Scroll to:

Effect of structure of unfluxed burnt titanomagnetite pellets on strength under static compression

https://doi.org/10.17073/0368-0797-2023-6-696-704

Abstract

Burnt pellets must retain their strength from the moment they are taken out of an induration machine until they are loaded into a blast furnace. One of the indicators of the burnt pellets’ strength is the compressive strength, i.e. the ultimate force. In experiments to determine compressive strength, the main type of fracture is occurrence and development of cracks that pass through the core center of pellets (where the maximum radial tensile stresses present) or near it. The paper presents the requirements for static compression strength imposed by blast furnace production to iron ore pellets. Using an optical and scanning electron microscope equipped with an energy-dispersive microanalyzer, we analyzed the relationship of structural components and pores in the core of burnt unfluxed iron ore titanomagnetite pellets with the ultimate force under static compression. By scanning electron microscopy and X-ray spectral microanalysis, it was established that the core of pellets is a multiphase material, and its main phases are titanomagnetite, magnetite, titanohematite, hematite and aluminosilicate binder. Optical microscopy made it possible to establish the microstructure of the pellet core, which has three types of microstructures: non-oxidized core (magnetite or titanomagnetite), partially oxidized core – around (magnetite or titanomagnetite) hematite grains (titanohematite) and oxidized core (hematite and titanohematite). The main factors for obtaining pellets with an ultimate force of more than 2.5 kN/pellet according to the requirements of blast furnace production are: the number of closed macropores and the number of large grains in the core. It is shown that with an increase in the number of closed macropores and the number of large grains in the core, the ultimate force is reduced from 3.5 kN to 0.87kN/pellet.

Keywords

For citations:

Dmitriev A.N., Smirnova V.G., Vyaznikova E.A., Vit’kina G.Yu., Smirnov A.S. Effect of structure of unfluxed burnt titanomagnetite pellets on strength under static compression. Izvestiya. Ferrous Metallurgy. 2023;66(6):696-704. https://doi.org/10.17073/0368-0797-2023-6-696-704

Introduction

Iron ore pellets are crucial raw materials for cast iron smelting in blast furnaces. In Russia and abroad, pellet production involves two interrelated processes: the formation of green pellets and their hardening. Green pellets are burned to achieve the necessary metallurgical characteristics, including compressive strength, impact resistance, abrasion resistance, and reduction strength. To enhance the pelletizing process and produce robust pellets, 0.5 – 1.0 % bentonite is added to the finely ground concentrate [1; 2]. Bentonite primarily consists of aluminum and silicon oxides with high moisture absorption capacity [3 – 5]. Bentonite is the most common binder for iron ore pellets [5 – 7]. Green pellets undergo hardening through oxidizing burning on conveyor induration machines. Papers [8 – 10] demonstrate that, in the temperature range of 200 to 1300 °C, moisture is removed, magnetite particles oxidize, magnetite or hematite grains sinter, and pores and the silicate bond are formed, leading to the enhancement of pellet strength properties. As moisture is removed, bentonite forms hard aluminosilicate interstices that contribute to the hardening process [11; 12].

Upon completion of oxidation processes, a uniform pellet structure is achieved [9]. The paper [13] highlights that the key factor influencing the intensity of the oxidation process is the pore size rather than the total porosity. The heightened oxidation characteristics of pellets can be attributed to the larger pore size of pellets with a lower specific surface area of the concentrate. This pertains to the oxidation period, during which the process is primarily governed by oxygen diffusion in the pellet pores. Additionally, when the hematite film forms on the grains, the transformation is contingent on the concentrate grain size.

Magnetite in pellets undergoes oxidation through three distinct mechanisms: complete oxidation across the entire cross-section of the pellet, complete oxidation of the pellet shell with a non-oxidized core, and partial oxidation of the pellet shell with a non-oxidized core [14]. According to findings in [15], introducing oxygen enrichment into the gas atmosphere during the continuous heating of magnetite pellets can result in oxidation throughout their volumes, effectively eliminating non-oxidized cores. The kinetics of magnetite concentrate oxidation suggest that such oxygen enrichment is particularly effective at lower temperatures. Research in [16] revealed that temperatures between 700 and 800 °C, with 21 % O2 , or increasing the oxygen content to 60 or 100 % at 800 °C, can achieve complete oxidation across the entire pellet cross-section. The proposed formula for calculating the oxidation reaction rate, as a function of temperature and partial pressure of oxygen in the gas phase, can be found in [17]. Additionally, in [18], observations were made of hematite whiskers growing on the oxidized surface of magnetite concentrate particles at temperatures ranging from 800 to 950 °C. The whisker thickness increased from 30 nm at 800 °C to 200 nm at 950 °C. These whiskers act as bridges between concentrate particles during pellet burning, contributing to the overall strength of the pellets.

The findings in the paper [19] illustrate that when a pellet initiates oxidation, a hematite shell forms around the pellet while the core remains magnetite. At 1100 °C, the diffusion rate of oxygen was limited by sintering in the magnetite core, taking place before oxidation rather than by the diffusion rate of oxygen through the oxidized hematite shell, as previously asserted in the literature. The oxidation rate peaked at around 1100 °C and substantially decreased at 1200 °C due to heavy sintering in both the hematite shell and the magnetite core. Another study [20] indicated that the hardening of iron ore pellets through sintering begins at 1100 °C. The compressive strength of pellets increases with the heating temperature, although the impact of structure is not considered.

Compressive strength is a crucial metallurgical characteristic of pellets. According to state standard GOST 24765 – 81, ore mining and processing enterprises that produce pellets utilize the results of compressive strength tests to evaluate product quality. Current requirements at most pelletizing plants stipulate a static compression strength of 2.0 kN/pellet, while in blast furnace production, the static compressive strength should exceed 2.5 kN/pellet [21 – 23].

The issue of pellet integrity under mechanical impact has garnered significant attention from researchers employing analytical, numerical, and experimental approaches to predict fracture. Mathematical modeling results [24; 25] indicate that when spherical pellets undergo compression, the most unfavorable stress state occurs in the center due to severe tensile radial stresses. Consequently, the ultimate force is commonly used as a measure to assess pellet strength in compressive strength tests. A study in [26] demonstrated that in compressive strength tests, the primary type of fracture involves the initiation and propagation of cracks passing through the center of the magnetite core, where radial tensile stresses are maximal or in close proximity. Interestingly, it was observed that pellets of both 10 – 12 mm and 14 – 16 mm fractions share a common pattern: the larger the relative size of the magnetite core, the smaller the ultimate force [26].

The scientific and technical literature lacks information on how the core structure influences pellet strength.

This study aims to conduct comprehensive research on the structural components (magnetite, titanomagnetite, hematite, titanohematite, aluminosilicate) and pores in the core of burnt unfluxed titanomagnetite pellets. The primary objective is to determine the dependency of the ultimate force under static compression on the pellet core structure.

Materials and methods

To investigate how the structure of pellets influences their compressive strength, we examined 13 burnt unfluxed titanomagnetite pellets within the 10 – 16 mm fraction range. These pellets underwent processing under the standard temperature-time burning conditions applied at JSC EVRAZ Kachkanarsky Mining and Processing Plant. Testing was conducted in accordance with ISO 4700 requirements, using the universal machine BT1-FR050THW.A1K (Zwick GmbH, Germany), with hammer heads moving at a speed of 10 mm/min, and the deformation curve was recorded. The total iron content (Fetotal) in the pellets was determined through titrometry according to GOST 32517.1, and FeO was defined based on GOST 53657. Chemical analysis of CaO, SiO2 , Al2O3 , MgO, TiO2 and V2O5 compounds was conducted using the atomic emission method with inductively coupled plasma on the SpectroBlue device (Spectro, Germany). The chemical composition of the studied pellets is as follows, wt. %: Fetotal 60.90; FeO 3.02; CaO 1.00; SiO2 3.89; Al2O3 2.83; MgO 2.59; TiO2 2.73; V2O5 0.59.

Microsections were prepared based on the fractures of the pellets.

The metallographic study was conducted using the Neophot-2 optical microscope, and the obtained images were analyzed with Siams-700 software. Measurements of grain size, closed macropore size, and the binding phase’s size in the core were carried out on five fields of vision with 20 line segments. The linear method, following the Cavalieri-Acker principle, was employed to determine the phase fraction, closed macropores, and the binding phase [27]. Grain size was determined according to GOST R ISO 643 – 2015, utilizing the conventional phase number classification: 3 – 8 (large), 9 (medium), 10 (small), 11 and higher (very small). To categorize pores, the following terminology was applied [28]: closed pores are located inside the sample and are completely isolated from neighboring ones, while open pores have an open channel connecting them with the external surface of the body. Pore size was assessed by measuring their maximum size in two perpendicular directions. The classification of pores was based on size criteria [29]: macropores – with a diameter dp > 20 µm; mesopores – 20 ≥ dp ≥ 0.2 μm; micropores – dp < 0.2 µm.

X-ray phase analysis (XRF) was performed using the Shimadzu XRD-7000 diffractometer equipped with CuKα radiation in the air, covering the 2θ range from 10 to 85°. The ICDD PDF4 (International Center for Diffraction Data) database was employed for phase identification and quantification.

X-ray spectral microanalysis (XRSM) of the phases was performed on the Tescan Vega II scanning electron microscope, equipped with an Oxford INCA ENERGY 450 energy-dispersive microanalyzer.

Results and discussion

The optical microscope revealed structures in the microstructure of the pellet core, which can be categorized into three types: type 1 (Table 1, samples 1, 3, 4, 5, 9, 10, 11) – the non-oxidized core – magnetite or titanium-magnetite; type 2 (Table 1, samples 2, 6, 7, 8, 12) – partially oxidized core – grains of hematite or titanohematite around magnetite or titanomagnetite; type 3 (Table 1, sample 13) – the oxidized core – hematite or titanohematite.

Table 1. Results of measuring the ultimate compressive force

|

The following phases were detected in the pellets by the XRF method: hematite, magnetite, quartz, magnesium silicate and ferruginous diopside. The XRSM method was used to specify the composition of phases, as diffractograms obtained by the XRF method showed overlapping reflexes for “hematite” and “titanohematite,” as well as “magnetite” and “titano-magnetite” (the ratio of intensity lines, angles 2θ of interplanar distances from the reflexes fully coincide with the ICDD PDF 4 (International Center for Diffraction Data)).

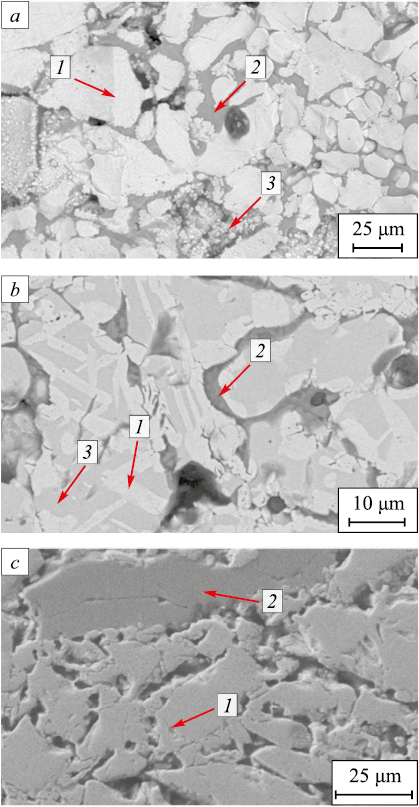

Fig. 1. Electron microscopic image of the pellets’ core structure

Table 2. Results of X-ray spectral microanalysis of the pellets

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The XRSM results (Fig. 1, Table 2) revealed that the pellet core consists of the following phases:

– type 1: phase at the point 1 – titanomagnetite (70.3 % Fe; 0.4 % Ti); phase at the point 2 – aluminosilicate binder composition, wt. %: FeO 19.28; SiO2 45.95; CaO 14.7; Al2O3 13.8; MgO 2.14; phase at the point 3 – magnetite (72.03 % Fe);

– type 2: phase at the point 1 – titanohematite (67.1 % Fe; 1.4 % Ti); phase at the point 2 – aluminosilicate binder composition, wt. %: FeO 26.0; SiO2 40.4; CaO 12.9; Al2O3 12.2; MgO 8.9; phase at the point 3 – hematite (60.86 % Fe);

– type 3: phase at the point 1 – titanohematite (67.5 % Fe; 1.9 % Ti); phase at the point 2 – aluminosilicate binder composition, wt. %: FeO 60.9; SiO2 23.53; CaO 5.6; Al2O3 5.67; MgO 1.3.

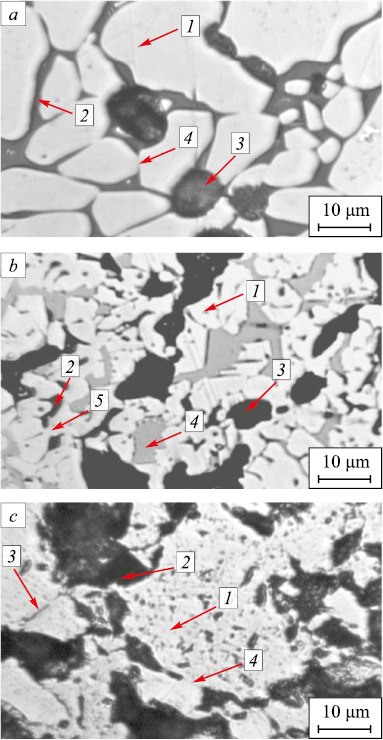

The microstructure of the non-oxidized core, type 1 (Fig. 2, a) consists of magnetite and titanomagnetite grains (1) separated by the aluminosilicate binder (2) and closed pores (3) of various sizes, ranging from spherical to near-spherical. The magnetite or titanomagnetite grains are interconnected, forming a magnetite or titanomagnetite surface contact during sintering (4). The microstructure of the partially oxidized core (type 2) (Fig. 2, b) comprises interconnected structural components of hematite and titanohematite (1), titanomagnetite and magnetite (4), and the aluminosilicate binder (2). Grain shells consisting of hematite (titanohematite) are connected, forming hematite (titanohematite) surface contact during sintering (5). Some grains are separated by closed pores (3). The microstructure of the oxidized core, type 3 (Fig. 2, c) consists of titanohematite and hematite grains (1) separated by open pores of complex shape (2), constituting narrow channels alternating with sharp bulging, aluminosilicate binder (3). The hematite (titanohematite) grains, when joined during sintering, form a hematite (titanohematite) surface contact (4).

Fig. 2. Typical microstructures of the pellet core in the plane of ultimate action: |

Upon comparing the results from [15 – 20] with the obtained core microstructure, it is assumed that the oxidation of magnetite (titanomagnetite) in type 1, pellets occurred in the temperature range of 700 – 900 °C, in type 2 pellets in the range of 400 – 600 °C, and in type 3 pellets in the range of 200 – 400 °С.

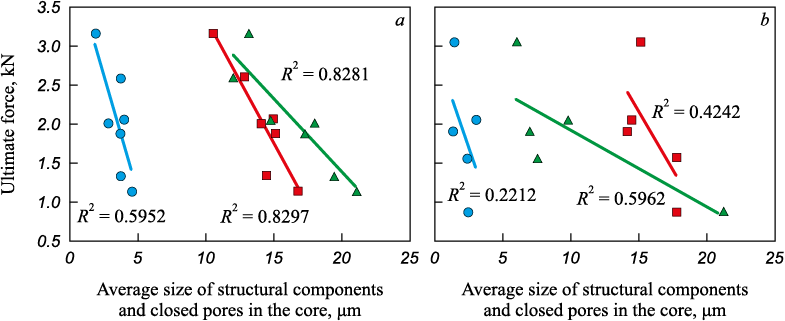

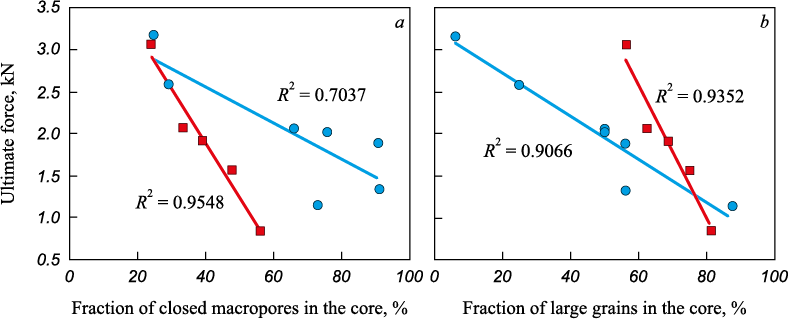

In Figs. 3 – 5, the research and calculation results are presented in graphical dependencies on the ultimate force.

Fig. 3 depicts the ultimate force as a function of the average size of grains of magnetite (titanomagnetite), hematite (titanohematite), closed macropores, and aluminosilicate binder in pellet cores. The analysis of these dependencies reveals a stable correlation (correlation coefficient R2 > 0.7). Fig. 3, a demonstrates that when the average sizes of magnetite (titanomagnetite) are 10 – 15 μm, closed macropores are 12 – 15 μm, and the aluminosilicate binder 1.5 – 2.0 µm, the static compressive strength requirements of 2.5 kN/pellet are met. In the structure under review, both structural components and macropores play a significant role in influencing the ultimate force. However, for type 2 structure (Fig. 3, b), no linear relationship was observed among the average grain size of hematite (titanohematite), average sizes of closed macropores, aluminosilicate binder, and ultimate force.

Fig. 3. Effect of the average grain structural components in the core on the ultimate force: |

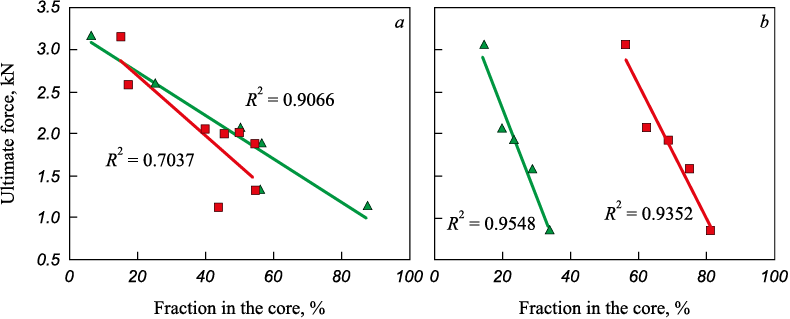

A linear relationship was identified between the ultimate force in pellet cores and the fraction of large magnetite (titanomagnetite) grains and closed macropores (Fig. 4, a). The trend shows that the smaller the fraction of closed macropores and large grains of magnetite (titanomagnetite), the greater the ultimate force. This pattern is also observed in the structure of type 2.

Fig. 4. Effect of the fraction of large grains and closed macropores in the core on the ultimate force: |

For all structures (type 1, 2), a consistent observation was made: as the number of closed macropores and large grains increased, the ultimate force decreased from 3.5 to 0.87 kN/pellet (Fig. 5).

Fig. 5. Effect of the fraction of closed macropores (a) and large grains (b) in the core |

To produce pellets with an ultimate force exceeding 2.5 kN/pellet, the following conditions should be met: for type 1 structure – the number of closed macropores should be less than 18 %, and the number of large grains should not exceed 25 %; for type 2 structure – these values should be 25 and 60 %, respectively. For pellets with an ultimate force exceeding 2 kN/pellet: for type 1 structure – the number of closed macropores should be less than 40 % and the number of large grains should not exceed 50 %; for type 2 structure – these values should be 25 and 65 %, respectively.

The ultimate force of 0.70 kN/pellet (Type 3) does not meet the static compressive strength requirements due to the large number of open macropores (47 %) and the number of large grains (75 %).

An important observation is that for both types of structures, pellets with ultimate forces exceeding 2.5 kN/pellet can be obtained.

Conclusions

The pellet core was found to exhibit three types of structures: type 1 (non-oxidized core): titanomagnetite and magnetite grains, including sintered ones, closed macropores, and aluminosilicate binder; type 2 (partially oxidized core): around magnetite (titanomagnetite), there are hematite and titanohematite grains, including sintered ones, closed macropores, and aluminosilicate binder; type 3 (oxidized core): hematite and titanohematite grains, including sintered ones, open pores, and aluminosilicate binder.

In the manufacturing of pellets capable of withstanding compressive loads exceeding 2.5 kN, it is essential to have the following criteria: for type 1 structure: the number of closed macropores should be less than 18 %, and the number of large grains should exceed 25 %; for type 2 structure: the values should be 25 % for closed macropores and 60 % for large grains.

The ultimate force decreases to 0.70 kN/pellet for the type 3 structure due to the presence of a significant number of open macropores and large grains in the pellet core.

References

1. Shumakov N.S., Dmitriev A.N., Garaeva O.G. Raw Materials and Fuel for Blast Furnace Smelting. Yekaterinburg: UrB RAS; 2007:392. (In Russ.).

2. Gul A., Sirkeci A.A., Boylu F., Guldan G., Burat F. Improvement of mechanical strength of iron ore pellets using raw and activated bentonites as binders. Physicochemical Problems of Mineral Processing. 2014;51(1):23–36. https://dx.doi.org/10.5277/ppmp150203

3. Bardavelidze G.G., Bragin V.V., Spirin N.A., Pigarev S.P. Research of pellets from concentrate of oxidized ferruginous quartzites of JSC “Mikhailovsky GOK”. Metallurg. 2021;(12):11–18. (In Russ.). https://doi.org/10.52351/00260827_2021_12_11

4. Shaik M.B., Sekhar C., Dwarapudi S., Gupta N., Paul I., Patel A.K., Tudu S., Kumar A. Characterization of colemanite and its effect on cold compessive strengh and swelling index of iron ore pellets. Mining, Metallurgy and Exploration. 2021;38(1):217–231. https://doi.org/10.1007/s42461-020-00331-5

5. Guo H., Shen F.-M., Jiang X., Gao Q.-J., Ding G.-G. Effects of MgO additive on metallurgical properties of fluxed-pellet. School of Metallurgy, Northeastern University. 2019;26:3238–3251. https://doi.org/10.1007/s11771-019-4249-6

6. Li W., Fu G., Chu M., Zhu M. Influence of MgO on the oxidation and induration of Hongge vanadium titanomagnetite pellets. Ironmaking and Steelmaking. 2019;47(8):837–843. https://doi.org/10.1080/03019233.2019.1615815

7. Yi Y., Li G., Gao P., Zhang X., Zhang Y., Zhang J., Huang J. Effect of humic acid binder on oxidation roasting of vanadium-titanium magnetite pellets via straight-grate process. Crystals. 2021;11(11):1–11. https://doi.org/10.3390/cryst11111283

8. Mohamed O.A., Shalabi M.E.H., El-Hussiny N.A., Khedr M.H., Mostafa F. The role of normal and activated bentonite on the pelletization of barite iron ore concentrate and the quality of pellets. Powder Technology. 2003;130(1-3):277–282. https://doi.org/10.1016/S0032-5910(02)00205-X

9. Abzalov V.M., Gorbachev V.A., Evstyugin S.N., Klein V.I., Leont’ev L.I., Yur’ev B.P. Physicochemical and Thermal Engineering Fundamentals of Iron Ore Pellets Production. Yekaterinburg: MITs; 2015:335. (In Russ.).

10. Yur’ev B.P., Bruk L.B., Spirin N.A., Sheshukov O.Yu., Gol’tsev V.A., Shevchenko O.I., Metelkin A.A. Fundamentals of the Theory of Processes in Iron Ore Pellets Firing. Nizhny Tagil: NTI (Branch) UrFU; 2018:310. (In Russ.).

11. Bhuiyan I.U., Mouson J., Schröppel B., Kaech A., Dobryden I., Forsmo S.P.E., Hedlund J. Microstructure of bentonite in iron ore green pellets. Microscopy and Microanalysis. 2014;20(1):33–41. https://doi.org/10.1017/S1431927613013950

12. Kawatra S.K., Ripke S.J. Effects of bentonite fiber formation in iron ore pelletization. International Journal of Mineral Processing. 2002;65(3-4):141–149. https://doi.org/10.1016/s0301-7516(01)00062-x

13. Yur’ev B.P., Dudko V.A. Influence of the pellets’ structural characteristics upon their metallurgical properties. Stal’. 2021;(4):2–6. (In Russ.).

14. Ericksson A., Andersson C., Ahmed H., Dahlin A., Kumar T.K.S., Semberg P. Effect of varied oxygen levels on the oxidation of a magnetite pellet bed during pot furnace induration. ISIJ International. 2021;61(5):1439–1449. https://doi.org/10.2355/isijinternational.ISIJINT-2020-469

15. Таng M., Cho H.J., Pistorius P.C. Early gaseous oxygen enrichment to enhance magnetite pellet oxidation. Metallurgical and materials Transactions B. 2014;45(4):1304–1314. https://doi.org/10.1007/s11663-014-0064-5

16. Kumar T.K.S., Viswanathan N.N., Ahmed H., Dahlin A., Andersson C., Bjorkman B. Developing the oxidation kinetic model for magnetite pellet. Metallurgical and Materials Transactions B. 2019;50(1):162–172. https://doi.org/10.1007/s11663-018-1423-4

17. Gorbachev V.A., Abzalov V.M., Yu’ev B.P. Conversion of magnetite to hematite in iron-ore pellets. Izvestiya. Ferrous Metallurgy. 2007;50(4):27–30.

18. Song S., Pistorius P.C. Formation of hematite whiskers during magnetite concentrate oxidation. ISIJ International. 2019;59(10):1765–1769. https://doi.org/10.2355/isijinternational.ISIJINT-2018-755

19. Forsmo S.P.E., Forsmo S.-E., Samskog P.-O., Björkman B.M.T. Mechanisms in oxidation and sintering of magnetite iron ore green pellets. Power Technology. 2008;183(2):247–259. https://doi.org/10.1016/j.powtec.2007.07.032

20. Timofeeva A.S., Nikitchenko T.V., Fedina V.V., Akul’shina I.I. Effect of flus on the hardening of pellet during heat treatment. Metallurgist. 2017;61(8):700–702. https://doi.org/10.1007/s11015-017-0552-3

21. Gao Q.-J., Shen F.-M., Wei G., Jiang X., Zheng H.-Y. Effects of MgO containing additive on low-temperature metallurgical properties of oxidized pellet. Journal of Iron and Steel Research International. 2013;20(7):25–28. https://doi.org/10.1016/S1006-706X(13)60121-1

22. Nikitchenko T.V., Timofeeva A.S., Kozhuhkov A.A. Modification additions influence on the iron ore pellets forming. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2018;1(4):67–72. (In Russ.).

23. Gan M., Sun Y.-F., Fan X.-H., Ji Z.-Y. Lv W., Chen X.-L., Jiang T. Preparing high-quality vanadium titano-magnetite pellets for large-scale blast furnaces as ironmaking burden. Ironmaking and Steelmaking. 2018;47(4):1–8. https://doi.org/10.1080/03019233.2018.1492500

24. Gustafsson G., Häggblad H-A., Nishida M., Larsson S., Jonsén P. Fracture probability modelling of impact-loaded iron ore pellets. International Journal of Impact Engineering. 2017;102:180–186. http://dx.doi.org/10.1016/j.ijimpeng.2016.12.014

25. Gustafsson G., Häggblad H.-A., Jonsén P. Multi-particle finite element modelling of the compression of iron ore pellets with statistically distributed geometric and material data. Powder Technology. 2013;239:231–238. http://dx.doi.org/10.1016/j.powtec.2013.02.005

26. Dmitriev A.N., Smirnova V.G., Vyaznikova E.A., Dolmatov A.V., Vit’kina G.Yu. Influence of structure of burned pellets on strength and destruction in static compression tests. Izvestiya. Ferrous Metallurgy. 2021;64(11):785–792. (In Russ.). https://doi.org/10.17073/0368-0797-2021-11-785-792

27. Saltykov S.A. Stereometric Metallography. Moscow: Metallurgiya; 1970:376. (In Russ.).

28. Klobes Р., Meyer К. Ronald, Munro R.G. Porosity and Specific Surface Area Measurements for Solid Materials. NIST Recommended Practice Guide. U.S. GOVERNMENT Printing Office; Washington: 2006.

29. Abzalov V.M., Klein V.I., Yur’ev B.P. Oxygen diffusion in pores of an iron ore pellet. Izvestiya. Ferrous Metallurgy. 2008;51(6):7–9. (In Russ.).

30.

About the Authors

A. N. DmitrievRussian Federation

Andrei N. Dmitriev, Dr. Sci. (Eng.), Chief Researcher of the Laboratory of Pyrometallurgy of Reduction Processes

101 Amundsen Str., Yekaterinburg 620016, Russian Federation

V. G. Smirnova

Russian Federation

Valentina G. Smirnova, Leading Engineer of the Laboratory of Pyrometallurgy of Reduction Processes

101 Amundsen Str., Yekaterinburg 620016, Russian Federation

E. A. Vyaznikova

Russian Federation

Elena A. Vyaznikova, Junior Researcher of the Laboratory of Pyrometallurgy of Reduction Processes

101 Amundsen Str., Yekaterinburg 620016, Russian Federation

G. Yu. Vit’kina

Russian Federation

Galina Yu. Vit’kina, Cand. Sci. (Eng.), Senior Researcher, Head of the Laboratory of Pyrometallurgy of Reduction Processes

101 Amundsen Str., Yekaterinburg 620016, Russian Federation

A. S. Smirnov

Russian Federation

Aleksandr S. Smirnov, Cand. Sci. (Eng.), Senior Researcher at the Laboratory of Deformation Mechanics

34 Komsomolskaya Str., Yekaterinburg 620049, Russian Federation

Review

For citations:

Dmitriev A.N., Smirnova V.G., Vyaznikova E.A., Vit’kina G.Yu., Smirnov A.S. Effect of structure of unfluxed burnt titanomagnetite pellets on strength under static compression. Izvestiya. Ferrous Metallurgy. 2023;66(6):696-704. https://doi.org/10.17073/0368-0797-2023-6-696-704