such metal in iron and steelmaking. Therefore, a process for the deep processing of copper-smelting slags is proposed to produce metal grinding media based on copper-containing iron-carbon-silicon alloys and ceramic proppants for the exploration and production sector [1]. Currently, white wear-resistant eutectic cast irons are employed in the manufacture of grinding media from copper-containing material [2; 3]. Additional knowledge about phase transformations in the iron-carbon system, in the presence of copper and silicon, is necessary to estimate the phase and structural composition of the alloys obtained from the processed slag material.

Research method

To construct the iron-carbon phase diagram with the presence of copper and silicon impurities, the Calphad method was employed using the ThermoCalc software package and the TCBIN database: TC Binary Solutions v1.11. The Calphad method within ThermoCalc leverages all available experimental data to derive the system’s thermodynamic functions, which are represented as polynomials of chemical composition and temperature. Consequently, the values of the polynomial coefficients are determined using numerical optimization methods2. To ascertain the phase transformations in the iron-carbon phase diagram, copper in quantities ranging from 0 to 1.5 wt. % and silicon in the range of 0 to 3.5 wt. % were introduced into the system during the calculations. The pressure was set to 105 Pa, and the temperature was defined automatically.

Simulation result

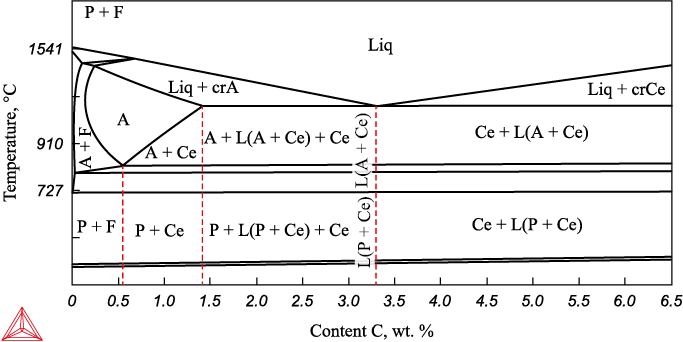

The iron-carbon system, known for its five phases – ferrite (F), austenite (A), cementite (Ce), graphite, and one liquid phase–exhibits changes in carbon solubility when copper and silicon admixtures are present within specified limits. Copper, at quantities ranging from 0 to 1.5 %, marginally decreases carbon solubility in austenite, reducing it from 2.14 to 2.0 %.

Additionally, adding silicon from 0 to 3.5 % along a vertical section of the iron – carbon – copper system (at 1 % copper) lowers the carbon solubility in austenite’s FCC lattice from 2.14 to 1.5 %. This addition also causes the ferrite phase region to expand and the eutectic point to shift towards a higher carbon concentration of 3.2 %, as illustrated in the accompanying figure.

Vertical section of the iron – carbon – copper system (1 %) with addition of silicon (3.5 %) |

Conclusions

The calculations indicate that to produce white wear-resistant cast iron with a eutectic composition suitable for manufacturing high-performance grinding balls, the slag processing material must contain approximately 1 % copper, 3.5 % silicon, and 3.5 % carbon.

References

1. Roshchin V.E., Adilov G.A., Povolotckii A.D., Kapelyushin Y. Complex processing of copper smelting slags with obtaining of cast iron grinding media and proppants. In: KnE Social Sciences. IV Congress “Fundamental Research and Applied Developing of Recycling and Utilization Processes of Technogenic Formations”. 2020:462–471. https://doi.org/10.18502/kms.v6i1.8126

2. Steblov A.B., Berezov S.N., Kozlov A.A. Cast iron balls for materials grinding. Lit’e i metallurgiya. 2012;(3S(66)): 45–49. (In Russ.).

3. Chizh E.V., Abenova M.B. Selection and analysis of grinding media manufacturing technology. Teoriya i tekhnologiya metallurgicheskogo proizvodstva. 2016;(2(19)):42–44. (In Russ.).

About the Authors

G. AdilovRussian Federation

Galymzhan Adilov, Research Associate of the Research Laboratory “Hydrogen Technologies in Metallurgy”

76 Lenina Ave., Chelyabinsk 454080, Russian Federation

N. T. Kareva

Russian Federation

Nadezhda T. Kareva, Cand. Sci. (Eng.), Assist. Prof. of the Chair of Materials Science and Physical Chemistry of Materials

76 Lenina Ave., Chelyabinsk 454080, Russian Federation

V. E. Roshchin

Russian Federation

Vasilii E. Roshchin, Dr. Sci. (Eng.), Prof. of the Chair of Pyrometallurgical and Foundry Technologies

76 Lenina Ave., Chelyabinsk 454080, Russian Federation

Review

For citations:

Adilov G., Kareva N.T., Roshchin V.E. Influence of copper and silicon on phase transformations in the iron – carbon system. Izvestiya. Ferrous Metallurgy. 2024;67(1):73-75. https://doi.org/10.17073/0368-0797-2024-1-73-75