Scroll to:

High-temperature strength of die steel with regulated austenitic transformation during exploitation after quenching and tempering

https://doi.org/10.17073/0368-0797-2023-4-442-444

Abstract

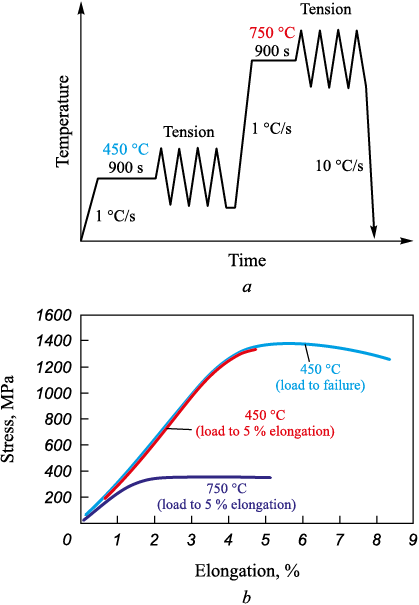

Steels with regulated austenitic transformation during exploitation (RATE) are a new class of ferritic-based tungsten-free tool steels for hot forming. The study obtained quantitative data on the high-temperature strength of RATE steel of new composition after quenching and tempering. The stress-strain curves are plotted and the tendency of steel to strain hardening at temperatures of 450 and 750 °C is estimated. It was established that at a temperature of 750 °C, corresponding to the operating temperature, RATE steel has a stronger tendency to work hardening than at a temperature of 450 °C.

For citations:

Kruglyakov A.A., Rogachev S.O., Molyarov A.V. High-temperature strength of die steel with regulated austenitic transformation during exploitation after quenching and tempering. Izvestiya. Ferrous Metallurgy. 2023;66(4):442-444. https://doi.org/10.17073/0368-0797-2023-4-442-444

Steels with regulated austenite transformation during exploitation (RATE) represent a novel category of tungsten-free ferritic steels designed for hot forming [1; 2]. These steels fall into either single-phase (γ) or two-phase (γ + α) region and demonstrate a propensity to maintain high-temperature hardening [3]. This effect enables the hot pre-hardening of the steel. Before being put into operation, the steel undergoes austenitization at 1150 °C, followed by a cooling process down to 450 °C. The steel retains its austenitic structure because the supercooled austenite is exceptionally stable. Subsequently, the steel becomes ready for shaping, resulting in sufficient hardness maintenance within the temperature range of 750 – 800 °С [4].

It is worth noting that RATE steels can operate at high temperatures even without pre-hardening, relying solely on quenching and tempering [5]. However, the newer, advanced RATE steel grades have not been extensively investigated in this context. Therefore, the objective of this study is to assess the high-temperature strength of the new RATE die steel after quenching and tempering.

We subjected the 5Kh2G4N3М2FSТB steel to guenching (1100 °C for 20 min in oil) and double tempering (590 °C for 2 h + 560 °C for 2 h in air) to achieve a hardness of 55 HRC [6]. The image depicts the Zwick machine employed for testing threaded cylindrical samples measuring 20 mm in length and 4 mm in diameter:

– the samples were heated to 450 °C, held for 15 min, and subsequently elongated until failure;

– the samples were heated to 450 °C, held for 15 min, and then elongated to 5 %;

– the samples were heated to 750 °C, held for 15 min, and then elongated to 5 %.

General diagram of the test process (а) |

The strain hardening factor (n) was calculated as outlined in [3].

At 450 °C, the steel displayed a yield offset and ultimate strength of 1277 and 1379 MPa, respectively. The relative elongation reached 9% (as shown in the figure). This suggests that plastic deformation at 450 °C leads to strain hardening of the steel (n = 0.03). Under the maximum load, deformation is concentrated ultimately leading to sample failure. When the sample is deformed at 450 °C to a 5 % relative elongation, the steel hardens to 1335 MPa. Subsequent heating to 750 °C results in a significant reduction in strength, with the offset yield strength during deformation measuring 311 MPa (a quarter of that at 750 °C). However, further deformation at 750 °C enhances the steel’s susceptibility to strain hardening (n = 0.06). The steel’s strength reaches 356 MPa at approximately 2 % relative elongation, attributed to the steel’s austenitization as a result of the α → γ transformation. The achieved hardening is maintained throughout further deformation, up to approximately 5 % relative elongation.

Conclusion

This study reveals that RATE steels experience strain hardening within the 450 – 750 °C operating temperature range, with higher strain hardening observed at 750 °C. The hot strength at 750 °C, with approximately 5 % relative elongation, reaches ~360 MPa. These results suggest that die tooling constructed from RATE steel can consistently operate at temperatures up to 750 °C.

References

1. Orlov Yu.G., Dudetskaya L.R. Materials and Technologies for Production of Cast Die Tools. Minsk: Belarus. Navuka; 2010:171. (In Russ.).

2. Poznyak L.A. Tool Steels. Kyiv: Naukova Dumka; 1996:488. (In Russ.).

3. Krugljakow A.A., Rogachev S.O., Lebedeva N.V., Sokolov P.Yu., Arsenkin A.M., Khatkevich V.M. On the nature of hot work hardening phenomenon in die steel with regulated austenitic transformation during exploitation. Materials Science and Engineering: A. 2022;833:142548. https://doi.org/10.1016/j.msea.2021.142548

4. Lebedeva N.V., Panova G.A., Kruglyakov A.A., Rogachev S.O. Method for hardening treatment of tool from die steels. Patent no. 2776893 RU. Publ. 28.07.2022. (In Russ.).

5. Krugljakow A.A. Structure and mechanical properties of die steels after quenching and tempering. Deformatsiya i razrushenie materialov. 2019;(10):42–45. (In Russ.). https://doi.org/10.31044/1814-4632-2019-10-42-45

6. Nikulin S.A., Kruglyakov A.A., Rogachev S.O., Panova G.A., Lebedeva N.V. Die steel. Patent no. 2744584 RU. Publ. 11.03.2021.

7.

About the Authors

A. A. KruglyakovRussian Federation

Aleksandr A. Kruglyakov, Cand. Sci. (Eng.), General Director

106 b Friedrichstrasse, Berlin D-10117, Germany

S. O. Rogachev

Russian Federation

Stanislav O. Rogachev, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Metallography and Physics of Strength”, National University of Science and Technology “MISIS”; Research Associate, Baikov Institute of Metallurgy and Materials Science, Russian Academy of Sciences

4 Leninskii Ave., Moscow 119049, Russian Federation

49 Leninskii Ave., Moscow 119991, Russian Federation

A. V. Molyarov

Russian Federation

Aleksei V. Molyarov, Engineer of the Chair “Metallography and Physics of Strength”

4 Leninskii Ave., Moscow 119049, Russian Federation

Review

For citations:

Kruglyakov A.A., Rogachev S.O., Molyarov A.V. High-temperature strength of die steel with regulated austenitic transformation during exploitation after quenching and tempering. Izvestiya. Ferrous Metallurgy. 2023;66(4):442-444. https://doi.org/10.17073/0368-0797-2023-4-442-444