Scroll to:

Transformation of fine structure of lamellar pearlite under deformation of rail steel

https://doi.org/10.17073/0368-0797-2023-1-50-56

Abstract

The defective substructure of polycrystalline bodies preconditions substructural hardening and mechanical properties. Pearlite, which is the main structural component of rails, is subjected under deformation to considerable transformation accompanied by a number of processes. In the present work, methods of the modern physical materials science were used to study and analyze the defective substructure of pearlite with lamellar morphology and properties of rail steel subjected to fracture under the conditions of uniaxial tensile strain of flat samples. It was established that the ultimate strength changes from 1247 to 1335 MPa, and the relative strain-to-fracture is from 0.69 to 0.75. The formation of three zones of the fracture surface is observed: fibrous, radial and shear zones. Their shapes and sizes have been analyzed. The deformation of rail steel is accompanied by fracture of cementite plates of pearlite colonies and re-precipitation of nanosized particles of tertiary cementite about 8.3 nm in size in the volume of ferrite plates. The main mechanisms of cementite plate fracture are cutting and dissolution. Dislocation substructure is represented by chaotic distribution of dislocations and their clusters. Scalar density of dislocations in ferrite increases from 3.2·1010 cm-2 in the initial state to 7.9·1010 cm–2 at failure. Deformation is accompanied by the formation of internal stress fields which manifest themselves as bending contours of extinction. The sources of stress fields are the interfaces of cementite and ferrite plates as well as grain interfaces. Fragmentation of ferrite and cementite plates has been revealed. The average size of cementite fragments is 9.3 nm. In the fracture zone of the rail steel sample, rotation of pearlite grains has been noted, indicating the presence of a rotational mode of strain. The electron microscopic images of cementite plates show a change in the contrast, which may be related to formation of the Cottrell atmospheres.

For citations:

Gromov V.E., Aksenova K.V., Ivanov Yu.F., Kuznetsov R.V., Kormyshev V.E. Transformation of fine structure of lamellar pearlite under deformation of rail steel. Izvestiya. Ferrous Metallurgy. 2023;66(1):50-56. https://doi.org/10.17073/0368-0797-2023-1-50-56

Introduction

One of the basic and most general types of strengthening of polycrystalline bodies is substructural, caused by the defective substructure. This largely determines the mechanical properties of materials. The nucleation and development of microcracks in plastic materials are closely related to the substructure evolution [1, 2].

Significant increase in the intensity of railway traffic and traffic concentration requires high operational durability of rails made of pearlitic steel. During operation, rails are subjected to significant strain effects, accompanied by evolution of the structural-phase state of pearlite [3, 4]. Importance of the information in this field is determined by the depth of understanding the fundamental issues of the physical materials science, on the one hand, and the practical importance, on the other hand. The practical importance is connected with the creation of high-quality rails with high performance properties, ensuring accident-free operation with a passing tonnage of more than 2 billion tons (gross). Creation of special types of rails for high-speed railways, low-temperature reliability, and increased contact-fatigue endurance requires a study of the dependence of hardening on the structural state of rails before strain and establishing cause-effect relations between the phenomena that determine the strain behavior [3, 4].

In the initial state, rails contain about 70 % of pearlite of lamellar morphology [5 – 7], the deformation of which is accompanied by a complex transformation of ferrite and cementite [8, 9] usually observed by transmission electron microscopy. Main attention is paid to the strain-induced fracture of cementite [10 – 12] which leads to an increase in the carbon concentration in ferrite and an additional hardening mechanism [13].

The purpose of the present work was to analyze the defective substructure of pearlite of rail steel lamellar morphology, fractured under the conditions of uniaxial tensile strain of flat samples.

Research materials and methods

Samples of rail steel, the properties and elementary composition of which are regulated by GOST R 51685–2013, were used as the research material. The chemical composition of rails of DT350 category, % (wt.) was as follows: C 0.73; Mn 0.75; Si 0.58; P 0.012; S 0.007; Cr 0.42; Ni 0.07; Cu 0.13; Ti 0.003; Mo 0.006; V 0.04; Al 0.003; Ti 0.008; and the rest was iron.

Mechanical tests were performed by uniaxial tensioning of flat proportional samples in the form of double-sided blades with the dimensions of the working area of the blades of 1.5×4.45×8.0 mm. Samples were cut from the head of 100-meter differentially hardened rails of DT350 category produced by JSC “EVRAZ – Joint West Siberian Metallurgical Plant”. Uniaxial tensile strain was applied on an Instron 3369 testing machine at a loading rate of 1.2 mm/min.

The structure of the fracture surface was studied by scanning electron microscopy (SEM 515 Philips device). The steel deformed substructure in the fracture zone was studied by transmission electron diffraction microscopy (thin-foil method) (JEM-2100 JEOL device) [14 – 16]. Foil for the transmission electron microscope was made by ion thinning (Ion Slicer EM-091001S installation, thinning achieved by argon ions) of plates cut from fractured samples on the Isomet Low Speed Saw installation perpendicular to the fracture surface. The methods for measuring the scalar and excess dislocation densities did not differ from those described in [3, 4].

Results and discussion

The tests showed that tensile strength varied in the range from 1247 to 1335 MPa, and strain of the samples at failure ranged from 0.69 to 0.75. As a rule, under tensile strain of the samples three zones are formed on the fracture surface: a fibrous zone (central part of the specimen); the radial zone following it; and the shear zone along the edge of the sample [17]. The fibrous zone is elliptical in shape with a large axis parallel to the long sides of the rectangle. The radial zone of the samples, whose width is much greater than their thickness, has a chevron or herringbone shape. Chevron patterns are often associated with unstable, relatively rapid crack propagation. The appearance of a chevron pattern is caused by the mismatch between the general direction of crack propagation and the shortest direction from the crack front to the free surface. In this case, radial scars propagate towards the free surface, forming chevron patterns [17]. The vertices of V-shaped chevrons are directed away from the fracture center.

Previously, it was shown in [2 – 4, 18] that the following components are distinguished in the structure of the steel studied according to the morphological feature: pearlite grains of lamellar morphology, grains of ferrite-carbide mixture (irregular pearlite grains) and grains of structurally free ferrite (ferrite grains with no carbide phase particles in their volume). The main type of structure of the steel under study is lamellar pearlite grains, the relative content of which in the material is 0.7. The relative content of ferrite-carbide mixture grains is 0.27; and the rest are grains of structurally free ferrite.

As a rule, the structure of lamellar pearlite is represented by alternating ferrite plates (solid solution based on iron crystal body-centered lattice) and cementite plates (iron carbide of Fe3C composition, orthorhombic crystal lattice) [19]. Fracture of steel under uniaxial tension conditions in flat samples does not change the morphology of the material. In the fracture zone and away from it, grains with a lamellar structure characteristic of pearlite are present. Change in the steel structure is detected at the level of the defective subsystem and is accompanied by multiple pearlite transformation.

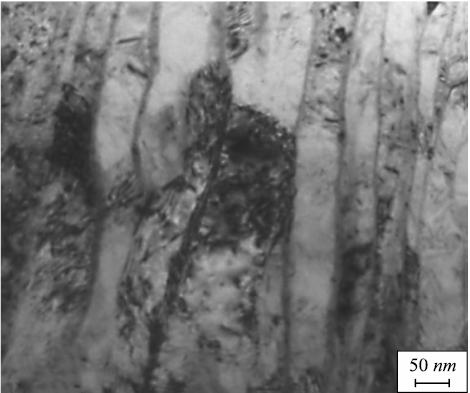

When considering the transformation of the ferrite plate structure, it was found that ferrite plates of pearlite colonies fragment, i.e., they split into the regions separated by low-angle boundaries. Deformation is accompanied by the formation of a dislocation substructure in the volume of ferrite plates (Fig. 1). Dislocations are distributed chaotically or form clusters. The scalar density of dislocations is 7.9·1010 cm–2, 3.2·1010 cm–2 in the initial state.

Fig. 1. Electron microscopic image of dislocation substructure |

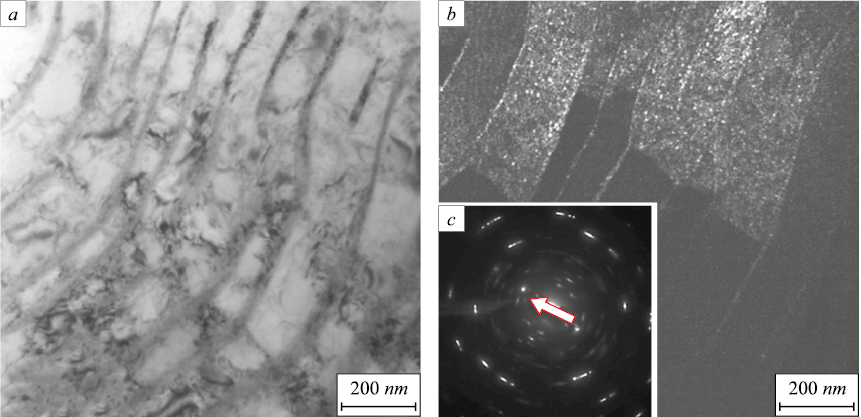

Deformation of steel is accompanied by the formation of stress fields in the sample. When the material is studied by electron microscopy of thin foils, the internal stress fields appear as bending contours of extinction, located mainly in ferrite plates. The sources of stress fields in the surveyed steel are the interfaces of cementite and ferrite plates (Fig. 2), as well as grain interfaces. It should be noted that the tensile stress of the steel studied is accompanied by pearlite grain rotation, which is most pronounced in the fracture zone of the samples (Fig. 2). The latter suggests the presence of a rotational mode of strain in the fracture zone of the specimen [20 – 22], associated with the formation of local lattice curvature. In this connection, it can be assumed that the development of a similar effect in rail steel makes it easier to move the carbon atoms.

Fig. 2. Electron microscopic image of pearlite grain structure |

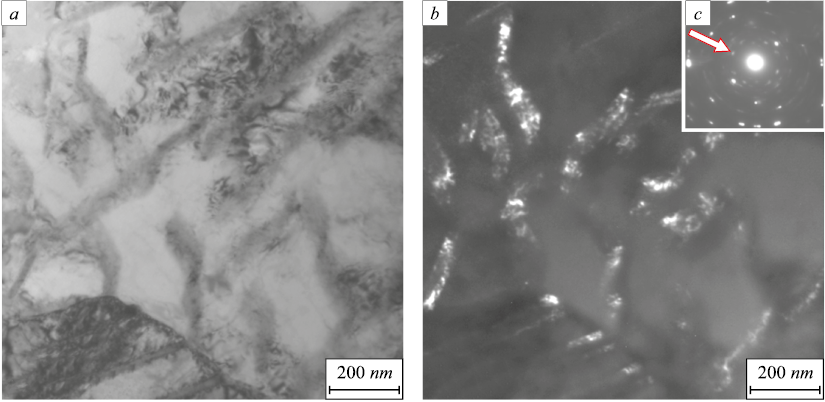

Deformation of the steel under study is accompanied by the fracture of cementite plates. Two possible mechanisms of cementite plates fracture are discussed in the scientific literature: cutting and dissolution [2, 3, 13]. Dissolution of cementite plates occurs due to greater binding energy of dislocations with carbon atoms (~0.6 – 0.7 eV) compared to the binding energy of carbon atoms in the cementite lattice [23 – 25]. According to the results of [26], an increase in free energy caused by geometric thinning of cementite plates and the formation of slip bands destabilizes the cementite and ensures its fracture. A similar thermodynamic model based on the Gibbs–Thomson effect and the diffusion controlled process of dissolution is proposed in [27]. Carbon atoms are carried out by moving dislocations into the volume of ferrite plates with the subsequent formation of nanosized particles of iron carbide (Fig. 3). The average size of the particles located in the ferrite plates is 8.3 nm. Particles of this size are most clearly detected by dark-field analysis (Fig. 3, b).

Fig. 3. Electron microscopic image of nanosized cementite particles formed in ferrite plates of rail steel: |

Dissolution of cementite is accompanied by the formation of a region of material around the plates which differs from the main grain volume in contrast (Fig. 4, a). It can be assumed that the change in the contrast is caused by a change in the chemical composition of the material surrounding the cementite plate, namely, an increased concentration of carbon. The carbon atoms pulled out of the cementite by dislocations are capable of forming Cottrell atmospheres, leading to a change in contrast.

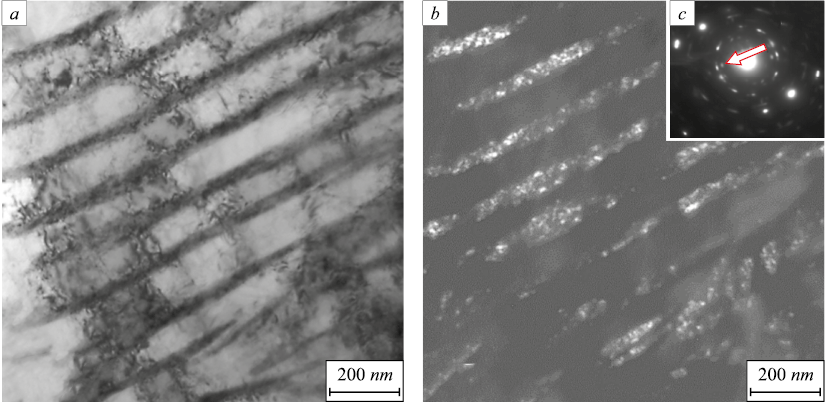

Along with dissolution, the plastic yield of steel is accompanied by fragmentation of cementite plates. It was found that in the fracture zone of samples the cementite plates, while retaining their original morphology, break into regions of coherent dispersion, the average size of which is 9.3 nm (Fig. 5).

Fig. 4. Electron microscopic image of rail steel structure near cementite plates:

Fig. 5. Electron microscopic image of fragmented structure of cementite: |

Conclusion

The methods of the modern physical materials science were used to study the mechanical properties, defective substructure of pearlite with lamellar morphology, and fracture surface of rail steel subjected to fracture under the conditions of uniaxial tensile stress. It was also established that the ultimate tensile strength varies from 1247 to 1335 MPa. The fracture strain of the samples ranges from 0.69 to 0.75. The formation of three zones of the fracture surface has been detected: fibrous, radial and shear zones. It has been demonstrated that the steel strain is accompanied by fragmentation of ferrite plates with low-angle boundaries and a significant increase in the scalar dislocation density to 7.9·1010 cm–2 (the scalar dislocation density of the initial steel is 3.2·1010 cm–2). The fracture of cementite plates by cutting and dissolution mechanisms was established with subsequent removal of carbon by moving dislocations to the ferrite plates volume with the formation of nanosized (8.3 nm) round-shaped tertiary cementite particles in them. Thermodynamic models of cementite fracture are discussed. It was shown that the dissolution of cementite plates is accompanied by their fragmentation (division into coherent diffusion regions with the average size of 9.3 nm).

References

1. Koneva N.A., Trishkina L.I., Kozlov E.V. Physics of substructural and grain-bound hardening. Fundamental problems of modern materials science. 2014; 11(1): 40–49. (In Russ.).

2. Ivanov Yu.F., Gromov V.E., Popova N.A., Konovalov S.V., Koneva N.A. Structural-Phase State and Mechanisms of Hardening of Deformed Steel. Novokuznetsk: Polygraphist; 2016: 510. (In Russ.).

3. Yuriev A.A., Ivanov Yu.F., Gromov V.E., Rubannikova Yu.A., Starostenkov M.D., Tabakov P.Y. Structure and Properties of Lengthy Rails after Extreme Long-Term Operation. USA: Materials Research Forum LLC; 2021: 190.

4. Gromov V.E., Peregudov O.A., Ivanov Yu.F., Konovalov S.V., Yur’ev A.A. Evolution of Structural-Phase States of Metal Rails during Long-Term Operation. Novosibirsk: Publishing House of SB RAS; 2017: 164. (In Russ.).

5. Hong M.H., Reynolds W.T., Tarui T., Hono K. Atom probe and transmission electron microscopy investigations of heavily drawn pearlitic steel wire. Metallurgical and Materials Transactions A. 1999; 30(3): 717–727. https://doi.org/10.1007/s11661-999-1003-y

6. Hono K., Ohnuma M., Murayama M., Nishida S., Yoshie A., Takahashi T. Cementite decomposition in heavily drawn pearlite steel wire. Scripta Materialia. 2001; 44(6): 977–983. https://doi.org/10.1016/S1359-6462(00)00690-4

7. Taniyama A., Takayama T., Arai M., Hamada T. Structure analysis of ferrite in deformed pearlitic steel by means of X-ray diffraction method with synchrotron radiation. Scripta Materialia. 2004; 51(1): 53–58. https://doi.org/10.1016/j.scriptamat.2004.03.018

8. Goto S., Kirchheim R., Al-Kassab T., Borchers C. Application of cold drawn lamellar microstructure for developing ultra-high strength wires. Transactions of Nonferrous Metals Society of China. 2007; 17(6): 1129–1138. https://doi.org/10.1016/S1003-6326(07)60238-6

9. Borchers C., Al-Kassab T., Goto S., Kirchheim R. Partially amorphous nanocomposite obtained from heavily deformed pearlitic steel. Materials Science and Engineering: A. 2009; 502(1-2): 131–138. https://doi.org/10.1016/j.msea.2008.10.018

10. Read H.G., Reynolds Jr. W.T, Hono K., Tarui T. APFIM and TEM studies of drawn pearlitic wire. Scripta Materialia. 1997; 37(8): 1221–1230. https://doi.org/10.1016/S1359-6462(97)00223-6

11. Maruyama N., Tarui T., Tashiro H. Atom probe study on the ductility of drawn pearlitic steels. Scripta Materialia. 2002; 46(8): 599–603. https://doi.org/10.1016/S1359-6462(02)00037-4

12. Tarui T., Maruyama N., Takahashi J., Nishida S., Tashiro H. Microstructure control and strengthening of high-carbon steel wires. Nippon Steel Technical Report. 2005; 91: 56–61.

13. Danoix F., Julien D., Sauvage X., Copreaux J. Direct evidence of cementite dissolution in drawn pearlitic steels observed by tomographic atom probe. Materials Science and Engineering: A. 1998; 250(1): 8–13. https://doi.org/10.1016/S0921-5093(98)00529-2

14. Egerton F.R. Physical Principles of Electron Microscopy. Basel: Springer International Publishing; 2016: 196. https://doi.org/10.1007/978-3-319-39877-8

15. Kumar C.S.S.R. Transmission Electron Microscopy. Characterization of Nanomaterials. New York: Springer; 2014: 717. https://doi.org/10.1007/978-3-642-38934-4

16. Carter C.B., Williams D.B. Transmission Electron Microscopy. Berlin: Springer International Publishing; 2016: 518.

17. Fractography and Atlas of Fractograms. Reference book. Fellows J. ed. Moscow: Metallurgiya; 1982: 489. (In Russ.).

18. Kuznetsov R.V., Gromov V.E., Ivanov Yu.F., Kormyshev V.E., Shlyarova Yu.A., Polevoi E.V., Yur’ev A.A. Evolution of structural-phase states and properties of differentially hardened rails during extremely long-term operation. Message 4. Formation of gradients of the structural-phase state of the metal of the rail head along the central axis after the missed tonnage of 1770 million tons gross. Problemy chernoi metallurgii i materialovedeniya. 2021; 3: 37–46. (In Russ.).

19. Schastlivtsev V.M., Mirzaev D.A., Yakovleva I.L., Okishev K. Yu., Tabatchikova T.I., Khlebnikova Yu.V. Perlite in Carbon Steels. Yekaterinburg: UB RAS; 2006: 312. (In Russ.).

20. Panin V.E., Egorushkin V.E., Panin A.V., Chernyavskii A.G. Plastic distortion as a fundamental mechanism in nonlinear mesomechanics of plastic deformation and fracture. Physical Mesomechanics. 2016; 19(3): 255–268. https://doi.org/10.1134/S1029959916030048

21. Panin V.E., Egorushkin V.E., Panin A.V. Nonlinear wave processes in a deformable solid as in a multiscale hierarchically organized system. Uspekhi fizicheskikh nauk. 2012; 182(12): 1351–1357. (In Russ.). https://doi.org/10.3367/UFNr.0182.201212i.1351

22. Grigorovich K.V., Gromov V.E., Kuznetsov R.V., Ivanov Yu.F., Shlyarova Yu.A. Formation of a thin structure of pearlite steel under ultra-long plastic deformation. Doklady Rossiiskoi akademii nauk. Fizika, tekhnicheskie nauki. 2022; 503(41): 69–72. (In Russ.). https://doi.org/10.31857/S2686740022020079

23. Li Y.J., Choi P., Borchers C., Westerkamp S., Goto S., Raabe D., Kirchheim R. Atomic-scale mechanisms of deformation-induced cementite decomposition in pearlite. Acta Materialia. 2011; 59(10): 3965–3977. https://doi.org/10.1016/j.actamat.2011.03.022

24. Gavriljuk V.G. Comment on “Effect of interlamellar spacing on cementite dissolution during wire drawing of pearlitic steel wires”. Scripta Materialia. 2001; 45(12): 1469–1472. https://doi.org/10.1016/S1359-6462(01)01185-X

25. Gavriljuk V.G. Decomposition of cementite in pearlite steel due to plastic deformation. Materials Science and Engineering: A. 2003; 345(1-2): 81–89. https://doi.org/10.1016/S0921-5093(02)00358-1

26. Languillaume J., Kapelski G., Baudelet B. Cementite dissolution in heavily cold drawn pearlitic steel wires. Acta Materialia. 1997; 45(3): 1201–1212. https://doi.org/10.1016/S1359-6454(96)00216-9

27. Sauvage X., Copreaux J., Danoix F., Blavette D. Atomic-scale observation and modelling of cementite dissolution in heavily deformed pearlitic steels. Philosophical Magazine A. 2000; 80(4): 781–796. https://doi.org/10.1080/01418610008212082

About the Authors

V. E. GromovRussian Federation

Viktor E. Gromov, Dr. Sci. (Phys.-Math.), Prof., Head of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

K. V. Aksenova

Russian Federation

Krestina V. Aksenova, Cand. Sci. (Eng.), Assist. Prof. of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Yu. F. Ivanov

Russian Federation

Yurii F. Ivanov, Dr. Sci. (Phys.-Math.), Prof., Chief Researcher of the Laboratory of Plasma Emission Electronics

2/3 Akademicheskii Ave., Tomsk 634055, Russian Federation

R. V. Kuznetsov

Russian Federation

Roman V. Kuznetsov, Candidates for a degree of Cand. Sci. (Eng.) of the Chair of Science named after V.M. Finkel’

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

V. E. Kormyshev

Russian Federation

Vasilii E. Kormyshev, Cand. Sci. (Eng.), Senior Researcher of Department of Scientific Researches

42 Kirova Str., Novokuznetsk, Kemerovo Region – Kuzbass 654007, Russian Federation

Review

For citations:

Gromov V.E., Aksenova K.V., Ivanov Yu.F., Kuznetsov R.V., Kormyshev V.E. Transformation of fine structure of lamellar pearlite under deformation of rail steel. Izvestiya. Ferrous Metallurgy. 2023;66(1):50-56. https://doi.org/10.17073/0368-0797-2023-1-50-56