Scroll to:

Occurrence of characteristic defects of grinding balls from rejects of continuously cast billets of rail steel

https://doi.org/10.17073/0368-0797-2023-2-222-228

Abstract

On the basis of metallographic studies, the authors determined the characteristic defects of grinding balls rolled from the rejects of continuously cast billets of K76F rail steel. Relationship of the presence of internal defects of the balls with their impact resistance was established. Defects in the form of internal cracks with accumulations of non-metallic inclusions in the area of their localization and flocks have the greatest impact on the reduction of balls impact resistance. Such defects are the cause of balls destruction during impact resistance tests in 62 and 17 % of cases, respectively. The effect of internal cracks without significant accumulations of non-metallic inclusions and quenching microcracks located along the boundaries of the phase interface was estimated at 12 and 9 %. The regularities and mechanism of influence of the rejects chemical composition of K76F rail steel billets on the probability of destruction of the balls produced from them during impact resistance tests were established. An increase in sulfur content in the billets of the studied rail steel reduces impact resistance of the balls produced from them, as it contributes to formation of non-plastic sulfides that concentrate in the area of internal cracks. An increase in hydrogen content in rail steel naturally contributes to an increase in probability of formation of the flocks, which significantly reduce the balls stability to shock loads. An increase in carbon content in the initial billets affects the increase in probability of destruction of K76F steel balls during copra tests. It is explained by formation of cementite-type carbides when carbon content corresponding to the eutectoid steel is reached. In general, the relative degree of influence of the K76F rail steel chemical composition on impact resistance of grinding balls is 48 %.

Keywords

For citations:

Umanskii A.A., Morozov I.S., Protopopov E.V., Simachev A.S., Dumova L.V. Occurrence of characteristic defects of grinding balls from rejects of continuously cast billets of rail steel. Izvestiya. Ferrous Metallurgy. 2023;66(2):222-228. https://doi.org/10.17073/0368-0797-2023-2-222-228

Introduction

Grinding balls are commonly used in various industries, including metallurgy, mining, and cement production, for the milling of initial materials [1 – 3]. The primary properties that determine the operational efficiency and lifetime of grinding balls are their hardness (both surface and bulk) and impact resistance [4 – 6]. These specifications are typically achieved by doping initial steels with chromium [7; 8] and applying heat treatment to the balls after their rolling process [9 – 11].

Previous research [12; 13] has established that internal defects can significantly affect the impact resistance of grinding balls. However, current regulations regarding the fabrication of these products do not include specifications for quality control of the ball macrostructure, and such control is not typically performed. As a result, there is a lack of substantiated information regarding the characteristic defects that may cause a decrease in the operational lifespan of grinding balls due to breakage under impact loads.

Therefore, studies on the characteristic defects of grinding balls in relation to their impact resistance are necessary.

This study focuses on grinding balls produced at OAO Gurievsk Metallurgical Plant (OAO GMZ) from rejects of continuously casted billets of rail steel supplied by Mechel company. In recent years, reprocessing of these billets into grinding balls has become increasingly popular due to the rising number of rejects [14 – 17], which is caused by more stringent rail quality requirements [18; 19]. Currently, OAO GMZ is one of the leading producers of grinding balls in Russia, annually rolling 25-40 thousand tones of balls from rejects of K76F rail steel, which account for 30 – 50 % of the total yield of these products. The results of studies on the defects of grinding balls produced from rejected billets of rail steels provide a scientific foundation for improving their impact resistance in the context of mass production. The practical application of these results is associated with significant economic benefits.

Experimental

The defects of grinding balls produced from rejected rail steel were analyzed using metallography, specifically an OLYMPUS GX-51 optical microscope, and X-ray structural analysis, specifically a Shimadzu XRD-6000 diffractometer. The study focused on grinding balls with a diameter of 60 mm made from K76F rail steel that were rejected after hardness drop tests. Twenty batches of balls were analyzed.

The study analyzed the microstructure parameters, liquation of the main chemical elements, and the distribution of hardness over the cross-section of the rejected grinding balls.

The liquation of chemical elements over the cross-section was analyzed through spectral analysis, specifically X-ray fluorescent analysis according to State Standard GOST 28033-89 using a Shimadzu XRF, and photoelectric spectral analysis according to State Standard GOST 18895-97 using a DFS-71 spectrometer.

Furthermore, the study analyzed the influence of the steel-making stage parameters on the probability of unsatisfactory results of the hardness drop tests using multiple regression analysis. The research object consisted of a random selection of 50 batches of balls with a diameter of 60 mm.

Results and discussion

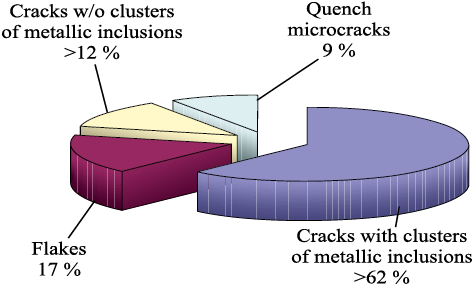

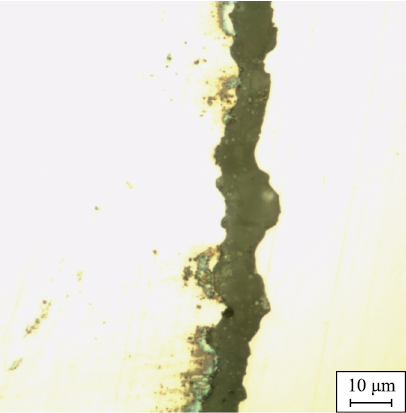

The distribution of defects leading to the destruction of grinding balls made from K76F rail steel in impact resistance tests is presented in Fig. 1. The majority of the defects are cracks with clusters of nonmetallic inclusions, as shown in Fig. 2. The nonmetallic inclusions observed in the region of defect localization are primarily composed of complex oxides such as Al2O3 – CaO – MgO, Al2O3 – CaO, Al2O3 – MgO, which are classified as non-plastic or fragile (capable of expanding into lines upon plastic deformation, but destructed after reaching a certain degree of deformation), as well as manganese and iron sulfides. The main bulk of nonmetallic oxide inclusions is formed during steel deoxidation.

Fig. 1. Distribution of defects of grinding balls

Fig. 2. Internal crack in grinding ball |

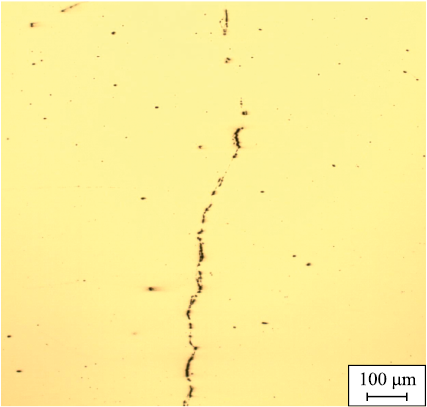

It should be noted that the rail steels are not deoxidized by aluminum in accordance with the current production technology, and the primary source of its addition to steel is ferroalloys, where aluminum is present in the form of residual impurity. The concentration of sulfide inclusions, which mainly formed during steel crystallization, is directly determined by sulfur content. Iron sulfides have a negative impact on the quality of rolled products, and their concentration can be reduced by increasing the manganese content in steel. The second most common type of defect are flakes, which are identified in accordance with the generally accepted classification of fractures [20]. On the destruction surface, there are segments in the form of light spots, characterized by a coarser crystalline structure in relation to the main metal, as shown in Fig. 3.

Fig. 3. Flakes in the balls fracture after impact resistance tests |

Cracks without clusters of nonmetallic inclusions (Fig. 4) in the region of their localization were the cause of unsatisfactory impact resistance tests of grinding balls in 12 % of cases.

Based on the above, it can be concluded that the defects that determine the impact resistance of grinding balls from made from K76F rail steel are primarily of steelmaking origin.

Fig. 4. Internal crack in the ball splitted up after 24 impacts |

To validate the results, further statistical analyses were conducted to examine the impact of billet chemical composition on the rejection rate of balls after hardness drop tests. The findings revealed that an increase in the content of sulfur, hydrogen, and carbon within the existing range of their concentration (as shown in Table 1) significantly contributed to the higher rate of ball rejection during impact resistance tests:

Rdrop = –12.9 + 3.7[H] + 102.3[S] + 11.8[C],

where Rdrop is the rejecting of balls based on the results of hardness drop tests, %; the variables [C], [S], and [H] represent the content of carbon and sulfur in steel, %, and hydrogen content in steel, ppm, respectively.

Table 1. Statistical characteristics of functions and optimization parameter

|

Based on the metallographic studies presented, it can be concluded that the concentration of hydrogen in steel has an impact on the probability of ball destruction during hardness drop tests, as evidenced by the formation of flakes detected in the fracture of some broken balls. Similarly, the concentration of sulfur has an impact on the formation of non-plastic sulfides.

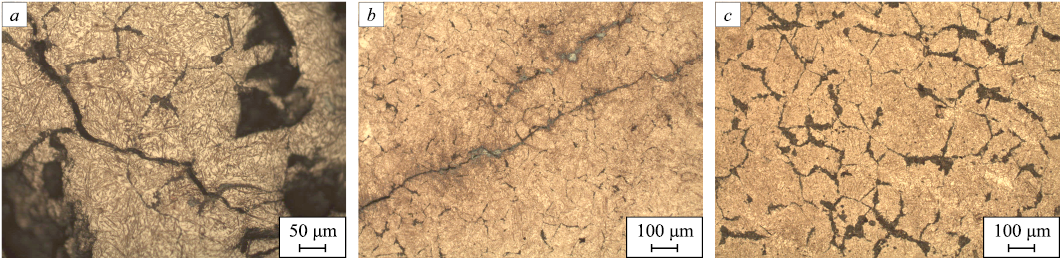

According to the metallographic studies, microcracks were found along the interface boundaries of martensite and troostite in the structure of the remaining 9 % of balls that did not pass the impact resistance tests (as shown in Fig. 5, a and b). The presence of troostite indicates deviation from the optimal thermal processing conditions, specifically a decreased cooling rate during cooling. The two-phase structure obtained is defective due to the significant difference in mechanical properties between martensite and troostite, leading to an increased probability of item destruction under impact loads. The hardness variation range in the ball core with martensite + troostite structure is 7 – 8 HRC, which confirms the aforementioned thesis about the heterogeneous distribution of mechanical properties. It is worth noting that this heterogeneity of properties is further exacerbated by the presence of cementite-type carbides in the core of such balls in addition to martensite and troostite (as shown in Fig. 5, c). The existence of carbides indicates an increase in carbon content, particularly in hypereutectoid compositing, as evidenced by liquation (as shown in Table 2). It is worth noting that the liquation of other chemical elements is negligible in comparison.

Fig. 5. Microstructure of the ball splitted up after 29 impacts:

Table 2. Distribution of content of the main chemical elements

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Therefore, the formation of cementite-type carbides after reaching the carbon content corresponding to hypereutectoid steel is the main factor contributing to the negative influence of increased carbon content on the impact resistance of balls.

The relative cumulative degree of influence of the concentration of these chemical elements on the rejection of balls after hardness drop tests was found to be 48 %. Based on these results, the remaining 52 % of the relative influence on the impact resistance of balls is related to the parameters of steel deoxidation and the heat treatment of balls after rolling. One efficient method to reducing the concentration of alumina oxide inclusions is the use of new grades of ferroalloys with decreased aluminum content. This is particularly relevant since some common types of ferroalloys can have significant levels of aluminum content, such as 1.0 – 3.5 % in ferrosilicon. Moreover, decreasing the concentration of nonmetallic inclusions is naturally promoted by reducing the oxidation degree of steel during tapping from melting facilities, which can be achieved through of improved blowdown modes. With regards to the influence of heat treatment parameters on defect formation in grinding balls, it can worth noting that an effective approach to decreasing the probability of quench cracks is through the use of quenching media with high cooing capacity.

Conclusions

Based on a series of metallographic and statistical studies, characteristic defects were identified that cause a decrease in the impact resistance of grinding balls made from rejects of K76F rail steel. Analysis of the nature of these defects revealed that they are mainly attributed to the steelmaking process, such as internal cracks with clusters of nonmetallic inclusions and flakes. The formation these defects is directly related to the sulfur, hydrogen, and carbon content in the steel. The relative influence of these chemical elements on the impact resistance of grinding balls made from K76F rail steel in actual range of variation of their concentration was found to be 48 %. Furthermore, significant influence of the parameters of the thermal treatment on the impact resistance of grinding balls was identified. This was confirmed by the existence of quench cracks in the fracture of 9 % of balls that failed to pass hardness drop tests.

References

1. Rakhutin M.G., Boiko P.F. Ways to improve assessment methods of the main characteristics of grinding balls. Ugol’. 2017;(12):49–52. (In Russ.). https://doi.org/10.18796/0041-5790-2017-12-49-52

2. Krutilin A.N., Bestuzhev N.I., Bestuzhev A.N., Kalenkovich D.N. Grinding bodies. Problems. Prospective. Lit’e i metallurgiya. 2009;(4(53)):26–33. (In Russ.).

3. Aldrich C. Consumption of steel grinding media in mills – A review. Minerals Engineering. 2013;49:77–91. https://doi.org/10.1016/j.mineng.2013.04.023

4. Naizabekov A.B., Mukhametkaliev B.S., Arbuz A.S., Lezhnev S.N. Reduction of consumption of steel grinding balls by improving their production technology. Vesti vysshikh uchebnykh zavedenii Chernozem’ya. 2016;(4(46)): 78–86. (In Russ.).

5. Lam M.M., Serov A.I., Smyrnov Y.N., Ternavskii A.N., Mykheiev V.V. Production of hard (class V) grinding balls at PJSC “DMPZ”. Steel in Translation. 2017;47(5):325–329. https://doi.org/10.3103/S0967091217050072

6. Umucu Y., Deniz V. The effect of ball type in fine particles grinding on kinetic breakage parameters. Inzynieria Mineralna. 2015;16(1):197–203.

7. Stalinskii D.V., Rudyuk A.S., Solenyi V.K. Choice of material and technologies for heat treatment of grinding balls operating mainly in conditions of abrasive wear. Stal’. 2017;(6):64–69. (In Russ.).

8. Bai X., Jin Y. Heat treatment of wear-resistant steel ball for large ball mills. Heat Treatment of Metals. 2017;42(5):193–196. https://doi.org/10.13251/j.issn.0254-6051.2017.05.040

9. Arlazarov A., Bouaziz O., Masse J.P., Kegel F. Characterization and modeling of mechanical behavior of quenching and partitioning steels. Materials Science and Engineering: A. 2015; 620:293–300. https://doi.org/10.1016/j.msea.2014.10.034

10. Zhang J., Ding H., Misra R.D.K., Wang C. Enhanced stability of retained austenite and consequent work hardening rate through pre-quenching prior to quenching and partitioning in a Q–P microalloyed steel. Materials Science and Engineering: A. 2014; 611:252–256. https://doi.org/10.1016/j.msea.2014.05.074

11. Camurri C., Carrasco C., Colàs R. Improving the working life of steel grinding balls by optimizing their hardness and tenacity. Materials Science Forum. 2014;783–786:2260–2265. https://doi.org/10.4028/www.scientific.net/MSF.783-786.2260

12. Efremenko V.G. Metallographic analysis of causes of destruction of rolled steel bodies for drum mills. Vestnik Priazovskogo gosudarstvennogo tekhnicheskogo universiteta. 2000;(9):89–91. (In Russ.).

13. Umanskii A.A., Golovatenko A.V., Oskolkova T.N., Simachev A.S., Shchukin A.G. Influence of macro- and microstructure of steel grinding balls on their impact resistance. Izvestiya. Ferrous Metallurgy. 2019;62(4):283–289. (In Russ.). https://doi.org/10.17073/0368-0797-2019-4-283-289

14. Pater Z., Tomczak J., Bulzak T., Cyganek Z., Andrietti S., Barbelet M. An innovative method for producing balls from scrap rail heads. International Journal of Advanced Manufacturing Technology. 2018;97(1-4):893–901. https://doi.org/10.1007/s00170-018-2007-9

15. Tomczak J., Pater Z., Bulzak T. The flat wedge rolling mill for forming balls from heads of scrap railway rails. Archives of Metallurgy and Materials. 2018;63(1):5–12. https://doi.org/10.24425/118901

16. Pater Z., Tomczak J., Bulzak T. A cross wedge rolling process for forming 70 mm diameter balls from heads of scrap railway rails. Procedia Manufacturing. 2017;11:466–473. https://doi.org/10.1016/j.promfg.2017.07.137

17. Baranov N.A., Tulupov O.N. Production of grinding balls from rail steel. Aktual’nye problemy sovremennoi nauki, tekhniki i obrazovaniya. 2017;(1):96–99. (In Russ.).

18. Golovatenko A.V., Volkov K.V., Aleksandrov I.V., Kuznetsov E.P., Dorofeev V.V., Sapelkin O.I. Commissioning of universal rail-and-beam mill and mastering the technology of rail production on modern equipment in the rail-and-beam workshop of JSC “EVRAZ ZSMK”. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2014;6(1374):32–38. (In Russ.).

19. Shaburov D.V., Popov A.E., Zagumennov O.V. Rail production on a universal mill. Steel in Translation. 2016;46(7): 503–504. https://doi.org/10.3103/S0967091216070111

20. Gerasimova L.P., Ezhov A.A., Maresev M.I. Structural Steel Fractures: Handbook. Moscow: Metallurgiya; 1987;272. (In Russ.).

About the Authors

A. A. UmanskiiRussian Federation

Aleksandr A. Umanskii, Dr. Sci. (Eng.), Assist. Prof. of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

I. S. Morozov

Russian Federation

Ivan S. Morozov, Candidates for a Degree of Сand. Sci. (Eng.) of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

E. V. Protopopov

Russian Federation

Evgenii V. Protopopov, Dr. Sci. (Eng.), Prof. of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

A. S. Simachev

Russian Federation

Artem S. Simachev, Cand. Sci. (Eng.), Assist. Prof. of the Chair “Metal Forming and Metal Science. “EVRAZ ZSMK”

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

L. V. Dumova

Russian Federation

Lyubov’ V. Dumova, Candidates for a Degree of Сand. Sci. (Eng.) of the Chair of Ferrous Metallurgy

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Umanskii A.A., Morozov I.S., Protopopov E.V., Simachev A.S., Dumova L.V. Occurrence of characteristic defects of grinding balls from rejects of continuously cast billets of rail steel. Izvestiya. Ferrous Metallurgy. 2023;66(2):222-228. https://doi.org/10.17073/0368-0797-2023-2-222-228