Scroll to:

Using calcium-containing injection wire filled with electrolytic calcium in steel ladle treatment

https://doi.org/10.17073/0368-0797-2023-3-337-343

Abstract

Aluminum is one of the most common deoxidizers; when it is used in the melt, refractory inclusions of alumina are formed. The presence of these non-metallic inclusions negatively affects the purity of liquid steel, mechanical properties, makes casting difficult due to tightening of the steel-pouring fittings. The modification of alumina inclusions with calcium promotes the formation of liquid calcium aluminates, which leads to an acceleration of their removal from the metal due to a higher ascent rate. Having a high affinity for sulfur, calcium reduces its harmful effect by binding it with the formation of calcium sulfides, reducing the anisotropy of steel properties during further rolling. For steel treatment with calcium, injection wires with a calcium-containing filler are used. As a filler can be used: electrolytic calcium, silicocalcium, aluminum-tremic calcium, or ferrocalcium. The paper describes results of the tests carried out on a calcium-containing wire filled with electrolytic calcium and silicocalcium. It is shown that the consumption of calcium when using silicocalcium wire is on average 35 % higher in comparison with calcium injection wire filled with electrolytic calcium. The calcium recovery rate for different steel grades was evaluated using calcium-containing wires of different designs and filler. In this work, the steel pourability was analyzed. As a determining parameter, dependence of change in position of the tundish stopper rod on calcium content in the metal was considered in the sample from CCM. It was established that a wire filled with electrolytic calcium shows a more effective result in comparison with a silicocalcium wire.

Keywords

For citations:

Khoroshilov A.D., Somov S.A., Katolikov V.D., Murysev V.A., Bocherikov R.E., Yarmukhametov M.R. Using calcium-containing injection wire filled with electrolytic calcium in steel ladle treatment. Izvestiya. Ferrous Metallurgy. 2023;66(3):337-343. https://doi.org/10.17073/0368-0797-2023-3-337-343

Introduction

The properties of rolled steel products largely are significantly influenced by the presence of impurities such as sulfur, phosphorus, nitrogen, hydrogen, and others, as well as the content of non-metallic inclusions (NMI) that enter the metal during melting process. The chemical composition, quantity, distribution pattern, and morphology of MNIs have a profound inpact on the quality and properties of steel.

In contemporary practice, aluminum is commonly added to steel for the purpose of final deoxidation. However, the deoxidation product (Al2O3), known as alumina, can form irregular shaped inclusions that tend to cluster together, as reported by Wasai K. et al. [1]. These inclusions have the potential to cause surface defects in rolled steel (Zaitsev A. et al. [2]) and adhere to casting equipment [3 – 5].

In order to mitigate these negative effects, the composition of NMI can be efficiently modified. Calcium is extensively employed as an additive through the use of calcium-containing cored wires [6 – 9]. The addition of calcium to steel enables control over the chemical and phase composition of NMI, making the steel more suitable for deep drawing operations and reducing the occurrence of hydrogen-induced cracking [10 – 13].

When calcium is added to the liquid metal, it dissolves throughout the entire volume. This leads to a reaction with Al2O3 inclusions [14; 15], resulting in their convertion to a liquid phase [16]. As a result, the refining rate is accelerated, with the liquid inclusions rising to the surface more rapidly. Lind M. [17] and Yang J. et al. [18] have documented the reaction responsible for the formation of calcium aluminates

\[\left( {x + \frac{4}{3}y} \right){\rm{A}}{{\rm{l}}_2}{{\rm{O}}_3}({\rm{s}}) + y[{\rm{Ca}}] = {\left( {{\rm{A}}{{\rm{l}}_2}{{\rm{O}}_3}} \right)_x}{\left( {{\rm{CaO}}} \right)_y} + \frac{2}{3}y[{\rm{Al}}].\]

Calcium, known for its strong affinity for sulfur, forms sulfide and oxysulfide NMI (also at the crystallization front). Insufficient level of calcium accumulation along the centerline of the continuous casting billet can result in the elongated manganese sulfide inclusions. This centerline region may contain NMI and micro-discontinuities, leading to the rejection of rolled sheets during ultrasonic inspection or an increased susceptibility to hydrogen-induced cracking in corrosive environment [19].

The modification of NMI with calcium is a complex process. One key challenge involves maintaining the optimal range of calcium concentration within the melt, as well as ensuring the stable assimilation of calcium. Calcium has a high vapor pressure and its addition can induce intense boiling, which may cause liquid metal ejection from the ladle. Therefore, the method by which calcium is added to the liquid metal is crucial. Calcium should be introduced to the depth of the melt, where the ferrostatic pressure balances the pressure of the calcium vapor [20]. The effectiveness of a calcium-containing wire depends on multiple factors, including the steel and slag composition, steel temperature [21] weight, wire insertion rate, as well as wire design and a filler composition.

The filler is enclosed in a steel outer layer [22; 23], which serves the following functions:

– protecting the filler during shipping and storage by preventing contact with air and moisture;

– preventing the filler oxidation by acting as a barrier as the wire passes through the slag layer on the metal’s surface;

– providing rigidity to the wire, enabling it to pass the slag layer;

– facilitating controlled wire introduction depth by preventing direct contact between the core and liquid metal; this can be achieved by adjusting the wire feed rate and the thickness of the outer layer.

– the key design features of the wire include the outer diameter, calcium-containing filler diameter, steel outer layer thickness, outer layer joint type.

In current practice, calcium can be used as a filler material in both powdered and solid forms. The different types of calcium fillers include:

– electrolytic calcium;

– aluminothermic calcium;

– ferrocalcium;

– silicocalcium.

Each of these fillers possesses distinct characteristics, such as variations in the content of metallic calcium, impurity elements, and consequently, the assimilation rate. These differences in wire properties contribute to inconsistencies in the calcium addition process.

The objective of this study is to compare the performance of different calcium-containing wires using pure electrolytic calcium filler and silicocalcium filler.

Materials and Methods

We conducted tests on a ladle-furnace line using calcium-containing wires. The filler material used was pure electrolytic calcium. The wire designs were as follows:

– outer diameter: 10 mm; outer layer thickness: 0.8 mm (10×0.8);

– outer diameter: 11 mm; outer layer thickness: 0.8 mm (11×0.8);

– outer diameter: 10 mm; outer layer thickness: 1.0 mm (10×1.0).

For each wire design, the wire feed rate was adjusted accordingly, ranging from 120 to 180 m/min.

The composition of the wire filler is listed below (in %):

|

The table presents the physical characteristics of the calcium-containing wire.

Physical characteristics of the wire

| ||||||||||||||||||||||||||||||

The wire was utilized in 43 melts, comprising 51 % medium-carbon (0.14 to 0.22 % carbon content), 37 % low-carbon (carbon content <0.14 %) and 12 % low-carbon, low-silicon steel products. A wire-feeding machine introduces the wire into the ladle with the molten metal. No instance of wire breakage were observed. We conducted a comparative analusis of the results obtained from this wire and the CK40 powder-cored wire.

Results and Discussion

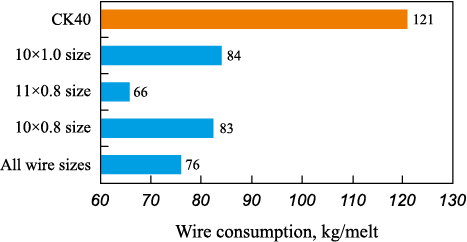

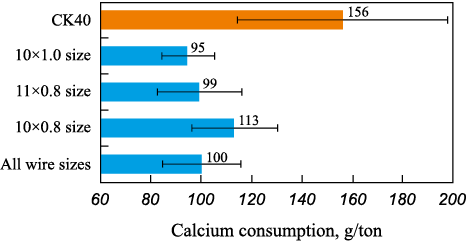

Initially, we compared the average consumption per melt and the calcium consumption (Fig. 1, 2). It is evident that the CK40 wire demonstrate a higher average consumption compared to the calcium-containing wire with an electrolytic calcium filler, ranging from 30 to 45 %. The calcium consumption is higher by 30 to 40 %.

Fig. 1. Consumption of calcium-containing wire for melting

Fig. 2. Calcium consumption for melting |

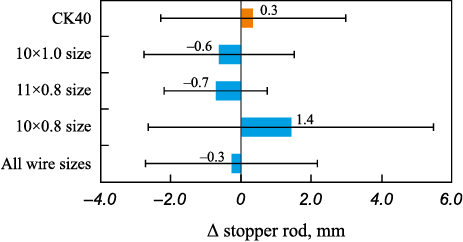

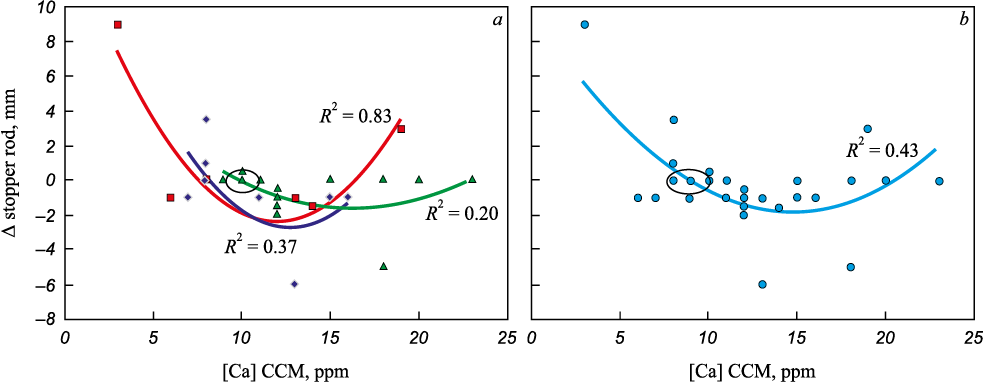

In addition, we conducted an analysis of the steel pourability to evaluate the impact of introducing calcium wire on pourability, while avoiding any obstruction to the casting equipment with with NMI). In order to achieve this, we recorded the positions of the intermediate tundish stopper rod during the steel casting process (Fig. 3). Positive values of this property may indicate the initiation of the NMI deposition, while negative values suggest erosion of refractory steel components. Our findings revealed that the stopper rod positions for calcium-containing wire sizes 10×1.0 and 11×0.8 are negative. This implies that the consumption of these wire sizes can be reduced in comparison to wires sizes 10×0.8 and CK40.

Fig. 3. Changing the tundish stopper position |

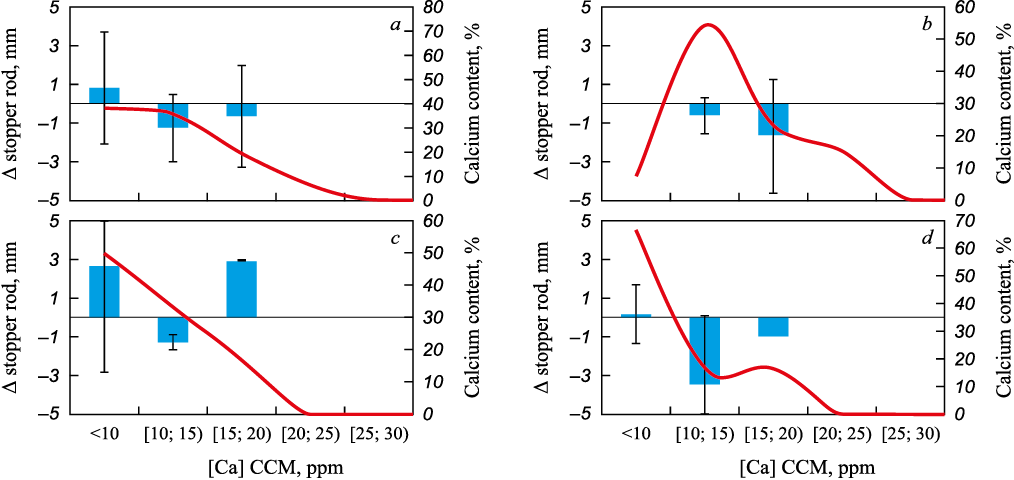

Fig. 4 illustrates the relationship between steel pourability and calcium content for the calcium-containing wire designs tested. It is evident that wire grades 10×1.0 and 11×0.8 exhibit the following trend: as the calcium content increases, the displacement of the intermediate tundish stopper rod shifts towards negative values. The obtained result aligns perfectly with Fig. 3. However, it is important to acknowledge that the variance in the displacement of the stopper rod is relatively high, indicating the presence of additional factors.

Fig. 4. Dependence of the tundish stopper rod from calcium according to the certification piece: |

We thoroughly examined Fig. 3 and 4 and determined the optimal calcium content in the liquid metal that ensures consistent steel pourability for the tested wire grades. The results are depicted in Fig. 5.

Fig. 5. Optimal calcium content in the metal: |

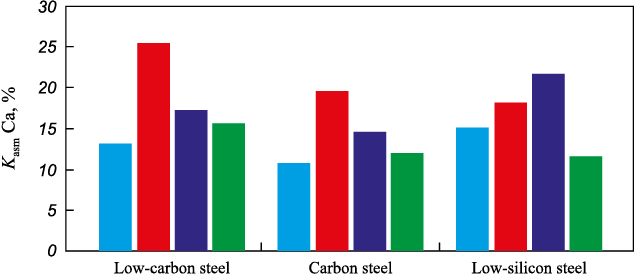

Fig. 6 displays the estimated calcium assimilation factors for each wire size tested, categorized by steel grade. The findings indicate that the 11×0.8 wire exhibits the highest assimilation factor for low-carbon and carbon steel grades, whereas the 10×1.0 wire yields the best results for low-silicon steel grades. On average, wires with electrolytic calcium cores demonstrate assimilation factors that are 35 to 45 % higher compared to the CK40 wire.

Fig. 6. Calcium recovery rate for various calcium-containing wires: |

Furthermore, it is important to emphasize that the primary objective of adding calcium to steel is to enhance the pourability and quality of rolled products. The calcium assimilation factor serves as a valuable tool for estimating the process variables required to achieve the desired calcium content in the melt under specific casting conditions.

Conclusions

We conducted a performance comparison between calcium injection wire filled with electrolytic calcium and the calcium-containing CK40 wire. Our findings reveal that, on average, the former wire exhibits a 30 to 45 % lower consumption (depending on the wire design) compared to the CK40 wire. To assess the steel pourability, we measured the position of the intermediate tundish stopper rod. Through our analysis, we determined that a minimum calcium content of 10 to 12 ppm in the metal guarantees consistent steel pourability. It is evident that expressing steel pourability in terms of the position of the intermediate tundish stopper rod serves as a convenient metric for evaluating the calcium-containing wire performance.

References

1. Wasai K., Mukai K., Miyanaga A. Observation of inclusion in aluminum deoxidized iron. ISIJ International. 2002;42(5):459–466. https://doi.org/10.2355/isijinternational.42.459

2. Zaitsev A.I., Rodionova I.G., Khoroshilov A.D., Mezin F.I., Semernin G.V., Mishnei P.A., Zhironkin M.V., Bikin K.B. Analysis of surface defects occurrence in cold-rolled products from IF-steels. Elektrometallurgiya. 2012;(7):36–40. (In Russ.).

3. Deng Z., Zhu M., Zhong B., Sichen D. Attachment of liquid calcium aluminate inclusions on inner wall of submerged entry nozzle during continuous casting of calcium-treated steel. ISIJ International. 2014;54(12):2813–2820. https://doi.org/10.2355/isijinternational.54.2813

4. Zhang L., Thomas B.G. State of the art in the control of inclusions during steel ingot casting. Metallurgical and Materials Transactions B. 2006;37:733–761. https://doi.org/10.1007/s11663-006-0057-0

5. Agarkov A.Yu., Rutskii D.V., Zyuban N.A., Babin G.V., Kirilichev M.V., Morozov V.V. Identification of nature of the formed “growths” on inner wall of the nozzle during continuous casting of C45E steel. Teoriya i tekhnologiya metallurgicheskogo proizvodstva. 2020;(1):11–17. (In Russ.).

6. Yang W., Zhang L., Wang X., Ren Y., Liu X., Shan Q. Characteristics of inclusions in low carbon Al-killed steel during ladle furnace refining and calcium treatment. ISIJ International. 2013;53(8):1401–1410. https://doi.org/10.2355/isijinternational.53.1401

7. Higuchi Y., Numata M., Fukagawa S., Shinme K. Effect of method of calcium treatment on composition and shape of non-metallic inclusions. Tetsu-to-Hagane. 1996;82(8):671–676. https://doi.org/10.2355/tetsutohagane1955.82.8_671

8. Ren Y., Zhang L., Li S. Transient evolution of inclusions during calcium modification in linepipe steels. ISIJ International. 2014;54(12):2772–2779. https://doi.org/10.2355/isijinternational.54.2772

9. Kushnerev I.V., Serov G.V., Tikhonov S.M., Kuznetsov D.V., Aksel’rod L.M. The non-metallic inclusion’s composition and quantity’s prediction in the low-alloyed tube steel production. Novye ogneupory. 2017;(12):36–41. (In Russ.). https://doi.org/10.17073/1683-4518-2017-12-36-41

10. Choudhary S.K., Ghosh A. Thermodynamic evaluation of formation of oxide-sulfide duplex inclusions in steel. ISIJ International. 2008;48(11):1552–1559. https://doi.org/10.2355/isijinternational.48.1552

11. Takahashi A., Ogawa H. Influence of microhardness and inclusion on stress oriented hydrogen induced cracking of line pipe steels. ISIJ International. 1996;36(3):334–340. https://doi.org/10.2355/isijinternational.36.334

12. Brown A., Jones C.L. Hydrogen induced cracking in pipeline steels. Corrosion. 1984;40(7):330–336. https://doi.org/10.5006/1.3593931

13. Moon J., Kim S.-J., Lee C. Role of Ca treatment in hydrogen induced cracking of hot rolled API pipeline steel in acid sour media. Metals and Materials International. 2013;19(1): 45–48. https://doi.org/10.1007/s12540-013-1008-3

14. Varma N., Pistorius P.C., Fruehan R.J., Potter M., Lind M., Story S. Transient inclusion evolution during modification of alumina inclusions by calcium in Liquid steel: Part I. Background, experimental techniques and analysis methods. Metallurgical and Materials Transactions B. 2011;42:711–719. https://doi.org/10.1007/s11663-011-9516-3

15. Varma N., Pistorius P.C., Fruehan R.J., Potter M., Lind M., Story S. Transient inclusion evolution during modification of alumina inclusions by calcium in Liquid steel: Part II. Results and discussion. Metallurgical and Materials Transactions B. 2011;42:720–729. https://doi.org/10.1007/s11663-011-9517-2

16. Guo J., Cheng S.-s., Guo H.-j., Mei Y.-g. Novel mechanism for the modification of Al2O3 – based inclusions in ultra-low carbon Al-killed steel considering the effects of magnesium and calcium. International Journal of Minerals, Metallurgy and Materials. 2018;25(3):280–287. https://doi.org/10.1007/s12613-018-1571-1

17. Lind M. Mechanism and kinetics of transformation of alumina inclusions in steel by calcium treatment: Doctoral Thesis. Helsinki: Helsinki University of Technology Publications in Materials Science and Engineering; 2006:89.

18. Yang J., Wang X.-h., Jiang M., Wang W.-j. Effect of calcium treatment on non-metallic inclusions in ultra-low oxygen steel refined by high basicity high Al2O3 slag. Journal of Iron and Steel Research International. 2011;(18):8–14. https://doi.org/10.1016/S1006-706X(11)60083-6

19. Khoroshilov A.D., Salikhanov P.A., Byzov D.P., Zhironkin M.V., Bikin K.B. Experience of application of calcium-containing cored wire with various fillers at steel ladle treatment. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2021;77(4):432–444. (In Russ.). https://doi.org/10.32339/0135-5910-2021-4-432-444

20. Krupennikov S.A., Filimonov Yu.P., Kuz’menko A.G., Mazurov E.F. Determination of optimal input speed of flux-cored wire with silicocalcium filler in a ladle with liquid steel. Elektrometallurgiya. 2000;(11):15–22. (In Russ.).

21. Lind M., Holappa L. Transformation of alumina inclusions by calcium treatment. Metallurgical and Materials Transactions B. 2010;41:359–366. https://doi.org/10.1007/s11663-009-9337-9

22. Kablukovskii A.F., etc. Steel Ladle Treatment with Flux-Cored Wire. Moscow: Metallurgizdat; 2006:288. (In Russ.).

23. Shalimov A.G., Semin A.E., Galkin M.P., Kosyrev K.L. Innovative Development of Electric Steelmaking. Moscow: Metallurgizdat; 2014:308. (In Russ.).

About the Authors

A. D. KhoroshilovRussian Federation

Andrei D. Khoroshilov, Chief Expert on the Product “Calcium Injection Wire and Alloying Elements”

49 Kashirskoe Route, Moscow 115409, Russian Federation

S. A. Somov

Russian Federation

Sergei A. Somov, Head of the Department

45 Br. Batashevykh Str., Vyksa, Nizhny Novgorod Region 607060, Russian Federation

V. D. Katolikov

Russian Federation

Vladimir D. Katolikov, Chief Expert on the Product “Calcium Injection Wire and Alloying Elements”

49 Kashirskoe Route, Moscow 115409, Russian Federation

V. A. Murysev

Russian Federation

Vladimir A. Murysev, Chief Specialist

45 Br. Batashevykh Str., Vyksa, Nizhny Novgorod Region 607060, Russian Federation

R. E. Bocherikov

Russian Federation

Roman E. Bocherikov, Postgraduate of the Chair “Energy-Efficient and Resource-Saving Industrial Technologies”

4 Leninskii Ave., Moscow 119049, Russian Federation

M. R. Yarmukhametov

Russian Federation

Marat R. Yarmukhametov, Technologist

45 Br. Batashevykh Str., Vyksa, Nizhny Novgorod Region 607060, Russian Federation

Review

For citations:

Khoroshilov A.D., Somov S.A., Katolikov V.D., Murysev V.A., Bocherikov R.E., Yarmukhametov M.R. Using calcium-containing injection wire filled with electrolytic calcium in steel ladle treatment. Izvestiya. Ferrous Metallurgy. 2023;66(3):337-343. https://doi.org/10.17073/0368-0797-2023-3-337-343