Scroll to:

Properties of spherical metal powder manufactured by plasma spraying of 03Cr17Ni10Mo2 stainless steel wire

https://doi.org/10.17073/0368-0797-2023-1-80-85

Abstract

Stainless steel spherical powders are commonly used as additives in such manufacturing processes as selective laser melting, selective laser sintering, direct laser sintering, electron beam melting, and others. These processes require high-quality spherical powders. The purpose of this study is to develop a manufacturing process for making spherical powder by plasma spraying of a 1 mm dia. wire, stainless steel 03Cr17Ni10Mo2 (US analog: 316L steel grade) and to analyze the powder suitability for additive manufacturing. We refined the spherical powder manufacturing process and studied the spraying conditions vs. –160 μm fraction yield relationship, since this fraction is required for additive manufacturing. As the arc power gas flow rate increases, the –160 μm fraction yield increases to over 70 %. The powder has high fluidity (17.6 ± 1 s), bulk density (4.15 ± 0.1 g/cm3), and tapped density (4.36 ± 0.2 g/cm3). It is suitable for additive manufacturing applications. We also studied the effect of the spherical powder fraction size distribution on the fluidity, bulk density, and tapped density. The best results (fluidity: 16.64 ± 1 s; bulk density: 4.16 ± 0.1 g/cm3; tapped density: 4.38 ± 0.2 g/cm3) were obtained for –90 μm fraction. With these properties, the powder meets the basic additive manufacturing requirements: less than the 30 s/50 g fluidity, and bulk density exceeding 3 g/cm3.

Keywords

For citations:

Kaplan M.A., Gorbenko A.D., Ivannikov A.Yu., Konushkin S.V., Mikhailova A.V., Kirsankin A.A., Baikin A.S., Sergienko K.V., Nasakina E.O., Kolmakov A.G., Sevost’yanov M.A. Properties of spherical metal powder manufactured by plasma spraying of 03Cr17Ni10Mo2 stainless steel wire. Izvestiya. Ferrous Metallurgy. 2023;66(1):80-85. https://doi.org/10.17073/0368-0797-2023-1-80-85

Introduction

Stainless steels have many applications (medical equipment, agriculture, aerospace, automotive, and food industries) for their high strength, ductility, and corrosion resistance [1 – 4]. A chromium-rich oxide layer builds up on the surface and protects the steel from corrosion. 03Cr17Ni10M2 (US analog: 316L) is a popular stainless steel grade. To date, it is the most cost-efficient material for corrosive environments. The steel is widely available, easy to manufacture, and has high corrosion resistance [5 – 9].

Advanced additive manufacturing processes can make complex parts without the limitations of conventional subtractive manufacturing [10 – 13]. The raw material is metallic spherical powder. Its quality is paramount for the properties of the final product [14]. Spherical powders for additive manufacturing should have such properties as high fluidity, bulk density, homogeneous chemical composition, and particle size distribution [15 – 18]. The particle size of additive manufacturing powders is less than 160 μm. For example, melting processes use powders with particle sizes less than 60 μm, and surfacing, less than 160 μm [19]. Powders with particle sizes over 160 μm can be used in other processes such as sintering and/or hot pressing.

We refined the plasma spraying process for a higher yield of the particle size fraction suitable for additive manufacturing. We also studied the particle size distribution, morphology, fluidity, bulk, and tapped density of the spherical powder.

Materials and Methods

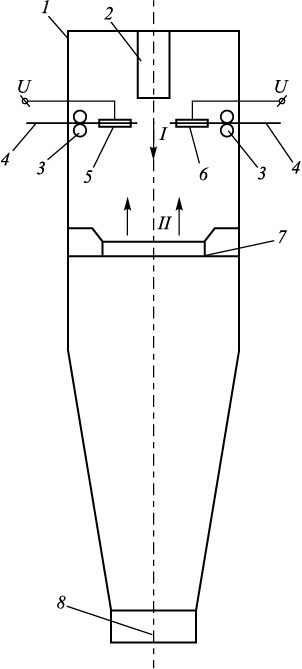

The powder was made from an industrial-grade wire, 1 mm dia., 03Cr17Nir10M2 (316L) steel grade. We made the spherical powder by wire spraying using a lab plasma spraying system (Russian Federation patent No. 2749403). Fig. 1 shows the system layout.

Fig. 1. Layout of wire plasma spraying system |

Air is evacuated from chamber 1 and then the chamber is filled with argon. Next, the plasmatron 2 is activated to generate a plasma jet, and wire feeder 3 feeds wire 4. An electric arc is excited between the free ends of the wires, and the wire melts. The system has feeders 5 and 6 delivering power to the wires to ignite an electric arc. Spherical particles are produced by pulverizing with the plasma jet. The atomized powder particles move along chamber 1 (direction I). Annular nozzle 7 produces a counter flow of cooling gas which slows down and cools the powder particles (direction II). The powder particles are collected in bin 8. Argon was used as the plasma-forming and atomizing gas.

After atomization, the powder was separated into fractions using an ANALYSETTE 3 SPARTAN vibratory sieve shaker (Germany). We used a JEOL JSM-IT500 scanning electron microscope (SEM) to obtain the powder particle images. An Analysette 22 NanoTec laser particle sizer was used for powder particle size analysis. The fluidity and bulk density were measured with an HFlow-1 Hall flowmeter, in accordance with the state standards GOST 20899-98 and GOST 19440-94, Part 1. The tapped density was measured in accordance with the state standard GOST 25279-93 using a BeDensi T1 analyzer.

Results and Discussion

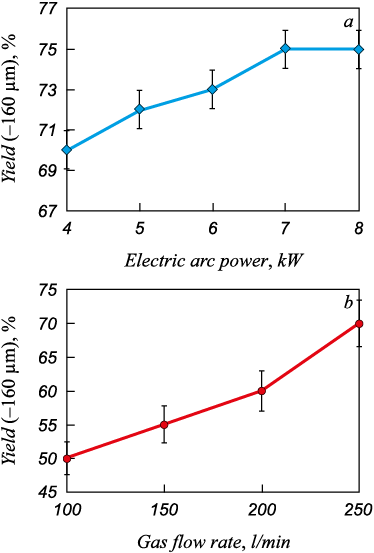

We investigated the effect of electric arc power and gas flow rate on the yield of fraction suitable additive manufacturing (less than 160 μm) using a 1 mm dia. industrial-grade wire, 03Cr17H10M2 (316L) steel grade. We selected the process variables to make spherical powder by plasma spraying. The results are shown on Fig. 2.

Fig. 2. Spraying conditions vs. yield (<160 µm) |

As the electric power and gas flow rate increase, the yield of the –160 μm fraction increases to over 70 %. When the power exceeds 4 kW, the chamber overheats rapidly, so the process has to be paused for cooling. We found the conditions (power: 4 kW; gas flow rate: 250 l/min) for continuous spherical powder manufacturing.

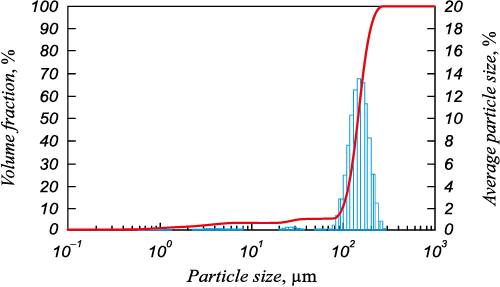

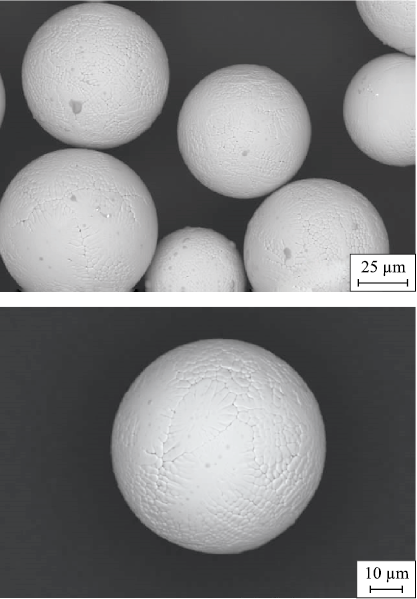

Then we studied the particle size distribution and morphology of the resulting spherical powder made of the 03Cr17Ni10M2 steel grade wire. It was found that 70 % of the particles are smaller than 167 μm (Fig. 3). The SEM images of the powder particles show that the shape of the particles is almost spherical with no visible defects. The powder is suitable for additive manufacturing (Fig. 4).

Fig. 3. Powder particle size distribution

Fig. 4. SEM images of the powder particles made |

We studied the bulk density, fluidity, and tapped density vs. particle size relations. The results are presented in the table.

Powder Properties

| |||||||||||||||||||||||||||||||||||

It can be concluded that the smaller the particle size, the higher the fluidity (16.64 to 22.9 s), while the bulk and tapped density for all particle sizes remain unchanged (average values: 4.15 and 4.38 g/cm3, respectively).

Conclusions

We studied the effect of spraying conditions on the yield of particles smaller than 160 μm suitable for additive manufacturing. As the arc power gas flow rate increase, the –160 μm fraction yield increases to over 70 %.

We refined the spherical powder manufacturing by plasma spraying on a 1 mm dia. industrial-grade wire, 03Cr17Ni10Mo2 (316L) steel grade. The optimum conditions are as follows: 4 kW arc power, 250 l/min gas flow rate. The yield of fractions smaller than 160 μm exceeds 70 %. The resulting powder properties are 17.6 ± 1 s fluidity, 4.15 ± 0.1 g/cm3 bulk density, and 4.36 ± 0.2 g/cm3 tapped density. The powder is suitable for additive manufacturing.

We also studied the effect of the spherical powder particle size on the fluidity, bulk density, and tapped density. The best results (fluidity: 16.64 ± 1 s; bulk density: 4.16 ± 0.1 g/cm3; tapped density: 4.38 ± 0.2 g/cm3) were obtained for a –90 μm fraction.

References

1. Grabco D., Shikimaka O., Pyrtsac C., Prisacaru A., Barbos Z., Bivol M., Alexandrov S., Vilotic D., Vilotic M. Microstructures generated in AISI 316L stainless steel by Vickers and Berkovich indentations. Materials Science and Engineering: A. 2021; 805: 140597. http://doi.org/10.1016/J.MSEA.2020.140597

2. Bekmurzayeva A., Duncanson W.J., Azevedo H.S., Kanayeva D. Surface modification of stainless steel for biomedical applications: Revisiting a century-old material. Materials Science and Engineering: C. 2018; 93: 1073–1089. http://doi.org/10.1016/j.msec.2018.08.049

3. Sheik S., Tirumalla A., Gurrala A.K., Mohammed R. Effect of microstructural morphology on corrosion susceptibility of austenitic and super austenitic stainless steels. Materials Today: Proceedings. 2022; 66(2): 514–518. http://doi.org/10.1016/j.matpr.2022.06.113

4. Feng W., Wang Z., Sun Q., He Y., Sun Y. Effect of thermomechanical processing via rotary swaging on grain boundary character distribution and intergranular corrosion in 304 austenitic stainless steel. Journal of Materials Research and Technology. 2022; 19: 2470–2482. https://doi.org/10.1016/j.jmrt.2022.06.032

5. Mehta H., Kaur G., Chaudhary G.R., Prabhakar N., Kaul S., Singhal N.K. Evaluation of corrosion resistant, antimicrobial and cytocompatible behaviour of cobalt based metallosurfactants self-assembled monolayers on 316L stainless steel surface. Surface and Coatings Technology. 2022; 444: 128657. https://doi.org/10.1016/j.surfcoat.2022.128657

6. Wongpanya P., Wongpinij T., Photongkam P., Siritapetawee J. Improvement in corrosion resistance of 316 L stainless steel in simulated body fluid mixed with antiplatelet drugs by coating with Ti-doped DLC films for application in biomaterials. Corrosion Science. 2022; 208: 110611. https://doi.org/10.1016/j.corsci.2022.110611

7. Zhang D.H., Meng X.C., Zuo G.Z., Huang M., Li L., Xu W., Li C.L., Tang Z.L., Yuan J.S., Liu Y.B., Cao X.G. Study of the corrosion characteristics of 304 and 316L stainless steel in the static liquid lithium. Journal of Nuclear Materials. 2021; 553: 153032. https://doi.org/10.1016/j.jnucmat.2021.153032

8. Kaplan M.A., Ivannikov A.Yu., Konushkin S.V., Nasakina E.O., Baikin A.S., Kartabaeva B.B., Gorbenko A.D., Kolmakov A.G., Sevost’yanov M.A. Study of the structure, mechanical characteristics, and antibacterial properties of corrosion-resistant steel alloyed with silver and titanium. Doklady Chemistry. 2022; 502(2): 37–44. https://doi.org/10.1134/S001250082202001X

9. Brooks E.K., Brooks R.P., Ehrensberger M.T. Effects of simulated inflammation on the corrosion of 316L stainless steel. Materials Science and Engineering: C. 2017; 71: 200–205. http://doi.org/10.1016/j.msec.2016.10.012

10. Singh R., Gupta A., Tripathi O., Srivastava S., Singh B., Awasthi A., Rajput S.K., Sonia P., Singhal P., Saxena K.K. Powder bed fusion process in additive manufacturing: An overview. Materials Today: Proceedings. 2020; 26(2): 3058–3070. http://doi.org/10.1016/j.matpr.2020.02.635

11. Ngo T.D., Kashani A., Imbalzano G., Nguyen K.T.Q., Hui D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B: Engineering. 2018; 143: 172–196. http://doi.org/10.1016/j.compositesb.2018.02.012

12. Haselhuhn A.S., Wijnen B., Anzalone G.C., Sanders P.G., Pearce J.M. In situ formation of substrate release mechanisms for gas metal arc weld metal 3-D printing. Journal of Materials Processing Technology. 2015; 226: 50–59. http://doi.org/10.1016/j.jmatprotec.2015.06.038

13. Yap C.Y., Chua C.K., Dong Z.L., Liu Z.H., Zhang D.Q., Loh L.E., Sing S.L. Review of selective laser melting: Materials and applications. Applied Physics Reviews. 2015; 2(4): 241101. http://doi.org/10.1063/1.4935926

14. Chen Q., Thouas G.A. Metallic implant biomaterials. Materials Science and Engineering: R: Reports. 2015; 87: 1–57. http://doi.org/10.1016/j.mser.2014.10.001

15. Egger G., Gygax P.E., Glardon R., Karapatis N.P. Optimization of powder layer density in selective laser sintering. In: 10th Int. Solid Freeform Fabrication Symp. 1999: 255–263. http://doi.org/10.26153/tsw/746

16. Sing S.L., An J., Yeong W.Y., Wiria F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. Journal of Orthopedic Research. 2016; 34(3): 369–385. http://doi.org/10.1002/jor.23075

17. Ganesan V.V., Amerinatanzi A., Jain A. Discrete Element Modeling (DEM) simulations of powder bed densification using horizontal compactors in metal additive manufacturing. Powder Technology. 2022; 405: 117557. http://doi.org/10.1016/j.powtec.2022.117557

18. Zhai W., Zhou W., Nai S.M.L., Wei J. Characterization of nanoparticle mixed 316 L powder for additive manufacturing. Journal of Materials Science & Technology. 2020; 47:162–168. http://doi.org/10.1016/j.jmst.2020.02.019

19. Kolmakov A.G., Ivannikov A.Yu., Kaplan M.A., Kirsankin A.A., Sevost’yanov M.A. Corrosion-resistant steels in additive manufacturing. Izvestiya. Ferrous Metallurgy. 2021; 64(9): 619–650. https://doi.org/10.17073/0368-0797-2021-9-619-650

About the Authors

M. A. KaplanRussian Federation

Mikhail A. Kaplan, Junior Researcher

49 Leninskii Ave., Moscow 119991, Russian Federation

A. D. Gorbenko

Russian Federation

Artem D. Gorbenko, Research Engineer, Baikov Institute of Metallurgy and Materials Science, Russian Academy of Sciences; Research Engineer, All-Russian Research Institute of Phytopathology

49 Leninskii Ave., Moscow 119991, Russian Federation

5 Institut Str., Bol’shie Vyazemy Vil., Odintsovo District, Moscow Region 143050, Russian Federation

A. Yu. Ivannikov

Russian Federation

Aleksandr Yu. Ivannikov, Cand. Sci. (Eng.), Senior Researcher

49 Leninskii Ave., Moscow 119991, Russian Federation

S. V. Konushkin

Russian Federation

Sergei V. Konushkin, Junior Researcher

49 Leninskii Ave., Moscow 119991, Russian Federation

A. V. Mikhailova

Russian Federation

Anna V. Mikhailova, Research Engineer, Baikov Institute of Metallurgy and Materials Science, Russian Academy of Sciences; Research Engineer, All-Russian Research Institute of Phytopathology

49 Leninskii Ave., Moscow 119991, Russian Federation

5 Institut Str., Bol’shie Vyazemy Vil., Odintsovo District, Moscow Region 143050, Russian Federation

A. A. Kirsankin

Russian Federation

Andrei A. Kirsankin, Cand. Sci. (Phys.-Math.), Senior Researcher

49 Leninskii Ave., Moscow 119991, Russian Federation

A. S. Baikin

Russian Federation

Aleksandr S. Baikin, Research Associate

49 Leninskii Ave., Moscow 119991, Russian Federation

K. V. Sergienko

Russian Federation

Konstantin V. Sergienko, Junior Researcher

49 Leninskii Ave., Moscow 119991, Russian Federation

E . O. Nasakina

Russian Federation

Elena O. Nasakina, Senior Researcher

49 Leninskii Ave., Moscow 119991, Russian Federation

A. G. Kolmakov

Russian Federation

Aleksei G. Kolmakov, Corresponding Member of RAS, Dr. Sci. (Eng.), Head of the Laboratory

49 Leninskii Ave., Moscow 119991, Russian Federation

M. A. Sevost’yanov

Russian Federation

Mikhail A. Sevost’yanov, Cand. Sci. (Eng.), Leading Researcher, Baikov Institute of Metallurgy and Materials Science, Russian Academy of Sciences; Head of the Center, All-Russian Research Institute of Phytopathology

49 Leninskii Ave., Moscow 119991, Russian Federation

5 Institut Str., Bol’shie Vyazemy Vil., Odintsovo District, Moscow Region 143050, Russian Federation

Review

For citations:

Kaplan M.A., Gorbenko A.D., Ivannikov A.Yu., Konushkin S.V., Mikhailova A.V., Kirsankin A.A., Baikin A.S., Sergienko K.V., Nasakina E.O., Kolmakov A.G., Sevost’yanov M.A. Properties of spherical metal powder manufactured by plasma spraying of 03Cr17Ni10Mo2 stainless steel wire. Izvestiya. Ferrous Metallurgy. 2023;66(1):80-85. https://doi.org/10.17073/0368-0797-2023-1-80-85