Scroll to:

Influence of combined electromechanical processing modes of 40Kh steel on its structure and hardness

https://doi.org/10.17073/0368-0797-2023-4-421-426

Abstract

The paper considers the effect of combined electromechanical processing in three different modes on the structure and hardness of the surface layers of 40Kh steel, which was in a normalized state (the original structure). The modes differ from each other by the different applied load and the number of pulses. The applied load in modes 1 and 2 (current strength 39 kA, pulse time 0.02 s, number of pulses 1) is 100 and 250 MPa, respectively. A distinctive feature of mode 3 compared to mode 2 is a greater number of pulses (two). Metallographically it was established that in all three cases a hardened surface layer of different thickness (from 300 to 1200 μm) with a hardness of 593 – 598 HV is formed, consisting of two zones (a surface zone with a structure of fine-needle martensite; a transition zone smoothly transitioning into the initial ferrite structure). The transition zone (treatment according to mode 1) in its structure contains martensite and ferrite. The transition zone (mode 2 processing) consists of a Widemannstett structure. A more substantial surface heating zone according to this mode (700 μm) in comparison with the processing according to mode 1 (300 μm) in combination with intensive heat removal contributed to the formation of a Widmanstett structure, which is defective and unacceptable for operation. The transition zone with the processing according to mode 3 has the structure of martensite and ferrite. The formation of a defective Widmanstett structure in the transition zone does not occur, since 2 times more pulses are used during processing than in mode 2. This contributes to the heating of the surface layer to a greater depth (1200 μm), and, consequently, the structure formation in the transition zone occurs from the intercritical interval Ag3 – Ag1 .

Keywords

For citations:

Simachev A.S., Oskolkova T.N., Shevchenko R.A. Influence of combined electromechanical processing modes of 40Kh steel on its structure and hardness. Izvestiya. Ferrous Metallurgy. 2023;66(4):421-426. https://doi.org/10.17073/0368-0797-2023-4-421-426

Introduction

The advancement of mechanical engineering in Russia is inconceivable without the integration of medium-carbon improved steels. These considered steels predominantly function under tribotechnical conditions, thus the establishment of hardened surface layers holds immense potential for substantially enhancing the dependability and longevity of machine components [1 – 3], alongside bolstering surface hardness [4; 5]. Such enhancements invariably result in an augmentation of the overall wear resistance exhibited by the utilized steel. To illustrate, the primary challenge faced by the metalworking industry lies in augmenting the wear resistance of cutting tools [6 – 8].

Currently, achieving high levels of surface hardness predominantly relies on employing diverse methodologies to harden component surfaces, aimed at generating layers and coatings with specific properties [9; 10]. An analysis of published data reveals the existence of numerous techniques for surface hardening of steels, encompassing approaches such as combined electro-mechanical and ultrasonic treatment, as well as electromechanical treatment involving dynamic force application [11 – 13].

In the context of [14; 15], the utilization of combined electromechanical processing (CEMP) emerges as an effective technique for enhancing the surface integrity of machine parts. This approach results in surface hardening through a combination of electromechanical processing (EMP) and the induction of plastic deformation within the surface layer.

Experimental

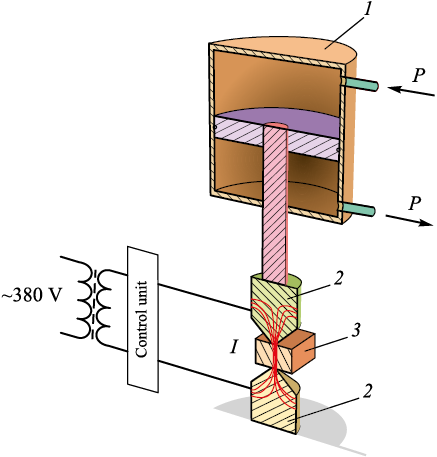

In this study, samples measuring 10×10×20 mm were employed following normalization of 40Kh steel, with a chemical composition that adheres to the specifications outlined in State Standard GOST 4543 – 2016. The process of surface hardening for these samples was executed using the CEMP technique on a MR 2517 relief welding machine, utilizing the parameters outlined in Table and visually depicted in Fig. 1.

Treatment modes of 40Kh steel

Fig. 1. Scheme of the installation for combined |

The MR 2517 AC machine features a solitary welding transformer with a rated welding current of 25 kA and is equipped with a pneumatic drive 1 for compressing the workpieces. The machine’s welding structure is configured as a rigid bracket. Сurrent modulation within the machine is facilitated by thyristor contactors, and this current traverses specialized electrodes 2 featuring a diminished cross-sectional area. This design facilitates the attainment of elevated electric current density on the treated surface of the sample 3. For management of the CEMP cycle is executed through contactless hardware, allowing for precise control of current, modulation, and multi-pulse switching.

The CEMP technique encompasses the application of a substantial electric current and subsequent surface plastic deformation. This amalgamation leads to the elevation of the steel surface temperature to the range of 1000 – 1300 °С [16 – 18]. In the process of rapid surface cooling, facilitated by the dissipation of heat into both the material’s interior and the surrounding environment, significant phase transformations take place, leading to the occurrence of superfast hardening. This phenomenon results in the formation of martensitic structures.

In order to examine the hardened layers, metallographic analyses were conducted utilizing an OLIMPUS – GX 50 microscope and the HVS-1000 instrument, adhering to the protocols stipulated by State Standard GOST 2999 – 75 “Metals and Alloys. Vickers Hardness Test by Diamond Pyramid”. The determination of grain size was executed following the guidelines of State Standard GOST 5639 – 82 “Steels and Alloys. Methods for Detection and Determination of Grain Size”.

Results and discussion

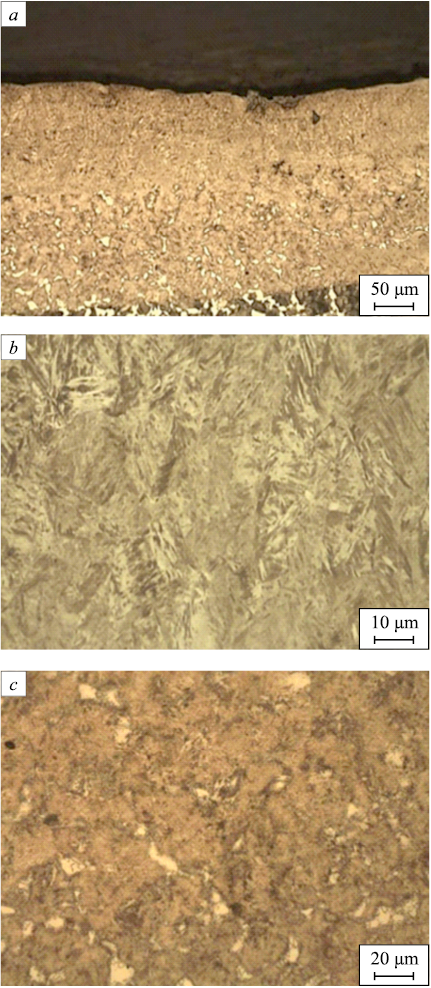

The application of CEMP under mode 1 conditions (current: 39 kA, pulse duration 0.02 s, number of pulses 1, applied load 100 MPa) on the samples yielded insights through optical metallography. This analysis disclosed the development of a layer on the steel surface, encompassing two distinct zones with an aggregate thickness of 300 µm. Notably, this layer exhibited a modified microstructure when compared to the original state (Fig. 2). The initial zone, situated at the surface and extending 150 µm deep (Fig. 2, a, b), was found to comprise finely acicular martensite, characterized by a hardness value of 598 HV and a grain count of 8. In contrast, the subsequent transition zone, also 150 µm thick (Fig. 2, a, c), was identified as a composite of martensite and ferrite, exhibiting a hardness of 275 HV along with a grain count of 7. The underlying structure featured an initial composition of ferrite and pearlite, denoting a hardness level of 188 HV and a grain count of 6 [19; 20].

Fig. 2. Microstructure of 40Kh steel after combined |

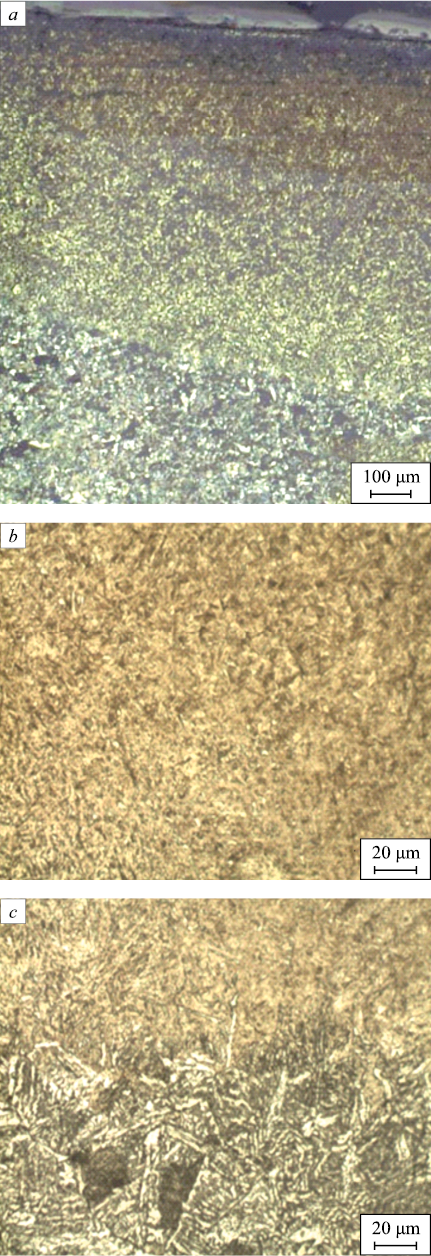

Samples subjected to CEMP under mode 2 conditions (current 39 kA, pulse duration 0.02 s, applied load 250 MPa, number of pulses 1) exhibit the development of a hardened layer with a substantial thickness of 700 µm (Fig. 3, a). This layer is characterized by a dual-zone composition: the initial (surface) zone, measuring 500 µm in depth, and possessing grain counts of 7 and 8, comprises finely acicular martensite (Fig. 3, a, b) characterized by a hardness value of 593 HV. Below lies a transition zone (Fig. 3, a, c), 200 µm in thickness, exhibiting a structure composed of pearlite and ferrite showcasing a Widmanstätten orientation. The hardness within this zone is measured at 233 HV, with grain counts of 4 and 5. The transition zone extends deeper, penetrating the initial ferrite-pearlite structure. It is important to highlight that the greater thickness of the surface heating zone observed in mode 2 (700 μm), in comparison to mode 1 (300 μm), in combination with the pronounced heat dissipation from this area, has contributed to the emergence of the Widmanstätten structure. However, this structure exhibits defects and proves unsuitable for operational use.

Fig. 3. Microstructure of 40Kh steel after combined |

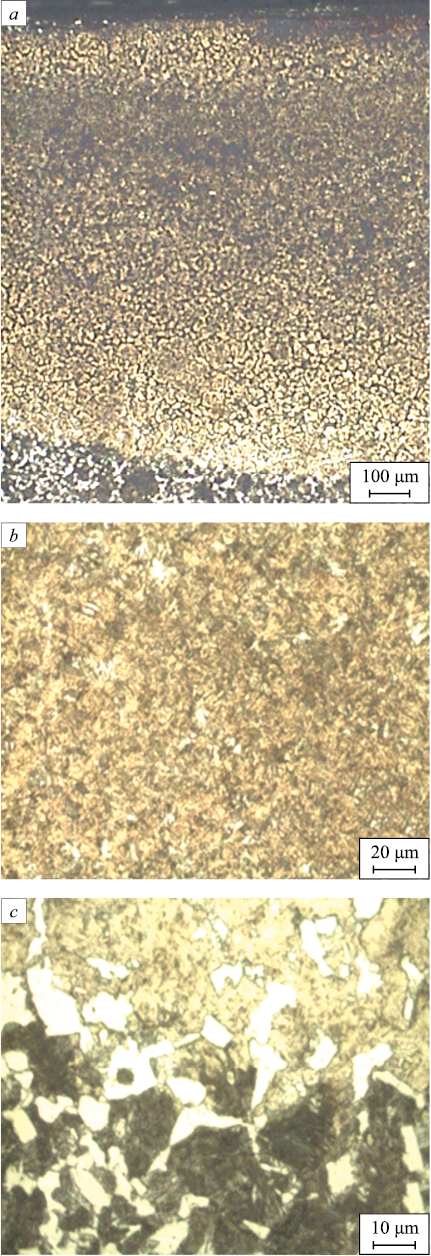

Processing under mode 3 was executed using the subsequent parameters: current 39 kA, pulse duration 0.02 s, applied load 250 MPa, and a pulse count of 2. The microstructural changes that emerged in the steel as a consequence of hardening through the CEMP method under mode 3 conditions are visibly presented in Fig. 4.

Fig. 4. Microstructure of 40Kh steel after combined |

Upon conducting a metallographic analysis, a discernible augmentation in the thickness of the hardened layer up to 1200 μm was ascertained (Fig. 4, a). Analogous to preceding instances, this layer is comprised of two discernible zones. The initial zone, extending to a depth of 1000 μm from the surface and characterized by a grain count of 7, showcases a microstructure of finely acicular martensite (Fig. 4, b), accentuated by a hardness rating of 598 HV. Beneath this surface zone, a transition zone spans 200 µm, displaying a composite structure of martensite and ferrite (with a hardness of 275 HV) and a grain count of 6 (Fig. 4, c). Subsequently, the hardened layer transitions seamlessly into the native ferrite and pearlite structure, marked by a grain count of 6 and a hardness of 190 HV.

A flawed Widmanstätten structure within the transition zone does not manifest as a discernible feature in metallographic analyses. This absence of identification arises from the fact that the application of treatment mode 3 on 40Kh steel leads to a more profound surface-layer heating, consequently inducing structure formation within the transition zone from the intercritical interval Ar3 – Ar1 (Fig. 4, c).

Conclusions

Surface layers characterized by thicknesses ranging from 300 to 1200 μm and featuring a finely acicular martensite structure exhibiting a hardness of 598 HV were successfully achieved on the 40Kh steel surface. This was accomplished through the application of combined electromechanical processing, particularly on steel structures initially present in a normalized state characterized by ferrite and pearlite. Detailed investigations underscored that the most effective treatment modes for the desired structure formation and subsequent enhancement in surface hardness are modes 1 and 3. The surface layers obtained under these conditions consist predominantly of finely acicular martensite. Beneath this surface layer lies a transitional zone characterized by the coexistence of martensite and ferrite structures, which seamlessly transitions into the original ferrite-pearlite structure.

References

1. Panin S.V., Klimenov V.A., Seifullina M.P., Pochivalov Yu.I., Ovechkin B.B. Effect of ultrasonic treatment of fused gas-thermal coatings on the character of deformation and fracture of “coating – substrate” compositions at three-point bending. Physical Mesomechanics. 2004;7(1-2):107–116.

2. Varga G. Effects of technological parameters on the surface texture of burnished surfaces. Engineering Materials. 2014;581:403–408. https://doi.org/10.4028/www.scientific.net/KEM.581.403

3. Malaki M., Ding H. A review of ultrasonic peening treatment. Materials and Design. 2015;87:1072–1086. https://doi.org/10.1016/j.matdes.2015.11.108

4. Lu K., Lu J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Materials Science and Engineering: A. 2004;375–377:38–45. https://doi.org/10.1016/j.msea.2003.10.261

5. Wang Z., Lu K. Diffusion and surface alloying of gradient nanostructured metals. Beilstein Journal of Nanotechnology. 2017;8:547–560. https://doi.org/10.3762/bjnano.8.59

6. Sidashov A.V., Kozakov A.T., Yaresko S.I. Auger and X-Ray photoelectron spectroscopy study of the tribocontact surface after laser modification. Materials Science Forum. 2016;870:298–302. https://doi.org/10.4028/www.scientific.net/MSF.870.298

7. Yaresko S.I. Application features of the cutting tool, hardened by laser pulsed radiation. Materials Science Forum. 2016;870:46–51. https://doi.org/10.4028/www.scientific.net/MSF.870.46

8. Ogin P.A., Levashkin D.G., Yaresko S.I., Block-modular principle of build composition automatically changeable laser modules for CNC machines. Procedia Engineering. 2017;206:1298–1302. https://doi.org/10.1016/j.proeng.2017.10.634

9. Ivancivsky V.V., Zverev E.A., Vakhrushev N.V., Bandyurov I.V. Adhesion strength research of wear-resistant ceramic-metal plasma coatings. Actual Problems in Machine Building. 2016;(3):77–82.

10. Loginova M.V., Yakovlev V.I., Sitnikov A.A., Filimonov V. Yu., Sobachkin A.V., Negodyaev A.Z., Gradoboev A.V. Structural transformations in mechanically activated powder mixtures Ti + Al under the influence of γ-irradiation. Actual Problems in Machine Building. 2016;(3):398–404.

11. Edigarov V.R., Litau E.V., Morgunov A.P. The influence of process parameters of the electromechanical handling on its features. Dynamics of Systems, Mechanisms and Machines (Dynamics). 2014:7005647. https://doi.org/10.1109/Dynamics.2014.7005647

12. Matlin M.M., Dudkina N.G., Dudkin A.D. Features of formation of the strengthened surface layer upon electromechanical treatment with dynamic effort. Uprochnyayushchie tekhnologii i pokrytiya. 2007;(6(30)):38–41. (In Russ.).

13. Kosogorov V.A., Bagmutov V.P., Zakharov I.N., Denisevich D.S., Kosogorova P.V. Combined surface hardening of steel based alloys on electromechanical and ultrasonic treatments. Izvestiya Volgogradskogo gosudarstvennogo technicheskogo universiteta. 2014;(1(128)):10–14. (In Russ.).

14. Edigarov V.R., Kilunin I.Yu., Degtyar’ V.V. Classification of combined processing methods based on electromechanical hardening. Sovremennye naukoemkie tekhnologii. 2012;(3):32–36. (In Russ.).

15. Edigarov V.R., Malyi V.V. Improving wear resistance of details of multi-purpose tracked machines’ running gear by combined methods of electromechanical processing. Vestnik Sibirskoi gosudarstvennoi avtomobil’no-dorozhnoi akademii. 2014;(4(38)):57–64. (In Russ.).

16. Kirichek A.V., Soloviev D.L., Lazutkin A.G. Technology and Equipment of Static Pulse Processing by Surface Plastic Deformation: Technologist’s Library. Moscow: Mashinostroenie; 2004:288. (In Russ.).

17. Edigarov V.R., Alimbaeva B.Sh., Perkov P.S. Hardening of blankets of details by electromechanical processing with additional deformation of a blanket. Nauchnyi al’manakh. 2016;10(3(24)):351–354. (In Russ.). https://doi.org/10.17117/na.2016.10.03.351

18. Gorlenko A.O. Hardening of friction surfaces of machine parts during electromechanical processing. Vestnik Bryanskogo gosudarstvennogo tekhnicheskogo universiteta. 2011;(3(31)):4–8. (In Russ.).

19. Kashin S.S., Shevchenko R.A., Oskolkova T.N. Hardening the surface of 40Kh steel by electromechanical processing. In: Proceedings of the All-Russ. Sci. Conf. of Students, Postgraduates and Young Scientists “Science and Youth: Problems, Searches, Solutions. Part 2. Technical Sciences”. Novokuznetsk, 2021;2:231–234. (In Russ.).

20. Kashin S.S., Oskolkova T.N., Shevchenko R.A. Surface hardening of 40Kh steel by combined electromechanical processing. In: Proceedings of the All-Russ. Sci. Conf. of Students, Postgraduates and Young Scientists “Science and Youth: Problems, Searches, Solutions. Part 2. Technical Sciences”. Novokuznetsk, 2021;2:34–36. (In Russ.).

About the Authors

A. S. SimachevRussian Federation

Artem S. Simachev, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Metal Forming and Metal Science. “EVRAZ ZSMK”

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

T. N. Oskolkova

Russian Federation

Tat’yana N. Oskolkova, Dr. Sci. (Eng.), Prof. of the Chair “Metal Forming and Metal Science. “EVRAZ ZSMK”

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

R. A. Shevchenko

Russian Federation

Roman A. Shevchenko, Cand. Sci. (Eng.), Assist. Prof. of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Simachev A.S., Oskolkova T.N., Shevchenko R.A. Influence of combined electromechanical processing modes of 40Kh steel on its structure and hardness. Izvestiya. Ferrous Metallurgy. 2023;66(4):421-426. https://doi.org/10.17073/0368-0797-2023-4-421-426

JATS XML