Scroll to:

Development of flux-cored wire of Fe – C – Si – Mn – Cr – W – V system with additives of carbon-fluorine-containing material and titanium

https://doi.org/10.17073/0368-0797-2023-4-403-409

Abstract

The paper considers research of quality of the electric arc coating obtained using flux-cored wire of the Fe – C – Si – Mn – Cr – W – V system with additives of carbon-fluorine-containing material and titanium. The formation of an electric arc coating was carried out using an automatic arc welding machine ASAW-1250 with a new chromium-containing flux-cored wire on plates made of St3 steel. To exclude mixing of the deposited metal with the substrate steel, multilayer surfacing was conducted. The surfacing mode was calculated and refined experimentally. The authors studied the composition and properties of the surface of the electric arc coating after surfacing. As a substitute for amorphous carbon they used a carbon-fluorine-containing material (dust of gas purification of aluminum production). Surfacing was carried out under a flux made from slag produced by silicomanganese with a high content of sulfur. A regression analysis of influence of the deposited layer’s chemical composition on its hardness and wear rate was carried out and mathematical models of the investigated performance characteristics of the electric arc coating were obtained. With an increase in the content of chromium, tungsten, carbon and silicon, hardness of the deposited metal and its resistance to abrasive wear increase. The results of the conducted research make it possible to develop measures ensuring the required level of performance characteristics of the electric arc coating and can be used to make a forecast of hardness of the deposited layer and its wear resistance when the chemical composition of the metal changes, to predict the operational resistance of rolling rolls deposited with wires of the PP-Np-35V9Kh3SF type. Mathematical models of hardness of the deposited layer and its wear resistance help to clarify the mechanism of hardening and formation of protective properties of the surface layers of rolling rolls by means of electric arc coatings deposited with flux-cored wires.

Keywords

For citations:

Usol’tsev A.A., Kozyrev N.A., Bashchenko L.P., Kryukov R.E., Zhukov A.V. Development of flux-cored wire of Fe – C – Si – Mn – Cr – W – V system with additives of carbon-fluorine-containing material and titanium. Izvestiya. Ferrous Metallurgy. 2023;66(4):403-409. https://doi.org/10.17073/0368-0797-2023-4-403-409

Introduction

Rolling rolls constitute the primary technological tool in the steel mill rolling process. During their operation, amidst the plastic deformation of the metal, these rolls endure significant specific pressures and thermal effects, leading to intensive wear [1 – 3]. In light of this, the issue of roller repair quality has become more critical. Recently, there has been a notable increase in the widespread application of restorative arc surfacing to repair rolling mill rolls, using powder wires [2; 4; 5]. However, the use of flux-cored wires for surface welding comes with various drawbacks. In order to ensure the execution of high-quality repair procedures, there arises an essential need to enhance the composition of the wire charge and refine its application technique [6 – 8]. Consequently, the theoretical and experimental exploration of the physical characteristics, processes, and mechanisms involved in reinforcing and developing protective properties within the surface layers of rolls through electric arc coatings, deposited using flux-cored wires, remains relevant and holds scientific and practical significance.

It is worth mentioning that the utilization of presently employed flux-cored wires for the surfacing of rolling rolls is linked to a series of defects that emerge during the surfacing process. These include the high cost and scarcity of surfacing materials, along with the imperfect nature of surfacing technologies [9 – 11]. Identifying and rectifying the flawed structure of these coatings, which contributes to their premature deterioration, holds significant importance [12 – 14]. The advancement of technological surfacing materials [15 – 17], capable of yielding low-carbon martensite structures in the deposited metal, is a subject of interest.

Flux-cored wires within the Fe – C – Si – Mn – Cr – W – V system find extensive application in the surfacing of rolling rolls [18 – 20]. Simultaneously, for the restoration of rolls that operate under the most demanding conditions, the flux-cored wires of the PP-Np-35V9Kh3SF grade in accordance with the State Standard GOST 26101–84 are predominantly employed [19 – 21]. By modifying the composition of the charge within these flux-cored wires and incorporating several elements into their makeup, it becomes feasible to enhance the wear resistance of the deposited layer and extend the operational lifespan of the deposited rolls. Enhancing and altering the chemical composition of the flux-cored wires employed in surfacing presents a multifaceted scientific and manufacturing challenge, requiring a solution that meets the criteria of both economic viability and environmental sustainability [21 – 23].

The objective of this study is to establish patterns governing the augmentation of wear resistance and hardness in electric arc coatings applied to rolling rolls via the use of flux-cored wires within the Fe – C – Si – Mn – Cr – W – V system. This enhancement is achieved through the introduction of titanium and carbon-fluorine-containing material into their composition.

Materials and methods

The processes involved in surfacing and the fabrication of flux-cored wire, as well as the formulation of the filler for the flux-cored wire under investigation and the welding flux, are elaborated upon in references [20 – 22].

In the pursuit of developing a new flux-cored wire, a comparative benchmark was established using wire PP-Np-35V9Kh3SF, produced with graphite grade GL-1 (sample 1). Subsequently, adjustments were made to the concentrations of titanium (samples 2 – 4) and the carbon-fluorine-containing material (samples 5 – 9) for comparison.

Before commencing the production of flux-cored wires, the quantities of powder materials were preliminarily calculated. These materials were meticulously weighed using laboratory analytical scales AUX 120. The blending of the powders was conducted on laboratory rotary mixers for a minimum of 30 min. The manufacturing of the flux-cored wire was executed using a laboratory machine: the strip was drawn through a die, resulting in the formation of the flux-cored wire, which was then wound onto a drum.

The surfacing of electric arc coatings was conducted using an ASAW-1250 welding tractor, employing a custom-made flux-cored wire on steel plates in five distinct layers. This stratification aimed to prevent the mingling of the deposited metal with the underlying substrate steel. The surfacing parameters were calculated and fine-tuned through experimental adjustments. Post-surfacing, an analysis of the composition and properties of the resulting electric arc coatings were undertaken.

The chemical composition of the deposited coatings was determined using X-ray fluorescence via an XRF-1800 spectrometer and atomic emission analysis with a DFS-71 spectrometer. For several samples, the metal’s chemical composition was ascertained using chemical techniques: carbon content was measured in accordance with State Standard GOST 12344–2003, sulfur levels were determined following State Standard GOST 12345–2001, and phosphorus content was evaluated adhering to State Standard GOST 12347–77.

Samples designated for macro- and microstructure examination, hardness testing, and wear resistance analysis were prepared using a methodology encompassing cutting via a KKS 315L cutting machine, subsequent grinding on a 3D725 surface grinder, and final polishing utilizing a FROMMIA 835 SE polishing machine.

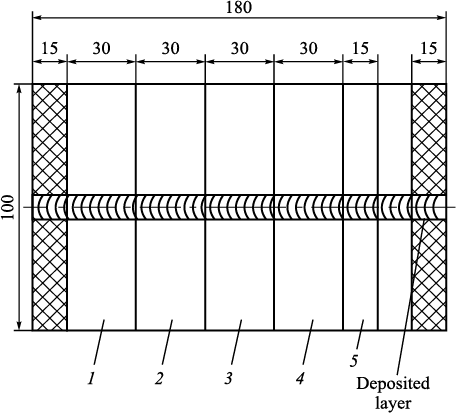

The configuration of sample cutting is depicted in Fig. 1.

Fig. 1. Scheme of samples cutting for testing: |

In order to assess the mechanical properties, macrosections measuring 20×55×14 mm were derived from the cut samples. Hardness measurements were conducted using the Rockwell method on a TK-14-250 hardness tester, following the specifications outlined in State Standard GOST 9013–59. This involved indenting a conical diamond tip with an apex angle of 120°.

Wear tests are presently conducted in accordance with State Standard GOST 23.208–79. This standard pertains to both metallic materials and metallic coatings, stipulating the method for evaluating their resistance to abrasive wear during friction against loosely bound abrasive particles. The core of this method involves rubbing test and reference material samples against abrasive particles introduced into the friction zone and pressed onto the sample by a rotating rubber roller. The wear of these test and reference material samples is measured, with the wear resistance of the test material estimated through a comparison of the wear on the reference and test samples. The outcomes are processed based on the recorded weight of the samples prior to and post the tests, determining the arithmetic mean values of weight loss for both the reference sample and the samples under study.

In order to analyze the influence of the chemical composition of flux-cored wires on the wear rate (degree) and hardness of electric arc coatings, we employed multifactorial correlation analysis. This approach enables us to scrutinize the patterns of changes in specific indicators as a function of various factors. Initially, we identified the factors affecting the indicator in question, selecting the most significant among them. Subsequently, we examined the initial data for reliability, uniformity, and adherence to the normal distribution law. This allowed us to formulate a model of the factor system, using deterministic factor analysis given the presence of independent factor characteristics in the systems being studied.

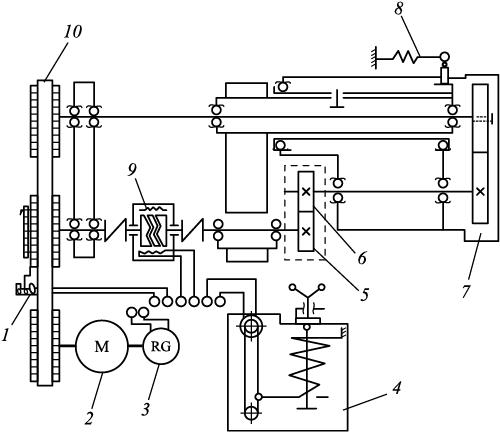

The rate of abrasion of the deposited layer of the test samples was determined through wear tests performed on a 2070 SMT-1 machine. The fundamental kinematic diagram of this machine is presented in Fig. 2. The lower sample’s shaft rotation frequency measurement range (range A) was 75 – 750 min\(^-\)1, while the friction torque measurement range (range I) spanned 1 – 10 N∙m. The friction machine 2070 SMT-1 can function with both closed and open power circuits, and operates as follows: power is transmitted from the electric motor 2 to both the lower 5 and upper 6 samples via a belt drive 10. Sample 6 is mounted on the shaft of the folding carriage 7, which is counterbalanced by the spring mechanism 8. An elastic torsion sensor 9 for friction torque, along with a non-contact current collector, is installed on the drive shaft of the lower sample, with its signal relayed control panel.

Fig. 2. Basic kinematic scheme of the 2070 СМТ-1 machine: |

The samples are subjected to loading through a spring bar mechanism 4. The applied normal force is adjusted by manipulating the loading unit’s handle, with the measurements conveyed to the control panel via a flexible link connected to a resistor situated within this unit.

The rotation speed is measured utilizing a rate generator 3, positioned on the engine shaft, while the rotations of the lower sample 5 are counted by means of a non-contact sensor 1. The shaft-bushing employed for sample wear, which is crafted from P18 steel, is incorporated.

Results and discussion

The chemical composition of the deposited layer obtained using the experimental powder wire is outlined in Table 1, and the wear rates of the samples are summarized in Table 2.

Table 1. Chemical composition of the deposited layers

Table 2. Wear rate of the samples

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

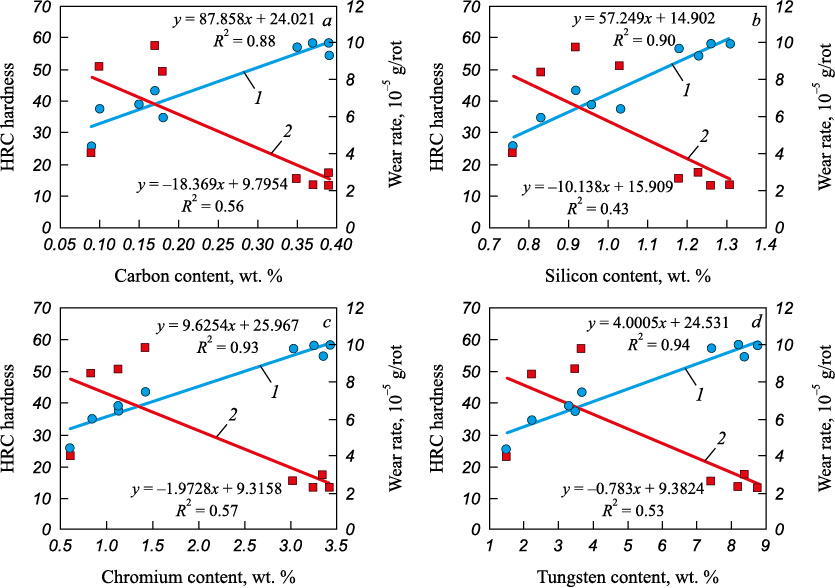

Variations in hardness and wear rate concerning the content of different elements are visualized in Fig. 3.

Fig. 3. Dependences of the deposited metal properties on content of carbon (a), |

The utilization of mathematical and statistical methods has facilitated the development of a mathematical model depicting the influence of the chemical composition of the deposited layer on its hardness and wear rate.

The validity of the acquired relationships was assessed through the mean approximation error, calculated as follows

\[\tilde \varepsilon = \frac{1}{m}\sum\limits_{i = 1}^m {\left| {\frac{{{Y_i} - {{\tilde Y}_i}}}{{{Y_i}}}} \right|} 100,\]

where m represents the number of observations; \(\tilde Y\)i stands for the calculated resultant indicator; \(\tilde Y\)i corresponds to the actual value of resultant indicator.

Regression analysis of the influence of the chemical composition of the deposited layer on its hardness and wear rate is expressed by the following equations:

– HRC hardness:

–39.056 + 58.725C + 4.983Si + 37.87Mn + 6.058Cr – 7.096Cu –

– 107.503Mo – 0.341V – 0.435W (approximation error is 0.0012 %);

– wear rate, g/rot:

–0.0000741 + 0.00042C – 0.00043Si + 0.000258Mn – 0.00022Cr +

+ 0.000398Cu + 0.00419Mo – 0.00019V + 0.0000372W

(approximation error is 0.0011 %).

The hardness and resistance to abrasive wear of the deposited metal exhibit an increase with an escalation in the concentration of chromium, tungsten, carbon, and silicon. The depicted relationships facilitate the prediction of hardness and wear rate outcomes when modifying the chemical composition of the deposited layers.

Conclusions

A regression analysis was undertaken to investigate the impact of the chemical composition of the deposited layer on both its hardness and wear rate. Consequently, mathematical models were derived to represent the examined operational attributes of the electric arc coating. Notably, the hardness of the deposited metal and its resistance to abrasive wear exhibit an augmentation with an increase in the concentrations of chromium, tungsten, carbon, and silicon.

The findings from these studies offer the potential to formulate strategies aimed at guaranteeing the desired level of operational attributes for the electric arc coating. Furthermore, they can be employed to prognosticate the hardness of the deposited layer and its wear resistance in response to variations in the chemical composition of the deposited metal. Additionally, they enable the anticipation of the operational longevity of rolls coated with wires of the PP-Np-35V9Kh3SF grade.

The mathematical models delineating the hardness of the deposited layer and its wear resistance provide insights that aid in clarifying the mechanism underlying the strengthening and development of protective properties within the surface layers of rolling rolls, achieved through the application of electric arc coatings deposited using flux-cored wires.

References

1. Metlitskii V.A. Flux-cored wires for arc welding and surfacing of cast iron. Welding International. 2008;22(11):796–800. https://doi.org/10.1080/09507110802593646

2. Filippov M.A., Shumyakov V.I., Balin S.A., Zhilin A.S., Lehchilo V.V., Rimer G.A. Structure and wear resistance of deposited alloys based on metastable chromium-carbon austenite. Welding International. 2015;29(10):819–822. https://doi.org/10.1080/09507116.2014.986891

3. Liu D.S., Liu R.P., Wei Y.H. Influence of tungsten on microstructure and wear resistance of iron base hardfacing alloy. Materials Science and Technology. 2014;30(3):316–322. https://doi.org/10.1179/1743284713Y.0000000359

4. Kejžar R., Grum J. Hardfacing of wear-resistant deposits by MAG welding with a flux-cored wire having graphite in its filling. Materials and Manufacturing Processes. 2005;20(6):961–976. https://doi.org/10.1081/AMP-200060424

5. Li R., He D.Y., Zhou Z., Wang Z.J., Song X.Y. Wear and high temperature oxidation behavior of wire arc sprayed iron based coatings. Surface Engineering. 2014;30(11):784–790. https://doi.org/10.1179/1743294414Y.0000000331

6. Ma H.R., Chen X.Y., Li J.W., Chang C.T., Wang G., Li H., Wang X.M., Li R.W. Fe-based amorphous coating with high corrosion and wear resistance. Surface Engineering. 2017;33(1):56–62. https://doi.org/10.1080/02670844.2016.1176718

7. Lim S.C., Gupta M., Goh Y.S., Seow K.C. Wear resistant WC – Co composite hard coatings. Surface Engineering. 1997;13(3):247–250. https://doi.org/10.1179/sur.1997.13.3.247

8. Zhuk Yu. Super-hard wear-resistant coating systems. Materials Technology. 1999;14(3):126–129. https://doi.org/10.1080/10667857.1999.11752827

9. Hardell J., Yousfi A., Lund M., Pelcastre L., Prakash B. Abrasive wear behaviour of hardened high strength boron steel. Tribology – Materials, Surfaces and Interfaces. 2014;8(2): 90–97. https://doi.org/10.1179/1751584X14Y.0000000068

10. Deng X.T., Fu T.L., Wang Z.D., Misra R.D.K., Wang G.D. Epsilon carbide precipitation and wear behaviour of low alloy wear resistant steels. Materials Science and Technology. 2016;32(4):320–327. https://doi.org/10.1080/02670836.2015.1137410

11. Kirchgaßner M., Badisch E., Franek F. Behaviour of iron-based hardfacing alloys under abrasion and impact. Wear. 2008;265(5-6):772–779. https://doi.org/10.1016/j.wear.2008.01.004

12. Hasui A., Morigaki O. Surfacing and Spraying. Moscow: Mashinostroenie; 1985:240. (In Russ.).

13. Paton B.E. Technology of Electric Welding of Metals and Alloys by Melting. Moscow: Kniga po Trebovaniyu; 2021:769. (In Russ.).

14. Gulyaev A.P. Metals Science. Textbook for Universities. Moscow: Metallurgiya; 1986:544. (In Russ.).

15. Khrushchov M.M., Babichev M.A. Abrasive Wear. Moscow: Nauka; 1970:251. (In Russ.).

16. Elagina O.Yu. Technological Methods of Increasing the Wear Resistance of Machine Parts. Moscow: Logos; 2009:488. (In Russ.).

17. Tylkin M.A. Improving the Durability of Metallurgical Equipment Parts. Moscow: Metallurgiya; 1971:608. (In Russ.).

18. Danil’chenko B.V. Selection of wear-resistant deposited metal for operation under abrasive wear. Svarochnoe proizvodstvo. 1992;(5):31–35. (In Russ.).

19. Gusev A.I., Romanov D.A., Kozyrev N.A., Gromov V.E., Ivanov Yu.F. Structure of weld of wear-resistant surfacing by flux-cored wire of Fe – C – Si – Mn – Cr – Ni – Mo system. Bulletin of the Siberian State Industrial University. 2021;(2(36)):3–10. (In Russ.).

20. Kozyrev N.A., Titov D.A., Kibko N.V. The study of the influence of the composition of flux-cored wire ПП-Нп-35В9Х3СФ on the properties surfaced roller. Actual Problems in Machine Building. 2016;3(3):60–64. (In Russ.).

21. Umanskii A.A., Kozyrev N.A., Titov D.A. The experimental investigations into the influence of the compositions of the cored wires of the C–Si–Mn–Cr–V–Mo and

22. C–Si–Mn–Cr–W–V alloying systems on the build-up mill roll layer structure. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2016;(4):74–78. (In Russ.).

23. Umanskii A.A., Kozyrev N.A., Titov D.A. Research and development of new compositions of flux-cored wire for surfacing of rolling rolls providing an increase in operational characteristics of the deposited metal. Proizvodstvo prokata. 2016;5:43–47. (In Russ.).

24. Kozyrev N.A., Gusev A.I., Galevskii G.V., Kryukov R.E., Osetkovskii I.V., etc. Flux-Cored Wire. Pat. RF 2641590. 2018. (In Russ.).

About the Authors

A. A. Usol’tsevRussian Federation

Aleksandr A. Usol’tsev, Cand. Sci. (Eng.), Assist. Prof. of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

N. A. Kozyrev

Russian Federation

Nikolai A. Kozyrev, Dr. Sci. (Eng.), Deputy Director of the Scientific Center for High-Quality Steels

23/9 Radio Str., Moscow 105005, Russian Federation

L. P. Bashchenko

Russian Federation

Lyudmila P. Bashchenko, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Thermal Power and Ecology”

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

R. E. Kryukov

Russian Federation

Roman E. Kryukov, Dr. Sci. (Eng.), Assist. Prof. of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. V. Zhukov

Russian Federation

Andrei V. Zhukov, Postgraduate of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Usol’tsev A.A., Kozyrev N.A., Bashchenko L.P., Kryukov R.E., Zhukov A.V. Development of flux-cored wire of Fe – C – Si – Mn – Cr – W – V system with additives of carbon-fluorine-containing material and titanium. Izvestiya. Ferrous Metallurgy. 2023;66(4):403-409. https://doi.org/10.17073/0368-0797-2023-4-403-409

JATS XML