Scroll to:

Preservation conditions of hot work hardening in die steel with regulated austenitic transformation during exploitation

https://doi.org/10.17073/0368-0797-2023-5-554-563

Abstract

Die steels with regulated austenitic transformation during exploitation (RATE steels) are a new class of tungsten-free steels for hot forming at operating temperatures up to 750 – 800 °C. High durability of the pressing tool and its long service life are ensured by the ability of these steels to preservation of hot work hardening. This circumstance distinguishes RATE steels from traditional alloy steels, which are prone to softening at high temperatures. However, the temperature ranges for the preservation of hot hardening in RATE steels was not systematically studied, which makes it difficult to use a pressing tool more efficiently. In this paper, we study the mechanical behavior of RATE die steel during thermo-mechanical treatment in a wide temperature range, including the stage of preliminary deformation at lower temperatures and the stage of main deformation at higher temperatures corresponding to operating temperatures of the pressing tool. The thermo-mechanical treatment was carried out using a hardening-deformation dilatometer DIL 805 A/D according to the compression mode. We obtained the true stress-strain curves and determined the mechanical characteristics and strain hardening index. Size of the former austenite grain in the steel structure after thermo-mechanical treatment was measured. The temperature-force conditions for enhancing hot hardening or stabilizing hot hardening, or softening, were established. It is shown that the hardening achieved at the stage of preliminary deformation at a temperature of 450 °C is enhanced at the stage of main deformation at temperatures in the range from 550 to 800 °C, while in this temperature range the tendency to increase hot hardening is weakened.

For citations:

Kruglyakov A.A., Rogachev S.O., Sokolov P.Yu., Priupolin D.V. Preservation conditions of hot work hardening in die steel with regulated austenitic transformation during exploitation. Izvestiya. Ferrous Metallurgy. 2023;66(5):554-563. https://doi.org/10.17073/0368-0797-2023-5-554-563

Introduction

The heat resistance of α-iron-based steels at temperatures around 690 – 700 °C is considered ultimate. Consequently, the most heat-resistant die steels, such as 5Kh3V3MFS, 3Kh2V8F (also known as DIN: X30WCrV9-3, AISI/SAE: H21 or H21A), 4Kh2V5MF, and 4Kh2V4FS, which boast high tungsten content, are typically limited to operating temperatures during hot pressing up to 660 – 680 °C [1 – 3]. Tungsten-free steels like 70Kh3G2FTR or 4Kh5MGFS have even lower operating temperatures [4; 5]. While the operating temperatures of austenitic steels are somewhat higher, their manufacturability is notably low [6 – 8].

In the 1980s, A.D. Ozerskii and A.A. Kruglyakov pioneered the development of die steels featuring a controlled austenitic transformation during exploitation, (RATE steels). These were tungsten-free steels primarily composed of α-iron, designed for high-pressure hot working at operating temperatures reaching up to 750 – 800 °C [9 – 11]. The exceptional durability of these press tools and their extended service life stem from the steels’ capability to maintain hot strain hardening, also known as hot work hardening [12; 13]. This quality distinguishes RATE steels from conventional alloy steels, which are susceptible to softening under high-temperature conditions. The primary cause of this softening lies in the onset of recovery processes and dynamic recrystallization [14 – 16]. As a consequence, there is a notable alteration in the shape of stress-strain curves at elevated temperatures [17; 18].

The inclination towards hot work hardening in RATE steels underwent experimental scrutiny through thermomechanical treatment, involving initial deformation at a lower temperature followed by subsequent deformation at a higher temperature [19 – 21]. The hardening level attained during the preliminary deformation stage was not only sustained but further augmented during the main deformation phase. However, these studies confined the preliminary deformation temperature to 450 °C and the main deformation temperature to 750 °С. Consequently, the temperature ranges conducive to showcasing hot hardening in such steels have not been comprehensively explored. This is a crucial aspect in determining pre-hardening temperatures for the die and operational temperatures that ensure optimal and prolonged die tool performance.

This study aims to investigate the impact of hot deformation temperature on the manifestation of hot hardening in RATE die steel, focusing on a medium-carbon Fe – C – Si – Cr – Ni – Mn – Mo – V – Ti – Nb steel as an illustrative example.

Materials and methods

In this study, RATE die steel, specifically of the 4Kh2N3M2G4FTBS type [22], was utilized subsequent to a softening heat treatment, resulting in an approximate hardness of ~34 HRC.

Thermomechanical treatment (TMT) was conducted using cylindrical samples measuring 10 mm in height and 5 mm in diameter on a DIL 805 A/D hardening-deformation dilatometer. The TMT process comprised the following sequential stages:

– austenitization at 1150 °C for 15 min;

– a 15 min holding period and preliminary plastic deformation at a temperature range of 400 – 500 °C (in intervals of 50 °C);

– a 15 min holding period and main plastic deformation at a temperature range of 550 – 850 °C (in intervals of 50 °C).

After TMT, the samples underwent free cooling (~10 °C/s).

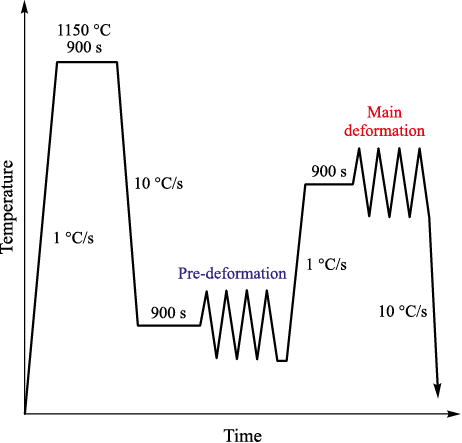

The layout of the TMT protocol is represented in Fig. 1.

Fig. 1. Thermo-mechanical treatment diagram |

The deformation process was carried out according to a compression sequence involving five cycles, with each cycle involving deformation within the range of 1 – 2 % and a deformation rate set at 1 – 2 %, rate: 0.1 s\(^–\)1 ). Process curves capturing “true stress – true deformation” coordinates were recorded throughout the deformation sequences.

The strain hardening index n was calculated utilizing the equation S = Ke\(^{n}\), where S is the true stress; K is the coefficient, and e is the true deformation.

Microstructural analysis of polished sections involved etching in a 5 % aqueous solution of nitric acid. The resulting microstructure was examined using an NIM-100 optical microscope at a magnification of 200x. The grain size was determined from the microstructure images obtained by employing the secant method.

Microhardness was assessed using the Vickers method with a Micromet 5101 Buehler instrument. The experimental parameters were as follows: a load of 300 g, load application time of 10 s, and microscope magnification set at 500x. Measurements were conducted on transverse polished sections of samples subsequent to TMT in two distinct zones: at the periphery and at the center of the sample.

Results and discussion

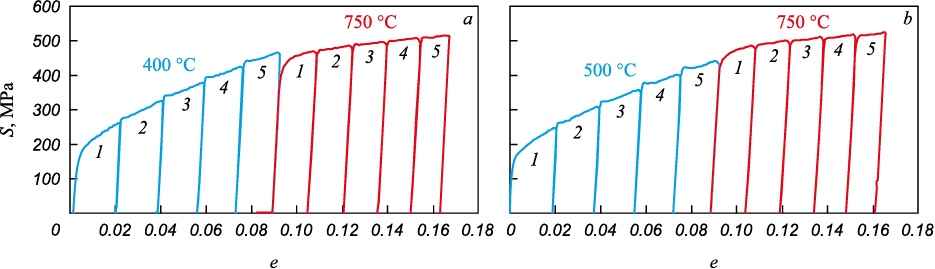

The mechanical characteristics of the RATE steel during TMT with varying temperatures for preliminary deformation and a consistent temperature for the main deformation are detailed in Table 1, while the strain curves are visually represented in Fig. 2. Similar to earlier investigations [19; 20], multiple plastic deformations at 450 °C led to a notable strengthening of the steel: the maximum cycle stress (Smax) escalated from the initial range of 248 – 263 to 441 – 467 MPa (1.8 times). This achieved level of hardening remained steady during the first cycle of main deformation at 750 °C and further increased across the subsequent four cycles: Smax rose to 517 – 523 MPa (1.1 times). Altering the temperature within the preliminary deformation stage from 400 to 500 °C exerted a marginal influence on the hardening level, both during preliminary and main deformations. At equivalent degrees of deformation, the maximum stress disparity was no more than 6 %. However, this difference diminished as the degree of primary deformation increased. The heightened hardening observed in the first cycle of main deformation, compared to the fifth cycle of preliminary deformation, was most pronounced (10 %) when the preliminary deformation temperature was set at 500 °C.

Fig. 2. Stress-strain curves of RATE steel during TMT with varying pre-deformation

Table 1. Mechanical characteristics of RATE steel during TMT

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

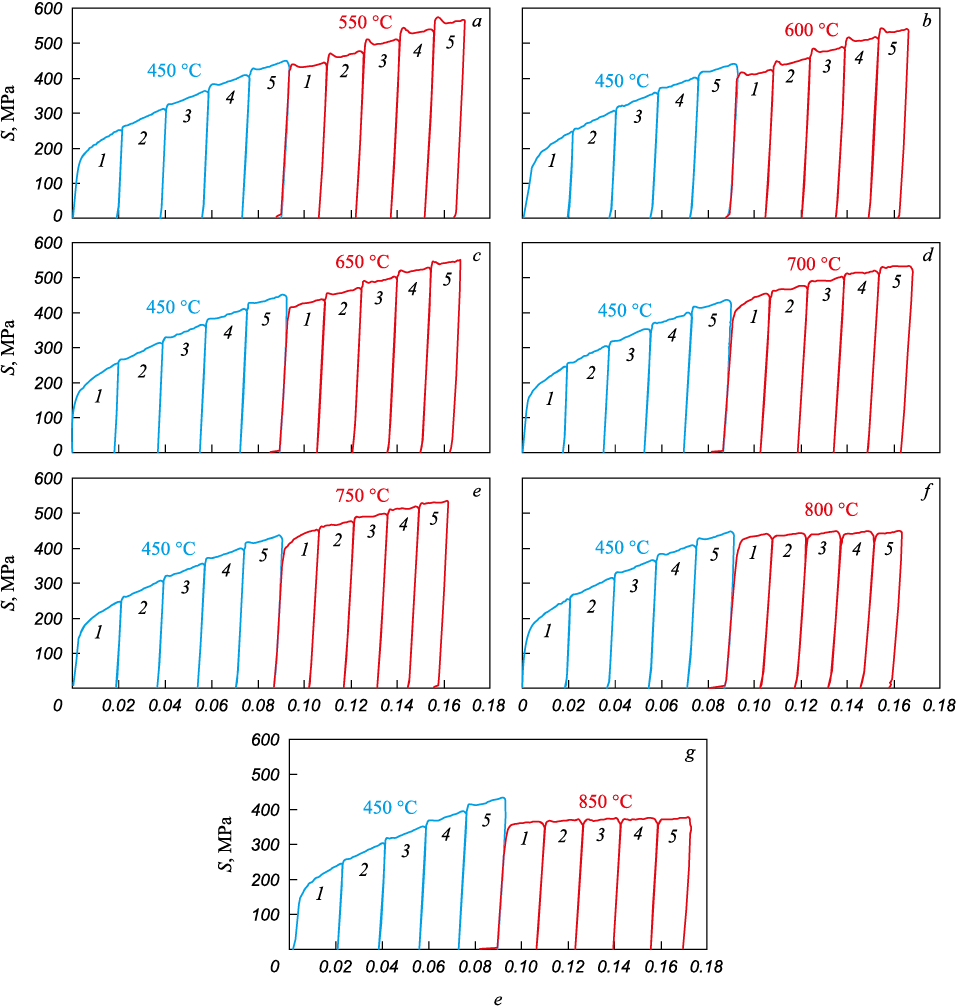

The mechanical characteristics of the RATE steel during TMT at a constant temperature for preliminary deformation while varying the temperature of the primary deformation are summarized in Table 2, with corresponding strain curves presented in Fig. 3.

Table 2. Mechanical characteristics of RATE steel during TMT

Fig. 3. Stress-strain curves of RATE steel during TMT with varying the main deformation temperature, °C: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The achieved level of hardening during the preliminary deformation stage at a temperature of 450 °C demonstrates intensification during the main deformation phase at temperatures ranging from 550 to 750 °C. Specifically, at 550 °C, Smax increases to 569 MPa (a 27 % increase), while at 750 °C, it reaches 518 MPa (a 15 % rise). Notably, as the temperature of the main deformation escalates from 550 to 750 °C, the propensity for hot hardening diminishes, indicated by a decrease in the strain hardening index ‘n’ from 0.16 to 0.06. Further elevating the temperature of the main deformation to 800 °C does not yield an additional increase in hot hardening; instead, it stabilizes at Smax levels of around 450 MPa (n = 0.01). Eventually, with a subsequent increase in the temperature of the main deformation to 850 °C, some softening of the steel becomes apparent: Smax in the initial deformation cycle drops to 368 MPa (a 20 % decrease), maintaining this level across the subsequent four deformation cycles (n = 0.02). It’s crucial to highlight that even at 850 °C, the Smax values surpass those observed during the initial hardening cycles at 450 °C. Remarkably, the strength level of the RATE steel at 850 °C exceeds that of high-alloy 10Cr–10Ni–5Mo–2Cu steel (under comparable degrees of deformation and loading rates) [23].

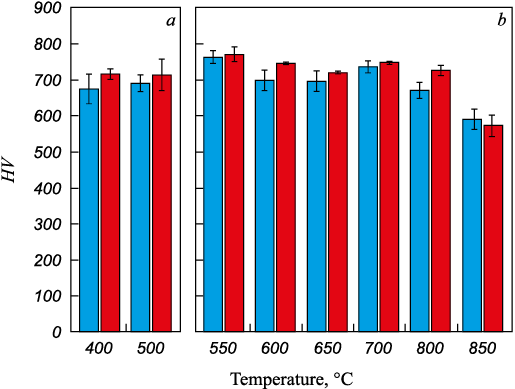

The microhardness of the RATE steel after TMT and cooling to room temperature mainly correlates with the level of hot hardening after the main deformation (Fig. 4). Consequently, following preliminary deformation within the range of 400 – 500 °C and subsequent cooling, the microhardness remains constant at approximately 700 HV. After cooling from main deformation temperatures spanning 550 – 800 °C, a minor decreasing trend in microhardness is observed, ranging from 770 to 700 HV. After main deformation at a temperature of 850 °C, the microhardness sharply drops to 580 HV. The disparity in microhardness between the sample’s center and its periphery is negligible.

Fig. 4. Dependence of RATE steel microhardness on temperature |

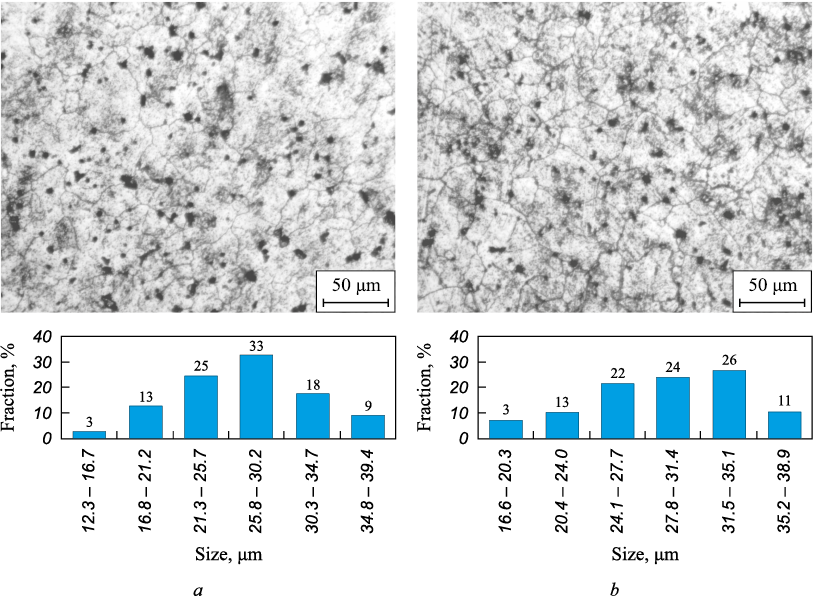

Fig. 5 illustrates the microstructure, specifically the former austenite grain of the RATE steel after TMT, varying the temperature of preliminary deformation, and cooling to room temperature, alongside histograms depicting grain size distribution.

Fig. 5. Former austenite grain in the structure of RATE steel after TMT |

Table 3 provides the former austenite grain size after TMT, showcasing that an increase in the preliminary deformation temperature from 400 to 500 °C doesn’t influence the former austenite grain’s size, which averages around 28 μm, aligning with 7 points according to State Standard GOST 5639–82.

Table 3. Size of the former austenite grain in the structure of RATE steel

|

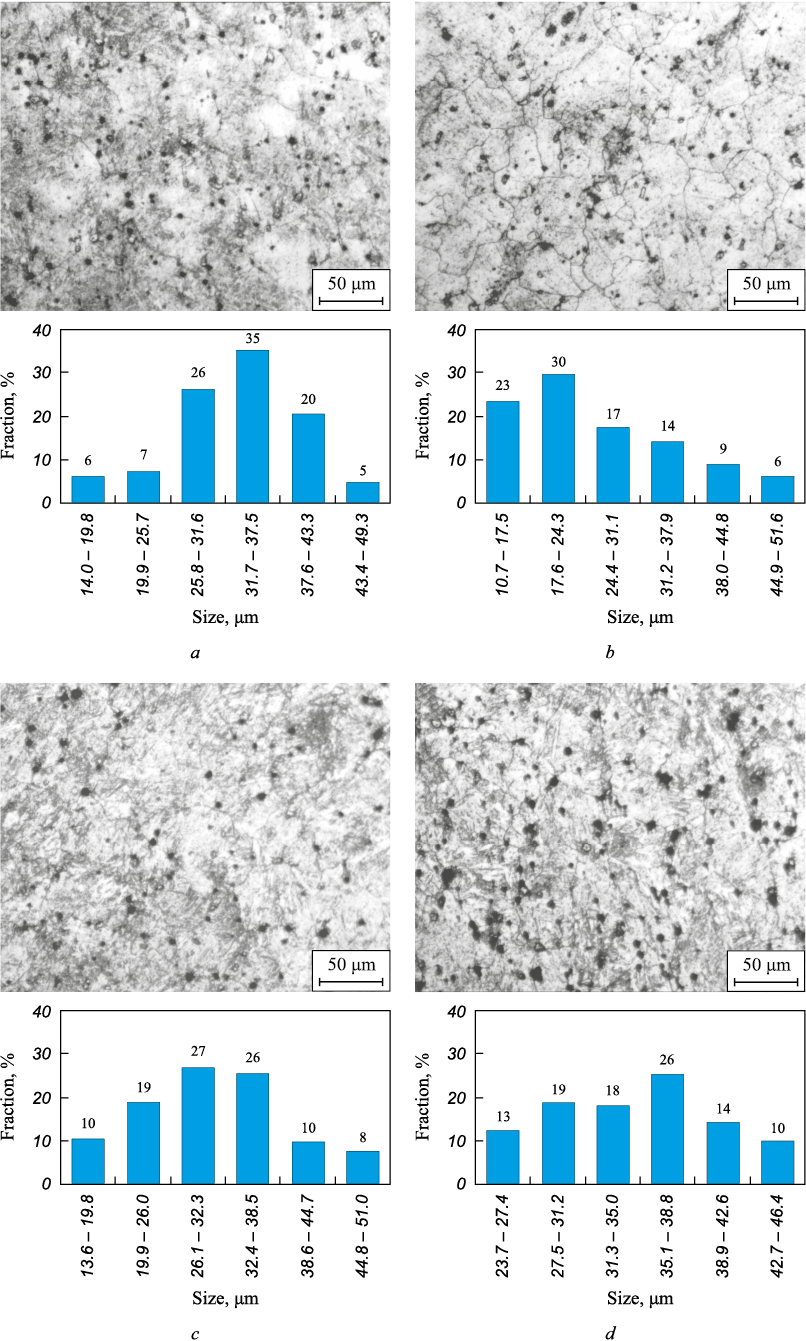

Fig. 6 illustrates the microstructure, particularly the former austenite grain of the RATE steel after TMT, while varying the temperature of the main deformation and subsequent cooling to room temperature. Additionally, histograms representing grain size distribution are provided.

Fig. 6. Former austenite grain in the structure of RATE steel after TMT |

Table 4 presents the former austenite grain size following TMT at various main deformation temperatures. The data reveals a slight inclination towards an increase in the former austenite grain size from 29 to 35 μm as the main deformation temperature escalates from 550 to 850 °C. This progression aligns with 7 points according to State Standard GOST 5639–82.

Table 4. Size of the former austenite grain in the structure of RATE steel

|

Conclusions

The rise in preliminary deformation temperature from 400 to 500 °C minimally impacts the strengthening of steel with RATE at both the preliminary and main deformation stages at a constant temperature of 750 °C.

At a constant preliminary deformation temperature of 450 °C, the level of hardening achieved intensifies during the main deformation stage within the range of 550 to 750 °C. However, this strain hardening tendency weakens with rising temperatures. Further elevation of the main deformation temperature to 800 °C results in a stabilized strengthened state. Subsequently, a marginal softening is observed up to 850 °C.

Increasing the preliminary deformation temperature from 400 to 500 °C at a constant main deformation temperature of 750 °C does not significantly alter the size of the former austenite grain, which averages around 28 μm. Conversely, a subtle increase in the former austenite grain size from 29 to 35 μm is noted when the main deformation temperature rises from 550 to 850 °C, while maintaining a constant preliminary deformation temperature of 450 °C.

The findings suggest that RATE steel demonstrates efficient performance across a broad range of tool heating temperatures, spanning from 550 to 800 °C. Notably, even at a heating temperature of 850 °C, the steel retains a considerably high strength margin of 380 MPa.

References

1. Gorbatyuk S.M., Morozova I.G., Naumova M.G. Development of the working model of production reindustrialization of die steel heat treatment. Izvestiya. Ferrous Metallurgy. 2017; 60(5):410–415. https://doi.org/10.17073/0368-0797-2017-5-410-415

2. Ozerski A.D., Kruglyakov A.A. Die Steel with Regulated Austenitic Transformation during Exploitation. Leningrad: LDNTP; 1988:28. (In Russ.).

3. Poznyak L.A. Tool Steels. Kyiv: Naukova Dumka; 1996:488. (In Russ.).

4. Orlov Yu.G., Dudetskaya L.R. Materials and Technologies for the Production of Cast Die Tools. Minsk, Belarus: Navuka; 2010:171. (In Russ.).

5. Kruglyakov A.A. Effect of alloying elements on the hardening of die steels in the austenitic state during high-temperature plastic deformation. Russian Metallurgy (Metally). 2019;2019(10):1096-1101. https://doi.org/10.1134/S0036029519100343

6. Kruglyakov A.A., Nikulin S.A. Structure and features of strain hardening of die steels with controlled austenite transformation. Deformatsiya i razrushenie materialov. 2014;(11):23-25. (In Russ.).

7. Loginov Yu.N., Inatovich Yu.V. Tools for Metal Pressing. Yekaterinburg: Ural. Gos. Univ.; 2014:224. (In Russ.).

8. Fedulov V.N. Influence of quantitative alloying of tool steels for hot deformation on their hardening level. Lit’e i metallurgiya. 2015;(3):123–131. (In Russ.).

9. Krylova S.E., Kletsova O.A., Gryzunov V.I., Fot A.P., Tavtilov I.Sh. Effect of heat treatment on the structure and properties of die steel 70Kh3G2FTR. Metal Science and Heat Treatment. 2017;59(10):4–10. https://doi.org/10.1007/s11041-018-0198-1

10. Wang L., Li H., Li G., Tang Z., Ma M. Microstructural evolution and flow behavior of 2205 and 2507 duplex stainless steel during double pass hot compressive deformation. Chinese Journal of Materials Research. 2016;30(12):888–896. https://doi.org/10.11901/1005.3093.2016.410

11. Fomina O.V. Structure formation of high strength nitrogen-bearing steel under hot deformation. Izvestiya. Ferrous Metallurgy. 2017;60(3):216–222. (In Russ.). https://doi.org/10.17073/0368-0797-2017-3-216-222

12. Alimi A., Fajoui J., Kchaou M., Branchu S., Elleuch R., Jacquemin F. Multi-scale hot working tool damage (X40CrMoV5-1) analysis in relation to the forging process. Engineering Failure Analysis. 2016;62:142–155. https://doi.org/10.1016/j.engfailanal.2015.11.031

13. Llanos L., Pereda B., Lopez B., Rodriguez-Ibabe J.M. Hot deformation and static softening behavior of vanadium microalloyed high manganese austenitic steels. Materials Science and Engineering: A. 2016;651:358–369. https://doi.org/10.1016/j.msea.2015.10.123

14. Petković R.A., Luton M.J., Jonas J.J. Recovery and recrystallization of carbon steel between intervals of hot working. Canadian Metallurgical Quarterly. 1975;14(2):137–145. https://doi.org/10.1179/000844375795050201

15. Graetz K., Miessen C., Gottstein G. Analysis of steady-state dynamic recrystallization. Acta Materialia. 2014;67:58–66. https://doi.org/10.1016/j.actamat.2013.12.005

16. Sakai T., Belyakov A., Kaibyshev R., Miura H., Jonas J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Progress in Materials Science. 2014;60:130–207. https://doi.org/10.1016/j.pmatsci.2013.09.002

17. Giordani E.J., Jorge Jr. A.M., Balancin O. Proportion of recovery and recrystallization during interpass times at high temperatures on a Nb- and N-bearing austenitic stainless steel biomaterial. Scripta Materialia. 2006;55(8):743–746. https://doi.org/10.1016/j.scriptamat.2006.05.015

18. Souza R.C., Silva E.S., Jorge Jr. A.M., Cabrera J.M., Balancin O. Dynamic recovery and dynamic recrystallization competition on a Nb- and N-bearing austenitic stainless steel biomaterial: Influence of strain rate and temperature. Materials Science and Engineering: A. 2013;582:96–107. https://doi.org/10.1016/j.msea.2013.06.037

19. Krugljakow A.A., Nikulin S.A., Rogachev S.O., Nguyen H.X., Lebedeva N.V., Panova G.A. Hot-hardening phenomenon in die steel during thermomechanical processing. Materials Letters. 2020;266:127475. https://doi.org/10.1016/j.matlet.2020.127475

20. Krugljakow A.A., Rogachev S.O., Lebedeva N.V., Sokolov P.Yu., Arsenkin A.M., Khatkevich V.M. On the nature of hot work hardening phenomenon in die steel with regulated austenitic transformation during exploitation. Materials Science and Engineering: A. 2022;833:142548. https://doi.org/10.1016/j.msea.2021.142548

21. Lebedeva N.V., Panova G.A., Kruglyakov A.A., Rogachev S.O. Method for hardening treatment of tool from die steels. Patent no. 2776893 RU. Publ. 28.07.2022. (In Russ.).

22. Nikulin S.A., Kruglyakov A.A., Rogachev S.O., Panova G.A., Lebedeva N.V. Die steel. Patent no. 2744584 RU. Publ. 11.03.2021. (In Russ.).

23. Abbasi S.M., Shokuhfar A. Prediction of hot deformation behaviour of 10Cr–10Ni–5Mo–2Cu steel. Materials Letters. 2007;61(11–12):2523–2526. https://doi.org/10.1016/j.matlet.2006.09.050

About the Authors

A. A. KruglyakovRussian Federation

Aleksandr A. Kruglyakov, Cand. Sci. (Eng.), General Director

106 b Friedrichstrasse, Berlin D-10117, Germany

S. O. Rogachev

Russian Federation

Stanislav O. Rogachev, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Metallography and Physics of Strength”, National University of Science and Technology “MISIS”; Research Associate, Baikov Institute of Metallurgy and Materials Science, Russian Academy of Sciences

4 Leninskii Ave., Moscow 119049, Russian Federation

49 Leninskii Ave., Moscow 119334, Russian Federation

P. Yu. Sokolov

Russian Federation

Pavel Yu. Sokolov, Senior Lecturer

4 Leninskii Ave., Moscow 119049, Russian Federation

D. V. Priupolin

Russian Federation

Denis V. Priupolin, Student

4 Leninskii Ave., Moscow 119049, Russian Federation

Review

For citations:

Kruglyakov A.A., Rogachev S.O., Sokolov P.Yu., Priupolin D.V. Preservation conditions of hot work hardening in die steel with regulated austenitic transformation during exploitation. Izvestiya. Ferrous Metallurgy. 2023;66(5):554-563. https://doi.org/10.17073/0368-0797-2023-5-554-563