Scroll to:

Features of formation of austenite grains in 12 % Cr heat-resistant ferritic-martensitic steels

https://doi.org/10.17073/0368-0797-2023-2-168-176

Abstract

Ferritic-martensitic heat-resistant high-chromium steels (FMHS) with chromium content of 11 – 12 % are quenched to martensite from temperatures of 1050 – 1100 °С. Possible undesirable consequences of heating to such high temperatures are an increase in the size of austenite grains, increase in the amount of delta ferrite in the final structure, and a decrease in mechanical characteristics. In this work, the change of all these factors during heating of FHMS to quenching temperatures in the range of 950 – 1250 °С was studied. Ratios of the contents of martensite (its amount was identified with the proportion of austenite before quenching) and high-temperature delta ferrite on metallographic sections were analyzed. It was found that behavior of structure of the studied FHMS upon heating to temperatures of 1150 °С and above depends on the steels structural class. In steels whose structure at room temperature consists of martensite and delta ferrite, or in which delta ferrite begins to form at heating temperatures of 1200 °С and higher, size of austenite grain decreases with increasing temperature in the range of 1200 – 1250 °С, and the amount of delta ferrite – increases. Such structural transformations can be associated with features of the phase equilibrium diagrams of steels of this class. Such structural transformations can be associated with a change in the position and (or) inclination of boundaries of the high-temperature region of coexistence of austenite and delta-ferrite in the phase equilibrium diagrams of FHMS at a change in heating temperature in this range. Compression tests at 20 °С of 15Cr12Mn3SiMoW2VB steel samples after heat treatment with heating to temperatures for hardening 1000 – 1250 °С showed that formation of an additional amount of delta ferrite at temperatures above 1200 °С is a stronger factor than the refinement of austenite grains. This causes a decrease in yield strength of the samples quenched from these temperatures followed by high tempering.

Keywords

For citations:

Belomyttsev M.Yu. Features of formation of austenite grains in 12 % Cr heat-resistant ferritic-martensitic steels. Izvestiya. Ferrous Metallurgy. 2023;66(2):168-176. https://doi.org/10.17073/0368-0797-2023-2-168-176

Introduction

Steels containing 10 – 13 wt. % of chromium (heat-resistant ferritic-martensitic high-chromium steels (FMHS)), depending on the alloying elements content, can experience martensitic transformation when cooled from high temperatures, and then have a mixed structure consisting of martensite, bainite and high-temperature delta-ferrite (δ-ferrite) [1 – 3]. Below is the rationale for using high heating temperatures for such steels during heat treatments:

– high content of alloying elements which causes an increase in critical temperatures (As1 and As3);

– formation in the structure of carbides of alloying elements (V, Mo, W, Nb, Ta) which have high dissolution temperatures in austenite [4];

– complex chemical composition which makes FMHS prone to the formation of highly developed chemical heterogeneity during crystallization, the basis of which is liquation of alloying elements [5].

All these reasons cause an increase in the heating temperature for quenching to 1000 °C (more often 1050 – 1100 °C) [6; 7], and the homogenizing annealing temperature to reduce the liquation phenomena to 1050 – 1240 °C with a dwell time up to 10 h [8; 9]. Heating to these temperatures raises concerns related to the growth of the austenitic grain size and change in the ratio of phase components (austenite and δ-ferrite). The possibility of the second process is illustrated by experimental phase equilibrium diagrams [10]. According to these diagrams, the relationship between austenite (which transforms into martensite upon cooling) and δ-ferrite can change at the specified temperatures due to transition of the alloy from phase region γ to phase region γ + δ, as well as due to change in the position of the boundary of regions γ ↔ γ + δ upon temperature change.

All the works describing the effect of high heating temperatures during homogenization on changes in the FMHS structure pay more attention to the amount of δ-ferrite which impairs certain mechanical and process characteristics of these steels [10 – 12]. The fundamental work [10] shows the possibility of non-monotonic (with minimum at some time of homogenization annealing) change of the δ-ferrite content in 1Cr16Ni4B steel. In [7] it is noted that final heat treatment performed after homogenizing annealing with heating to 1050 °C for steel 07Cr12NiMoVB provides some average content of δ-ferrite regardless of its content after homogenizing annealing. However, the authors of work [6] did not observe changes in the amount of δ-ferrite in 10Cr9Co3W2MoVBR, 02Cr9Co3W2MoVBR, or 005Z9Co3W2MoVBR steels at homogenizing temperatures of 1000 – 1200 °C. The researchers [8] noted only reduction in the amount of δ-ferrite upon heating of steel 10Cr11W3Co2VBTaNdP (SAVE12) to 1050 – 1100 °C with a weld time for up to 20 h. Studies [13 – 15] paid practically no attention to the size of δ-ferrite grains and austenite grains formed. The results obtained in [16] for steel R92 are presented in the same way. The growth or constancy [7] of δ-ferrite grain sizes for 07Cr12NiMoVB steel in the homogenizing temperature range of 1150 – 1240 °C, the constancy [6] or increase [6; 17; 18] of the austenite grain size in 10Cr9Co3W2MoVBR, 02Cr9Co3W2MoVBR, and 005Cr9Co3W2MoVBR (at 1000 – 1200 °C) [6] and in steel 27Cr16Mo2W2V at 900 – 1150 °C [18] are noted as accompanying the homogenizing annealing. In general, there is no uniform structure behavior for all FMHS in the analyzed temperature range.

The purpose of this work is to study the effect of the heating temperature in the austenite + δ-ferrite phase region on the austenite grain size, grain size (regions) of δ-ferrite and the yield strength of experimental FMHS with different “initial” ratios of structural components: martensite – δ-ferrite.

Research methodology

Studies were carried out on five steels of experimental composition, smelted in a vacuum induction furnace, and steel 40Cr12 of commercial smelting.

The steels presented in the work were selected according to their δ-ferrite content. They illustrate the “extreme points” in terms of the δ-ferrite content (0 and 100 %) (Table 1, steels 1 and 5), with the minimum (~0 – 1.5 %) content of δ-ferrite (Table 1, steel 2), the most frequently obtained values in steels with optimum mechanical properties (Table 1, steel 3), and steel with high (40 %) content of δ-ferrite (Table 1, steel 4).

Experimental steel ingots weighing 3 kg were hot forged into square bars with a side of ~14 mm. Steel 40Cr12 was used as a round bar with a diameter of 40 mm. The chemical composition of all steels was determined by the mass spectrometric method and is given in Table 1.

Table 1. Chemical composition and some indicators of the studied steels

Steel | Content of alloying elements, wt. % | Values of chromium-nickel equivalents | Values of critical | Content of | ||||||||||||||

C | Cr | Ni | Si | Mn | Mo | W | V | Nb | Ta | B | Cr-equivalent | Ni-equivalent | Аs1 | Аs3 | Мn | 1100* | 1250* | |

1** | 0.38 | 12.1 | 0.24 | 0.23 | 0.51 | – | – | – | – | – | – | 9.82 | 9.1 | 810 | 870 | 323 | 0 | 0 |

2 | 0.13 | 11.7 | 0.28 | 0.48 | 1.98 | 0.11 | 0.06 | 0.30 | – | – | 0.004 | 10.86 | 4.29 | 760 | 880 | 250 | 0 | 1,5 |

3 | 0.15 | 12.2 | 0.11 | 0.50 | 2.80 | 0.56 | 1.42 | 0.17 | – | – | 0.006 | 11.97 | 4.78 | 780 | 965 | 240 | 2.8 | 9.8 |

4 | 0.11 | 11.8 | 0.20 | 0.21 | – | 1.70 | – | 0.12 | 0.35 | – | 0.004 | 11.98 | 2.92 | 900 | 1010 | 220 | 40 | 65 |

5 | 0.14 | 12.3 | 0.13 | 0.55 | 1.33 | 1.60 | 2.10 | 0.31 | 0.34 | 0.1 | 0.004 | 15.21 | 5.07 | – | – | – | 100 | 100 |

* Indication of quenching temperature, °C ** This steel has an additional copper content of 0.1 wt. % | ||||||||||||||||||

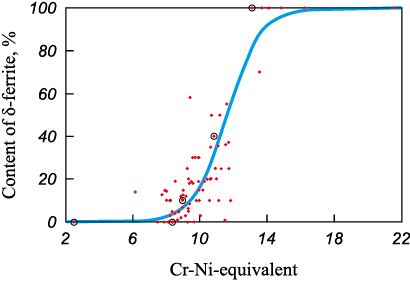

The structure and mechanical properties of steels are largely determined by the ratio of alloying elements that help to stabilize either austenite (γ-stabilizers) or ferrite (α-stabilizers). The Cr- and Ni-equivalents according to Schaeffler [1] are commonly used as generalized parameters to describe this property. The formulas used for their calculations can vary (variants of such formulas by Schaeffler, Schneider, Biduli, Potak, Raghavan, Yufarov, etc. are known). Each author chooses the model which gives the best coincidence of the predicted values of the structural composition with that observed. In this paper, we used our own version of such formulas found experimentally. In the following formulas used to determine the equivalents, concentrations of alloying elements designated by their chemical symbols are taken in weight percentages. The calculated Cr- and Ni-equivalents are given in Table 1. The parameter “generalized Cr-Ni-equivalent = (Cr-equivalent) – (Ni-equivalent)” uses the sigmoidal dependence to describe the amount of δ-ferrite in the steels used in the investigations, which also includes data on all the steels studied (more than 70) (Fig. 1). The values of generalized equivalents together with the values of critical points As1, As3, Mn are shown in Table 1.

Cr-equivalent = 0.75Cr + 4.13Al + 3.75V + 1.5Si + 1.31Nb +

+ 1.13Mo + 1.88Ti + 0.56W + 0.38Ta + 0.75Zr + 1.5Ce,Y + 1.157;

Ni-equivalent = 0.75Ni + 22.5C + 18.78N + 0.75Co + 0.38Mn + 0.23Cu – 0.593.

Heat treatment of the samples in all cases was carried out in an argon environment. The samples in the ampoule filled with inert gas were placed in a preheated furnace. After holding for 15 min they were quenched in oil.

Fig. 1. Relationship between generalized Cr-Ni-equivalent and amount of δ-ferrite |

The typical heat treatment for ferritic-martensitic steels of the class studied and used for obtaining the required set of operational properties, is quenching at temperatures of 1050 – 1120 °C with tempering at 650 – 780 °C [19]. The normalization of ferritic-martensitic steel samples is carried out in order to determine their structural class (according to the Gaultier method) from the same temperatures of 1050 – 1200 °C. In the present study quenching from 1100 °C followed by tempering at 720 °C for 2 h was used to produce the same initial state for all samples. It was in this condition that the content of δ-ferrite in steels was determined. The data is presented in Fig. 1 and in Table 1 in the column corresponding to a quenching temperature of 1100 °C. In order to study the effect of quenching temperature proper on the structure of pilot steels, the samples were reheated to 900 – 1250 °C, held at these temperatures for 15 min and quenched in oil. Tempering after repeated quenching was not performed on the samples for metallographic studies.

The samples for structure studies were cubes with sides of 6 – 8 mm. A metal layer at least 0.7 mm thick was removed from the selected plane before preparing a thin section. The structure of the metal was determined by glyceregia (a weak solution of hydrochloric, nitric and picric acids in ethanol) and then analyzed using an Axio Lab.A1 microscope. The images were saved as electronic documents. The sizes of the austenitic grains (identified with the sizes of martensitic regions) were determined by the secant method. The sizes of the regions (grains) of δ-ferrite were almost always calculated from measurements of their maximum diameters. The same data was used to calculate the volume fraction of δ-ferrite.

In order to estimate the mechanical properties from “cubes” with ~8 mm sides, subjected to quenching, we made cylindrical samples with a diameter and height of 5 – 6 mm, after which they were tempered at 720 °C for 2 h in an argon environment, followed by cooling in air. Compression tests at 20 °C were carried out with determination of the yield strength.

Research and discussion

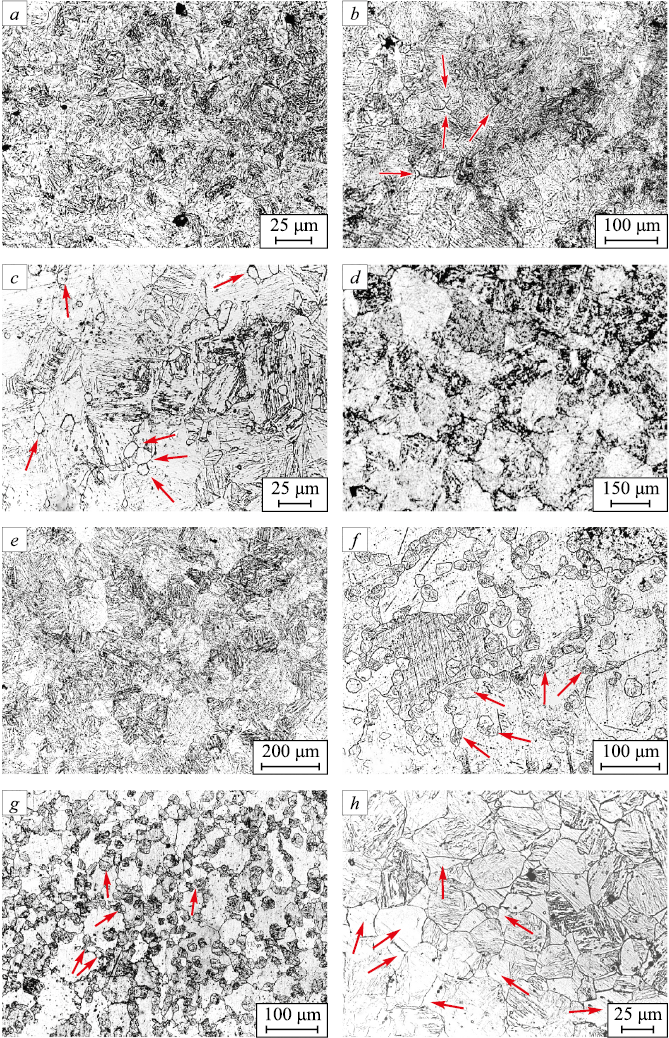

The typical structure of FMHS after quenching with the variable content of δ-ferrite and martensite grain size is shown in Fig. 2.

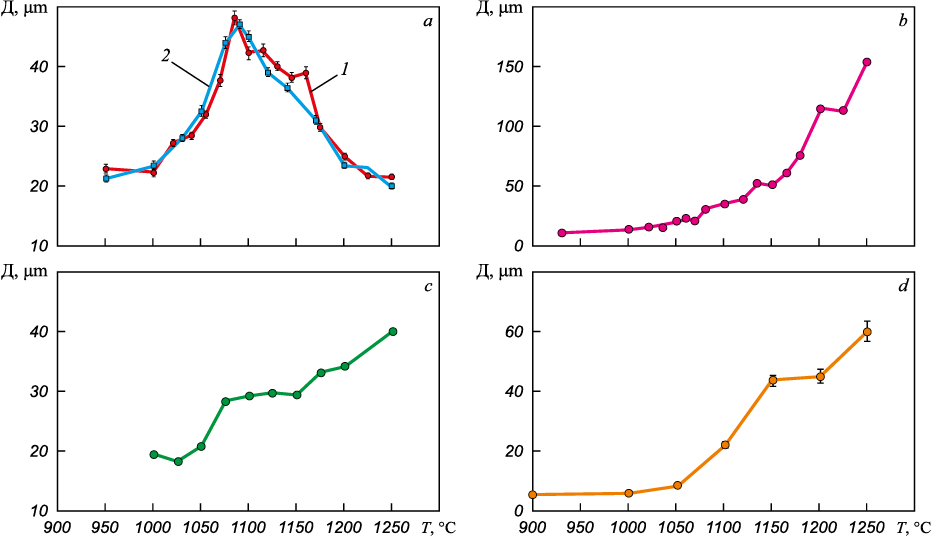

Analysis of the steel structure as a function of the heating temperature for quenching shows that for all steels in the temperature range of 950 – 1175 °C, an expected growth of the austenitic grain is observed. However, in all steels with the initial ferritic-martensitic and martensitic structure (except for steel 40Cr12), the pattern changes with further increase in temperature and the size of the austenitic grain formed begins to decrease. At the same time, the amount of δ-ferrite increases (Fig. 3). This behavior is characteristic of steels 2 – 4.

Fig. 2. Structures of FMHS after heat treatment: |

This effect is observed only if δ-ferrite begins to appear in the steel at a given heating temperature (steel 2), and its amount begins to increase sharply (steel 3, 4). For example, in steel 2 δ-ferrite is not detected by metallographic method after quenching from 1100 °C, allowing this steel to be referred to the martensitic class. However, this begins to be fixed at heating temperatures of 1200 °C and above, accompanied by refinement of the austenitic grain formed (Fig. 3, a).

Fig. 3. Dependence of grain size of austenite in steels on heating temperature: |

In steel 1 (grade 40Cr12) no δ-ferrite is detected after heating to any (of the studied) temperatures. The classic uninterrupted growth of austenitic grains in this steel occurs as the heating temperature for quenching increases from 950 to 1250 °C (Fig. 3, b). In single-phase steels (steel 5 with 100 % ferrite or austenitic steel 08Cr18Ni10T), a grain refinement effect with increasing heating temperature is not observed (Fig. 3, c, d).

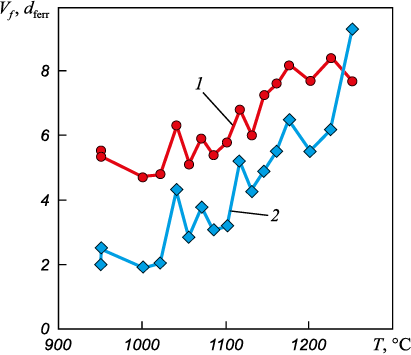

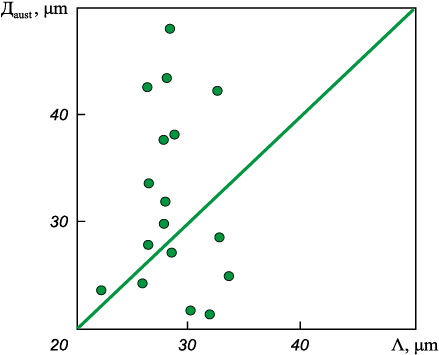

Delta-ferrite, while being a temperature-resistant form of iron, does not undergo polymorphic transformations during heating. This contrasts to martensite, which is the main structural component of FMHS at room temperature. In this respect, δ-ferrite could be the phase that serves as a “mechanical” obstacle to the growth of austenitic grains. However, comparison of the distance between the volumes of δ-ferrite (“inter-ferrite distance”) and the size of the resulting austenitic grain (Fig. 4) does not support this assumption (Fig. 5) (otherwise, the points in Fig. 5 would be located along a solid line drawn at an angle of 45° to the coordinate axes).

Fig. 4. Dimensions (dferr ), µm (1) and number (Vf ), vol. % (2)

Fig. 5. Relationship between grain sizes of austenite (Дaust ) |

The described sequence of change in the austenitic grain size in steels 2 – 4 and the characteristics of δ-ferrite as a function of quenching temperature does not depend on the initial state of the BCC-phase prior to heating (quenched martensite or isothermal transformation ferrite). Thus, a completely ferrite structure (a mixture of α and δ-ferrite) with some amount (~0.3 %) of primary carbides precipitated at the first stage of isothermal decomposition of supercooled austenite was formed in steel 3 by means of isothermal quenching at 650 – 680 °C and a dwell time of 350 – 500 h. Subsequent experiments carried out on steel with this structure give a similar dependence of the austenitic grain size on temperature, as in the case of steel with the original martensite + δ-ferrite structure (Fig. 3, a).

The unusual dependence of the structure on the heating temperature raised the question of the reversibility of the observed changes. For the study, two-stage experiments were carried out with heating to a high-temperature region of steel 3:

– first heating to 1200 – 1250 °C, to form a conditionally large amount of δ-ferrite (~9 %);

– second heating to typical quenching temperatures of 1080 – 1110 °C, at which the amount of δ-ferrite in steels is much less (~3 %).

The results of such experiments showed that repeated heating to the region, where the δ-ferrite content is expected to be small (with a dwell time in this region up to 3 h), does not lead to the recovery of both contents and sizes of δ-ferrite “regions” to the values typical for “low” temperature (Table 2): 6 – 8 % of δ-ferrite is still observed in steel. However, the characteristics of martensite regions (originally, at high temperature, they corresponded to austenite regions) tend towards their initial values after repeated quenching from lower temperatures. As in the case of single-phase quenching, the sizes of martensitic regions (martensite grains) after two-stage quenching correlate poorly with the distance between δ-ferrite regions.

Table 2. Characteristics of ferrite and martensite regions in steel 3

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

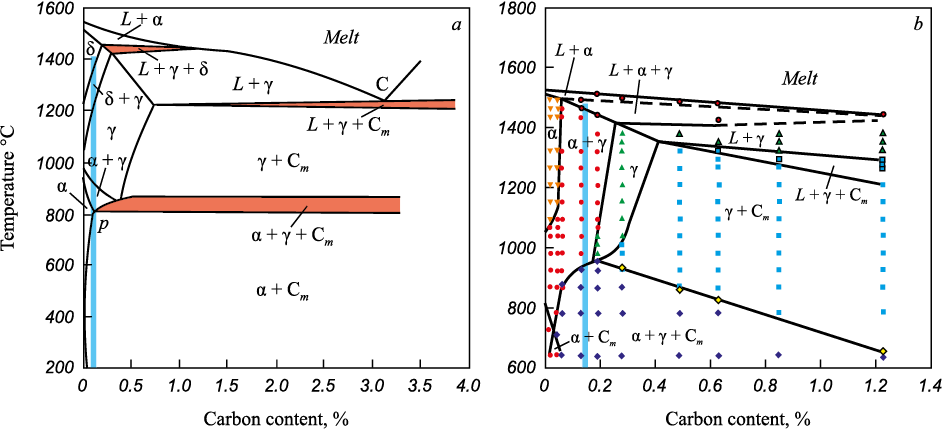

The observations describing changes in the amount of δ-ferrite with increasing heating temperature in the region of temperatures above 1080 °C may reflect the features of “movement” of a point corresponding to the chemical compositions of steels in phase state diagrams. Fig. 6 shows variants of phase diagrams for steels with 12 – 16 % Cr of the Fe – 12 % Cr – C and Fe – 16 % Cr – 2 % Ni – C systems [9 – 10]. The experimental phase diagrams built for steels with a more entangled alloying complex, such as in modern FMHS, have not been found, and the diagrams built by phase region synthesis programs of TermoCalc type do not appear to be sufficiently reliable. In the diagrams presented, the dull vertical line marks the region with the carbon content characteristic of the studied FMHS. Two conclusions follow from the diagrams presented:

– the amount of δ-ferrite may appear (if it was not observed at lower heating temperatures) or increase with increasing heating temperatures; this is determined by the position and slope of the line delimiting the region of δ + γ with the region of existence of phase γ only;

– as the alloying of steels increases, a δ + γ coexistence region is observed at increasingly lower temperatures and expands to increasingly higher carbon contents. This effect is evident in the experiments carried out in the present work.

Fig. 6. Phase equilibrium diagrams of the systems Fe – 12 % Cr – C (a) |

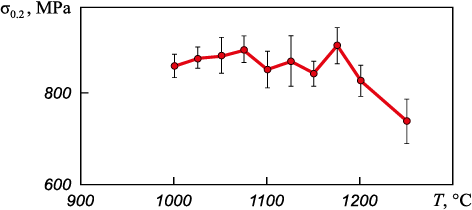

Analysis of the yield strength of steels measured at 20 °C as a function of heating temperature shows that an increase in the δ-ferrite amount in the structure when the quenching temperature increases from 1200 °C and higher causes a decrease in characteristic \(\sigma _{0.2}^{20}\) (Fig. 7).

Fig. 7. Dependence of yield strength of steel 3 during compression test |

The difference in strength characteristics is determined by two factors:

– grain refinement should cause hardening of steels in accordance with the Hall–Petch law [20]:

\[\Delta \sigma \sim \frac{{{K_{\rm{у}}}}}{{\sqrt {{{\rm{Д}}_{{\rm{drain}}}}} }};\]

where Kу is the Hall–Petch constant; Дdrain is the grain size;

– an increase in the amount of δ-ferrite in the steel structure should reduce its strength:

\[\Delta \sigma \sim \left( {1 - kV_f^n} \right),\]

where k, n are constants, Vf is the volume fraction of ferrite [20], since the yield strength of ferrite is about half the yield strength of martensite of the same composition, as was shown in [21].

A decrease in strength indicates that, under these test conditions, hardening from a decreasing austenite grain size is a weaker factor than strength degradation from an increase in the amount of δ-ferrite. The relationship between the measured characteristics (\(\sigma _{0.2}^{20}\) , Vf , Дdrain ) in this temperature range (1175 – 1250 °C) can be described by the general equation

\[\sigma _{0.2}^{20} = 201V_f^{0,053}{\rm{Д}}_{{\rm{drain}}}^{0,41}.\]

The above-described phenomena indicate that the amount of δ-ferrite, the content of which may be a rejection feature for industrial FMHS, can be reduced within certain limits by reducing the heating temperature for quenching and simultaneously increasing the dwell time at this temperature. This can be accomplished either at the homogenizing annealing stage or at the final heat treatment stage of quenching + tempering type.

Conclusion

The size of martensitic grains in heat-resistant high-chromium steels with a martensitic-ferritic structure does not behave monotonously with increasing heating temperature: when heated to 1200 °C and above it decreases. In this case, the content of δ-ferrite in the structure increases.

In FMHS, δ-ferrite is formed not only in the high-temperature region of the phase-equilibrium diagram (in the crystallization temperature range), but also significantly below – up to typical heating temperatures for quenching of such steels.

An increase in the δ-ferrite content in FMHS at quenching temperatures of 1200 °C and above leads to a decrease in the yield strength of such steels at 20 °C, despite the refinement of the austenitic grain.

References

1. Kalin B.A., Platonov P.A., Tuzov Yu.V., Chernov I.I., Shtrombach Ya.I. Physical Materials Science. Vol. 6. Structural Materials of Nuclear Technology. Moscow: National Research Nuclear University MEPhI; 2012:736. (In Russ.).

2. Escobar J.D., Faria G.A., Maia E.L., Oliveira J.P., Boll T., Seils S., Mei P.R., Ramirez A.J. Fundamentals of isothermal austenite reversion in a Ti-stabilized 12Cr – 6Ni – 2Mo super martensitic stainless steel: Thermodynamics versus experimental assessments. Acta Materialia. 2019;174:246–259. http://doi.org/10.1016/j.actamat.2019.05.026

3. Bettanini A.M., Ding L., Mithieux J.-D., Parrens C., Idrissi H., Schryvers D., Delannay L., Pardoen T., Jacques P.J. Influence of M23C6 dissolution on the kinetics of ferrite to austenite transformation in Fe-11Cr-0.06C stainless steel. Materials and Design. 2019;162:362–374. https://doi.org/10.1016/j.matdes.2018.12.005

4. Olenin M.I., Pavlov V.N., Bykovskii N.G., Osipova I.S., Bashaeva E.N., Gusel’nikova T.M., Priimina T.A. Effect of homogenization on the cold resistance of high-strength corrosion-resistant steel 07Kh16N4V. Voprosy materialovedeniya. 2009;2(58):33–37. (In Russ.).

5. Berezhko B.I., Olenin M.I., Gorynin V.I., Stol’nyi V.I. Increasing resistance of high-chromium martensitic and ferritic-martensitic steels to brittle fracture by homogenizing. Voprosy materialovedeniya. 2016;3(87):7–13. (In Russ.).

6. Kozlov P.Yu, Skorobogatykh V.N., Shchenkova I.A., Dub V.K., Astakhov M.V. Influence of carbon on structure and properties of high-temperature steels with 9% of chromium. Izvestiya. Ferrous Metallurgy. 2011;54(3):48–51. (In Russ.).

7. Kudryavtsev A.S., Okhapkin K.A., Markova Yu.M. Influence of technological parameters of hot rolling on the structure and properties of 12 %-Cr steel. Metallurg. 2018;(10): 48–53. (In Russ.).

8. Eliniyaz Z., Zhang L., Suna F., Shen Y., Shan A. Microstructural evolution of delta ferrite in SAVE12 steel under heat treatment and short-term creep. Materials Characterization. 2012;73:144–152. https://doi.org/10.1016/j.matchar.2012.08.009

9. Olenin M.I., Kashtanov A.D., Romanov O.N., Makhorin V.V. Influence of homogenizing annealing on the reduction of δ-ferrite content in high-strength high-chromium martensitic steel grade 07Kh15N5D4B obtained by selective laser alloying. Voprosy materialovedeniya. 2021;2(106):47–54. (In Russ.).

10. Chernyavskaya S.G., Krasnikova S.N., Sulimenko A.V. Change of delta ferrite in steel 1Kh16N3B during homogenization. Metallovedenie i termicheskaya obrabotka metallov. 1972;(9):66–67. (In Russ.).

11. Korneev E.A., Gromov A.F., Kiselev A.M. Effect of delta ferrite on the properties of martensitic steels. Metallovedenie i termicheskaya obrabotka metallov. 2013;698(8):46–50. (In Russ.).

12. Kuper M.W., Alexandrov B.T. Retention of delta ferrite in the heat-affected zone of Grade 91 steel dissimilar metal welds. Metallurgical and Materials Transactions A. 2019;50(6): 2732–2747. https://doi.org/10.1007/s11661-019-05182-4

13. Niessen F., Tiedje N.S., Hald J. Kinetics modeling of delta-ferrite formation and retainment during casting of supermartensitic stainless steel. Materials and Design. 2017;118: 138–145. https://doi.org/10.1016/j.matdes.2017.01.026

14. Ji Y.P., Li Y.M., Zhang M.X., Qu W., Zhao T.X., Ren H.P. Grain refinement mechanism of the δ-ferrite in steels through cerium addition. Metallurgical and Materials Transactions A. 2020;51:1707–1718. https://doi.org/10.1007/s11661-020-05645-z

15. Zhou X., Liu Y., Qiao Z., Guo Q., Liu C., Yu L., Li H. Effects of cooling rates on ferrite-austenite formation and martensitic transformation in modified ferritic heat resistant steel. Fusion Engineering and Design. 2017;125:354–360. https://doi.org/10.1016/j.fusengdes.2017.05.095

16. Saini N., Mulik R.S., Mahapatra M.M., Kannan R., Sharma N.K., Li L. Dissolution of δ-ferrite and its effect on mechanical properties of P92 steel welds. Materials Science and Engineering: A. 2020;796:139370. https://doi.org/10.1016/j.msea.2020.139370

17. Chen K., Yan J., Li N., Luo M., Shi H., Zhu X., Liu Y., Zhao X., Zhang R. The effect of the annealing temperature on the damping capacity under constant prestress, mechanical properties and microstructure of an Fe-11Cr-2.5Mo-0.1Zr-1.0Ni forged damping alloy. Journal of Alloys and Compounds. 2020;815:152429. https://doi.org/10.1016/j.jallcom.2019.152429

18. Zheng S., Yuan X., Gong X., Le T., Ravindra A.V. Hot deformation behavior and microstructural evolution of an Fe-Cr-w-Mo-V-C steel. Metallurgical and Materials Transactions A. 2019;50(5):2342–2355. https://doi.org/10.1007/s11661-019-05162-8

19. Bobkov V.P., Rumyantsev V.N., Solov’ev V.A., Tarasikov V.P. Handbook on the Properties of Materials for Advanced Reactor Technologies. Vol. 5. Properties of Reactor Steels and Alloys. Moscow: IzdAT; 2014:584. (In Russ.).

20. Shtremel’ M.A. Alloy Strength. Part 2. Deformation. Moscow: MISIS; 1997:527. (In Russ.).

21. Belomyttsev M.Yu., Obraztsov S.M., Molyarov A.V. Effect of ferrite content on high temperature strength of ferritic-martensitic steels with 12% Cr. Metallurg. 2017;(9):46–51. (In Russ.).

About the Author

M. Yu. BelomyttsevRussian Federation

Mikhail Yu. Belomyttsev, Dr. Sci. (Eng.), Prof. of the Chair “Metallography and Physics of Strength”

4 Leninskii Ave., Moscow 119049, Russian Federation

Review

For citations:

Belomyttsev M.Yu. Features of formation of austenite grains in 12 % Cr heat-resistant ferritic-martensitic steels. Izvestiya. Ferrous Metallurgy. 2023;66(2):168-176. https://doi.org/10.17073/0368-0797-2023-2-168-176

JATS XML