Scroll to:

Microstructure and elemental analysis of iron-based powder composite materials

https://doi.org/10.17073/0368-0797-2023-2-148-153

Abstract

This paper studies the kinetics of structure formation of an iron-bronze composite containing solid lubricants. Depending on the compacting pressure and sintering temperature, binary and complex phases are detected in the iron-bronze structure. The presence of solid lubricants in the composition of the composite material significantly reduces interaction of the liquid (bronze) and solid (iron) phases during sintering. Talc and graphite, which are heat–resistant at a sintering temperature of 850 – 1150 °C, were used as solid lubricants. The presence of talc, located on the surface of compressed particles of iron, copper, tin and graphite, significantly reduces the effect of their interaction. At the same time, the micro-talc particles envelop them, and its thermal stability retains this state up to high temperatures (approximately 900 °C). It was established that there is no perlite in the microstructure of iron-bronze sintered at a temperature of 850 °C. This can be explained by the talc adsorbing ability on the surface of iron particles which prevents diffusion of carbon into the iron crystal lattice. An increase in the sintering temperature up to 1000 °C leads to the formation of perlite in the iron-bronze structure, while the amount of perlite predominates over ferrite. This indicates the partial burnout of talc from the surface of iron particles and the opening of diffusion paths to carbon. At a sintering temperature of 1150 °C, perlite and a grid of light inclusions are formed in the microstructure of the iron-bronze samples. According to the results of electron microprobe analysis, the light inclusions are solid solutions of variable compositions such as Fe – Cu – Sn, Cu – Fe – Sn, Cu – Sn – Fe. In order to confirm these assumptions, a phase X-ray diffraction analysis was performed. Diffraction patterns of these samples are represented by reflections of iron and copper crystals. The absence of diffraction effects (characteristic of tin crystals) is conditioned by tin solubility in the copper lattice. This is due to the low melting point of tin (232 °C) and its ionic radius, which allows isomorphically replacing of copper and iron ions with tin ions (their difference is less than 15 %).

Keywords

For citations:

Musurzaeva B.B. Microstructure and elemental analysis of iron-based powder composite materials. Izvestiya. Ferrous Metallurgy. 2023;66(2):148-153. https://doi.org/10.17073/0368-0797-2023-2-148-153

Introduction

Studies [1 – 3] investigate the kinetics of structure formation during sintering of composite material containing 3.0 % Cu, 1.5 % Sn, remainder: iron. It was established that at a temperature above 232 °C, due to melting of tin, a liquid phase is formed in the system. However, due to existence of oxide layers on fine iron and copper particles, they are not wetted by tin [4; 5]. With an increase in the sintering temperature to 850 °C, there occurs active recovery of all particles of solid phase and their dissolution in liquid phase [6 – 9].

The studies demonstrate that the interaction of the liquid phase with iron particles at the sintering temperature of 850 °C in 1 h, and the subsequent cooling lead to the formation of a fine grain multiphase heterogeneous structure. X-ray studies demonstrated that the structure of the sintered samples contains binary chemical phases (Cu3Sn, CuSn, FeSn2 , Fe3Sn2 , FeSn), as well as the phases of complex composition.

Experimental

The chemical composition of mixtures of the considered iron bronze composite materials containing solid lubricants are summarized in Table 1. The mixtures also contain solid lubricants (graphite and talcum in combination with copper and iron).

Table 1. Chemical composition of the charge

| ||||||||||||||||||||||||||||||||||||

The components were mixed in a Y-type mixer in 1 h. The charges were compacted using a Mannesmann hydraulic press under pressure of 400, 700 and 1000 MPa. Sintering was carried out in a Koyo Lindberq conveyer furnace at temperatures of 850, 1000 and 1150 °C in an environment of endothermal gas.

The microstructures of the experimental samples were analyzed using a Neofot-21 metallographic microscope, and elemental analysis at certain points using a Camsan X-ray spectral microanalyzer.

Results and discussion

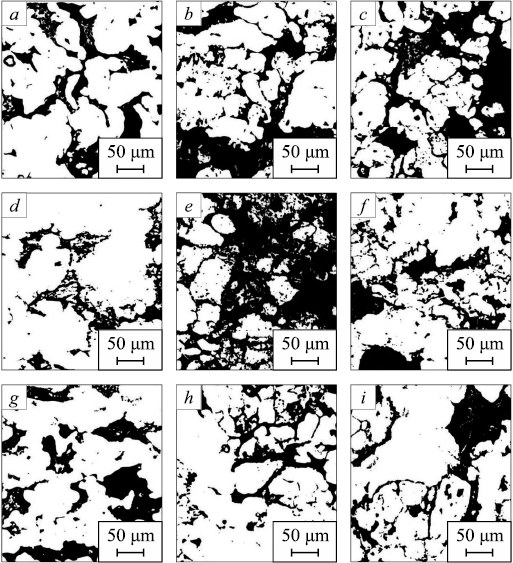

The metallographic analysis of all samples considered demonstrates that their structure at 850 °C nearly does not contain perlite (Fig. 1). This, first of all, is related to the fact that talcum is adsorbed on the surface of metal particles with high adhesion, preventing carbon diffusion across iron surface [10; 11]. In addition, it was established that a sintering temperature of 850 °C is insufficient in the thermodynamic conditions considered herein for carbon diffusion [8; 12; 13].

Fig. 1. Microstructure of sintered iron-bronze at a temperature of 850 °C: |

Talcum and graphite at 850 °C are characterized by thermal stability and screen the surface of copper and iron particles, thus maintaining them separately. Presumably, due to the same reason iron and copper particles are not wetted by the tin liquid phase.

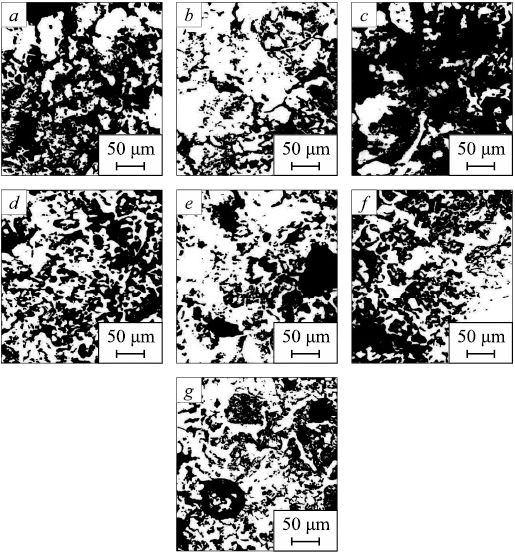

With an increase in the sintering temperature to 1000 °C, the perlite structure in the alloy with the composition A dominates over the ferrite structure with solid lubricants, and single highlighted bright inclusions are visible (Fig. 2).

Fig. 2. Microstructure of sintered iron-bronze powder |

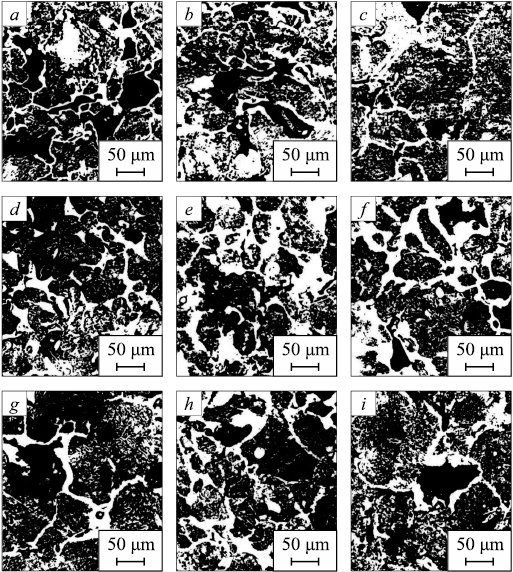

An increase in the sintering temperature to 1150 °C leads to formation of cementite in the alloy with the composition A in the form of grid around the pores and along the particle boundaries.

In the structure of these samples single highlighted bright inclusions are not detected, while particles of solid lubricants are hardly noticeable (Fig. 3).

Fig. 3. Microstructure of a sintered iron-bronze composite |

The microstructure of the alloy with the composition B is comprised of fine particles of bright inclusions and cementite in a high amount. In some places these particles surrounding the perlite matrix, form a continuous lattice. The matrix of alloys is comprised of fine perlite, which is characteristic of the cuprous compositions on the basis of iron [8; 14 – 16].

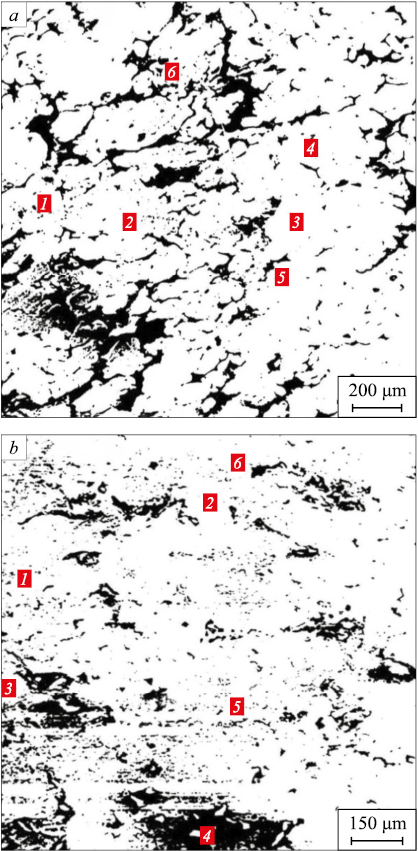

In order to study the chemical composition of the particles in a Camsan X-ray spectral microanalyzer, the microstructure was analyzed at certain selected points of the alloys with the compositions B and C (Fig. 4). The chemical compositions (Table 2) at different points sharply differ from each other. For instance, the alloy with the compositing B is comprised of Fe – Cu – Sn solid solution at high concentrations of copper in points 1, 2 and 6 (97.88, 98.76 and 94.38 % (hereinafter wt. %)). The amount of elements on certain particles is summarized in Table 2.

Fig. 4. Location of the points determining chemical composition

Table 2. Chemical composition of the iron-bronze in micro-volume

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper is the predominant element in points 3 and 4. At the boundaries of these points, Fe – Cu – Sn solid solutions are located with a higher (34.22 %) copper content. The amount of non-metal inclusions is very low [17; 18], indicating destruction of the talcum structure at a heating temperature of 1500 °C and complete disappearance of free graphite [19 – 21].

It was established that in the points of the alloy with the composition C analyzed herein, there exist Fe – Cu – Sn solutions on the basis of iron and copper. However, due to high content of copper and tin in the alloy the chemical composition at the points significantly differs from the respective points of the alloy with the composition B. This shows that they are rich in copper and tin. In points 3 and 4, a significant amount of non-metal inclusions (graphite and talcum) was detected, confirming the thermal stability of talcum at 1000 °C.

The presence of talcum located along the pores and between the particles significantly reduces interaction between the liquid and solid phase.

As a consequence of the sintering of iron, copper, and tin, a new composite structure of iron–bronze type is formed. The misconstrue of these compositions is comprised of solid solutions of variable Fe – Cu – Sn composition on the basis of iron. This indicates heterogeneity of structure of the sintered composite

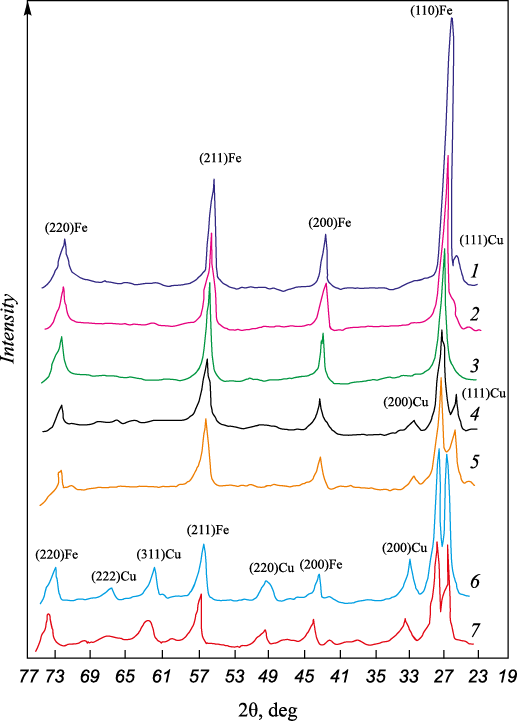

In order to confirm this, a phase X-ray structure analysis of iron bronze composite powdered material was performed. Diffractometric curves were plotted using a DRON-2.0 facility in filtered iron beams. The reflections specific for iron and copper are mainly revealed in the diffraction patterns (Fig. 5) of the samples considered.

Fig. 5. Дифрактометрические кривые железо-бронзовых |

For example, in the reflections of crystals reflected from crystallographic planes (110), (200), (211), (220), the wavelength is 0.2024 nm. In the reflections of crystals reflected from crystallographic planes (111), (200), (220), (311), (222), the wavelength is 0.2083; 0.1803; 0.1272; 0.1086 and 0.1040 nm.

The absence of diffraction effects characteristic of tin and zinc is related, on the one hand, to their solubility in iron and copper lattices. This is due to the low melting points of tin (232 °C) and zinc (420 °C), on the other hand, with their ionic radii, allowing the copper and iron ions to be substituted isomorphically with tin and zinc ions (their difference is less than 15 %).

The stability of copper and iron lattices differs slightly from that of pure copper and iron:

\[a = d(nkl)\sqrt {{h^2} + {k^2} + {l^2}} ,\]

where d, n, k, l, h are the coefficients.

A comparison of the diffraction effects of iron and copper demonstrates that the sample of composition A at 800 °C contains a minor amount of copper. Therefore, the diffraction pattern is presented mainly by iron.

Sample 3 with an increase in the sintering temperature to 1000 °C contains only traces of copper. This confirms the aforementioned statement that copper particles at 800 °C are isolated by the tin liquid phase. Copper at this temperature is unsolved in iron.

In points 4 and 5 of the alloy with the composition B, sintered at 850 and 1000 °C, the amount of copper or Cu – Sn is nearly by twice higher than in the alloy with the composition A. The highest amount of copper and Cu – Sn was detected in point 6 of the alloy with the composition C, sintered at 1150 °C.

Conclusions

The microstructure of sintered iron with solid lubricants is multiphase. The compositions of complex phases were determined using X-ray studies and spot microanalysis. It was established that these are iron based Fe – Cu, Sn–C solid solutions of type and copper based Cu – Fe – Sn–C solid solutions. It was determined that the content of these solid solutions significantly decreases with an increase in the sintering temperature from 850 to 1000 °C. Nevertheless, the higher the graphite content and the sintering temperature, the higher the chance of the formation of free cementite in the structure. This is despite the existence of heat resistance in the composition.

References

1. Mamedov A.T., Abbasov A.K., Aliyarly A.M. Charge for Sintered Material. Certificate of authorship USSR 1563841. Publ. 15.05.90. (In Russ.).

2. Kilmiter G.T. The use of porous materials in externally pressurized gas bearings. Powder Metallurgy. 1969;12(24): 400–409. https://doi.org/10.1179/pom.1969.12.24.009

3. D’yachkova L.N., Kerzhentseva L.F., Fraiman L.I. Intensification of diffusion during sintering of alloyed iron-based materials. Poroshkovaya metallurgiya. 1991;(2):44–49. (In Russ.).

4. Mamedov A.T. Structural and Antifriction Powder Materials. Baku: Elm; 2005:458. (In Russ.).

5. Geller Yu.A., Rakhshtadt A.G. Materials Science. Moscow: Metallurgiya; 1980:383. (In Russ.).

6. Mamedov A.T., Mamedov V.A. Phenomenological approach to plastic deformation of metal powders in a closed volume. In: Proceedings of the 29th Int. Conf. and Seminar “Composite Materials in Industry”. Kiev; 2009: 413–416. (In Russ.).

7. Мamedov A.T., Mamedov V.A. Microstructure, mechanical properties and tribological behaviour of PM Fe–Cu–Zn alloys containing solid lubricants. Powder Metallurgy. 2002;46(4): 311–318. https://doi.org/10.1179/003258903225008517

8. Mamedov A.T., Mamedov V.A. New technological approach to fabrication of high density PM parts by cold pressing sintering. Powder Metallurgy. 2004;47(3):278–283. https://doi.org/10.1179/003258904225020738

9. Mamedov A.T., Aliev N.A., Rumyantsev V.V. Features of the manufacturing technology of porous sliding bearings made of iron powder. Poroshkovaya metallurgiya. 1986;(7): 96–100. (In Russ.).

10. Mamedov A.T., Kelbiev F.M. Calculation and optimization of structural parameters of microheterogenic composite materials. Uchenye zapiski AzTU. 2005;(3):35–37. (In Russ.).

11. Danninger H., Zangin Z.O., Drozda M. High pressure compaction of ferrous PM parts. Metal Powder Report. 2006; 41(11):833–835.

12. Clogh G., Croks G.S. Further developments in metal-graphite bearing materials. Powder Metallurgy. 1969;12(24): 386–409. https://doi.org/10.1179/pom.1969.12.24.008

13. Babayev Y., Karadeniz S., Mamedov A. Fe–Cu karışımı tozmalremesinin tribolocik özelliklerinin injelenmesi. In: III Makina Tasarın və İmalat Tecnolocileri Kongresi. 16–17 eylülç 2005ç Konya (Turkiye): 127–129. (In Turk.).

14. Mamedov A.T., Mamedov V.A., Aliev A.T. Recent developments in the field of pressing powder materials. Materialy, tekhnologiya, instrumenty. 2002;7(1):98–101. (In Russ.).

15. Hausner H.H. Handbook of Powder Metallurgy. New York: Chom publication Co.; 2003:482.

16. Mamedov A.T., Mamedov V.A. Peculiarities of powder materials with utilization of cast iron shavings. In: The 3rd Int. Powder Metallurgy Conf. 2002, Ankara, Turkey. 2002: 418–430.

17. Mamedov A.T., Musurzaeva B.B. Composition, structure and properties of antifriction powder composition. Vestnik mashinostroeniya. 2016;(1):69–79. (In Russ.).

18. Mamedov A.T. Gasanova S.M. Investigation of spatial redistribution of particles of soft and solid phases during their joint plastic deformation. In: Proceedings of the 2nd Int. Sci. and Pract. Conf. April 14–17, 2009 “Resource-Saving Technologies of Repair, Equipment, Tools and Technological Equipment from Nano- to Macrolevel”. Part 2. St. Petersburg: 2009:187–190. (In Russ.).

19. Domsa A. Effect of copper additions on the bearing properties of sintered iron – qraphite. In: Perspectives in Powder Metallurgy Fundamentals, Methods, and Applications. 1970: 273–281. https://doi.org/10.1007/978-1-4684-3015-8_20

20. Mamedov A.T., Mamedov V.A. Properties of highly-dense iron‐base powder metallurgy materials pressed without zinc stearate. Powder Metallurgy and Metal Ceramics. 2003; 42(5):245–248. https://doi.org/10.1023/A:1025759326877

21. Mamedov A.T., Mamedov V.A. Mamedov A.T., Mamedov V.A. Reduction annealing for cast iron powder and its effect on sintered antifriction material properties. Powder Metallurgy and Metal Ceramics. 2003;42(3):209–216. https://doi.org/10.1023/A:1024774218853

About the Author

B. B. MusurzaevaRussian Federation

Batura B. Musurzaeva, Dissertation Student of the Chair of Materials Technology

25 H. Javid Ave., Baku, AZ1073, Azerbaijan

Review

For citations:

Musurzaeva B.B. Microstructure and elemental analysis of iron-based powder composite materials. Izvestiya. Ferrous Metallurgy. 2023;66(2):148-153. https://doi.org/10.17073/0368-0797-2023-2-148-153