Scroll to:

Influence of barium and strontium on calcium recovery degree upon ladle treatment of steel by complex modifiers with alkaline earth metals

https://doi.org/10.17073/0368-0797-2023-1-97-104

Abstract

Increasingly rigid requirements in terms of the steel products quality are forcing the metallurgy technologists to search for innovative solutions to stabilize the steel quality. Much attention is paid to ladle treatment of melt and selection of rational composition of modifiers, which enables the content of non-metallic inclusions to be reduced. In order to solve the formulated problem, complex modifiers are used containing both calcium and other alkaline earth metals (barium and strontium). This article presents the results of a pilot campaign on metal ladle treatment by complex modifiers with alkaline earth metals (calcium, barium, strontium) upon production of steel with higher requirements for non-metallic inclusions under conditions of electric-furnace melting at JSC “Ural Steel”. In the course of experimental activities, the maximum level of inclusions content of sheet rolled products from pipe steel grades was decreased in terms of brittle silicates (according to State Standard GOST 1778) from 4.0 to 1.5 – 2.5, and in terms of non-deforming silicates from 4.0 to 3.0 – 3.5. Substitution of silicocalcium, grade SK40, with experimental modifiers resulted in improvement of strength properties of rolled products both during tension tests and during impact bending tests at lower temperatures. This influence was observed in all variants of consumption of the experimental modifiers. With increase in the consumption of modifiers positive influence on steel mechanical properties also increased. As a consequence of substitution of silicocalcium with experimental modifiers, the calcium recovery with the use of Si – Ca – Ba increased in average by 1.6 times, and with the use of Si – Ca – Ba – Sr in average by 2.4 times. The use of the complex modifiers enabled the targeted value of residual calcium in steel sample from tundish to be obtained at significantly lower calcium consumption.

Keywords

For citations:

Bakin I.V., Shapovalov A.N., Kalyaskin A.V., Kuznetsov M.S. Influence of barium and strontium on calcium recovery degree upon ladle treatment of steel by complex modifiers with alkaline earth metals. Izvestiya. Ferrous Metallurgy. 2023;66(1):97-104. https://doi.org/10.17073/0368-0797-2023-1-97-104

Introduction

The continuously tightening of requirements with regard to the quality of metal products has lead metallurgy technologists to search for innovative solutions which enable a steady high quality of metal to be obtained. In particular, much attention is paid to ladle treatment of melt and selection of rational composition of modifiers which enables the content of non-metallic inclusions (NMI) to be reduced. The general principles of decreasing the NMI level of steel deoxidized by aluminum are known [1 – 4]. Treatment of steel by calcium containing materials is a common practice which allows metal to be refined from the products by aluminium deoxidizing [5 – 8]. In this respect, good results are also steadily achieved with the use of complex modifiers with alkaline earth metals (AEM) both in Russia [9 – 12] and abroad [13 – 14]. Nowadays much attention is paid to the use of strontium as a component of complex alloy with AEM together with calcium and barium. The promising potentials of this element are confirmed both by the theoretical studies [15], and by results of the pilot projects [16, 17].

The execution of certain contracts for pipe steel grades at JSC “Ural Steel” requires compliance with higher specifications (State Standard GOST 1778-70) in terms of NMI points:

– in terms of oxides, sulfides, and brittle silicates (BS) – not higher than 2.5 points regarding average level and not higher than 3.0 points regarding maximum level;

– in terms of non-deformed silicates (NDS) – not higher than 3.0 points regarding average level and not higher than 3.5 points regarding maximum level.

However, upon steel treatment by conventionally used silicocalcium SK40, the achieved performance of steel quality in terms of content of various NMI does not always comply with the targeted values. Thus, in terms of non-deformed silicates the inclusions content in the metal equals in average 2.5 points, the maximum content being 4.5 points. These NMI are calcium aluminates of complex composition. In order to decrease their sizes and content, industrial tests of complex modifiers were performed (Table 1). The technological parameters were verified providing maximum efficiency of their use.

Table 1. Properties of experimental modifiers

|

The modifiers mentioned proved to be successful in production of corrosion resistance, high carbon (wheel steel), and structural steels under conditions of Taganrog Iron & Steel Factory [18], OMZ Special Steel plant, as well as in the course of R&D project of development of production technology of sheet rolled products with normalized level of corrosion active NMI in the electric-furnace melting shop of JSC “Ural Steel” [19, 20].

The aim of this work is to develop a set of recommendations on the technology of the ladle treatment of melt, in order to reduce the content of non-deformed silicates (in terms of maximum level) lower than 3.5 points and achieve targeted content of residual calcium together with reduction of cumulative production expenses.

Experimental

In order to solve the formulated problems, a series of pilot experiments were performed on production of steel, grade K52 – K60, using complex modifiers with AEM in comparison with standard silicocalcium, grade SK40. Chemical composition of the modifiers with AEM is summarized in Table 2. The composition of test alloys with AEM was selected by the results of positive experience of their use under various production conditions, including those of the electric-furnace melting shop of JSC “Ural Steel” [20]. Consumption of the modifiers was determined on the basis of analysis of large scale laboratory and commercial tests of alloys with AEM.

Table 2. Actual chemical composition of modifiers

| |||||||||||||||||||||||||||||||||

In accordance with the pilot experiment plan, each modifier was used for the treatment of more than 20 melt heats of steel, grade K52 – K60. Melting and ladle treatment of comparative and test melt heats were carried out in comparison with valid process specifications. The steel was modified at steel vacuum degasser (SVD) after deoxidizing by aluminum. Consumption of modifiers in test melt heats was varied in the range of 80 – 100 % (of comparative variant with SK40) in terms of overall AEM [20].

Sampling and assessment of NMI content in steel were carried out in accordance with State Standard GOST 1778-70 (method Sh6). Spectral microanalysis and NMI assessment in sheet rolled products from steel of test and comparative melt heats were carried out using a JSM-6490LV scanning electron microscope in combination with an INCA Energy 250 energy dispersion analyzer at 200× magnification.

Results and discussion

The main parameters of modification in comparative and test melts are summarized in Table 3.

Table 3. Average parameters of steel modifying treatment

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

As can be seen from Table 3, the consumption of INSTEEL®1.5 modifier according to several variants, provided for the addition of AEM from 82 % (variant 1) to 103 % (variant 3) of the basic technology with SK40. In the case of INSTEEL®9.4 modifier the amount of AEM supplied with the wire varied from 79 % to 90 %, respectively. Therefore, the modifier consumption provides the calcium addition:

– for INSTEEL®1.5: from 47.7 % (variant 1) to 59.6 % (variant 3) with respect to the basic technology;

– for INSTEEL®9.4: from 36.4 % (variant 1) to 41.7 % (variant 3) with respect to the basic technology.

The contents of NMI in sheet rolled products obtained from slabs after comparative and test melt heats according to several variants are summarized in Table 4.

Таблица 4. Assessment of contamination with nonmetallic inclusions of sheet metal

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

Analysis of NMI content in metal (Table 4) demonstrated the following:

– substitution of silicocalcium with test variants of modifiers decreases the maximum points in terms of BS from 4.0 to 1.5 – 2.5;

– maximum inclusions content of NDS decreased from 4.0 points for standard technology to 3.5 points with the use of INSTEEL®9.4 modifiers according to variants 1 and 2; and to 3.0 points with the use of INSTEEL®1.5 modifier according to variants 2 and 3, as well as with the maximum consumption of INSTEEL®9.4 modifier (variant 3).

Therefore, the results of test melt heats and integrated studies of metal rolled products demonstrated that the metal produced with the use of INSTEEL® modifiers was characterized by lower NMI content, in comparison with the rolled products manufactured by standard technology with the use of silicocalcium SK40.

As a final result of decrease in NMI content in steel with the use of test modifiers, the main physical properties of metal rolled products were improved. The results of mechanical tests of samples after comparative and test melt heats are summarized in Table 5.

Table 5. Mechanical properties (State Standards GOST 1497-84 and GOST 9454-78) of sheet metal

|

Table 5 shows that substitution of silicocalcium with the test modifiers resulted in improvement of strength properties of rolled products both upon static tension tests, and upon dynamic impact bending tests at lower temperatures. The influence was observed in all variants of consumption of the test modifiers. The increased consumption of modifiers showing positive influence on mechanical properties of steel has been also increased. However, the mentioned improvement of properties can be attributed not only with the use of the test materials, but also with other simultaneously acting factors. Therefore, it should be verified on larger array of melt heats.

In addition to a decrease in NMI content, an important parameter is the content of residual calcium after treatment by the modifier. It is precisely this parameter that is critical upon express assessment of the efficiency of this or that composition of modifier under production conditions. The content of residual calcium is an important factor in providing stable conditions of casting (with minimum submerged entry nozzle clogging), as well as the favorable form and position of NMI in the structure of a workpiece, especially with consideration of the possible reoxidation process and decrease in oxygen solubility.

In this regard an important issue is the selection of consumption of complex modifier, which allows metal from NMI to be refined with high quality, in order to obtain the required content of residual calcium without increased expenses for steel treatment. In addition, a disputable issue is whether the influence mechanism of calcium and other AEM is more modifying or deoxidizing.

In the course of pilot experiments, in order to assess the deoxidizing action of calcium during modifying treatment, the content of active oxygen was measured before and after metal treatment by silicocalcium using Heraeus Electro-Nite equipment. The results demonstrated that during high quality deoxidizing of melt by aluminum the treatment by silicocalcium slightly decrease the content of active oxygen (by 1 – 2 ppm). This is an indirect evidence that calcium works to a higher extent as a modifier than a deoxidizing agent.

Table 6 summarizes averaged contents of main elements in test and comparative metals.

Table 6. Content of the main chemical elements

| |||||||||||||||||||||||||||||||||||||||||

Table 6 shows that the chemical compositions of steel in comparative and test melt heats in terms of main elements are comparable. The calcium content of steel sample from tundish corresponded to targeted values approved upon production of steel of these grades. Herewith, the content of added calcium with the use of comparative and test modifiers differed several times (Table 3). Steel casting was carried out according to standard procedure at normalized parameters of temperature and rate. No violations were revealed upon casting and rolling of steel of comparative and test melt heats. No submerged entry nozzle clogging was observed.

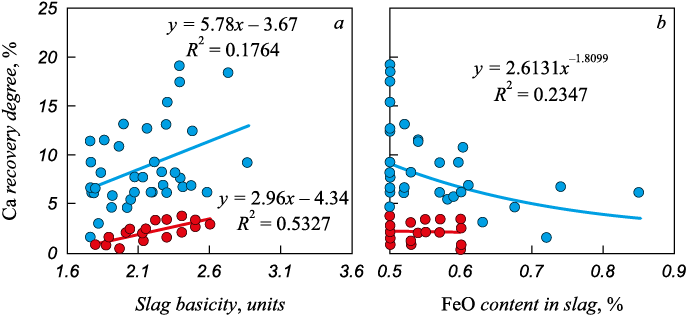

It is known that calcium recovery significantly depends on slag composition before modification. Average basicity and FeO content in slag before addition of powdered wire in comparative and test melt heats were comparable. Furthermore, the slag parameters varied in wide range, which allowed their influence on calcium recovery to be analyzed (Figure).

Ca recovery degree as a function of slag basicity (а) and FeO (б) content in slag |

Comparative and test melt heats with increase in the slag basicity demonstrate a steady trend towards the increase in calcium recovery degree (Figure, a). As for the influence of slag oxidation degree (Figure, b) generally characterized by FeO content in slag, then, in the region of normal oxidation degree of 0.5 – 0.6 % FeO, the influence of this parameter on calcium recovery was not statistically noticeable. This can be observed in comparative melt heats. In tests melts, there were cases of higher FeO content in excess of 0.6 %, which influenced the decrease in calcium recovery (Figure, b). However, even under such unfavorable conditions, the calcium recovery in test melts was higher than the results of comparative melt heats. Therefore, FeO content in slag melt before modification should not exceed 0.6 %. The confidence of the dependences characterized by coefficients of determination (R2) is at a sufficiently low level. This is related to the moderate sample size and simultaneous influence of numerous factors. However, the dependences obtained qualitatively confirm the known theoretical regularities.

It should be mentioned that both average and maximum temperature of treatment at SVD with the use of complex alloys was higher than upon treatment by silicocalcium SK40: SK40 – 1569 – 1633 °C (average: 1606.4 °C); INSTEEL®1,5 – 1599 – 1648 °C (average: 1619 °C); INSTEEL®9.4 – 1593 – 1650 °C (average: 1617.6 °C). Comparative data analysis for melt heats at higher temperature demonstrated that in this case the specific flow rate of argon is higher, which can be attributed to the need for adjustment of metal temperature before ladle transfer to continuous-casting machine. As a consequence, during melt heats at higher temperatures, it is required to blow metal after the end of modification with a higher intensity and inevitable exposure of metal, accompanied by additional waste of calcium. The analysis of the data on pilot campaign, shows a trend towards a decrease in calcium recovery degree with increase in argon flow rate at SVD from 0.08 to 0.10 m3/t and higher. Furthermore, blowing by argon with a normal flow rate (up to 0.08 m3/t) and intensity not causing excessive metal exposure and reoxidation promotes the removal of NMI from metal. This is further demonstrated by a decrease in the content of non-deformed silicates in rolled products.

Therefore, despite the significantly lower content of calcium added to metal with test modifiers and non-optimum treatment parameters of SVD, the content of residual calcium in metal was at the level of comparative melt heats. The mechanical properties of metal rolled products were improved and the NMI content was decreased.

Conclusions

The use of complex modifiers with AEM allows the problems of modification at the consumption to be resolved, thus providing cumulative addition of AEM of 80 – 90 % of calcium content predefined according to regular technology.

In the course of pilot activities, the calcium recovery from Si – Ca – Ba modifier was by 1.6 times and from Si – Ca – Ba – Sr modifier by 2.4 times higher in comparison with the use of conventional silicocalcium SK40.

The use of complex modifiers allowed the content of non-deformed silicates in steel to be reduced (in terms of maximum rank) to a level lower than 3.5 points under conditions of the electric-furnace melting shop of JSC “Ural Steel”.

In the case of the use of complex alloys with AEM the mechanical properties of sheet rolled products were improved both during tension tests and during impact bending tests at lower temperatures.

References

1. Emi T. Improving steelmaking and steel properties. In: Fundamentals of Metallurgy. Seetharaman S. ed. Woodhead Publishing, Cambridge UK Inst. of Materials, Minerals & Mining; 2005: 503–554.

2. Turkdogan E.T. Fundamentals of Steelmaking. London: The institute of materials; 1996: 331.

3. Dyudkin D.A., Kisilenko V.V. Modern Technology of Steelmaking. Moscow: Teplotekhnik; 2007: 529. (In Russ.).

4. Gulyaev A.P. Clean Steel. Moscow: Metallurgiya; 1975: 184. (In Russ.).

5. Ren Y., Zhang L., Li S. Transient evolution of inclusions during calcium modification in linepipe steels. ISIJ International. 2014; 54(12): 2772–2779. https://doi.org/10.2355/isijinternational.54.2772

6. Zhao D., Li H., Cui Y., Yang J. Control of inclusion composition in calcium treated aluminum killed steels. ISIJ International. 2016; 56(7): 1181–1187. https://doi.org/10.2355/isijinternational.ISIJINT-2016-123

7. Veerababu Gollapalli, Venkata Rao M.S., Phani S. Karamched, Chenna Rao Borra, Gour G. Roy, Prakash Srirangam. Modification of oxide inclusions in calcium-treated al-killed high sulphur steels. Ironmaking and Steelmaking. 2019; 46(7): 663–670. https://doi.org/10.1080/03019233.2018.1443382

8. Liu C., Kumar D., Webler B.A., Pistorius P.C. Calcium modification of inclusions via slag/metal reactions. Metallurgical and Materials Transactions B. 2020; 51: 529–542. https://doi.org/10.1007/s11663-020-01774-3

9. Ryabchikov I.V., Golubtsov V.A., Usmanov R.G., Lunev V.V. Effect of complex alloys with alkaline-earth metals on characteristics of steel castings for transport applications. Liteinoe proizvodstvo. 2016; (5): 4–7. (In Russ.).

10. Rozhikhina I.D., Nokhrina O.I., Dmitrienko V.I., Platonov M.A. Modification of steel by barium and strontium. Izvestiya. Ferrous Metallurgy. 2015; 58(12): 871–876. (In Russ.) https://doi.org/10.17073/0368-0797-2015-12-871-876

11. Morozov S.S., Kuznetsov A.A., Boldyrev D.A. Improving service durability for tooling made of heat resistant austenitic steel by barium-strontium carbonatite treatment. Steel in Translation. 2020; 50(4): 266–269. https://doi.org/10.3103/S0967091220040051

12. Grigorovich K.V., Demin K.Yu., Arsenkin A.M., Garber A.K. Prospects for application of barium-bearing alloys for deoxidation and modification of transport metal. Metally. 2011; (5): 146–156. (In Russ.).

13. Irons G.A., Tong X.-P. Treatment of steel with alkaline-earth elements. ISIJ International. 1995; 35(7): 838–844. https://doi.org/10.2355/isijinternational.35.838

14. Mukai K., Han Q. Application of barium-bearing alloys in steelmaking. ISIJ International. 1999; 39(7): 625–636. https://doi.org/10.2355/isijinternational.39.625

15. Makrovets L.A., Samoilova O.V., Mikhailov G.G., Bakin I.V. Phase equilibrium occurring during low-carbon iron-based melt deoxidation with silicostrontium. Izvestiya. Ferrous Metallurgy. 2021; 64(6): 413–419. (In Russ.) https://doi.org/10.17073/0368-0797-2021-6-413-419

16. Bakin I.V., Shaburova N.A., Ryabchikov I.V., Mizin V.G., Belov B.F., Mikhailov G.G., Senin A.V. Experimental study of refining and modification of steel with Si–Ca, Si–Sr and Si–Ba alloys. Steel in Translation. 2019; 49(8): 543–547. https://doi.org/10.3103/S0967091219080023

17. Ryabchikov I.V., Bakin I.V., Mizin V.G., Novokreshchenov V.V., Golubtsov V.A. Secondary steelmaking with compound alloys with AEMs – an economically feasible approach to improve steel quality. Steel in Translation. 2021; 51(5): 324–329. https://doi.org/10.3103/S0967091221050107

18. Golubtsov V.A., Milyuts V.G., Tsukanov V.V. Impact of complex modifying treatment for non-metallic inclusions contamination of shipbuilding steel. Tyazheloe mashinostroenie. 2013; (1): 2–5. (In Russ.).

19. Bakin I.V., Shapovalov A.N., Kuznetsov M.S., Shaburova N.A., Usmanov R.G., Golubtsov V.A., Ryabchikov I.V., Mizin V.G., Panov V.N. Industrial tests of microcrystalline complex alkaline earth metal alloys when casting pipe steel. Steel in Translation. 2020; 50(11): 795–800. https://doi.org/10.3103/S0967091220110030

20. Kunitsyn G.A., Kuznetsov M.S., Shapovalov A.N., Bakin I.V. Application of complex modifiers in the production of steel with increased requirements for non-ferrous metallic inclusions. Chernye Metally. 2022; (5): 9–16. (In Russ.). https://doi.org/10.17580/chm.2022.05.02

About the Authors

I. V. BakinRussian Federation

Igor’ V. Bakin, Cand. Sci. (Eng.), Lecturer of the Chair of Materials Science and Physical Chemistry of Materials, South Ural State University; Head of the Division of Innovation, Modernization and Technical Development, LLC RPE “Technology”

76 Lenina Ave., Chelyabinsk 454080, Russian Federation

25 Vodrem Vil. - 40, Chelyabinsk 454901, Russian Federation

A. N. Shapovalov

Russian Federation

Aleksei N. Shapovalov, Сand. Sci. (Eng.), Assist. Prof. of the Chair “Metallurgical Technology and Equipment”

8 Frunze Str., Novotroitsk, Orenburg Region 426359, Russian Federation

A. V. Kalyaskin

Russian Federation

Artem V. Kalyaskin, Postgraduate of the Chair of Pyrometallurgical and Foundry Technologies

76 Lenina Ave., Chelyabinsk 454080, Russian Federation

M. S. Kuznetsov

Russian Federation

Maksim S. Kuznetsov, Cand. Sci. (Eng.), Deputy Head of the Workshop

1 Zavodskaya Str., Novotroitsk, Orenburg Region 462356, Russian Federation

Review

For citations:

Bakin I.V., Shapovalov A.N., Kalyaskin A.V., Kuznetsov M.S. Influence of barium and strontium on calcium recovery degree upon ladle treatment of steel by complex modifiers with alkaline earth metals. Izvestiya. Ferrous Metallurgy. 2023;66(1):97-104. https://doi.org/10.17073/0368-0797-2023-1-97-104