Scroll to:

Effect of ring groove in a heat-insulating insert on efficiency of its work in blast channel of blast furnace tuyere

https://doi.org/10.17073/0368-0797-2023-4-415-420

Abstract

One of the main disadvantages when supplying natural gas to the air tuyere of a blast furnace is low intensity of its combustion inside the tuyere blast channel. Ring groove on the surface of blast channel improves the mixing of natural gas with blast and increases completeness of gas combustion in it, but reduces the tuyere durability. One of the ways to simultaneously solve these problems is to install a heat-insulating ceramic insert in the tuyere blast channel. The insert significantly reduces heat losses through the tuyere surface, improves natural gas combustion in the blast channel due to its contact with hot walls of the insert instead of cold copper walls in its absence. This increases the temperature of the hot blast at the tuyere outlet. In addition, the insert affects the tuyere durability by reducing the heat flow acting on the tuyere. In this work, we studied influence of the ring groove and its parts in the insert on efficiency of its work. In the Ansys 21.1 software, the processes occurring in the blast channel of a blast furnace tuyere with a ceramic insert installed in it, having a groove of a quadrangular section in the form of a ring or its part in the circumferential direction, were simulated. It was established that improvement of natural gas combustion in the tuyere blast channel is achieved using a ring groove or part of it from the side of gas supply.

Keywords

For citations:

Albul S.V., Kobelev O.A., Levitskii I.A. Effect of ring groove in a heat-insulating insert on efficiency of its work in blast channel of blast furnace tuyere. Izvestiya. Ferrous Metallurgy. 2023;66(4):415-420. https://doi.org/10.17073/0368-0797-2023-4-415-420

Introduction

The air tuyeres supply a mixture of oxygen-enriched blast and natural gas [1 – 3] or natural gas and pulverized coal into the blast furnace. The injection of gas and coal reduces the coke consumption during pig iron manufacturing [4 – 6]. As the share of natural gas increases, its mixing with the blast deteriorates [7 – 9] and blowing efficiency decreases [10 – 12]. We have proposed solutions to enhance the ignition and combustion of natural gas in the tuyere blast channel [13 – 16]. Numerous improved technologies for mixing natural gas with the blast have been invented [17 – 20].

Gas preheating has been proven to be efficient [21; 22].

Another promising approach to improving gas/blast mixing is adding cavities to the blast channel to increase flow turbulence in the tuyere. Such elements could be a groove in the tuyere nose [23], blowpipe, [24], or in the natural gas feed tube [25]. However, more intense gas combustion in the tuyere blast channel may result in blowpipe deformation or burnout. For this reason, as gas combustion improves, the blowpipe should be heat protected. Durable insulating ceramic inserts [26 – 28, 29 – 31] can be used.

A large number of studies [32 – 34] are dedicated to modeling processes occurring in the air tuyere and the blast furnace tuyere zone, including the simultaneous supply of combustible natural gas and pulverized coal into the blast channel of the tuyere [35; 36].

Problem statement

We investigated the effects of a ring roove or its segments on ceramic insert performance.

The purpose of this study is to simulate the flow, heat exchange, and gas combustion in the blast channel. We considered the following ceramic insert designs:

– no groove in the insert (basic design);

– with a quadrangular section (3 mm deep, 40 mm wide) ring groove located 20 mm from the insert bottom;

– with a semi-ring groove of the same size located at the top (on the gas feed pipe side);

– with a semi-ring groove of the same size located at the bottom (opposite the gas feed pipe side).

The depth and width of the groove were selected to meet two conditions: provide a measurable improvement in the gas combustion process and maintain structural integrity. The groove was placed near the edge of the insert to intensify gas combustion in the area close to the tuyere nose and the tuyere zone.

We conducted CFD, combustion, and heat transfer simulations in Ansys Fluent 21.1 using the actual tuyere operating conditions and some simplifying assumptions proposed by Levitskii I. et al. [18]. The key assumptions are:

– extended boundary conditions include heat transfer to the cooling water;

– radiation heat exchange inside the air passage is neglected;

– the Finite Rate / Eddy dissipation model is employed to simulate chemical reactions and turbulence;

– to reduce computational costs, half of the symmetrical structure is simulated;

– the problem is assumed to be stationary;

– the pressure solver is utilized;

– the realizable k-ε turbulence model with standard wall functions is used to solve the energy and convective diffusion equations for the methane-air mixture, taking possible combustion into account.

In contrast to the approach presented in [18], our approach involved solving a combined heat transfer problem, explicitly analyzing heat transfer through solid bodies (specifically, the insert).

We constructed a symmetric geometric model using Design Modeler and subsequently generated the mesh using Ansys Meshing.

The simulation addressed a stationary problem. The components of the methane-air mixture were treated as perfect gases, meaning we assumed that density varies with pressure and temperature. The tuyere nose and the blowpipe were composed of copper, with their properties available in the Ansys Fluent database. The insert was fabricated from corundum, characterized by a density of 3583 kg/m3, specific heat capacity of 1291 J/(kg·K), and thermal conductivity of 83 W/(m·K). The gap between the insert and the blowpipe was assumed to be filled with sealant, featuring a density of 1200 kg/m3, specific heat capacity of 840 J/(kg·K), and thermal conductivity 0.4 W/(m·K).

The boundary conditions for the blast process are detailed in Table 1, while those for the natural gas feed are outlined in Table 2.

Table 1. Blast parameters in the inlet section

Table 2. Parameters of natural gas in the inlet section

|

In order to account for the 2 mm thick gap and the 6 mm thick copper layer on the outer surface of the insert within the simulation domain, the boundary conditions on this surface were extended. Convective heat exchange with the environment occurred on the outer surface of the copper layer, maintaining a temperature of 27 °C and a heat conductivity of a = 5815 W/(m2∙K).

The boundary conditions at the fluid-to-tuyere nose interface were also extended due to the presence of a 14 mm thick copper layer. Similar to the 6 mm thick copper layer, there was convective heat exchange with the environment occurring on the outer surface of this copper layer.

Simulation results and discussion

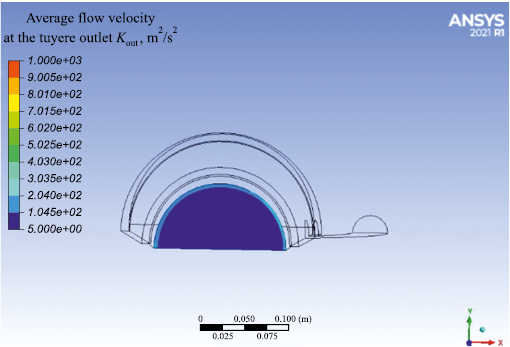

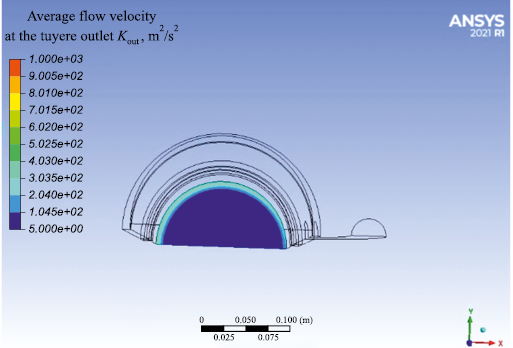

Table 3 presents the crucial simulation results, and Figs. 1 and 2 illustrate the distribution of turbulent kinetic energy.

Table 3. Design parameters of the air tuyere

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Both Table 3 and Figs. 1 and 2 indicate that the presence of a ring groove in the insert or a groove on the natural gas feed side enhances the mixing of natural gas and hot air. Consequently, this leads to increased gas combustion heat, higher CO2 content, and as a result, elevated temperature and flow velocity at the tuyere outlet. This implies that the natural gas ratio in the tuyere mixture can be raised.

Fig. 1. Distribution of turbulence kinetic energy at the outlet

Fig. 2. Distribution of turbulence kinetic energy at the outlet |

Conclusions

The presence of a ring groove in the tuyere blowpipe’s heat-insulating insert has a significant impact on gas combustion:

– a semi-ring groove located at the gas feed pipe side enhances gas/hot air mixing and accelerates combustion;

– an ring groove further improves the gas/hot air mixing and accelerates combustion;

– a semi-ring groove opposite the gas feed pipe side leads to a deterioration in gas/hot air mixing and combustion compared to the standard, no-groove design.

References

1. Radyuk A.G., Titlyanov A.E., Skripalenko M.M. Modeling of the temperature field of blast furnace tuyeres using Deform-2D software. Metallurgist. 2017;60(9–10):1011–1015. https://doi.org/10.1007/s11015-017-0400-5

2. Filatov S., Kurunov I., Tihonov D. Reserves for rising the efficiency of blast furnace process. Proceedings of 7th European Coke and Ironmaking Congress – ECIC. 2016;184–191.

3. Peacey J.G., Davenport W.G. The Iron Blast Furnace: Theory and Practice. Pergamon; 1989.

4. Majeski A., Runstedtler A., D’Alessio J., Macfadyen N. Injection of pulverized coal and natural gas into blast furnaces for iron-making: Lance positioning and design. ISIJ International. 2015;55(7):1377–1383. https://doi.org/10.2355/isijinternational.55.1377

5. Silaen A.K., Okosun T., Chen Y., Wu B., Zhao J., Zhao Y., D’Alessio J., Capo J., Zhou C.Q. Investigation of high rate natural gas injection through various lance designs in a blast furnace. Iron and Steel Technology. 2015;1(3):1536–1549.

6. Okosun T., Street S., Chen Y., Zhao J., Wu B., Zhou C.Q. Investigation of co-injection of natural gas and pulverized coal in a blast furnace. Proceedings of the AISTech 2015. 2015;1581–1594.

7. Murao A., Fukada K., Matsuno H., Sato M., Akaotsu S., Saito Y., Matsushita Y., Aoki H. Effect of natural gas injection point on combustion and gasification efficiency of pulverized coal under blast furnace condition. Tetsu-to-Hagane. 2018;104(5):243–252. https://doi.org/10.2355/tetsutohagane.TETSU-2017-087

8. Ueki Y., Yoshiie R., Naruse I., Matsuzaki S. Effect of hydrogen gas addition on combustion characteristics of pulverized coal. Fuel Processing Technology. 2017;161:289–294. https://doi.org/10.1016/j.fuproc.2017.02.034

9. Shen Y., Zhou Y., Zhu T., Duan G. Thermotechnical performance of an air-cooled tuyere with air cooling channels in series. Heat and Mass Transfer. 2017;53(1):81–98. https://doi.org/10.1007/s00231-016-1801-x

10. Pistorius P.C. Technical and economic evaluation of top gas recycling blast furnace ironmaking. Proceedings of the Fray Int. Symp., 27 November - 1 December 2011, Cancun, Mexico. 2011;5:223-232.

11. Filatov S.V., Kurunov I.F., Grachev S.N., etc. Blast furnace production at NLMK: Traditions, innovations, development Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2014;(10):30–34. (In Russ.).

12. Jampani M. Increased use of natural gas in blast furnace iron-making: Ph.D. Thesis. Pittsburgh, PA: Carnegie Mellon University; 2016.

13. Liu X., Tang G., Silaen A.K., Street S.J., Zhou C.Q. Investigation of heat transfer phenomena in blast furnace tuyere/blowpipe region. ASME 2017 Heat Transfer Summer Conf. 2017:HT2017-4961. https://doi.org/10.1115/HT2017-4961

14. Zhou Z., Wang G. Effect of recycled gas temperature on coal combustion in oxygen blast furnace. Proceedings of the 2017 6th Int. Conf. on Energy and Environmental Protection (ICEEP 2017), AER-Advances in Engineering Research. 2017;143:1076–1079. https://doi.org/10.2991/iceep-17.2017.186

15. Pistorius P.C., Gibson J., Jampani M. Natural gas utilization in blast furnace ironmaking: tuyere injection, shaft injection and prereduction. In: Applications of Process Engineering Principles in Materials Processing, Energy and Environmental Technologies. Wang S., Free M., Alam S., Zhang M., Taylor P. eds. The Minerals, Metals & Materials Series. Springer, Cham; 2017. https://doi.org/10.1007/978-3-319-51091-0_26

16. Wojewodka M.J., Keith J.P., Horvath S.D., Alter M.A., McGovern C.C. Natural gas injection maximization on C and D blast furnaces at ArcelorMittal Burns Harbor. Proceedings of Iron & Steel Technology Conf. AISTech, 5-8 May 2014, Indianapolis, Indiana U.S.A. 2014;767-780.

17. Loginov V.N., Netronin V.I., Shatlov V.A., etc. Air tuyere of a blast furnace. Patent RF no. 2191830 RF, S21V7/16; no. 2001129265/02. Byulleten’ izobretenii. 2002;(30). (In Russ.).

18. Levitskii I.A., Radyuk A.G., Titlyanov A.E., Sidorova T.Yu. Influence of the method of natural gas supplying on gas dynamics and heat transfer in air tuyere of blast furnace. Izvestiya. Ferrous Metallurgy. 2018;61(5):357–363. (In Russ.). https://doi.org/10.17073/0368-0797-2018-5-357-363

19. Loginov V.N., Sukhanov M.Yu., Ukhov A.D., etc. Blowing tuyere of a blast furnace. Patent RF no. 2245373 RF, S21V7/16; no. 2003111093/02. Byulleten’ izobretenii. 2005;(3). (In Russ.).

20. Gorbatyuk S.M., Tarasov Yu.S., Levitskii I.A., Radyuk A.G., Titlyanov A.E. Effect of a ceramic insert with swirler on gas dynamics and heat exchange in a blast furnace tuyere. Izvestiya. Ferrous Metallurgy. 2019;62(5):337-344. (In Russ.). https://doi.org/10.17073/0368-0797-2019-5-337-344

21. Zainullin L.A., Filatov S.V., Kushnarev A.V., etc. Method of air blast tuyere cooling and supply of natural gas to a blast furnace and device for its implementation. Patent RF no. 2449022 RF, S21V7/16; no. 2010123224/02. Byulleten’ izobretenii. 2011;(35). (In Russ.).

22. Jampani M., Gibson J., Pistorius P.C. Increased use of natural gas in blast furnace ironmaking: Mass and energy balance calculations. Metallurgical and Materials Transactions B. 2019;50:1290–1299. https://doi.org/10.1007/s11663-019-01538-8

23. Mokrinskii A.V., Shatlov V.A., Yur’ev A.B., etc. Blast furnace air tuyere. Patent RF no. 2280698 RF, S21V7/16; no. 2005104595/02. Byulleten’ izobretenii. 2006;(21). (In Russ.).

24. Mikhailov A.A., Shirshov S.YA., Chernobrivets B.F. Blast furnace air tuyere. Certificate of authorship USSR no. 517638 СССР, С21В7/16. Publ. 15.06.76.

25. Gimmel’farb A.A., Medvedev N.M., Dzhusov A.B., etc. Blast furnace air tuyere. Certificate of authorship USSR no. 910769 СССР, С21В7/16. Publ. 07.03.82.

26. Radyuk A.G., Titlyanov A.E., Yakoev A.G., Pedos S.I. Improvement in service life of blast furnace tuyeres due to gas thermal spraying. Stal’. 2002;(6):11–12.

27. Kirillova N.L., Radyuk A.G., Titlyanov A.E., Reducing heat loss through the surface of blast-furnace tuyeres. Metallurgist. 2014;57(9–10):878–882. https://doi.org/10.1007/s11015-014-9816-3

28. Vinogradov E.N., Radyuk A.G., Volkov E.A., Terebov A.L., Sidorova T.Yu. Reducing heat losses through blast furnace tuyeres. Steel in Translation. 2019;49(11):778–782. https://doi.org/10.3103/S0967091219110160

29. Tarasov Yu.S., Skripalenko M.M., Radyuk A.G., Titlyanov A.E. Computer simulation of thermal and stress–strain state of blast furnace tuyeres. Metallurgist. 2019;62(11–12): 1083–1091. https://doi.org/10.1007/s11015-019-00760-8

30. Zainullin L.A., Epishin A.Y., Spirin N.A. Extending the life of blast-furnace air tuyeres. Metallurgist. 2018;62(3-4):322–325. https://doi.org/10.1007/s11015-018-0663-5

31. Radyuk A.G., Titlyanov A.E., Sidorova T.Yu. Effect of slurry coating on the resistance of thermal insulation insert in blast furnace air tuyere. Metallurgist. 2020;63(11–12):1153–1159. https://doi.org/10.1007/s11015-020-00935-8

32. Fu D., Tang G., Zhao Y., D’Alessio J., Zhou C.Q. Integration of tuyere, raceway and shaft models for predicting blast furnace process. JOM. 2018;70(6):951–957. https://doi.org/10.1007/s11837-017-2614-1

33. Dong Z., Wang J., Zuo H., She X., Xue Q. Analysis of gas-solid flow and shaft-injected gas distribution in an oxygen blast furnace using a discrete element method and computational fluid dynamics coupled model. Particuology. 2017;32:63–72. https://doi.org/10.1016/j.partic.2016.07.008

34. Radyuk A.G., Titlyanov A.E., Sidorova T.Y. Thermal state of air tuyeres in blast furnaces. Steel in Translation. 2016;46(9): 624–628. https://doi.org/10.3103/S0967091216090084

35. Yeh C.P., Du S.W., Tsai C.H., Yang R.J. Numerical analysis of flow and combustion behavior in tuyere and raceway of blast furnace fueled with pulverized coal and recycled top gas. Proceedings of the ICE – Energy. 2012;42(1):233–240. https://doi.org/10.1016/j.energy.2012.03.065

36. Chen Y., Fu D., Zhou C.Q. Numerical simulation of the co-injection of natural gas and pulverized coal in blast furnace. Proceedings of the AISTech 2013. 2013;573–580. https://doi.org/10.13140/RG.2.1.2948.2967

37.

38.

39.

40.

41.

About the Authors

S. V. AlbulRussian Federation

Sergei V. Albul, Senior Lecturer of the Chair “Engineering of Technological Equipment”

4 Leninskii Ave., Moscow 119049, Russian Federation

O. A. Kobelev

Russian Federation

Oleg A. Kobelev, Dr. Sci. (Eng.), Prof., National University of Science and Technology “MISIS”, Chief Specialist of State Corporation “ROSATOM”, JSC Russian State Research Center “CNIITMASH”

4 Leninskii Ave., Moscow 119049, Russian Federation

4 Sharikopodshipnikovskaya Str., Moscow 115088, Russian Federation

I. A. Levitskii

Russian Federation

Igor’ A. Levitskii, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Energy-Efficient and Resource-Saving Industrial Technologies”

4 Leninskii Ave., Moscow 119049, Russian Federation

Review

For citations:

Albul S.V., Kobelev O.A., Levitskii I.A. Effect of ring groove in a heat-insulating insert on efficiency of its work in blast channel of blast furnace tuyere. Izvestiya. Ferrous Metallurgy. 2023;66(4):415-420. https://doi.org/10.17073/0368-0797-2023-4-415-420

JATS XML