Scroll to:

Structural-phase transformations of 12 % chromium ferritic-martensitic steel EP-823

https://doi.org/10.17073/0368-0797-2023-6-725-732

Abstract

The features of phase transformations of 12 % chromium ferritic-martensitic steel EP-823 under heating and cooling conditions in the temperature range from 30 to 1100 ℃ were studied by the methods of high-temperature X-ray diffraction analysis (XRD) in situ and differential scanning calorimetry (DSC). According to XRD in situ data, upon heating, the temperatures of the beginning and end of the (α → γ) transformation of ferrite (martensite – austenite) are Ac1 ≈ 880 °C, Ac3 ≈ 1000 °C, respectively. Upon cooling, a diffusion (γ → α) transformation occurs with critical points – Аr1 ≈ 860°С (beginning temperature) and Аr3 ≈ 840 °С (end temperature). According to DSC data, during heating, the critical points of the (α → γ) transformation are Ac1 ≈ 840 °C and Ac3 ≈ 900 °C. During cooling, a martensitic (γ → α) transformation is realized with critical points of the beginning of Ms = 344 ℃ and the end of Mf = 212 ℃ of this transformation. The XRD in situ analysis revealed no precipitation of carbide phases under heating and cooling conditions of steel EP-823. Position of the critical points of phase transformations depends on the research method (XRD in situ or DSC), which is determined by the difference in effective (taking into account the time for shooting in the XRD method) heating-cooling rate. The effect of elemental composition on the position of critical points of phase transformations and the formation of structural-phase states of ferritic-martensitic steels is discussed. It is shown that the increased content of ferrite-stabilizing elements (Cr, Mo, Nb) in composition of EP-823 steel, compared with other steels of the same class, expands the region of existence of the ferrite phase, which can contribute to an increase in the temperature of Ac1 .

Keywords

For citations:

Spiridonova K.V., Litovchenko I.Yu., Polekhina N.A., Linnik V.V., Borisenko T.A., Chernov V.M., Leont’eva-Smirnova M.V. Structural-phase transformations of 12 % chromium ferritic-martensitic steel EP-823. Izvestiya. Ferrous Metallurgy. 2023;66(6):725-732. https://doi.org/10.17073/0368-0797-2023-6-725-732

Introduction

Generation IV fast neutron nuclear reactors with lead or lead-bismuth coolant are currently in development [1 – 5]. The 12 % chromium ferriticmartensitic steel EP-823 is considered one of key materials for manufacturing fuel element cans in Russian nuclear reactors [6 – 9]. This steel is distinctive for its elevated silicon content, providing excellent corrosion resistance, particularly when in contact with liquid metal coolant [7].

The physical and mechanical properties of steel EP-823 underwent comprehensive scrutiny in the late 20\(^{th}\) century [7]. Researchers explored the microstructure and mechanical properties of the steel after various treatments, including traditional heat treatment (THT), stepwise heat treatment (STT), and hightemperature thermomechanical treatment (HTMT)) [7 – 9]. They analyzed hardening mechanisms [10], investigated creep resistance, studied thermophysical properties, temperature dependencies of elastic modulus, and internal friction characteristics [11; 12]. Additionally, they examined short-term and long-term mechanical properties after high-dose neutron irradiation [13 – 15]. The findings demonstrated that this steel is on par with other 12 % chromium ferritic-martensitic steels concerning physical-mechanical, heat-resistant, corrosion, and radiation properties [16].

Although steel EP-823 has been a subject of scientific interest for a considerable period, detailed studies on phase transitions during its heating and cooling, utilizing Differential Scanning Calorimetry (DSC) and high-temperature X-ray Diffraction (XRD) in situ methods, have not been conducted before. The use of these two methods allows us to complement the obtained results and determine the dependence of critical points on the effective heating (cooling) rate. The data on the values of critical points of steel phase transitions are crucial for determining the temperature intervals suitable for practical applications of the steel and for developing high-temperature thermomechanical treatments.

Materials and methods

The elemental composition of ferritic-martensitic steel EP-823 is as follows [6 – 8], wt. %: C 0.14; Cr 11.56; Mn 0.58; Mo 0.74; Nb 0.40; V 0.34; W 0.68; Ni 0.68; N 0.03; Si 1.09; Ce 0.10; Ti 0.01; B 0.006; Al 0.02.

To investigate the phase transformations of the steel during heating and cooling, we employed high-temperature X-ray diffraction analysis (XRD) in situ on the D8 Advance diffractometer with HTK 1200 N high-temperature chamber using CuKα-radiation in a helium protective atmosphere. This method involved the following steps:

– heating from 30 to 1100 °C (shooting at 30 ℃, from 30 to 800 °C without shooting, from 800 to 1000 °C – shooting with a step of 20 °C, heating from 1000 to 1100 °C without shooting, shooting at 1100 °С);

– exposure at 1100 °C for 40 min to obtain a uniform solid solution, followed by shooting;

– subsequent cooling from 1100 to 30 ℃ (from 1100 to 900 ℃ without shooting, from 900 to 600 ℃ – shooting with a step of 20 ℃, from 600 to 30 ℃ without shooting, shooting at 30 ℃).

The study utilized plates measuring 1 mm in thickness and 15 mm in diameter as samples. The range of 2θ angles was set at 40 – 80°, with a shooting step of Δ2θ approximately 0.02°. The heating and cooling rates were maintained at 12 °C/min, and the shooting time at each temperature was 7 min. The XRD method was employed to investigate the steel samples post-quenching in water at T = 1100 °C (1 h holding time). The temperature intervals for shooting were chosen based on previously obtained results for steel of the same class [16].

Critical points of phase transformations were determined using differential scanning calorimetry (DSC) during continuous heating (from 20 to 1100 °C) at a rate of 10 °C/min and cooling (from 1100 to 20 °C) of the samples in a protective argon atmosphere using a NETZSCH STA 409 PC device. The inflection temperatures on the DSC curves were identified as the beginning and end of the phase transformation. The mass of the samples ranged from 90 to 100 mg. DSC studies were conducted on steel samples after traditional heat treatment (THT), involving quenching in water from a temperature of 1100 °C (1 h holding time) and subsequent tempering at 720 °C (for 3 h).

Results and discussion

The study [9] provided a comprehensive analysis of the microstructure and phase composition of ferritic-martensitic steel EP-823 using Scanning Electron Microscopy (SEM) in the Electron Back-Scatter Diffraction (EBSD) mode and Transmission Electron Microscopy (TEM). The primary structural features crucial for discussing the peculiarities of its phase transitions during heating and cooling are outlined below.

The microstructure of steel after quenching reveals martensitic lamellae with a high density of dislocations (up to 1015 m\(^–\)2), ferrite grains, a minimal quantity of coarse and fine particles of MeX type (where Мe is Nb, Mo; X – C, N), as well as coarse particles of Мe23C6 type (where Мe – Fe, Cr). In the tempering conditions following quenching (THT mode), the main structural elements (martensitic lamella and ferrite grains) are retained. The density of dislocations decreases, while the density of coarse (Me23C6 type) and fine (MeX type) particles significantly increases compared to the state after quenching.

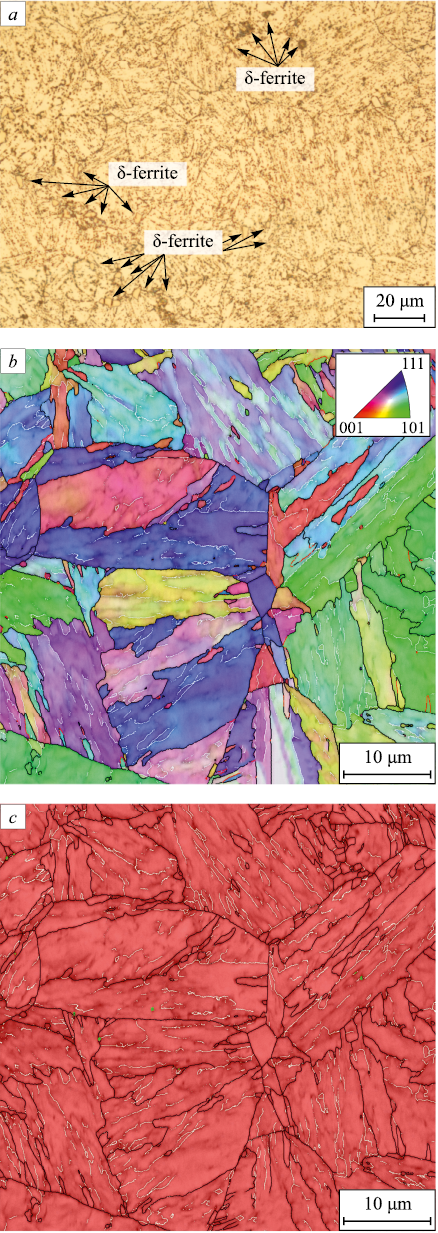

After THT (Fig. 1), former austenitic grains in steel EP-823 exhibit sizes up to 60 µm. A small number of δ-ferrite grains were also evident. Within the former austenitic grains, martensite blocks are observed, clustering together with predominantly high-angle misorientations between adjacent blocks (Fig. 1, b, c). Low-angle misorientation boundaries (Fig. 1, c) represent the boundaries of the martensitic lamellae forming the blocks. The average size of martensite blocks and ferrite grains, as per the EBSD method, is 3.1 μm [9]. Fig. 1, c displays coarse (submicron, micron) particles of МeХ type.

Fig. 1. Images of steel microstructure after traditional heat treatment: |

Transmission Electron Microscopy data [9] indicate that the average width of martensitic lamellae is approximately 300 nm. Мe23С6 carbides are situated along the boundaries of martensitic lamellae and ferrite grains, with sizes ranging from 50 to 250 nm. Fine carbonitrides of MeX type (5 – 20 nm in size) are positioned on dislocations, anchoring them. These particles are predominantly liberated during steel tempering. Coarse particles of the same type appear to have originated from metallurgical operations and remain unchanged in size under heat treatment conditions.

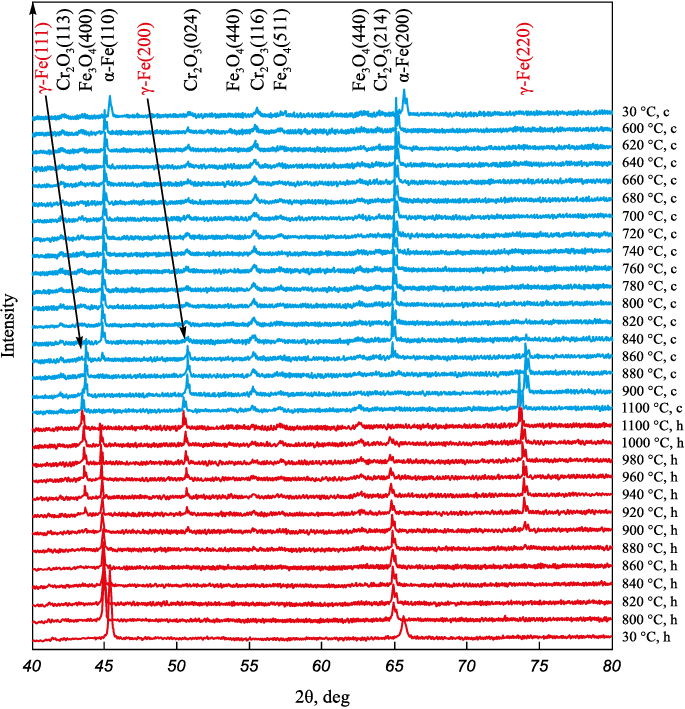

Fig. 2 presents X-ray line profiles of steel EP-823 (after quenching) obtained through heating and cooling in the temperature range 30 – 1100 – 30 ℃. At room temperature (30 ℃), in the initial state, this exhibits a typical X-ray diffraction pattern of ferrite-martensitic steel with a BCC lattice. Upon heating, the X-ray peaks shift towards smaller 2θ angles due to the thermal expansion of the crystal lattice. The analysis of X-ray profiles at different temperatures reveals that the α → γ transition initiates at T = 880 ℃ (Ас1) and completes at T = 1000 ℃ (Ас3 ). The intercritical temperature interval (Ас3 – Ас1 ) is approximately 120 ℃. Besides the γ and α phase reflections, X-ray diffraction patterns during heating exhibit reflections from Fe3O4 and Cr2O3 oxides. Evidently, an oxide layer forms on the sample surface due to the presence of residual oxygen in the argon protective atmosphere.

Fig. 2. Profiles of X-ray diffraction lines of steel EP-823 (heating from 30 to 1100 ℃, |

Upon cooling, the diffusive transformation from austenite (γ) to ferrite (α) begins at Аr1 = 860 ℃ and concludes at Аr3 = 840 . In the high-temperature region, as the temperature decreases, reflections from oxide phases (Fe3O4 , Cr2O3 ) intensify, signifying an increase in their volume fraction. Notably, the Fe3O4 (400) and Cr2O3 (024) reflections closely match those of γ-Fe (111) and γ-Fe (200), respectively. However, at T = 30 ℃, there are no reflections from austenite. Oxide reflections are observed under shooting conditions at 30 ℃ after the heating – holding – cooling cycle.

X-ray diffraction patterns do not exhibit peaks from carbide (Me23C6 ) and carbonitride (MeX) particles. The XRD method is unlikely to identify these particles due to their small volume fraction (up to several percent). In [9] it is noted that after THT, the volume fraction of fine particles of MeX type in steel EP-823 is ≈0.6 % and that of coarse particles of Me23C6 type is about 5.5 %. In the state after quenching, the volume fractions of these particles are lower than the indicated values.

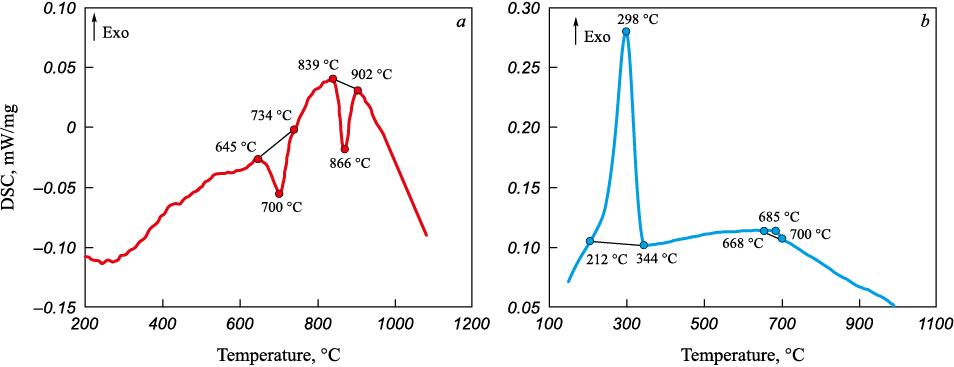

Fig. 3 presents the results of the investigation of α → γ and γ → α transformations in steel EP-823 obtained by the DSC method during continuous heating and cooling. During heating (Fig. 3, a), two dips are observed on the DSC curve. One of them is associated to the phase α → γ transformation, where the points Ас1 = 839 ℃ and Ас3 = 902 ℃. When the study is conducted using this method, the intercritical temperature interval (Ас3 – Ас1 ) is 63 ℃. According to sources [16; 17], the second dip at temperatures 645 – 734 ℃ is attributed to the magnetic transformation of ferromagnetic α-Fe into paramagnetic α-Fe.

Fig. 3. DSC curves of steel EP-823 during heating (a) and cooling (b) |

Upon cooling, a peak corresponding to a martensitic transformation (γ → α) is observed on the DSC curve. This transformation occurs between Ms = 344 ℃ and Mf = 212 . Additionally, the DSC curve shows a slight inflection in the temperature range of 700 – 668 ℃. In [16], it is noted that inflections at such temperatures are characteristic of the diffusive transformation of austenite to ferrite. The cooling rate during the DSC study is likely to have been high enough. Under such cooling conditions, diffusion-free (martensitic) transformation is realized, while diffusion transformation is practically suppressed.

The table displays the values of critical points for the phase transitions of steel EP-823 determined during continuous heating and cooling using XRD in situ and DSC methods. The comparison reveals that the difference in the values of the points Aс1 and Ас3 for the two methods is about 40 – 100 ℃, with the difference in the values of the intercritical interval being 57 ℃. These peculiarities are associated with the specific nature of each method, including the variance in effective heating (cooling) rates, taking into account the shooting time when the XRD method is employed. With the application of the DSC method, the effective heating rate is higher, causing the α → γ transformation to commence at lower temperatures, resulting in a shorter intercritical interval compared to the XRD in situ method.

Values of critical points of phase transitions of steel EP-823,

| ||||||||||||||||||||||||||||||

Comparing the critical points of phase transitions obtained in this investigation (refer to the Table) with experimental and calculated results from prior studies [16; 18 – 20] on various 9 – 12 % chromium ferrito-martensitic steels, we can draw the conclusion that our results are comparable. In the majority of the considered steels, the α → γ transformation during heating occurs within the temperature range of approximately 800 – 900 ℃; however, it may be completed at a higher temperature (1000 ℃), as observed in the case of steel EP-823 examined through the XRD in situ method in this study (see the Table). Diffusive transformation during cooling takes place in a temperature range close to the aforementioned one. The martensitic transformation in the majority of 9 – 12 % chromium ferrite-martensitic steels is observed within the temperature range of approximately 450 – 200 ℃.

Differences in the position of critical points are contingent on the elemental composition of steels and the rates of heating and cooling. An elevation in the content of ferrite-stabilizing elements (Cr, Mo, Nb) in the steel composition expands the ferrite phase region, potentially contribute to the to the increase in temperature at Ас1 . The presence of dispersed carbide particles of Me23C6 , binding carbon, deplets the solid solution in carbon and can consequently contribute to the expansion of the temperature range required for ferrite existence. The temperature and holding time in the austenitic region determine the homogeneity of the austenite solid solution and the size of the initial austenitic grain, influencing the martensitic transformation. During cooling, the reduction in the size of the austenitic grain contributes to the decrease Ms and Mf points values [17].

Conclusions

We have identified the critical points of structural-phase transformations during the heating and cooling of 12 % chromium ferrite-martensitic steel EP-823 using in situ X-ray diffraction analysis and differential scanning calorimetry.

According to the X-ray research, during continuous heating, the temperatures for the beginning and end of the α → γ transformation are Ас1 = 880 ℃ and Ас3 = 1000 ℃, respectively. During cooling, the beginning and end of the γ → α-transformation are Ar1 = 860 ℃ and Ar3 = 840 ℃. Based on differential scanning calorimetry data: Ас1 = 839 ℃, Ас3 = 902 ℃; martensitic transformation during cooling occurs in the interval between Мs ≈ 340 ℃ and Мf ≈ 210 ℃. The Curie point for the investigated steel is in the temperature range of 645 – 734 ℃.

Разница в положениях критических точек, полученных разными методами, обусловлена различием в эффективных скоростях нагрева (охлаждения) с учетом времени съемки в рентгеновском методе. Увеличение скорости нагрева способствует снижению температуры начала α → γ-превращения на ≈40 ℃ и сужению межкритического интервала температур. При охлаждении с повышенной скоростью (при ДСК исследовании) диффузионное γ → α-превращение подавляется и реализуется мартенситное превращение.

References

1. Cabet C., Dalle F., Gaganidze E., Henry J., Tanigawa H. Ferritic-martensitic steels for fission and fusion applications. Journal of Nuclear Materials. 2019;523:510–537. https://doi.org/10.1016/j.jnucmat.2019.05.058

2. Yvon P. Structural Materials for Generation IV Nuclear Reactors. Amsterdam, Netherlands: Elsevier; 2017:664.

3. Odette R.G., Zinkle S.J. Structural Alloys for Nuclear Energy Applications. Amsterdam, Netherlands: Elsevier; 2019:655.

4. Zinkle S.J., Ghoniem N.M. Operating temperature windows for fusion reactor structural materials. Fusion Engineering and Design. 2000;51-52:55–71. https://doi.org/10.1016/S0920-3796(00)00320-3

5. Kurtz R.J., Odette G.R. Chapter 3 – Overview of reactor systems and operational environments for structural materials in fusion reactors. In: Structural Alloys for Nuclear Energy Applications. Amsterdam, Netherlands: Elsevier; 2019:51–102. https://doi.org/10.1016/B978-0-12-397046-6.00003-4

6. Maloy S.A., Natesan K., Holsomb D.E., Fazio C., Yvon P. Chapter 2 – Overview of reactor systems and operational environments for structural materials in GEN-IV fission reactors. In: Structural Alloys for Nuclear Energy Applications. Amsterdam, Netherlands: Elsevier; 2019:23–49. https://doi.org/10.1016/B978-0-12-397046-6.00002-2

7. Ioltukhovskii A.G., Lanskaya K.A., Belomyttsev Yu.S., Saratovskii L.N. Choice of heat treatment modes of 12 % chromium steel EP823 in relation to operating conditions of fuel assembly covers of BN-600 reactor. Voprosy atomnoi nauki i tekhniki. Ser. Atomnoe materialovedenie. 1985;(2(19)):65–70. (In Russ.).

8. Polekhina N.A., Litovchenko I.Yu., Almaeva K.V., Akkuzin S.A., Linnik V.V., Moskvichev E.N., Chernov V.M., Naumenko I.A., Saifutdinova M.S., Leontieva-Smirnova M.V. Special features of the surface layer structure of ferritic-martensitic EP-823-Sh steel after prolonged exposure to the flowing lead at 630 °C under low oxygen concentration. Journal of Nuclear Materials. 2022;572:154039. https://doi.org/10.1016/j.jnucmat.2022.154039

9. Litovchenko I., Almaeva K., Polekhina N., Akkuzin S., Linnik V., Moskvichev E., Chernov V., Leontyeva-Smirnova M. The microstructure and mechanical properties of ferritic-martensitic steel EP-823 after high-temperature thermomechanical treatment. Metals. 2022;12(1):79. https://doi.org/10.3390/met12010079

10. Almaeva K.V., Litovchenko I.Yu., Polekhina N.A., Linnik V.V. Mechanisms of hardening of 12 % chromium ferritic-martensitic steel EP-823. Izvestiya. Ferrous Metallurgy. 2022;65(12):887–894. (In Russ.). https://doi.org/10.17073/0368-0797-2022-12-887-894

11. Belomyttsev M.Yu., Molyarov V.G. Creep resistance of ferritic-martensitic steel 16Cr12MoWSiVNbB (EP-823). Izvestiya. Ferrous Metallurgy. 2019;62(4):290–302. (In Russ.). https://doi.org/10.17073/0368-0797-2019-4-290-302

12. Kruglov A.B., Kruglov V.B., Struchalin P.G., Kharitonov V.S. Study of thermophysical properties of EP-823 steel in the temperature range of 200–900 ℃. Bulletin of the Lebedev Physics Institute. 2015;42(9):264–267. https://doi.org/10.3103/S1068335615090031

13. Porollo S.I., Veremeev A.M., Konobeev Yu.V., Ivanov A.A., Shulepin S.V. Study of the long-term strength of neutron-irradiated austenitic and ferrite-martensite steel. Atomic Energy. 2018;124(2):98–104. https://doi.org/10.1007/s10512-018-0381-x

14. Maloy S.A., Romero T., James M.R. Tensile testing of EP-823 and HT-9 after irradiation in STIP II. Journal of Nuclear Materials. 2006;356(1-3):56–61. http://dx.doi.org/10.1016/j.jnucmat.2006.05.003

15. Grachev A.F., Zherebtsov A.A., Zabud’ko L.M., Zvir E.A., Kryukov F.N., Nikitin O.N., Skupov M.V., Ivanov Yu.A., Porollo S.I. Results of investigations of BREST-type reactor fuel rods with mixed uranium-plutonium nitride fuel, irradiated in BOR-60 and BN-600. Atomic Energy. 2019;125(5):314–321. https://doi.org/10.1007/s10512-019-00487-4

16. Polekhina N.A., Litovchenko I.Yu., Almaeva K.V., Bulina N.V., Korchagin M.A., Tyumentsev A.N., Chernov V.M., Leontyeva-Smirnova M.V. Features of phase transformations of low-activation 12 %-chromium ferritic-martensitic steel EK-181. Russian Physics Journal. 2020;62(12):2314–2318. https://doi.org/10.1007/s11182-020-01982-z

17. Lanskaya K.A. High-Chromium Heat-Resistant Steels. Moscow: Metallurgiya; 1976:216. (In Russ.).

18. Raju S., Ganesh B.J., Rai A.K., Mythili R., Saroja S., Raj B. A study on martensitic phase transformation in 9Cr–1W–0.23V–0.063Ta– 0.56Mn–0.09C–0.02N (wt. %) reduced activation steel using differential scanning calorimetry. Journal of Nuclear Materials. 2010;405(1):59–69. http://dx.doi.org/10.1016/j.jnucmat.2010.07.036

19. Lu Sh., Liang T., Li Y., Li D., Rong L., Li Y. Microstructure and mechanical properties of simulated heat-affected zones of EP-823 steel for ADS/LFR. Journal of Materials Science and Technology. 2015;31(8):864–871. http://dx.doi.org/10.1016/j.jmst.2014.08.015

20. Ma T., Hao X., Wang P. Effect of heat treatments on microstructural evolution and tensile properties of 15Cr12MoVWN ferritic/martensitic steel. Metals. 2020;10(9):1271. http://dx.doi.org/10.3390/met10091271

21.

About the Authors

K. V. SpiridonovaRussian Federation

Kseniya V. Spiridonova, Cand. Sci. (Phys.-Math.), Junior Researcher of the Laboratory of Materials Science of Shape Memory Alloys

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

I. Yu. Litovchenko

Russian Federation

Igor’ Yu. Litovchenko, Dr. Sci. (Phys.-Math.), Assist. Prof, Head of the Laboratory of Materials Science of Shape Memory Alloys

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

N. A. Polekhina

Russian Federation

Nadezhda A. Polekhina, Cand. Sci. (Phys.-Math.), Research Associate of the Laboratory of Materials Science of Shape Memory Alloys

2/4 Akademicheskii Ave., Tomsk 634055, Russian Federation

V. V. Linnik

Russian Federation

Valeriya V. Linnik, Postgraduate

36 Lenina Ave., Tomsk 634050, Russian Federation

T. A. Borisenko

Russian Federation

Tat’yana A. Borisenko, Junior Researcher of the Laboratory of Materials for Additive Technologies

18 Kutateladze Str., Россия, Novosibirsk 630128, Russian Federation

V. M. Chernov

Russian Federation

Vyacheslav M. Chernov, Dr. Sci. (Phys.-Math.), Prof., Chief Researcher

5a Rogova Str., Moscow 123098, Russian Federation

M. V. Leont’eva-Smirnova

Russian Federation

Mariya V. Leont’eva-Smirnova, Cand. Sci. (Eng.), Assist. Prof., Head of Department

5a Rogova Str., Moscow 123098, Russian Federation

Review

For citations:

Spiridonova K.V., Litovchenko I.Yu., Polekhina N.A., Linnik V.V., Borisenko T.A., Chernov V.M., Leont’eva-Smirnova M.V. Structural-phase transformations of 12 % chromium ferritic-martensitic steel EP-823. Izvestiya. Ferrous Metallurgy. 2023;66(6):725-732. https://doi.org/10.17073/0368-0797-2023-6-725-732

JATS XML