Scroll to:

Reserves for reducing energy consumption when rolling section bars on modern rolling mills

https://doi.org/10.17073/0368-0797-2023-3-290-293

Abstract

Metallurgical production is a highly energy-intensive process, and the search for solutions to reduce energy costs remains an urgent task for all stages. In this regard, the production of finished rolled products is considered as the most promising direction for the implementation of energy-saving technologies. There are two ways to reduce energy costs in hot rolling of section bars: saving energy for heating and improving the use of the main equipment to reduce intermediate energy costs. Due to the difference in silt conditions at the moment of capture and at the steady stage of the rolling process, a reserve of retracting friction forces arises, which can be used for additional shaping in non-drive devices and thereby increase the efficiency of the main equipment and reduce overall energy costs. For the practical implementation of the proposed concept, dependence was obtained that makes it possible to estimate the power potential that is not used at the steady stage of the rolling process. Using the obtained dependence, it was found that when rolling in smooth rolls, the potential of friction forces is used only by 50 – 60 %, and when rolling in calibers, by 35 – 40 %. It was experimentally established that during the rolling of shaped sections in passes with an elongation ratio of less than 1.10 – 1.15, more than 50 % of the energy is spent on idling. However, by replacing drive stands in these passes with non-drive cassettes (in continuous groups), it is possible to increase the efficiency of adjacent stands by 4 – 5 % and reduce energy costs.

Keywords

For citations:

Fastуkovskii A.R., Glukhov M.I., Vakhrolomeev V.A. Reserves for reducing energy consumption when rolling section bars on modern rolling mills. Izvestiya. Ferrous Metallurgy. 2023;66(3):290-293. https://doi.org/10.17073/0368-0797-2023-3-290-293

Metallurgical production is considered one of the most energy-intensive industries, consuming up to 90 % of coking coal, 50 % of generated electricity, and 25 % of natural gas [1]. The final stage of metallurgical processing, known as rolling production, requires a significant amount of fuel for both heating the billet before rolling (1.30–1.65 GJ/t) and during the rolling process itself (0.45–1.20 GJ/t) [2]. These figures convincingly highlight the importance of efforts to reduce energy costs in rolled product manufacturing.

Enhancing the utilization of friction forces within the deformation zone of a rolling stand represents a key opportunity for reducing energy consumption in the production of section bars on modern continuous rolling mills [3 – 5]. By doing so, the overall efficiency of the primary rolling equipment can be increased. To implement this approach, additional non-driven devices, located in close proximity to the drive stands, can be employed for the deformation or longitudinal separation of the strip [6 – 9].

It is widely recognized that the rolling process relies on friction forces between the metal and the rolls. The more effectively these friction forces are harnessed during the forming process, the higher the process efficiency and the more efficiently energy is utilized. However, the varying force conditions during the initial gripping of the metal by the rolls and during the steady stage of the rolling process create circumstances where the potential of friction forces within the deformation zone is not fully realized. Addressing this issue necessitates the use of continuous devices, such as rolls and dividing devices, which facilitate additional work to be performed.

In order to quantify the untapped potential of friction forces during the steady stage of the rolling process, we can calculate the unused power (∆N) by considering the disparity in friction coefficients between the gripping phase (μg ) and the steady stage (μs ) of hot rolling, where μg /μs ≈ 1.2 ÷ 1.4 [10]. This can be determined using the equation:

∆N = Ns – Nd ,

where Ns represents the power that can be generated by friction forces during the steady stage of hot rolling; Nd is the power required for deformation in the driven stand.

The maximum power generated by friction forces during the steady stage of hot rolling (assuming a zero-length advance zone) can be calculated using the equation:

Nу = 2pavg μs bavg ld v,

where рavg denotes the average normal pressure; bavg represents the average strip width; ld is the length of contact arc; v is the rolling speed.

To determine the power required during deformation, we utilize the well-known Fink equation [11], with the substitution:

\[\Delta h \approx {h_{{\rm{avg}}}}\ln \left( {\frac{{{h_0}}}{{{h_1}}}} \right),\]

where ∆h is the absolute reduction; havg is the average strip height; h0 and h1 refer to the strip height before and after rolling in the driven stand, respectively.

It should be noted that this assumption introduces an error of 1 – 3 % for degrees of deformation up to 60 %. After appropriate transformations and incorporating the μg /μs ratio, we obtain:

∆N = pavg bavg v (1.54μg ld – ∆h).

The obtained ∆N value makes it possible to estimate the unused potential of friction forces in the deformation zone during hot rolling. The calculations reveal that, when rolling a rectangular strip on smooth rolls, only 50 – 60 % of the maximum potential of friction forces is utilized under maximum reductions and 35 – 40 % in subsequent passes due to differences in force conditions between gripping and the steady stage of rolling. This inefficiency significantly impacts the rolling process, resulting in increased energy consumption. Therefore, the implementation of non-driven devices for deformation and longitudinal separation is recommended.

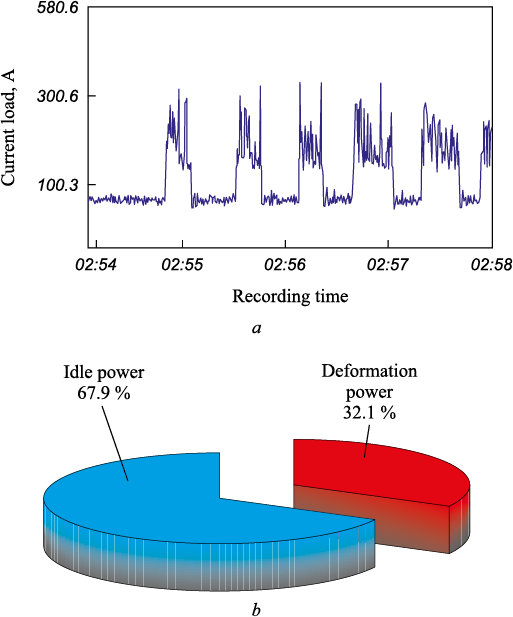

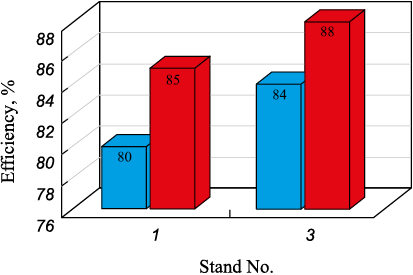

To enhance the efficiency of rolling bars, a more complete utilization of the potential of friction forces can be achieved by replacing driven stands with non-driven ones in sections where the elongation coefficient falls below 1.10 – 1.15. Fig. 1, a presents a diagram illustrating the recording of the current of the main engine in the second stand of a medium-section mill during the production of angle No. 9, with a drawing ratio of 1.03. Fig. 1, b depicts the power distribution for this case, with the majority of power being used for idling (67.9 %), while only a small fraction (32.1 %) is allocated to product formation. To address this issue, the implementation of a non-driven stand, specifically a cassette, in place of the drive stand for the given pass can be considered. This adjustment enables the redistribution of power for product deformation across adjacent stands from the same group without the need for stopping. Such an approach will lead to a reduction in energy costs by minimizing idle power consumption and an increase in the efficiency of adjacent stands (Fig. 2).

Fig. 1. Energy costs during rolling in the second stand

Fig. 2. Change in efficiency of 1 and 3 stands when replacing |

The medium-section mill being considered has an assortment comprising 83 % of shaped profiles, such as angles, beams, and channels. Within this assortment, there are sections with an elongation ratio of less than 1.10 – 1.15, indicating areas where improvement is needed. By incorporating non-driven stands in these passes, and with an annual production output of 1.4 million tons of finished products, energy savings of up to 0.75 kWh/t can be achieved. In monetary terms, this translates to an annual savings of 4.8 million rubles. Additionally, the use of non-driven stands in the form of cassettes results in reduced metal consumption, costs, depreciation deductions, and operating expenses compared to traditional rolling stands. This provides an additional benefit of 15 million rubles per year. Considering the costs associated with manufacturing the new equipment, the investment in non-driven stands is projected to have a payback period of 0.8 years.

Conclusions

During the steady state stage of hot rolling, there exists an untapped potential of frictional forces in the deformation zone due to the differing force conditions between gripping and the steady state stage of the process. This inefficient utilization of energy can result in suboptimal performance.

In order to enhance the efficient utilization of frictional forces in the deformation zone during the steady stage of the rolling process, it is proposed to incorporate non-driven devices in close proximity to the driving stands for additional deformation and longitudinal separation. Research indicates that when the drawing ratio falls below 1.10 – 1.15, it is advisable to replace the drive stands with non-drive stands. This approach not only reduces energy consumption and operating costs but also enhances the efficiency of the primary equipment.

References

1. Volkova I.A. Review of new directions for energy. Metallurg. 2005;(8):32–36. (In Russ.).

2. Dubina O.V. Dynamics of energy consumption in rolling shops. Proizvodstvo prokata. 2003;(1):29–32. (In Russ.).

3. Fastykovskii A.R., Fastykovskii D.A. Evaluation of the possibilities of contact friction forces in order to intensify the rolling process at an established stage. Proizvodstvo prokata. 2013;(7):9–12. (In Russ.).

4. Matsuo G., Suzuki M. The latest technology of multi-slit rolling. SEA. ISI Quaterly. 1995;(3):49–58.

5. Sidelnikov S.B., Galiev R.I., Bespalov V.M., Samchuk A.P. Determining power–energy parameters of combined rolling–extrusion process for low-plastic aluminium alloys. Non-Ferrous Metals. 2018;44(1):30–36. https://doi.org/10.17580/nfm.2018.01.06

6. Sidelnikov S., Galiev R., Lopatina E., Samchuk A. Analysis of energy–force parameters of combined processing for receiving modifying bars from Al–5Ti–1B alloy. Non-Ferrous Metals. 2017;42(1):30–35. https://doi.org/10.17580/nfm.2017.01.07

7. Fastykovskii A.R. Region for extrolling and effective deformation modes. Russian Journal of Non-Ferrous Metals. 2011;52(3):230–233. https://doi.org/10.3103/S1067821211030084

8. Grzyb R., Misiolek Z. The concept and the theoretical fundaments of a new combined process of rolling and extrusion. Archiwum Hutnitwa. 1983;28(3):305–319.

9. Grzyb R., Misiolek Z. The experimental investigations on the force parameters and metal flow in the combined process of rolling and extrusion. Archiwum Hutnitwa. 1983;28(3):321–340.

10. Grudev A.P. Theory of Rolling. Moscow: Intermet Engineering; 2001:280. (In Russ.).

11. Nikitin G.S. Theory of Continuous Longitudinal Rolling. Moscow: Bauman Moscow State Technical University; 2009:399. (In Russ.).

About the Authors

A. R. FastуkovskiiRussian Federation

Andrei R. Fastykovskii, Dr. Sci. (Eng.), Prof. of the Chair “Metal Forming and Metal Science. OJSC “EVRAZ ZSMK”

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

M. I. Glukhov

Russian Federation

Maksim I. Glukhov, Postgraduate of the Chair “Metal Forming and Metal Science. OJSC “EVRAZ ZSMK”

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

V. A. Vakhrolomeev

Russian Federation

Vladimir A. Vakhrolomeev, Postgraduate of the Chair “Metal Forming and Metal Science. OJSC “EVRAZ ZSMK”

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Fastуkovskii A.R., Glukhov M.I., Vakhrolomeev V.A. Reserves for reducing energy consumption when rolling section bars on modern rolling mills. Izvestiya. Ferrous Metallurgy. 2023;66(3):290-293. https://doi.org/10.17073/0368-0797-2023-3-290-293